Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Galv Check

Caricato da

Ravi Lohar0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

60 visualizzazioni1 paginag

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentog

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

60 visualizzazioni1 paginaGalv Check

Caricato da

Ravi Loharg

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

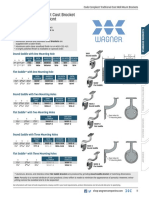

The Galvanizing Check Tool (new!) works in conjuction with the Galvanizing Options setup window.

The tool was developed in

coordination with the American Galvanizing Association, and its icon is the American Galvanizing Association logo. This icon may be found

in the "Command group" called 'Model - Parametric' in Toolbar Configuration.

<= Galvanizing Check Tool

When you run the Galvanizing Check Tool, one or more members can be selected. You need to select members that are set to "

Galvanized." The checks will not run on non-galvanized members, miscellaneous members or stairs. The following checks can

be run on galvanized members:

Check for kettle tank fit. This check compares the size of each selected galvanized member with the kettle "Length" "Width"

and "Depth." If " Allow progressive dipping" is on (checked) is setup, the Galvanizing Check Tool uses the "Maximum length"

instead of the actual kettle "Length."

Check for conflicking material thickness. If materials being galvanized differ significantly in their thicknesses, they expand

at different rates when subjected to galvanizing temperatures, and this can potentially result in breakage of welds. This check

looks at plate thicknesses, web and flange thicknesses on wide flanges and tees, leg thicknesses on angles, and wall thicknesses of

tubes (HSS rectangular). If the thicknesses any of these materials, on the same galvanized member, are more than 3/2 times

greater than another material's thickness on that member, you get the message, "Member xxx contains material that if welded

together may cause warping." The materials that caused this warning message may or may not be welded together -- you need to

check that for yourself. The American Galvanizing Association's Design Guide, which you can download from this window,

discusses these issues on page 9.

Check for proper vents and drains. This checks base plates on columns to see if at least one "Hole type" is a 'Vent/Drain.' If

the base plate does not have a vent/drain hole, you get the message, "Member xxx has a base plate with no holes." Users need to

manually add vent/drain holes in SDS/2 -- the program does not add them for you.

Check for proper use of galvanized fasteners. This check reports if "Member xxx" -- a selected galvanized member -- "is

connected connected to non-galvanized members." If bolts associated with the selected member have a "Finish" other than 'Hot

dipped galvanized" or "Mechanically galvanized," the check reports, "Member xxx has non-galvanized fasteners." The American

Galvanizing Association's Design Guide discusses fastener issues on page 19.

Check against kettle crane capacity. This check estimates the total weight of each selected galvanized member and crosschecks each member's total against the "Crane capacity" entered in setup. You are notified if each selected galvanized member

passes or fails the check and are also told the estimated total weight of the member as well as the setup value being checked

against. The reported weight is an underestimate of a galvanized member's true weight since the calculation adds up the weights

of component materials, but not the weights of bolts.

Check for proper use of seal/stagger welds. Overlapping surfaces should be seal welded before they are galvanized. This

check looks at each weld to determine whether or not it is set to "Weld-all-around." If a weld is not set to "Weld-all-around," the

program reports, "Weld check failed on member xxx, material xxx is not seal welded." The American Galvanizing Association's

Design Guide discusses seal welding on page 19.

Check for ungalvanized material. If a user adds material to a member that is set to be " Galvanized," that material should

also be set to have a galvanized finish. This checks the materials of each selected galvanized member to see if their "Surface

finish" is set to 'Galvanized.' For each selected galvanized member on which at least one material is not galvanized, the program

reports, "Member xxx has non-galvanized material."

Parametrics: The Galvanizing Check Tool is written in Python code. The script can be found in the plugins/DesignData folder (

) for your current version of SDS/2.

contents | graphics, objects & decorations | top

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Aluminium Wall Rail BracketDocumento1 paginaAluminium Wall Rail BracketRavi LoharNessuna valutazione finora

- Osha BasicsDocumento3 pagineOsha BasicsRavi LoharNessuna valutazione finora

- AISC Important TablesDocumento1 paginaAISC Important TablesRavi Lohar100% (1)

- Standard BracketDocumento1 paginaStandard BracketRavi LoharNessuna valutazione finora

- Encroachment ChartDocumento1 paginaEncroachment ChartRavi LoharNessuna valutazione finora

- Join Brochure 03032022Documento17 pagineJoin Brochure 03032022Ravi LoharNessuna valutazione finora

- 300-C Slotted Channel Product Data - Multi-PageDocumento8 pagine300-C Slotted Channel Product Data - Multi-PageRavi LoharNessuna valutazione finora

- Summary of Project LatestDocumento4 pagineSummary of Project LatestRavi LoharNessuna valutazione finora

- Structural Bolting: Note That The ASTM Designation Is Indicated On The Head of The Bolts AboveDocumento4 pagineStructural Bolting: Note That The ASTM Designation Is Indicated On The Head of The Bolts AboveRavi LoharNessuna valutazione finora

- Resume VKPDocumento2 pagineResume VKPRavi LoharNessuna valutazione finora

- Typical Single Plate Connection Schedule 7 Typical Double Angle Connection Schedule 8Documento1 paginaTypical Single Plate Connection Schedule 7 Typical Double Angle Connection Schedule 8Ravi LoharNessuna valutazione finora

- Sr. No. AnswersDocumento2 pagineSr. No. AnswersRavi LoharNessuna valutazione finora

- Osha Standard LadderDocumento15 pagineOsha Standard LadderRavi LoharNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- DLookup Function - Access - Microsoft OfficeDocumento2 pagineDLookup Function - Access - Microsoft OfficevinahackNessuna valutazione finora

- CNCProDocumento94 pagineCNCProramjoceNessuna valutazione finora

- DmallocDocumento60 pagineDmallocbojke2000Nessuna valutazione finora

- Special Information Release Notes Flexi Soft Designer en IM0038815Documento22 pagineSpecial Information Release Notes Flexi Soft Designer en IM0038815jamNessuna valutazione finora

- Resume JsonDocumento9 pagineResume Jsonbcr9srp4100% (2)

- Palo Alto SyllabusDocumento1 paginaPalo Alto SyllabusVamsi ChowdaryNessuna valutazione finora

- Kasus LegoDocumento10 pagineKasus LegocitraNessuna valutazione finora

- PSTOOLSDocumento5 paginePSTOOLSNithyavadivelan ThulasiNessuna valutazione finora

- Groupware HciDocumento38 pagineGroupware HciSharqa FatimaNessuna valutazione finora

- Project Report On Hospital Managment SysytemDocumento22 pagineProject Report On Hospital Managment Sysytemhrushikesh dangeNessuna valutazione finora

- GlideRecord Query Cheat Sheet - ServiceNow GuruDocumento20 pagineGlideRecord Query Cheat Sheet - ServiceNow Gurubmkmanoj50% (2)

- Running Head: CASE STUDY I-6: HH GREGG 1Documento7 pagineRunning Head: CASE STUDY I-6: HH GREGG 1Anisa PutriNessuna valutazione finora

- Security Center System Requirements Guide 5.10: Document Last Updated: July 12, 2021Documento34 pagineSecurity Center System Requirements Guide 5.10: Document Last Updated: July 12, 2021Luiz Henrique AraújoNessuna valutazione finora

- STAAD - Pro Manual ContentDocumento20 pagineSTAAD - Pro Manual Contentkhlee.mitra50% (2)

- MPI General CCDocumento21 pagineMPI General CCMạnh TiếnNessuna valutazione finora

- Imessage: How To Quote A Message in Chat RoomDocumento54 pagineImessage: How To Quote A Message in Chat RoomyyNessuna valutazione finora

- Audit: Airline CompanyDocumento4 pagineAudit: Airline CompanyArianna Maouna Serneo BernardoNessuna valutazione finora

- NCS Device Discovery Package: Cisco SystemsDocumento18 pagineNCS Device Discovery Package: Cisco SystemsAla JebnounNessuna valutazione finora

- Course Content - Dell BoomiDocumento7 pagineCourse Content - Dell BoomiSrikanth ReddyNessuna valutazione finora

- PoC Proposal TemplateDocumento43 paginePoC Proposal TemplateHromit Prodigy100% (1)

- Ravi K OracleDocumento7 pagineRavi K Oraclevipul tiwari100% (1)

- EIM ScenariosDocumento19 pagineEIM Scenarioschan-Nessuna valutazione finora

- CW COMP1475 May 22 23Documento4 pagineCW COMP1475 May 22 23Academic SolutionNessuna valutazione finora

- Welcome To KPT Effects - . - . - . - 3Documento41 pagineWelcome To KPT Effects - . - . - . - 3Jhon DanielsNessuna valutazione finora

- iVIZION Quick Reference PDFDocumento16 pagineiVIZION Quick Reference PDFjoseNessuna valutazione finora

- Foundations of Breach & Attack Simulation: Lab GuideDocumento19 pagineFoundations of Breach & Attack Simulation: Lab GuideJonathan GillNessuna valutazione finora

- Santorini Resume TemplateDocumento1 paginaSantorini Resume TemplateNuthan TejNessuna valutazione finora

- FCUBS FD03!01!01 Extensibility Getting StartedDocumento18 pagineFCUBS FD03!01!01 Extensibility Getting StartedcuonglunNessuna valutazione finora

- U 6010 AmanualDocumento14 pagineU 6010 AmanualAngel Rafael Acosta MuñozNessuna valutazione finora

- Salesforce SAP Integration Guidelines and Client StoriesDocumento31 pagineSalesforce SAP Integration Guidelines and Client StoriesPitchaya Jarernmuengmool100% (2)