Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

16.30 Ferdinand Pecson, NLSupervision

Caricato da

Mohd AliCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

16.30 Ferdinand Pecson, NLSupervision

Caricato da

Mohd AliCopyright:

Formati disponibili

World Class Plant Performance with NLS O&M

Ferdinand A. Pecson Ph. D, MBA, BS ME

Cemtech Dubai, 5-8 March 2011

Company Profile

NLSupervision A/S specializes in

offering everything needed for the

successful commissioning of a cement

plant and its subsequent

management, operation and

maintenance.

NLSupervision Egypt currently has

O&M contracts with Arabian Cement

Company located in Suez

Governorate and Wadi El-Nile

Cement Company located in Bene

Suef Governorate.

Outside Egypt, NL Supervision A/S

has contracts in four other countries:

Iran, Libya, Angola and Tunisia

Cemtech Dubai, 5-8 March 2011

NLSupervision Company A/S

Hffdingsvej 34

DK-2500 Valby

Denmark

Tel.: +45 3618 3780

Fax: +45 3645 6415

Our Value Proposition to Our Customers

Maximize your return on your investment by achieving rapid ramp-up from

commissioning and guaranteeing high plant availability and high levels of

production throughout the life of the project.

Support your goal of being a dependable provider of excellent quality

cement to your customers

Help you be an attractive business partner for users of cement by operating

your cement plant according to international standards for Quality (ISO

9001), Environment (ISO 14001) and Safety (OSHAS 18001)

Enable you to focus your resources on revenue generation

Help you sustain high levels of productivity and performance even after the

O&M contract, by providing your plant with state-of-the art systems and a

highly competent organization.

Cemtech Dubai, 5-8 March 2011

Our Mission: Sustained Excellent Performance

Cemtech Dubai, 5-8 March 2011

The Five Key Drivers of Our Success

Customer Focus

Excellence in Operation & Maintenance

Passion for Safety

Engaged Employees

Care for the Environment

Cemtech Dubai, 5-8 March 2011

Delivering Results by Being Close to our Customer

Philosophy of Our customers

success is our success

Daily Coordination Meetings at

Plant Level

Quarterly Planning of

Production

Planning shutdowns according

to customer needs

Joint Iftar Parties

Cemtech Dubai, 5-8 March 2011

Delivering Results by Engaging our People

Action areas

Result areas

Perception

Reputation

Behaviour

Satisfaction

Senior Management

Retention

Satisfaction

& Motivation

Immediate Superior

Loyalty

Co-operation

Motivation

Daily Work

Commitment

Remuneration

Development

Employees continued to run Ramliya Plant all throughout the Egypt Crisis!

Cemtech Dubai, 5-8 March 2011

Delivering Results through State-of-the Art O&M Systems

Measures of

Performance

Communication

Continuous

Improvement

Production &

Maintenance

Planning

Quality of

Execution

Failure

Reporting &

Root-cause

analysis

O&M

Organization

Training/

Coaching

Preventive

Maintenance

Celsius

160.0 94.7

90.0

85.0

80.0

WINDING JUNCTION

95.1

75.0

70.0

65.0

60.0

55.0

50.0

WINDING JUNCTION

100.3

45.0

-20.0

38.9

Thermoteknix VisIR 3:32:01 PM 2/16/2007 e : 1.00 Bg : 25.0C

Cemtech Dubai, 5-8 March 2011

Delivering Results through Continuous Improvement

Raw Mill Situation

Improvements

Quartz content of materials on

grinding table is up to 23% compared

with just 7% in raw materials

High load of large particles on the

separator due to high gas velocity in

the nozzle ring and in the transition

zone between mill and separator

High wear at outlet duct & cyclones

Switched to sintercast roller

segments

Increased nozzle ring area

Raised lower housing of separator by

2m

Installed densit lining at outlet duct

& cyclones

Cemtech Dubai, 5-8 March 2011

Delivering Results through Continuous Improvement

Kiln Situation

Improvements

High wear of refractory of tertiary air

damper

Alkali attack on kiln nose ring area

Process control by Operator

Switched to silicon carbide castable

for the tertiary air damper, nose ring

and area between nose ring and

retainer ring

Installed Process Control Expert

(PXP)

Cemtech Dubai, 5-8 March 2011

10

Delivering Results through Continuous Improvement

Cooler Situation

Improvements

Cross-bar cooler designed for 6000

tpd

Recurring red rivers

Upgraded cross-bar cooler to

seagull design, which increased

kiln output to 6700 tpd

After upgrade

Before upgrade

Cemtech Dubai, 5-8 March 2011

11

Delivering Results through NLS Copenhagen Technical Support

Performance Diagnostic

Center

Spare Parts Support

Bottleneck assessment

Efficiency improvements

Mechanical Inspections

Technical Training

Research &Development

Cemtech Dubai, 5-8 March 2011

12

Delivering Results by Preparing Future Cement Engineers

Partnership with Helwan

University

Total of 40 Engineering

Students in the First Year

Theoretical and Practical

Cement Technology

Training

Cemtech Dubai, 5-8 March 2011

13

Delivering Results, SAFELY

Building a Culture of Safety

Focus on hazards control

Work Safety Guidelines

OHSAS 18001 Certification

5S Implementation together

with Arabian Cement

Cemtech Dubai, 5-8 March 2011

14

Delivering Results, by having FUN!

Cemtech Dubai, 5-8 March 2011

15

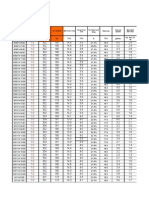

Actual Results

Kiln Average Production Rate, %

of design capacity

Kiln Net Availability, %

Kiln MTBF, hrs

Safety LTIFR

Cemtech Dubai, 5-8 March 2011

2,009

103%

2,010

106%

92%

301

6.9

92%

256

2.81

16

What Our Customer Has to Say

We signed a second contract with NL Supervision

because they deliver their commitments and can

be depended on to support us even in difficult

times. They are strongly focused on solving

bottleneck issues, improving plant productivity

and ensuring long-term plant reliability.

Arabian Cement aspires to be the clinker and

cement producer of reference; we see NL

Supervision as the partner who can support us

with that aspiration.

Jose Maria Magrina

CEO

Arabian Cement Company

Cemtech Dubai, 5-8 March 2011

17

Potrebbero piacerti anche

- False Air CaluculationDocumento4 pagineFalse Air CaluculationMohd AliNessuna valutazione finora

- Nozzle Ring Area of Raw MillDocumento6 pagineNozzle Ring Area of Raw MillMohd Ali100% (7)

- Nox TestDocumento10 pagineNox TestMohd AliNessuna valutazione finora

- House Value 8,000,000 Initial Payment 20% Loan Value 6,400,000 Launch Project Initial Amount 1,600,000 Monthly 133,333Documento1 paginaHouse Value 8,000,000 Initial Payment 20% Loan Value 6,400,000 Launch Project Initial Amount 1,600,000 Monthly 133,333Mohd AliNessuna valutazione finora

- KünneDocumento28 pagineKünneMohd AliNessuna valutazione finora

- Notes On Cemtech 2011 Dubai PresentationsDocumento8 pagineNotes On Cemtech 2011 Dubai PresentationsMohd AliNessuna valutazione finora

- 14.30 Joel Grau Lara, ClarksonsDocumento7 pagine14.30 Joel Grau Lara, ClarksonsMohd AliNessuna valutazione finora

- 11.30 Michel Folliet, International Finance CorporationDocumento11 pagine11.30 Michel Folliet, International Finance CorporationMohd AliNessuna valutazione finora

- 16.00 Luc Rudowski, PolysiusDocumento14 pagine16.00 Luc Rudowski, PolysiusMohd AliNessuna valutazione finora

- 09.30 Cemengal Tanger BK6 FDDocumento18 pagine09.30 Cemengal Tanger BK6 FDMohd AliNessuna valutazione finora

- 09.30 Hettish Karmani, Global Investment HouseDocumento10 pagine09.30 Hettish Karmani, Global Investment HouseMohd AliNessuna valutazione finora

- 11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHDocumento15 pagine11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHMohd AliNessuna valutazione finora

- 10.00 Heinrich Höse, Aumund Fördertechnik GMBHDocumento25 pagine10.00 Heinrich Höse, Aumund Fördertechnik GMBHMohd Ali100% (1)

- Thermal Energy Efficiency in Cement IndustryDocumento105 pagineThermal Energy Efficiency in Cement IndustryHoang Nguyen100% (6)

- APP Booklet of Cement TechnologyDocumento232 pagineAPP Booklet of Cement TechnologySunil Kumar DwivediNessuna valutazione finora

- 15.00 Paolo Bossi, MD, Sinai White CementDocumento38 pagine15.00 Paolo Bossi, MD, Sinai White CementMohd AliNessuna valutazione finora

- 09.00 Daniel Strohmeyer, Loesche GMBHDocumento16 pagine09.00 Daniel Strohmeyer, Loesche GMBHMohd Ali100% (1)

- Thermo Power Generation Tech SeminarDocumento31 pagineThermo Power Generation Tech SeminarMohd AliNessuna valutazione finora

- 17.00 Loïc Pottier, Fives FCBDocumento11 pagine17.00 Loïc Pottier, Fives FCBMohd AliNessuna valutazione finora

- Thermoelectric Energy ConversionDocumento17 pagineThermoelectric Energy ConversionMohd AliNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Dibakar Das - ResumeDocumento4 pagineDibakar Das - Resumeswadeshi cablesNessuna valutazione finora

- TropicanaDocumento34 pagineTropicanamorad1974Nessuna valutazione finora

- Business Model GenerationDocumento56 pagineBusiness Model GenerationBianca Bia80% (5)

- 5-Page Resume Template - USDocumento5 pagine5-Page Resume Template - USPlayerOne ComputerShopNessuna valutazione finora

- Barrysbeans Final For JayaDocumento17 pagineBarrysbeans Final For JayaAnonymous yJcp7XIE100% (1)

- Case Study On "Unilever in Brazil-Marketing Strategies For Low Income Consumers "Documento15 pagineCase Study On "Unilever in Brazil-Marketing Strategies For Low Income Consumers "Deepak BajpaiNessuna valutazione finora

- Sports Marketing Conceptual Framework Fuller Ton 1Documento20 pagineSports Marketing Conceptual Framework Fuller Ton 1memkmemk5Nessuna valutazione finora

- Online-Retailing Ch4Documento11 pagineOnline-Retailing Ch4Sami AlkharabshehNessuna valutazione finora

- Cashstar Fast Track Success in Mpayments PaperDocumento12 pagineCashstar Fast Track Success in Mpayments PaperRoshan KumarNessuna valutazione finora

- Boots Hair CareDocumento3 pagineBoots Hair CaremonuagarNessuna valutazione finora

- Case Study MKTG 306Documento11 pagineCase Study MKTG 306Yara100% (7)

- 856 Economics QPDocumento4 pagine856 Economics QPRudra SahaNessuna valutazione finora

- Himanshu Shah: Professional Quantity SurveyorDocumento3 pagineHimanshu Shah: Professional Quantity SurveyorAjay DevNessuna valutazione finora

- Handcrafted History Brand ManualDocumento26 pagineHandcrafted History Brand ManualBriony DurbinNessuna valutazione finora

- A Presentation On NokiaDocumento16 pagineA Presentation On Nokiajay2012jshmNessuna valutazione finora

- Presentation ON Spectrum Brands, Inc. The Sales Force DilemmaDocumento21 paginePresentation ON Spectrum Brands, Inc. The Sales Force DilemmaNaresh Vemisetti0% (1)

- Determinants of Resource DemandDocumento3 pagineDeterminants of Resource DemandSherazButtNessuna valutazione finora

- The Stages of Growth Model QuotesDocumento4 pagineThe Stages of Growth Model QuotesAndrea RioNessuna valutazione finora

- Advertising and Sales Promotion PDFDocumento118 pagineAdvertising and Sales Promotion PDFShubham Bhasin100% (1)

- TaniyaDocumento10 pagineTaniyamittal_parmar5224Nessuna valutazione finora

- Brand Audit Toolkit 2017Documento18 pagineBrand Audit Toolkit 2017basaNessuna valutazione finora

- Digital Marketing Services in DelhiDocumento5 pagineDigital Marketing Services in DelhiMemen IndiaNessuna valutazione finora

- Porter's 5 Forces Model MACRDocumento16 paginePorter's 5 Forces Model MACRDarshan GaragNessuna valutazione finora

- EntreprenuershipDocumento14 pagineEntreprenuershippeace.missileNessuna valutazione finora

- Assignment PDFDocumento15 pagineAssignment PDFpavanihirushaNessuna valutazione finora

- Customer Ship Management in Retail Sector (Big Bazar)Documento28 pagineCustomer Ship Management in Retail Sector (Big Bazar)Bharat Wadhwa50% (2)

- Dadar ListDocumento14 pagineDadar ListMahan PilankarNessuna valutazione finora

- Get A New Client Today FinalDocumento22 pagineGet A New Client Today FinalValaki Aki100% (1)

- Ashok LeylandDocumento21 pagineAshok LeylandmyidyNessuna valutazione finora

- Nursyazana Aqilah Binti Nor Az Azlan (2017378235)Documento14 pagineNursyazana Aqilah Binti Nor Az Azlan (2017378235)Syazana azlanNessuna valutazione finora