Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Coeiicient of Friction

Caricato da

Kamlesh DalavadiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Coeiicient of Friction

Caricato da

Kamlesh DalavadiCopyright:

Formati disponibili

Coefficients Of Friction

Page 1 of 8

Disclaimer: The information on this page has not been checked by an independent person.Usethisinformationatyourown

risk.

ROYMECH

Family Health Insurance Instant Policy, Huge Tax saving 5% Bonus for every Claim-Free year!RoyalSundaram.in/Buy_Online_Now

Video Systems Srl Sensors, measure systems, quality systems, automation control systemswww.videosystems.it/en/Home.

Scan-Pac Manufacturing Friction Materials Phenolic Bearings and Bushingswww.scanpac.com

Home

Tribology_Index

Friction Factors

Note: I have tried to include a wide range of relevant information on this topic. It will be noted that friction values in one section do not

necessarily agree with values in another section...Please use the linked references at the bottom of the page for more detailed

information.

Factors Affecting friction..... Static Friction..... Sliding/dynamic/kinetic friction..... Coefficients of Friction.....

Rolling Friction..... Plain Bearings Friction..... Rolling Bearing Friction..... Clutch Brake Friction.....

Bolted Joints..... Power Screws..... Press Fits.... Test Methods.... Linked Reference Info

Factors affecting the friction between surfaces

Dry surfaces

1. For low surface pressures the friction is directly proportional to the pressure between the surfaces. As the

pressure rises the friction factor rises slightly. At very high pressure the friction factor then quickly increases to

seizing

2. For low surface pressures the coefficient of friction is independent of surface area.

3. At low velocities the friction is independent of the relative surface velocity. At higher velocities the coefficent of

friction decreases.

Well lubricated surfaces

1. The friction resistance is almost independent of the specific pressure between the surfaces.

2. At low pressures the friction varies directly as the relative surface speed

3. At high pressures the friction is high at low velocities falling as the velocity increases to a minimum at about

0,6m/s.Thefrictionthenrisesinproportionthe velocity 2.

4. The friction is not so dependent of the surface materials

5. The friction is related to the temperature which affects the viscosity of the lubricant

Please refer to... Surface Friction Notes

Static Coefficient of Friction

The static friction coefficient () between two solid surfaces is defined as the ratio of the tangential force (F) required to produce sliding

divided by the normal force between the surfaces (N)

= F /N

For a horizontal surface the horizontal force (F) to move a solid resting on a flat surface

F= x mass of solid x g.

If a body rests on an incline plane the body is prevented from sliding down because of the frictional resistance. If the angle of the plane

is increased there will be an angle at which the body begins to slide down the plane. This is the angle of repose and the tangent of this

angle is the same as the coefficient of friction.

.

Sliding Coefficient of Friction

When the tangential force F overcomes the frictional force between two surfaces then the surfaces begins to slide relative to each other.

Inthecaseofabodyrestingonaflatsurfacethebody starts to move. The sliding frictional resistance is normally different to the static

frictional resistance. The coefficient of sliding friction is expressed using the same formula as the static coefficient and is generally

lower than the static coefficient of friction..

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Coefficients Of Friction

Page 2 of 8

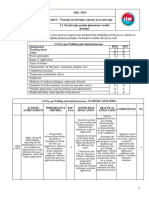

Friction Coefficients

A table below shows approximate friction coefficients for various materials. Allvaluesareapproximateandareonlysuitablefor

guidance only. The sliding/lubricated values must be used with extreme care. The only way to determine the accurate coefficient of

friction between two materials is to conduct experiments.

Coefficients of friction are sensitive to atmospheric dust and humidity, oxide films, surface finish, velocity of sliding, temperature,

vibration, and extent of contamination.Inmanycasesthedegreeofcontaminationis perhaps the most important single variable..

Table of Coefficients of Friction

Link

The friction values provided are obtained by different test methods under different ambient conditions. This factor can also affect the

results. Link Test Methods

Rolling Friction

When a cylinder rolls on a surface the force resisting motion is termed rolling friction. Rolling friction is generally considerably less than

sliding friction. If W is the weight of the cylinder converted to force, or the force between the cylinder and the flat surface, and R is

radius of the cylinder and F is the force required to overcome the rolling friction then.

center>F = f x W/R

f is the coefficient of rolling friction and has the same unit of length as the radius R -in the example below m (metres)

Typical values for f are listed below

Note: Values for rolling friction from various sources are not consistent and the following values should only be used for approximate

calculations.

Steel on Steel f = 0,0005m

Wood on Steel f = 0,0012m

Wood on Wood f = 0,0015m

Iron on iron f = 0,00051m

Iron on granite f = 0,0021m

Iron on Wood f = 0,0056m

Polymer on steel f = 0,002m

Hardrubber on Steel f = 0,0077m

Hardrubber on Concrete f = 0,01 -0,02m

Rubber on Concrete f = 0,015 -0,035m

Plain Bearing Friction factors

For values of rolling bearing friction Plain Bearing Friction Values

Rolling Bearing Friction

For values of rolling bearing friction Rolling Bearing Friction Values

Clutch - Brake Friction Values

The coefficient of friction value is important in the design and brakes and clutches.

Various values are provided on the following linked page Clutch/Brake Materials

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Coefficients Of Friction

Page 3 of 8

Friction coefficient Bolted Joints

The coefficient of friction is required in calculating tightening torques and resulting bolt tensile forces and stress and in calculating the

resulting friction between the connected surfaces. Below are provided a small number of values showing approximate values of friction

coefficients to be used for steel screw fastened connections.Thevaluesareonlyrepresentativevaluesand should be confirmed

against other sources of information and preferably testing.

Coefficient of Friction for screw threads

Female Thread -Nut or Tapped Hole in steel(untreated)

Male screw

Friction Coefficient (Dry) Friction Coefficient (lub)

Untreated Steel

0,12 - 0,18

0,10 - 0,17

Phosphated Steel

0,12 - 0,18

0,10 - 0,17

Cadmium Plated Steel

0,09 - 0,14

0,08 -0,23

Galvanised steel

0,14 - 0,23

0,12 - 0,2

Degreased steel

0,19 - 0,25

Female Thread -Nut or Tapped Hole in steel(Galvanised)

Friction Coefficient

Male screw

Friction Coeffient (Dry)

(Lub.)

Untreated Steel

0,14 - 0,2

0,12 - 0,18

Phosphated Steel

0,14 - 0,2

0,12 - 0,18

Cadmium Plated Steel

0,1 - 0,16

0,09 - 0,15

Galvanised steel

0,14 - 0,25

0,12 - 0,2

Degreased steel

0,19 - 0,25

Coefficient of Friction Nut/Bolt Face against Clamped surface

Clamped Surface = Steel

Friction Coefficient

(Lub.)

Untreated Steel

0,10 - 0,18

0,08 - 0.15

Phosphated Steel

0,10 - 0,18

0,08 - 0,15

Galvanised steel

0,10 - 0,2

0,09 - 0,18

Clamped Surface -Galvanised Steel

Bolt/Nut Mat'l

Friction Coefficient (Dry) Friction Coefficient (lub)

Untreated Steel

0,10 - 0,18

0,08 - 0,15

Phosphated Steel

0,10 - 0,18

0,08 - 0,15

Galvanised steel

0,16 - 0,22

0,09 - 0,18

Bolt/Nut Mat'l

Friction Coeffient (Dry)

Coefficient of friction between surfaces clamped by bolts /screws.

These values allow calculation of the shear force necessary to cause slip between surfaces when clamped by bolts.

Contact Surfaces

Steel On Steel- No treatment

Steel On Cast Iron- No treatment

Steel On Steel- Machined (Degreased)

Steel On Cast Iron- Machined (Degreased)

Grit -Sandblasted surfaces

slip coefficient

0,15- 0,25

0,18 - 0,3

0,12- 0,18

0,15 - 0,25

0,48 - 0,55

Friction Factors for Power Screws

The following factors are typical friction factors for power screw torque and efficiency calculations..

1) Screw Thread Friction values (s)

(Friction factors apply mainly for screw thread friction (s) - can be applied to collar friction( c)

Screw Material

Steel(Dry)

Steel (Lubricated)

Bronze (Lubricated)

Nut Material

Steel

Brass

Bronze Cast Iron

0,15-0,25 0,15-0,23 0,15-0,19 0,15-0,25

0,11-0,17 0,10-0,16 0,10-0,15 0,11-0,17

0,08-0,12 0,04-0,06

0,06-0,09

2) Thrust collar Friction values (c)

Surface Combinations

Soft Steel on Cast Iron

Hard Steel on Cast Iron

Soft Steel on Bronze

Hard Steel on Bronze

Moving

0,12

0,09

0,08

0,06

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

Starting

0,17

0,15

0,10

0,08

12/14/2010

Coefficients Of Friction

Page 4 of 8

Press Fit Mechanical Joints

In mechanical engineering rotary motion can be transferred by mechanical connections between a shaft and hub using only a tight fit.

Methods of achieving this type of connection include the engineered interference fit, the taper lock bush and hydraulic fit bush. These

keyless shaft/hub connections all transfer torque by friction.

The coefficient of friction used for designing these types of connections is dependent on the interface pressure, materials, surface

condition, surface coatings etc. The coefficient of friction is also dependent on the method of installation.Adifferentvalueresultifthe

shaft is forced into the hub (force fit) compared to the value if the assemble is completed by heating the hub or freezing the shaft prior to

assembly (shrink fit)...

Various values of relevant coefficients of friction are provided below;

Steel Hub , Steel Shaft unlubricated - force fit ...C. of Friction = 0,07 to 0,16

Steel Hub , Steel Shaft greased - force fit ...C. of Friction = 0,05 to 0,12

Steel Hub , Steel Shaft unlubricated - Shrink fit ...C. of Friction = 0,15 to 0,25

Steel Hub , Steel Shaft greased - Shrink fit ...C. of Friction = 0,08 to 0,16

The manufacturers of the proprietary keyless hub/shaft systems indicate that their products are based on a coefficient of friction of 0,12

for lightly oiled connections and 0,15 for dry assemblies. These companies can provide surface coating fluids containing particles to

increase the coefficient of friction i.e. coefficient of friction to 0,25 to 0,3. (ref links 1 below)

The American Gear Manufactures Association (AGMA) recommends a value of between 0,12-0,15 for hydraulically expanded hubs and

0,15-0,20 for shrink or press fit hubs.

When calculated the torque to be transmitted it is generally sufficient to use the simple equation

T= ..d2.L.P c/2

d= the shaft diameter

L is the length of the interference joint.

The surface pressure Pc is calculated typically using lame's equation.

Calculators are available for obtaining the transmitted toque very conveniently.

Tribology -abc

Engineers edge - press fit calculatgor

Testing Methods

There are a number of test methods for coefficient of frictions as some of which are listed below

Flat block pressed against a OD of rotating ring (FOR)

Flat block against another flat block (FOF)

Flat block sliding down an inclined runway(IS)

Pin pressed against a OD of rotating ring (POR

Reciprocating loaded spherical end pin pressed on a flat surface(RSOF)

It is clear that the different test methods provide different friction results..

Coefficient of Friction

Extreme care is needed in using friction coefficients and additional independent references should be used. For any specific application

the ideal method of determining the coefficient of friction is by trials.Ashorttableisincludedabovethemaintableto illustrate how the

coefficient of friction is affected by surface films.Whenametalsurfaceisperfectlycleaninavacuum, the friction is much higher than

the normal accepted value and seizure can easily occur.

......The links below the tables provide further information.

Effect of oxide film etc on coefficient of static friction

Material

Clean Dry

Thick

Oxide Film

Sulfide

Film

Steel-Steel

0,78

0,27

0,39

Copper-Copper

1,21

0,76

0,74

The level of uncertainty of the information below is indicated by using steel on steel as an example. Various reference sources provide

values similar to the values below.(0,74 Static- 0,42 sliding) Gieck(7thed)providesvaluesof(0,15...0,30Static- 0,10...0,30 sliding).

Concise Metals Data Handbook by J.R. Davis (table 14,1) includes values (0,31 static -0,23 sliding - for steel 1032? on steel 1032?)..

The same table includes a value for mild steel on mild steel of 0,62 sliding.

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Coefficients Of Friction

Page 5 of 8

Coefficient Of Friction

Material 1

Material 2

DRY

Static

Test

method

Greasy

Sliding

Static

Sliding

Aluminum

Aluminum

1,05-1,35

1,4

0,3

Aluminum

Mild Steel

0,61

0,47

Brake Material

Cast Iron

0,4

Brake Material

Cast Iron (Wet)

0,2

Brass

Cast Iron

0,3

Brick

Wood

0,6

Bronze

Cast Iron

0,22

Bronze

Steel

0,16

Cadmium

Cadmium

0,5

0,05

Cadmium

Mild Steel

0,46

Cast Iron

Cast Iron

1,1

0,15

0,07

Cast Iron

Oak

0,49

0,075

Chromium

Chromium

0,41

0,34

Copper

Cast Iron

1,05

0,29

Copper

Copper

1,0

0,08

Copper

Mild Steel

0,53

0,36

0,18

Copper

Steel

0,8

SPOF

Copper

Steel (304 stainless)

0,23

0,21

FOF

Copper-Lead Alloy

Steel

0,22

Diamond

Diamond

0,1

0,05 - 0,1

Diamond

Metal

0,1 -0,15

0,1

Glass

Glass

0,9 - 1,0

0,4

0,1 - 0,6

0,09-0,12

Glass

Metal

0,5 - 0,7

0,2 - 0,3

Glass

Nickel

0,78

0,56

Graphite

Graphite

0,1

0,1

Graphite

Steel

0,1

0,1

Graphite (In vacuum)

Graphite (In vacuum)

0,5 - 0,8

Hard Carbon

Hard Carbon

0,16

0,12 - 0,14

Hard Carbon

Steel

0,14

0,11 - 0,14

Iron

Iron

1,0

0,15 - 0,2

Lead

Cast Iron

0,43

Lead

Steel

1,4

SPOF

Leather

Wood

0,3 - 0,4

Leather

Metal(Clean)

0,6

0,2

Leather

Metal(Wet)

0,4

Leather

Oak (Parallel grain)

0,61

0,52

Magnesium

Magnesium

0,6

0,08

Nickel

Nickel

0,7-1,1

0,53

0,28

0,12

Nickel

Mild Steel

0,64;

0,178

Nylon

Nylon

0,15 - 0,25

Oak

Oak (parallel grain)

0,62

0,48

Oak

Oak (cross grain)

0,54

0,32

0,072

Platinum

Platinum

1,2

0,25

Plexiglas

Plexiglas

0,8

0,8

Plexiglas

Steel

0,4 - 0,5

0,4 - 0,5

Polystyrene

Polystyrene

0,5

0,5

Polystyrene

Steel

0,3-0,35

0,3-0,35

Polythene

Steel

0,2

0,2

Rubber

Asphalt (Dry)

0,5-0,8

Rubber

Asphalt (Wet)

0,25-0,75

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Coefficients Of Friction

Page 6 of 8

Rubber

Concrete (Dry)

0,6-0,85

Rubber

Concrete (Wet)

0,45-0,75

Saphire

Saphire

0,2

0,2

Silver

Silver

1,4

0,55

Sintered Bronze

Steel

0,13

Solids

Rubber

1,0 - 4,0

--

Steel

Aluminium Bros

0,45

Steel

Brass

0,35

0,19

Steel(Mild)

Brass

0,51

0,44

Steel (Mild)

Cast Iron

0,23

0,183

0,133

Steel

Cast Iron

0,4

0,21

Steel

Copper Lead Alloy

0,22

0,16

0,145

Steel (Hard)

Graphite

0,21

0,09

Steel

Graphite

0,1

0,1

Steel (Mild)

Lead

0,95

0,95

0,5

0,3

Steel (Mild)

Phos. Bros

0,34

0,173

Steel

Phos Bros

0,35

Steel(Hard)

Polythened

0,2

0,2

Steel(Hard)

Polystyrene

0,3-0,35

0,3-0,35

Steel (Mild)

Steel (Mild)

0,74

0,57

0,09-0,19

Steel (Mild)

Steel (Mild)

0,62

Steel(Hard)

Steel (Hard)

0,78

0,42

0,05 -0,11 0,029-,12

Steel

Zinc (Plated on steel)

0,5

0,45

Teflon

Steel

0,04

0,04

0,04

Teflon

Teflon

0,04

0,04

0,04

Tin

Cast Iron

,32

Titanium Alloy Ti-6Al-4V(Grade 5)

Aluminium Alloy 6061-T6

0,41

0,38

FOF

Titanium Alloy Ti-6Al-4V(Grade 5)

Titanium Alloy Ti-6Al-4V(Grade 5)

0,36

0,30

FOF

Titanium Alloy Ti-6Al-4V(Grade 5)

Bronze

0,36

0,27

FOF

Tungsten Carbide

Tungsten Carbide

0,2-0,25

0,12

Tungsten Carbide

Steel

0,4 - 0,6

0,08 - 0,2

Tungsten Carbide

Copper

0,35

Tungsten Carbide

Iron

0,8

Wood

Wood(clean)

0,25 - 0,5

Wood

Wood (Wet)

0,2

Wood

Metals(Clean)

0,2-0,6

Wood

Metals (Wet)

0,2

Wood

Brick

0,6

Wood

Concrete

0,62

Zinc

Zinc

0,6

0,04

Zinc

Cast Iron

0,85

0,21

FOR

Coefficient Of Friction

Material 1

Material 2

DRY

Static

LUBRICATED

Sliding

Static

Test

method

Sliding

FOR = Flat against rotating Cylinder, FOF = Flat against flat, POF = Pin on flat, IS = inclined surface,SPOF Spherical end pin on flat.

Source of above values.... The values are checked against a variety of internet and literature sources including the links below eg Link 6Page 16.IhavereferredtobooksincludingMachinerysHandbook Eighteenth edition, Kempes Engineers Year Book 1980, Concise

Metals Handbook by J.R.Davis ASM - (Good source of referenced data) and Kurt Giecks Engineering Formulas 7th Edition.. 1980, etc

etc

Table of friction Values for elements

I provide the table below as a consistent set of values for simple elements using the simplest of test methods. It can be seen that values

are generally different to the values in the table above...

Friction tests in air at room temperature. (50% relative humidity)

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Coefficients Of Friction

Page 7 of 8

Fixed Surface

Moving Block

Friction

coefficient

Static

Sliding

Test Method

Silver (Ag)

Silver (Ag)

0,5

Incline Plane

Gold(Au)

0,53

Incline Plane

Copper(Cu)

0,48

Incline Plane

Iron(Fe)

0,49

Incline Plane

Aluminium(Al)

Aluminium(Al)

0,57

Incline Plane

Titanium (Ti)

0,54

Incline Plane

Gold(au)

Silver (Ag)

0,53

Incline Plane

Gold(Au)

0,49

Incline Plane

Cadmium(Cd)

Cadmium(Cd)

0,79

Incline Plane

Iron(Fe)

0,52

Incline Plane

Cobalt(Co)

Cobalt(Co)

0,56

Incline Plane

Chromium(Cr)

0,41

Incline Plane

Chromium(Cr)

Cobalt(Co)

0,41

Incline Plane

Chromium(Cr)

0,46

Incline Plane

Copper(Cu)

Cobalt(Co)

0,44

Incline Plane

Chromium(Cr)

0,46

Incline Plane

Copper(Cu)

0,55

Incline Plane

Iron(Fe)

0,50

Incline Plane

Nickel(Ni)

0,49

Incline Plane

Zinc(Zn)

0,56

Incline Plane

Iron(Fe)

Cobalt(Co)

0,41

Incline Plane

Chromium(Cr)

0,48

Incline Plane

Iron(Fe)

0,51

Incline Plane

Maganese(Mg)

0,51

Incline Plane

Molybdenum(Mo)

0,46

Incline Plane

Titanium(Ti)

0,49

Incline Plane

Tungsten(W)

0,47

Incline Plane

Zinc(Zn)

0,55

Incline Plane

Indium(In)

Indium(In)

1,46

Incline Plane

Maganese(Mg)

Maganese(Mg)

0,69

Incline Plane

Molybdenum(Mo)

Iron(Fe)

0,46

Incline Plane

Molybdenum(Mo)

0,44

Incline Plane

Niobium(Nb)

Niobium(Nb)

0,46

Incline Plane

Nickel(Ni)

Chromium(Cr)

0,59

Incline Plane

Nickel(Ni)

0,50

Incline Plane

Platinum(Pt)

0,64

Incline Plane

Lead(Pb)

Silver (Ag)

0,73

Incline Plane

Gold(Au)

0,61

Incline Plane

Copper(Cu)

0,55

Incline Plane

Chromium(Cr)

0,53

Incline Plane

Iron(Fe)

0,54

Incline Plane

Lead(Pb)

0,90

Incline Plane

Platinum(Pt)

Nickel(Ni)

0,64

Incline Plane

Platinum(Pt)

0,55

Incline Plane

Tin(Sn)

Iron(Fe)

0,55

Incline Plane

Tin(Sn)

0,74

Incline Plane

Titanium(Ti)

Aluminium(Al)

0,54

Incline Plane

Titanium(Ti)

0,55

Flat Sliding

Tungsten(W)

Copper(Cu)

0,41

Incline Plane

Iron(Fe)

0,47

Incline Plane

Tungsten(W)

0,51

Incline Plane

Zinc(Zn)

Copper(Cu)

0,56

Incline Plane

Iron(Fe)

0,55

Incline Plane

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Coefficients Of Friction

Page 8 of 8

Zinc(Zn)

0,75

Incline Plane

Links to Friction Information

1. Carbide Depot.. Friction Coefficients

2. Supercivilcd Com.. Coefficient of Sliding Friction for various civil Materials

3. Fastener Design Manual...NASA GRC RP-1228 (9,6 Mbyte pdf file) Includes comprehensive table with friction

values.

4. Physlinks - Coefficient of Friction...A Table of Friction Coefficients

5. Engineers Edge- Coefficient of Friction...A Table of Friction Coefficients

6. School for Champions...Lots of very useful Notes

7. Bolt Council...Guide to Design Criteria for Bolted and Riveted Joints.(6,7 Mbyte pdf ). Info on Slip coefficients (P.82)

etc

8. MD Metric...Datasheet for PTFE

9. Friction coefficients in "Rail- Wheel" contacts .......Downloadable paper providing very theoretical information

10. Hypertextbooks _Physics Factbooks.....Physics Factbook .A page inlcuding a number of very good (school) articles

on coe-fficents of friction of different materials

11. Fund'ls of Friction and Wear of Automobile Brake Materials .....Paper Download ..Very informative document

12. Classical Friction...A very simple and clear description of what determines the coefficient of friction.

13. 12 Friction...Brown University-Division of Engineering..Very clear document on friction

14. Rolling Friction...Very useful notes on rolling friction

Ads by Google

Friction Force

Steel I Beam

Steel Sections

Mild Steel

This Page is being developed

Home

Tribology_Index

Please Send Comments to Roy@roymech.co.uk

Last Updated 10/09/2010

http://www.roymech.co.uk/Useful_Tables/Tribology/co_of_frict.htm

12/14/2010

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Basic Hydraulic Systems and ComponentsDocumento67 pagineBasic Hydraulic Systems and Componentsnareshkumaran100% (8)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Cci PDFDocumento4 pagineCci PDFKamlesh DalavadiNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Sheet Metal Design-Handbook-Rev3 PDFDocumento12 pagineSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Welding SymbolsDocumento60 pagineWelding Symbolskimboon_ngNessuna valutazione finora

- Pressure Seal ValveDocumento5 paginePressure Seal ValveWilson WongNessuna valutazione finora

- Eamcet Practice PapersDocumento61 pagineEamcet Practice PapersudaysrinivasNessuna valutazione finora

- Insulated Pipe - Temperature Loss CalculationDocumento5 pagineInsulated Pipe - Temperature Loss CalculationnopNessuna valutazione finora

- O-Ring (Metric Size)Documento63 pagineO-Ring (Metric Size)Kamlesh DalavadiNessuna valutazione finora

- O-Ring (Metric Size)Documento63 pagineO-Ring (Metric Size)Kamlesh DalavadiNessuna valutazione finora

- Pipeline Design Factor ReviewDocumento94 paginePipeline Design Factor ReviewpiolinwallsNessuna valutazione finora

- Robinair Bombas de Vacío 15401 601Documento32 pagineRobinair Bombas de Vacío 15401 601MarcWorld100% (1)

- 4102 - Chap 9 Creep Notes PDFDocumento19 pagine4102 - Chap 9 Creep Notes PDFjonthemesNessuna valutazione finora

- Motor Torque CalculationDocumento5 pagineMotor Torque CalculationSanjula Darshana WickramasingheNessuna valutazione finora

- Recent Advance Reactive Extrusion in PolymerDocumento24 pagineRecent Advance Reactive Extrusion in Polymershanshicn8351Nessuna valutazione finora

- Ball Valve CalculationDocumento5 pagineBall Valve CalculationKamlesh Dalavadi50% (2)

- CCI Choke ValveDocumento8 pagineCCI Choke ValveEssJayJoeNessuna valutazione finora

- Et 0000 0 000 04 750Documento83 pagineEt 0000 0 000 04 750RenatoNessuna valutazione finora

- Positive ThoughtsDocumento5 paginePositive ThoughtsBalasubramaniam MuruganNessuna valutazione finora

- Stainless - 304 Vs F593C ArticleDocumento2 pagineStainless - 304 Vs F593C ArticleOswaldo Leyva R100% (8)

- Pressure Rating of Steel PipeDocumento2 paginePressure Rating of Steel PipeKamlesh DalavadiNessuna valutazione finora

- Gambar 1Documento10 pagineGambar 1Mario HanamiciNessuna valutazione finora

- Inconel Alloy 718Documento28 pagineInconel Alloy 718hosseinidokht86Nessuna valutazione finora

- Viton Material - Dopont PDFDocumento1 paginaViton Material - Dopont PDFKamlesh DalavadiNessuna valutazione finora

- Material Selection & Design PDFDocumento9 pagineMaterial Selection & Design PDFKamlesh DalavadiNessuna valutazione finora

- V 2 Chap 1Documento34 pagineV 2 Chap 1guruvashisthaNessuna valutazione finora

- Calculation 2Documento5 pagineCalculation 2salhikarimNessuna valutazione finora

- 3 ElectricArcWeldingDocumento34 pagine3 ElectricArcWeldingKamlesh DalavadiNessuna valutazione finora

- Factors Affect SelectionDocumento4 pagineFactors Affect SelectionSajay SuryaNessuna valutazione finora

- NPT - National Pipe Thread: Laydown Threading InsertsDocumento1 paginaNPT - National Pipe Thread: Laydown Threading InsertsKamlesh DalavadiNessuna valutazione finora

- Casting GradeDocumento2 pagineCasting GradeKamlesh DalavadiNessuna valutazione finora

- Wind CalcDocumento4 pagineWind Calc06l01a0224100% (1)

- Delrin Mold Guide 11 06Documento48 pagineDelrin Mold Guide 11 06ibmufnman100% (2)

- Mild SteelDocumento4 pagineMild SteelKamlesh DalavadiNessuna valutazione finora

- Frekote 55 NC PDFDocumento2 pagineFrekote 55 NC PDFKamlesh DalavadiNessuna valutazione finora

- Composite ManufacturingDocumento45 pagineComposite ManufacturingKamlesh DalavadiNessuna valutazione finora

- Mandi Gobindgarh Hazardous Waste Report NGT April2021Documento7 pagineMandi Gobindgarh Hazardous Waste Report NGT April2021arbaz khanNessuna valutazione finora

- Instrumental 3.2Documento4 pagineInstrumental 3.2deon kumukwayaNessuna valutazione finora

- Yttria Stabilized Zirconia Ceramic Safety SheetDocumento6 pagineYttria Stabilized Zirconia Ceramic Safety SheetAli Ali AsjariNessuna valutazione finora

- Palruf PVC BrochureDocumento19 paginePalruf PVC BrochureSerguei DobrinNessuna valutazione finora

- 2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciDocumento25 pagine2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciticmaNessuna valutazione finora

- California Bearing RatioDocumento5 pagineCalifornia Bearing RatioAbhishek Sharma67% (6)

- Natural Shilajit ResinDocumento2 pagineNatural Shilajit ResinMadhav RaghavanNessuna valutazione finora

- N2XSEBY cable specificationsDocumento5 pagineN2XSEBY cable specificationsKiki WidyaNessuna valutazione finora

- Waste Disposal Information Municipality WallisellenDocumento1 paginaWaste Disposal Information Municipality WallisellenCalimeroNessuna valutazione finora

- R.C.C Beam Design GuideDocumento20 pagineR.C.C Beam Design Guidebishal dasNessuna valutazione finora

- MAT224 User Guide-Aug25-2020Documento32 pagineMAT224 User Guide-Aug25-2020YJ WangNessuna valutazione finora

- Insulating Glass Panels With Metal Interlayer Other Glass FacadesDocumento10 pagineInsulating Glass Panels With Metal Interlayer Other Glass Facadesvikina34Nessuna valutazione finora

- Nitoseal MS600 sealant for immersed conditionsDocumento4 pagineNitoseal MS600 sealant for immersed conditionsmilanbrasinaNessuna valutazione finora

- National Senior Certificate: Physical Sciences: Chemistry (P2) JUNE 2023Documento14 pagineNational Senior Certificate: Physical Sciences: Chemistry (P2) JUNE 2023Aneess ChouaneNessuna valutazione finora

- Kevlar MSDSDocumento5 pagineKevlar MSDSsoumsarkar1Nessuna valutazione finora

- Removal of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaDocumento3 pagineRemoval of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaมาร์ค มัธยมNessuna valutazione finora

- Cookery Summative TestDocumento10 pagineCookery Summative TestSonia CamposanoNessuna valutazione finora

- SoapDocumento4 pagineSoapSi OneilNessuna valutazione finora

- Fibre Rope - Terminology and Good PracticesDocumento19 pagineFibre Rope - Terminology and Good PracticesLe Quyen NguyenNessuna valutazione finora

- Crane Wheel Heat Treating MethodsDocumento20 pagineCrane Wheel Heat Treating Methodsgmurdzhev67% (3)

- Thermodynamically Stabilized B-Cspbi - Based Perovskite Solar Cells With Efficiencies 18%Documento6 pagineThermodynamically Stabilized B-Cspbi - Based Perovskite Solar Cells With Efficiencies 18%HalfAton BaiNessuna valutazione finora

- 4232-5 AeroWhip Foam StabilizersDocumento2 pagine4232-5 AeroWhip Foam StabilizerspedrazasNessuna valutazione finora

- Chemsheets A2 1029 (Catalysis)Documento17 pagineChemsheets A2 1029 (Catalysis)Jon HadleyNessuna valutazione finora

- Mechanics of Solid (Mos) : Introduction - Concept of StressDocumento28 pagineMechanics of Solid (Mos) : Introduction - Concept of StressKHAKSARNessuna valutazione finora