Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Scorbot Tutorial

Caricato da

Peru HayaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Scorbot Tutorial

Caricato da

Peru HayaCopyright:

Formati disponibili

ENGN4627 - Robotics.

Scorbot Information.

Tutorial for the Scorbot-ER VII

Robert Mahony,

Dep. Engineering, ANU, ACT, 0200, Australia.

The Department of Engineering, has two Scorbot-ER VII five degree of freedom robotic

manipulators and two Controller-A control units. Each combined system has a typical

functionality of a commercial robotic system. There are 4 components in each robotic

system:

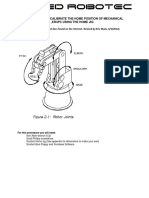

Scorbot-ER VII Manipulator arm: The Scorbot-ER VII arm is a 5 degree of freedom

robotic arm designed for education purposes. The base/shoulder/elbow configuration

is a standard industrial anthropomorphic manipulator configuration. The wrist mechanism is a two degree of freedom (Y-Z co-located axis) design. The gearing system

is belt gear reduction followed by a harmonic drive gear driven by brush-commutated

permanent magnet motors rated to 18A at 24VDC. This configuration ensures the system is relatively safe for operation outside a safety enclosure, however, the maximum

workload that can be carried is 2kg (including the weight of the end effector).

Controller-A: The proprietary Scorbot controller has the ACL programming language

burnt into EPROM. It has the potential to control 11 axes that are separated into

3 groups: Group-A is the the first 6 axes corresponding to the Scorbot-ER VII and

gripper, axes 1-5 are rated to 18A at 24V while axis 6 (for the gripper) is rated to 2A

at 12V; Group-B is for peripheral devices, axes-7 & 8 are both rated to 18A at 24V

for linear-slidebase, rotating-table or conveyer belt peripherals. Group-C axes are for a

second peripheral device, axes 9 & 11 rated to 18A at 24V while axis 10 is rated to 2A

at 12V. Only axes 1-6 have operable driver cards installed in the ANU controller unit.

Advanced Control Language: The controller-A unit is programmed in the advanced

control language (ACL) developed by Eshed Robotec Pty Ltd. The ACL protocol

allows both direct control commands and edited programs to be run. Direct commands are sent in serial ascii directly to the controller, edited programs are best written

in an ascii and downloaded. ACL is not case sensitive.

Advanced Terminal Software: The advanced terminal software provides a good means

of communication with the controller unit. In fact, any ascii serial connection could

be used for direct communication with the controller unit, however, the ATS software

offers backup and print facilities as well as a better command interface than is available

in a standard serial channel.

i) ATS. The ATS software can be activated from the icon on the desktop, or from

a DOS prompt window (change directory to the directory containing ATS and

type ATS. Commands entered on the command line of the terminal are interpreted

directly by the controller unit. Programs can be entered directly in edit mode

using edit command.

ENGN4627 - Robotics.

Scorbot Information.

ii) ATS-offline. An ascii text file can be downloaded directly to the controller unit

using the download command in a DOS prompt

DOWNLOAD /R /Y filename.dnl

The .dnl file is written as though the commands were to be entered directly in the

ATS.

Safety First

First and foremost, look after your own safety when working with the robot. Do not become

blase and use your common sense.

The following list of safety measures should be followed while working with the robot.

i) Check that the manipulator workspace is free of obstacles before operation of the

robot.

ii) Make sure loose hair and clothing is tied back when you work with the robot.

iii) Always home the robot before use.

iv) Verify that you can reach the red abort button on the teach pendant while the robot

is operating (the red emergency button on the controller can also be used if reachable

without passing into the range of the robot). One person should always be in a position

to abort control using the emergency switch during operation.

v) If you abort the motion of the robot at any time using the red emergency button or

the Abort button on the teach pendant you will clear the encoder reference register.

After any use of the abort button you must home the robot again!

vi) Do not enter the robots safety range or touch the robot during operation.

vii) If you need move into the robot workspace when it is not in use, then disable the

motors of the robot using the green switch on the controller.

viii) Do not drive the robot arm into any physical obstacle deliberately.

ix) Do not use physical force to move or stop any part of the robot arm - unless it is to

avoid injuring a human.

x) If the robot impacts the workspace it should trigger the impact protection override

and all motors will halt. To recover from this situation:

a. Depress the green motor switch on the controller unit to turn off the motors.

b. Manually move the robot arm until it is no longer in contact with the environment.

c. Type CLRBUF into the ATS command window to clear the movement buffer

and ensure the robot doesnt try the same movement again when you turn it on

again.

2

ENGN4627 - Robotics.

Scorbot Information.

d. Switch on the motors with the green button.

e. Use the Teach-pendant to manoeuvre the robot to a safe pose or use the MOVE

command to reposition the robot in safe position.

Note: If the abort button was not used then the robot should still retain the encoder

references and be able to be used without running the homing routine. If in doubt, it

is a good idea to move the robot to a known home position and visually check that the

encoder references are correct if they are incorrect the robot will be wrongly positioned.

If you are still in doubt then home the robot again.

xi) Always leave the robot in the parked home position with all power switches in the

off position at the end of every session.

Initialising the robot:

i) Turn on the controller and motors.

ii) Open up a DOS prompt and change directory to C:\ATS

iii) Run the advanced terminal software by typing ATS.

iv) Turn the controller on by typing CON in the ATS window. Alternatively the control

can be activated or deactivated from the Teach-pendant by pressing Control On/Off.

v) Home the robot by using the HOME command in ATS environment. The robot can also

be homed with the Teach-pendant:

Press: Run

Press: 0

Press: Enter

It is important that the robot is homed every time that the controller is

turned on or after any situation in which it is possible that the encoder

count registers are invalidated. This happens when any of the emergency

abort switches are thrown. The robot should not require homing if only

the green motor switch has been thrown or if there was a normal joint

impact or thermal overload error.

vi) After homing the robot is in the parked or parked home position. Define a reference

point at this position. Using the teach pendant:

Press: Record position

Press: 01

Press: Enter

Using the ATS command line interface:

DEFP 01

ENGN4627 - Robotics.

Scorbot Information.

HERE 01

When working on the worktable, return the manipulator to the parked home position

(using the move command not the homing routine) to avoid knocking the manipulator

arm.

The manipulator arm should always be left in the parked home position at the end of

each lab session to avoid long term strain on the joint drive transmissions.

vii) There is a second home position, 0, defined automatically in the controller memory

during the homing routine. We refer to this home position as the active home position.

To see where this home position is use the teach pendant to move to the active home

position

Press: Go position

Press: 0

Press: Enter

or using the command line in ATS

MOVE 0

Return the robot to the parked home position 01 you defined earlier.

viii) There is a third home position termed the reference home position. The reference

home position is such that all axis are aligned in a horizontal plane including the gripper or tool reference. The encoder counts for each axis for the reference home position

are specified by encoder values stored in parameter registers 52-56, see Table 1 for the

values. Define a point for this home position. For robot B, the encoder values are 0,

10500, 8500, 266, 1225 for the 5 axes. To define a point with these encoder values use

DEFP to create a data point and SETPV to specify the data values. That is type

DEFP home

SETPV home

[1] - 0

[2] - 10500

[3] - 8500

[4] - 266

[5] - 1225

Now you can move the robot to the reference home position using

MOVE home

The forward and inverse kinematics of the robot should be computed with respect to

the reference home position.

Downloading and running a program:

i) Activate and home the robot. Leave the robot in the parked home position.

ENGN4627 - Robotics.

Scorbot Information.

ii) Sticky tape a piece of paper on the worktable with its centre approximately 500mm

from the base axis of the robot.

iii) Put a felt pen in the pen holder. (You may want to move the robot to the active home

position to make this easier.) Only use the Pilot felt tip pens that are available from

the departmental administrators (or identical pens that you buy yourself.) Remove

the pen after the experiment.

iv) Ensure that you have saved the drawS.dnl file and either the SdatA.dnl file, if you

are working on robot A, or the SdatB.dnl file, if you are working on robot B, into

the ATS directory on the computer. These data files are plain ascii text files and can

be edited with any ascii text editor.

Data names for ACL files can be at most 8 ascii letters long before the .dnl

tag. Dont use control characters like underlines or hyphens in file names.

Also beware of Microsoft helpfully adding and then hiding .txt, .rtf or

.doc tags on file names when you edit them.

Have a look at the two files.

The data file SdatA.dnl first defines a new vector of trajectory points PTW with 104

points using the command

DIMP PTW[104]

Then it individually assigns joint coordinates to each point in the vector PTW using the

command

SETPV PTW[1]

3832 ; Axis 1

6812 ; Axis 2

-6861 ; Axis 3

-13213 ; Axis 4

0 ; Axis 5

The semi-colon ; indicates a remark and text after a semi-colon (on the same line) is

not parsed by the controller unit. Joint axis references are given in encoder counts.

The program file drawS.dnl defines the program drawS. The initial command

PROGRAM drawS

defines the program. The second line

MOVE PTW[1]

moves the robot to the initial point of the trajectory using the standard move command. This is done to avoid an initial fast transient that will cause the end-effector

to bounce into the table. The motion command

MPROFILE PARABOLE A

is used to select a parabolic velocity profile for the motion. And finally the trajectory

itself is tracked using

MOVES PTW 2 104 1000

moving along the vector variable PTW from element 2 to element 104 in 1000 tenths of

seconds (or 10 seconds). The program is terminated with the command

END

5

ENGN4627 - Robotics.

Scorbot Information.

The controller time slice is 10ms. Durations are specified in clock ticks so

a duration of 1000 in the MOVES command corresponds to 10s.

v) Download the data file onto the robot controller.

Make sure that you have exited ATS (shift-F9) and are in the DOS terminal.

type DOWNLOAD /R /Y SdatA.dnl

It will take a minute or so for the points to download due to the slow serial link. There

may be an initial error message due to the DIMP command if the variable PTW is already

defined in the controller memory.

Download the program file

type DOWNLOAD /R /Y drawS.dnl

You must run ATS at least once before you run the download routine to

establish the serial link with the controller unit.

If you dont see any output on the terminal screen during a download then there has

almost certainly been an error. The error report is not shown on screen, however, it

can been found in the REPORT.DLD file in the ATS directory after a failed download.

If the program or data that you are downloading already exists in the controller RAM

you will get a visible error message when downloading. This is OK as the programs

should be overwritten if you use the /r /y modifiers with the download command.

However, you may want to delete the program using the REMOVE <prog> command

and the data using the DELP <pvect> command within ATS prior to downloading

a modified program and data just to make sure the controller is running the latest

version.

Only those data points that you specify are rewritten in a data download.

If you have a vector of point references PTW stored on the machine with

50 points, and then define a shorter path with only 40 points and download

to the same name,s the controller will retain the original vector values for

points 41-50.

vi) Run ATS by typing ATS.

vii) Turn the controller on by typing CON.

viii) Has the main control unit of the robot been turned off? Was the previous motion of

the robot aborted? If you are in any doubt as to whether the robot is properly homed

then home the robot again.

ix) Move the robot down until the pen tip is only a centimetre or two off the centre of the

paper. This is done to avoid an initial fast move from home to the paper that might

lead to the end effector bouncing into the paper. Use the Teach-pendant to move the

robot axis.

x) List programs in the controller unit using

DIR

to verify that program drawS has been loaded.

ENGN4627 - Robotics.

Scorbot Information.

xi) Run program drawS by typing

RUN drawS

xii) Move the robot back to its home position using the MOVE 01 command.

ENGN4627 - Robotics.

Scorbot Information.

Parameters of Esched Scorbot-ERVII.

A parameter can be viewed by using the ACL command SHOW PAR. For example to check

the value of parameter 33 type:

SHOW PAR 33

Do not modify the controller parameters without asking the lecturer or lab

technician.

The present parameter settings are shown in Table 1. Note that the encoder reference

for the home position for robot A and robot B are different.

Additional Documentation

In addition to this tutorial, there are four manuals that cover all aspects of operation of the

Scorbot:

Scorbot-ER VII User Manual: The User manual contains hardware and software specifications for the robot and controller systems. It contains a tutorial on operating the

robot and on programming in ACL. In Appendix A it describes the joint controller

design.

ACL reference guide: This manual contains comprehensive lists of ACL commands.

ATS reference guide: This manual contains an overview of the operation of the Advanced

terminal software (terminal emulation software).

ATS-offline reference guide: This manual contains an overview of the operation of the

offline capability of the ATS software. It is recommended that you use the command

line version of the ATS software and this manual is unlikely to be of use.

ENGN4627 - Robotics.

param.

PAR 33

PAR 34

PAR 35

PAR 36

PAR 37

PAR 52

PAR 53

PAR 54

PAR 55

PAR 56

PAR 92

PAR 93

PAR 94

PAR 95

PAR 96

PAR 97

Scorbot Information.

explanation

Number of encoder counts for +90 rotation

Number of encoder counts for +90 rotation

Number of encoder counts for +90 rotation

Number of encoder counts for +90 rotation

Number of encoder counts for +90 rotation

Value of encoder 1 at home position

Value of encoder 2 at home position

Value of encoder 3 at home position

Value of encoder 4 at home position

Value of encoder 5 at home position

of

of

of

of

of

axis

axis

axis

axis

axis

1

2

3

4

5

Y -coordinate in tenths of millimetres (offset from center along the Y -axis) of

the gripper tip when robot is in the home position.

X-coordinate in tenths of millimetres of the rotation axis of arm link 2 when

the robot is in the home position.

Z-coordinate in tenths of millimetres of the rotation axis of arm link 2.

Length of the (upper) arm link from the first articulated joint in tenths of

millimetres.

Length of the (lower) arm link from the second articulated joint in tenths of

millimetres.

Distance from the pitch axis to the tip of the gripper in tenths of millimetres.

Table 1: Parameter codes for the Denavit-Hartenburg parameters and encoder settings for

the Scorbot ER-VII.

A

23040

-23040

23040

28800

9600

0

11130

8380

682

7658

B

23040

-23040

23040

28800

9600

0

10500

8500

266

1225

-353

-353

500

500

3585

3585

3000

3000

2500

2500

2928

2880

Potrebbero piacerti anche

- RobotDocumento5 pagineRobotSonal Mehir RamjununNessuna valutazione finora

- AssignmentqDocumento12 pagineAssignmentqDirajen PMNessuna valutazione finora

- Feedback 35-001-USB PDFDocumento2 pagineFeedback 35-001-USB PDFFrancisco OchoaNessuna valutazione finora

- PR2Documento14 paginePR2JenesaVillahermosaNessuna valutazione finora

- Robo CellDocumento84 pagineRobo CelldviryNessuna valutazione finora

- Johnny5 RobotDocumento2 pagineJohnny5 RobotXavier MuñozNessuna valutazione finora

- Scorbot ER-III Arm Calibration & Testing (EDM)Documento15 pagineScorbot ER-III Arm Calibration & Testing (EDM)pauloNessuna valutazione finora

- A Low-Cost Compliant 7-DOF Robotic Manipulator: Morgan Quigley, Alan Asbeck, and Andrew Y. NGDocumento8 pagineA Low-Cost Compliant 7-DOF Robotic Manipulator: Morgan Quigley, Alan Asbeck, and Andrew Y. NGsigmateNessuna valutazione finora

- Down-Line Loading On Hero RobotDocumento40 pagineDown-Line Loading On Hero RobotAnonymous qTKCWlxNessuna valutazione finora

- IRobot 310 SUGV SpecsDocumento2 pagineIRobot 310 SUGV Specsdas1717Nessuna valutazione finora

- Arm Robot (Scorbot ER-III) : A. IntroductionDocumento3 pagineArm Robot (Scorbot ER-III) : A. IntroductionYehezkiel88Nessuna valutazione finora

- Ce 1983 01 PDFDocumento140 pagineCe 1983 01 PDFJose Cedillo ElBuenoNessuna valutazione finora

- 01 HistoryDocumento12 pagine01 HistoryJefferson MagallanesNessuna valutazione finora

- Servo Magazine 2010-12 Building The Arduino Bof PDFDocumento72 pagineServo Magazine 2010-12 Building The Arduino Bof PDFMichael LeydarNessuna valutazione finora

- PackBot RobotDocumento5 paginePackBot Robotpankaj1chokadiNessuna valutazione finora

- Oie751 Robotics: Faculty Name K.Manikandan Associate Professor /mech A.HOD. MamceDocumento48 pagineOie751 Robotics: Faculty Name K.Manikandan Associate Professor /mech A.HOD. MamcemaniNessuna valutazione finora

- Introduction To Mentor Robotic ArmDocumento2 pagineIntroduction To Mentor Robotic ArmSAMIE KHANNessuna valutazione finora

- Servo Magazine - October 2010-TV PDFDocumento84 pagineServo Magazine - October 2010-TV PDFCristian PuiuNessuna valutazione finora

- Ce 1983 01Documento140 pagineCe 1983 01ProbhakarRoyNessuna valutazione finora

- Robotic Arm Packaging and ParrelitizingDocumento12 pagineRobotic Arm Packaging and ParrelitizingAdeel Ahmad WattooNessuna valutazione finora

- Robot-B ER - IXDocumento54 pagineRobot-B ER - IXDuy Hưng100% (1)

- 6servo Robot Arm EngDocumento18 pagine6servo Robot Arm EngĐỗ ThànhNessuna valutazione finora

- ScaraDocumento7 pagineScaraAnand Kumar MishraNessuna valutazione finora

- Gryphon EC Final ReportDocumento12 pagineGryphon EC Final Reportsanjiv0909Nessuna valutazione finora

- Project 1 - Robotic ArmDocumento19 pagineProject 1 - Robotic ArmAizzat ZackNessuna valutazione finora

- 510 PackBot Spec SheetDocumento1 pagina510 PackBot Spec SheetDavid Fernández VillanuevaNessuna valutazione finora

- Scorbot Er4u User ManualDocumento41 pagineScorbot Er4u User Manualdaniel2442Nessuna valutazione finora

- Graphical Teach Pendant: - The FlexpendantDocumento11 pagineGraphical Teach Pendant: - The FlexpendantAMINTA MANZANILLANessuna valutazione finora

- Industrial Robotics: History and Definition Classification of Robot Robot Anatomy and Robot Motion Work VolumeDocumento73 pagineIndustrial Robotics: History and Definition Classification of Robot Robot Anatomy and Robot Motion Work VolumeSiddharth Gupta0% (1)

- RoboCare Manual enDocumento17 pagineRoboCare Manual enVoxine OuscularenNessuna valutazione finora

- IAT0922 Industrial Robotics Chapter2 Rev4Documento79 pagineIAT0922 Industrial Robotics Chapter2 Rev4visionNessuna valutazione finora

- Microsoft Kinect Sensor PDFDocumento7 pagineMicrosoft Kinect Sensor PDFAndré QuirinoNessuna valutazione finora

- Final Year Project Report Robotic ArmDocumento11 pagineFinal Year Project Report Robotic ArmAmr ElsakkaNessuna valutazione finora

- Microsoft Robotics: Ryan Fernandes Pranoti Barge Kaustubh Gage Vaikunth BhandareDocumento15 pagineMicrosoft Robotics: Ryan Fernandes Pranoti Barge Kaustubh Gage Vaikunth BhandareVaikunth BhandareNessuna valutazione finora

- A Black and Red TriangleDocumento3 pagineA Black and Red TriangleJunn Ree MontillaNessuna valutazione finora

- EncoderDocumento44 pagineEncoderdaiduongxanh14113Nessuna valutazione finora

- Hand Gesture-Controlled Robotic Arm With All-Terrain Surveillance CarDocumento7 pagineHand Gesture-Controlled Robotic Arm With All-Terrain Surveillance CarIJRASETPublicationsNessuna valutazione finora

- Robotics BookDocumento137 pagineRobotics BookdineshkumarbaskaranNessuna valutazione finora

- Field RoboticsDocumento70 pagineField RoboticsSkanda SwaroopNessuna valutazione finora

- Robotica 1 3 Fotos2 PDFDocumento121 pagineRobotica 1 3 Fotos2 PDFSubhashish AnandNessuna valutazione finora

- Pioneer RobotDocumento69 paginePioneer RobotSummer TriangleNessuna valutazione finora

- RV N e PDFDocumento60 pagineRV N e PDFdavev2005Nessuna valutazione finora

- EEE 1207 021 6 DOF Robotic Arm ManipulatorDocumento7 pagineEEE 1207 021 6 DOF Robotic Arm ManipulatorUNsha bee komNessuna valutazione finora

- ILXVol1No1 PDFDocumento10 pagineILXVol1No1 PDFDaniel AjoyNessuna valutazione finora

- Automated Industrial Robot Path Planning For Pick and Plcae Applications FinalDocumento1 paginaAutomated Industrial Robot Path Planning For Pick and Plcae Applications FinalPablo GonzalezNessuna valutazione finora

- Scara RobotDocumento13 pagineScara RobotMuhammad Ikhsan Al-fatihNessuna valutazione finora

- PIC Based Frequency and RMS Value MeasurementDocumento8 paginePIC Based Frequency and RMS Value MeasurementIJIRSTNessuna valutazione finora

- Product Maintenance Manual: HIK/72XXHVI-SVDocumento15 pagineProduct Maintenance Manual: HIK/72XXHVI-SVMilton Pereira Dos SantosNessuna valutazione finora

- Kawasaki Robotics B SeriesDocumento6 pagineKawasaki Robotics B SeriescarrizolocoNessuna valutazione finora

- Nachi Robot Catalog 2012Documento20 pagineNachi Robot Catalog 2012Xanti Zabala Da RosaNessuna valutazione finora

- PDF Roboics1Documento65 paginePDF Roboics1Sai Krishna TejaNessuna valutazione finora

- Unit 6 Industrial RoboticsDocumento74 pagineUnit 6 Industrial RoboticsMURALIGOCAM_29070605Nessuna valutazione finora

- Robotics ManualDocumento80 pagineRobotics ManualPOOJAN VANANINessuna valutazione finora

- Robot Assist Users Manual PDFDocumento80 pagineRobot Assist Users Manual PDFIvan AvramovNessuna valutazione finora

- Controlling Kuka Industrial Robots Flexible Communication Interface JopenshowvarDocumento14 pagineControlling Kuka Industrial Robots Flexible Communication Interface JopenshowvarMihail AvramovNessuna valutazione finora

- Design Ideas for Drones, Multicopters and QuadcoptersDa EverandDesign Ideas for Drones, Multicopters and QuadcoptersNessuna valutazione finora

- Scorbot IntroDocumento11 pagineScorbot IntroHeber AlmeidaNessuna valutazione finora

- ABB Robot Basic TrainingDocumento20 pagineABB Robot Basic Trainingelmacuarro5100% (1)

- Readme eDocumento3 pagineReadme eJosé Antonio Velásquez CostaNessuna valutazione finora

- Cylindrical Type BR SeriesDocumento6 pagineCylindrical Type BR SeriesPeru HayaNessuna valutazione finora

- Teach Pendant Manual ER4u PDFDocumento19 pagineTeach Pendant Manual ER4u PDFnamnp2007Nessuna valutazione finora

- Scorbot Er4u User ManualDocumento41 pagineScorbot Er4u User Manualdaniel2442Nessuna valutazione finora

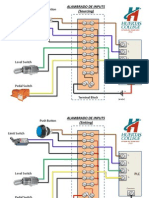

- Alambrado de Inputs OutputsDocumento4 pagineAlambrado de Inputs OutputsIñaki EseberriNessuna valutazione finora

- PLC ApplicationDocumento56 paginePLC ApplicationMohamed Gawad ARaya88% (8)

- Flagword 5 of CPU Address 58: 3555 Flagword 5 Is To Be Modified 3555Documento1 paginaFlagword 5 of CPU Address 58: 3555 Flagword 5 Is To Be Modified 3555Peru HayaNessuna valutazione finora

- InstallDocumento1 paginaInstallRaúl Leonel Castañeda AguilarNessuna valutazione finora

- Lab Volt Trainer Allen Bradley Micologix 1200 Rslogix 500 Screen FotoDocumento2 pagineLab Volt Trainer Allen Bradley Micologix 1200 Rslogix 500 Screen FotoPeru HayaNessuna valutazione finora

- Teach PendDocumento1 paginaTeach PendPeru HayaNessuna valutazione finora

- Program CreditsDocumento1 paginaProgram CreditsPeru HayaNessuna valutazione finora

- Readme eDocumento3 pagineReadme eJosé Antonio Velásquez CostaNessuna valutazione finora

- Teach Pendant Manual ER4u PDFDocumento19 pagineTeach Pendant Manual ER4u PDFnamnp2007Nessuna valutazione finora

- InstallDocumento1 paginaInstallRaúl Leonel Castañeda AguilarNessuna valutazione finora

- 100343-b ER - 4u - 1Documento45 pagine100343-b ER - 4u - 1Peru HayaNessuna valutazione finora

- Experiment 1 Robocell & Scorbase: 1.objectiveDocumento9 pagineExperiment 1 Robocell & Scorbase: 1.objectivePeru HayaNessuna valutazione finora

- Experiment 1 Robocell & Scorbase: 1.objectiveDocumento9 pagineExperiment 1 Robocell & Scorbase: 1.objectivePeru HayaNessuna valutazione finora

- ACLmanual (English)Documento203 pagineACLmanual (English)Peru HayaNessuna valutazione finora

- ACLmanual (English)Documento203 pagineACLmanual (English)Peru HayaNessuna valutazione finora

- Teach Pendant Manual ER4u PDFDocumento19 pagineTeach Pendant Manual ER4u PDFnamnp2007Nessuna valutazione finora

- EFY - Electronics For You - June-2022-Magazine PDFDocumento90 pagineEFY - Electronics For You - June-2022-Magazine PDFBoobalan jNessuna valutazione finora

- Employment After Lockdown"Documento3 pagineEmployment After Lockdown"20ECF042 VIGNESH SNessuna valutazione finora

- Diffusion of Artificial Intelligence in Human Resource Domain With Specific Reference To Recruitment Function A Literature Review StudyDocumento8 pagineDiffusion of Artificial Intelligence in Human Resource Domain With Specific Reference To Recruitment Function A Literature Review StudyInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Experience With Introducing Robotics Toolbox For MATLAB in A Senior Level Undergraduate CourseDocumento8 pagineExperience With Introducing Robotics Toolbox For MATLAB in A Senior Level Undergraduate CourseMiguel SilvaNessuna valutazione finora

- Introduction To ROBOTICSDocumento25 pagineIntroduction To ROBOTICSNyandaMadili MalashiNessuna valutazione finora

- RFID Warehouse RobotDocumento6 pagineRFID Warehouse RobotShravani ThombreNessuna valutazione finora

- Application Manual: Additional Axes and Stand Alone ControllerDocumento196 pagineApplication Manual: Additional Axes and Stand Alone ControllercheloooxxxNessuna valutazione finora

- Encounter - Smart Factory, 2015Documento74 pagineEncounter - Smart Factory, 2015AUDI AG100% (4)

- DHL Trendreport RoboticsDocumento37 pagineDHL Trendreport RoboticsirhoNessuna valutazione finora

- Moving & Rotating Equipment: Hazard RecognitionDocumento35 pagineMoving & Rotating Equipment: Hazard RecognitionMuhammad Faisal JavedNessuna valutazione finora

- UiPath Academy Training CatalogDocumento38 pagineUiPath Academy Training CatalogAdiCNessuna valutazione finora

- A Robotics Project Submitted To DR Ali AhsanDocumento4 pagineA Robotics Project Submitted To DR Ali Ahsanasim_ali82Nessuna valutazione finora

- Welding RobotsDocumento18 pagineWelding RobotsPraveen Bhadula67% (3)

- A Review On The Effects of Chanting and Solfeggio Frequencies On Well-BeingDocumento689 pagineA Review On The Effects of Chanting and Solfeggio Frequencies On Well-BeingJan LAWNessuna valutazione finora

- Can Robots Replace Humans Completely in The Workplaces?: View PointDocumento3 pagineCan Robots Replace Humans Completely in The Workplaces?: View PointYehezkiel ImannuelNessuna valutazione finora

- Presentation Flex Sensor Based RobotDocumento9 paginePresentation Flex Sensor Based RobotAnkit Kumar SinghNessuna valutazione finora

- Aquarian Technology PDFDocumento9 pagineAquarian Technology PDFVíctor VelascoNessuna valutazione finora

- Robotic ArmDocumento20 pagineRobotic ArmSesha AceNessuna valutazione finora

- MiR Charge 48V User Guide 3.0 - enDocumento46 pagineMiR Charge 48V User Guide 3.0 - enMike lmlNessuna valutazione finora

- Mitsubishi Controller Manual CR1, CR2, CR3, CR4, CR7, CR8, CR9 - Instruction Manual (Troubleshooting) BFP-A5993-M (09.09)Documento46 pagineMitsubishi Controller Manual CR1, CR2, CR3, CR4, CR7, CR8, CR9 - Instruction Manual (Troubleshooting) BFP-A5993-M (09.09)James Jdf100% (1)

- Robot Comedy British English Teacher Ver2Documento6 pagineRobot Comedy British English Teacher Ver2Mage AlterNessuna valutazione finora

- Mark The Letter A, B, C, or D On Your Answer Sheet To Indicate The Correct Answer To Each of The Following QuestionsDocumento38 pagineMark The Letter A, B, C, or D On Your Answer Sheet To Indicate The Correct Answer To Each of The Following QuestionsThanh TùngNessuna valutazione finora

- Search and Rescue RobotsDocumento10 pagineSearch and Rescue RobotsDivya VaniNessuna valutazione finora

- 2019 Issue-1Documento84 pagine2019 Issue-1Tao HouNessuna valutazione finora

- S151122 Hand Motion Controlled Robotic Arm PDFDocumento5 pagineS151122 Hand Motion Controlled Robotic Arm PDFSara AlabwainiNessuna valutazione finora

- Robotics Research PlanDocumento7 pagineRobotics Research PlanRuth Carin - MalubayNessuna valutazione finora

- Cyberpsychology and Artificial Intelligence in Society: DR Marta R. JabłońskaDocumento50 pagineCyberpsychology and Artificial Intelligence in Society: DR Marta R. JabłońskaKarolek100% (1)

- DronesDocumento55 pagineDronesmackyprinting100% (1)

- Towards Interactive Robots in Autism TherapyDocumento35 pagineTowards Interactive Robots in Autism TherapyMihaela VișanNessuna valutazione finora

- Diploma in Civil Engineering: Project ReportDocumento42 pagineDiploma in Civil Engineering: Project ReportSuraj DubeyNessuna valutazione finora