Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5S Grading Sheet

Caricato da

Josh PeraltaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5S Grading Sheet

Caricato da

Josh PeraltaCopyright:

Formati disponibili

Score

Condition Observed

Very Good (perfect condition)

Good (1-2 problems)

OK (3-4 problems)

Bad (5-6 problems)

Very Bad (above 7 problems),

or non existant

Score (check box)

0 1 2 3 4

To calculate 5S score

PRODUCTION 5S CHECKSHEET

Item

2. Add each column together to get total

3. Divide total by 280

4. Multiply this score by 5

5. This is now your 5S score

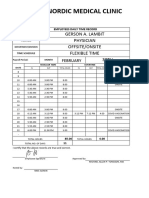

Audited By : Cornejo,Dhaven M.

Date : March 2,2011

Number

1. Add up all columns

Sort

(Means removing from the

workplace all items that are

not needed for current

production)

Straighten

(Can be defined as

arranging items so that

they are easy to use and

labelling them so that

they are easy to find and

put away)

Score

2 3

Shine

(Means sweeeping floors,

wiping off machinery, and

generally making sure

that everything in the

factory stays clean)

Score

0 1 2 3 4

Score

Standardise

(It is the state that exists

when the first three S's

are being maintained)

0 1 2 3 4

Score

Sustain

(Making a habit of

properly maintaining

correct procedures)

0 1 2 3 4

0 1 2 3 4

All fire extinguishers are

charged, eye wash

stations labelled and first

aid equipment available

and labelled

Are safety glasses clean

and in good condition

Area plan identifies eye

wash stations, fire

extinguishers, and fire

exits

Are PPE and safety

standards being adhered

to by all employees in the

area

H&S

Are there fire extinguishers,

fire exits clear, PPE available,

eye wash stations and first aid

equipment available

Environmental

Are recyclable materials in

non-recyclable containers

Each area has specified

recycling containers

All outside surfaces of

recycling containers are

clean

Waste disposal standards

exist and are displayed

Employees in the area

are using the containers

to standard

Facilities

Are facility items in the area

broken, damaged

Have items in the area

been identified that are

broken or damaged ?

The area has floors

swept, machinery clean

and generally clean

Has maintenance request

been raised ?

Does an area have a

planned maintenance

schedule for all facilities

issues ?

Floors & Gangways

Free of obstructions

Floor Marked per plant

standard

Clean (No Dirt, No Spills,

No Oil)

Floor marking standard

created and posted in the

area

Daily checksheet in place

with sign off & date with

improvement action items

Duty Technician

Does Duty technician rota &

standard exist

Rota (time table) is

displayed and labelled

Is rota board clean / good

condition

Duty technician standard

exists for the area

Duty technician rota is

being carried out to

standard

Area plan identifies

location of tooling,

fixtures & jigs

Are all tooling standards

adhered to at all times ?

Area plan identifies

location of wires, cabling

& hoses

Are all wires, cabling &

hose standards adhered

to at all times ?

Does a standard exist in

the area that describes

what the workbenches

and surfaces should

require

Are all workbenches &

surfaces standards

adhered to at all times ?

Tooling, Fixtures, Jigs

No Tools, fixtures & jigs on

workstations unless in use

Point of use Items have

designated and clearly

organized storage

location

Wires , cabling & Hoses

No un-used wiring, & hoses

present or trailing

Are all Wiring , cabling

and hoses organised and

identified?

No tooling (measuring

equipment, torque

wrenches, pressure

gauges) in area out of

calibration

Are all hoses, cabling &

wires clean, in good

condition and blanked

(hoses only) ?

Workbenches & surfaces

No un-necessary items on

workbenches or work surfaces

Workbenches and work

surfaces are organized

Workbenches and work

surfaces are clean and in

good condition

Visual tracking boards

All information is current and

necessary ?

Department visual

tracking board layout

constant with plant

standard

All postings are neat &

orderly in appearance

Area standard exists and

is posted to define layout

and format

Are all visual tracking

board standards adhered

to at all times ?

10

Red Tag

Are there items requiring red

tags within the area

Red Tag area is

designated and labeled,

all items tagged with date

placed in area

Red tag area to be clean

Area plan identifies red

tag area

Red tag area is

maintained to correct

procedure

11

Mobile Equipment

No un-necessary mobile

equipment present

Storage locations for

mobile equipment are

designated and labeled

All are free of debris and

none are damaged

Area plan identifies

location mobile

equipment

Mobile equipment is

located in correct area

when not in use

12

Storage

No material storage areas are

overflowing

All material storage areas

are clearly designated

and labeled

Material storage areas

only contain WIP and/or

pre-kitted items

Area plan identifies

location of material

storage

Items are returned to

designated area when not

in use

13

Cleaning Standards

Cleaning standards and or

cleaning station exist

Cleaning standards &

cleaning station are

designated and labelled

Cleaning equipment is

u stored in correct location

and in good condition

Cleaning standards exist

and have daily sign off

and date

Daily cleaning standards

are adhered to

14

Machine Guards,

Windows & Interlocks

All interlocks are operational

Guards and shields in

place where required

All machine windows are

cleaned regularly to area

standard

Machine guards,

interlocks have planned

maintenance standard

and schedule

Machine guards,

interlocks are maintained

to planned maintenance

standard

SECTION TOTALS :

53

/ 56

54

/ 56

55

/ 56

55

/ 56

Conclusion: The group used a 5S checksheet to evaluate the company's way on how they provide safety rules and regulations for their workers and at the same time how they implement waste management

progams.The group conducted this sheet in a systematic approach in order to easily identify whether they pass or failed the 5S test checksheet.Based on the data we gathered,their 5S score was 1.09 which means they

failed to pass the performance that companies should have for safety and sanitary.PME justifies that any company shoulld impose cleanliness and should implement rules and regulations that will help not only the

profitability of the company but also the performance of the workers.They should apply and put it into practice for them to sustain their productivity at the same time the quality.

Score

GRAND TOTAL

5S SCORE

56

/ 56

273

/ 280

4.88

PRODUCTION 5S AUDIT COMMENTS SHEET

Date :_____________________________

Number Item

Audited By :_________________________

Straighten

Shine

Sort

(Can be defined as arranging items so that they are (Means sweeeping floors, wiping off machinery, and

Standardise

(Means removing from the workplace all items that easy to use and labelling them so that they are

generally making sure that everything in the factory (It is the state that exists when the first three S's

are not needed for current production)

easy to find and put away)

stays clean)

are being maintained)

Comments

H&S

Environmental

Facilities

Floors, Walkways &

Gangways

Duty Technician

Tooling, Fixtures, Jigs

Wires , cabling & Hoses

Workbenches & surfaces

Visual tracking boards

10

Red Tag

11

Mobile Equipment

12

Storage

13

Cleaning Standards

14

Machine Guards, Windows &

Interlocks

Area Audited : _________________________

'file:///var/www/apps/conversion/tmp/scratch_1/260713672.xls'#$5S Comments & Actions Form

Comments

Comments

Comments

Sustain

(Making a habit of properly maintaining correct

procedures)

Comments

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Ie 303 - Methods Engineering: Figure 12. "Organigramme" - Organizational ChartDocumento1 paginaIe 303 - Methods Engineering: Figure 12. "Organigramme" - Organizational ChartJosh PeraltaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- (Journal) An Analysis of Nike's Outbound Flow DistributionDocumento94 pagine(Journal) An Analysis of Nike's Outbound Flow DistributionJosh PeraltaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- (Case Study) Utilization of DFMA To TRIZ MethodologyDocumento11 pagine(Case Study) Utilization of DFMA To TRIZ MethodologyJosh PeraltaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- (Book Chapter) TRIZ - Design Problem Solving With Systematic InnvationDocumento24 pagine(Book Chapter) TRIZ - Design Problem Solving With Systematic InnvationJosh PeraltaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Process Improvement and Cycle Time Reduction in The Checking and Loading Process of The Outbound Department of A Logistics CompanyDocumento1 paginaProcess Improvement and Cycle Time Reduction in The Checking and Loading Process of The Outbound Department of A Logistics CompanyJosh PeraltaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Bose's Mexico PlantDocumento7 pagineBose's Mexico PlantLani SilvaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- DBMS Lab FileDocumento44 pagineDBMS Lab Filesaumya_ŠšNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- BCDA V COADocumento3 pagineBCDA V COADanielle LimNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Employee Wwelfare ProjectDocumento11 pagineEmployee Wwelfare ProjectVijay KishanNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Day 4 - LOTO AwarenessDocumento17 pagineDay 4 - LOTO AwarenesssobemileNessuna valutazione finora

- SLB Land Rig BRDocumento9 pagineSLB Land Rig BRIkhwan100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Option FormDocumento3 pagineOption FormShadow100% (1)

- Gers-Lambit-Dtr May15Documento3 pagineGers-Lambit-Dtr May15Butch NorielNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- My Project 1Documento42 pagineMy Project 1doppalapudi umamahesh100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- A Siesta For JackilouDocumento5 pagineA Siesta For JackilouGilbert Base Jr.Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Home Health Auto Enrolment - General NoticeDocumento4 pagineHome Health Auto Enrolment - General NoticeViorel OpreaNessuna valutazione finora

- Human Resource Management Notes 2Documento48 pagineHuman Resource Management Notes 2DengAwutNessuna valutazione finora

- Heriot-Watt University Organisational Behaviour - December 2015 Section I Case StudyDocumento14 pagineHeriot-Watt University Organisational Behaviour - December 2015 Section I Case StudyIzhamKhairiNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ClearPoint-HR KPI LibraryDocumento9 pagineClearPoint-HR KPI LibraryLialunaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- HK Org ChartDocumento38 pagineHK Org ChartMhel DemabogteNessuna valutazione finora

- JSA-excavation & RefillDocumento7 pagineJSA-excavation & RefillArnfel Jamil Cabil100% (1)

- Occupational Health and SafetyDocumento2 pagineOccupational Health and SafetyGwenn CastroNessuna valutazione finora

- Government of Andhra Pradesh: 1 ChairpersonDocumento2 pagineGovernment of Andhra Pradesh: 1 ChairpersonQC&ISD1 LMD COLONYNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Opcrf of School Heads and Ipcrfs of Teaching and NonDocumento9 pagineOpcrf of School Heads and Ipcrfs of Teaching and NonJoey ManalastasNessuna valutazione finora

- Structuring Business LettersDocumento7 pagineStructuring Business LettersAvinab DasNessuna valutazione finora

- Department of Labor: 2005 05 27 17 FLSA ShiftsDocumento2 pagineDepartment of Labor: 2005 05 27 17 FLSA ShiftsUSA_DepartmentOfLaborNessuna valutazione finora

- A Project Report On ATTRITION MANAGEMENT PDFDocumento120 pagineA Project Report On ATTRITION MANAGEMENT PDFFebson Lee MathewNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- HRMDocumento2 pagineHRMPiyush SinhaNessuna valutazione finora

- W 4tDocumento1 paginaW 4tfredlox92% (13)

- Industrial Relations Assignment: Submitted By-: Mridushi PuriDocumento12 pagineIndustrial Relations Assignment: Submitted By-: Mridushi Puripranjal bankarNessuna valutazione finora

- Comm3020 AssignmentDocumento7 pagineComm3020 Assignmentapi-291849652Nessuna valutazione finora

- Factors Influencing Employee Engagement by Kimberly AlesnaDocumento9 pagineFactors Influencing Employee Engagement by Kimberly AlesnaKimaii AlesnaNessuna valutazione finora

- DocumentDocumento5 pagineDocumentMadan ChaturvediNessuna valutazione finora

- Human Resource Management PresentationDocumento12 pagineHuman Resource Management PresentationM.Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)