Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Alumínio Cold ASM Material Data Sheet

Caricato da

marcelogf74Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Alumínio Cold ASM Material Data Sheet

Caricato da

marcelogf74Copyright:

Formati disponibili

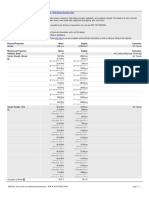

ASM Material Data Sheet

1 de 2

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA508...

Aluminum 5083-H112

Subcategory: 5000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal

Close Analogs:

Composition Notes:

Aluminum content reported is calculated as remainder.

Composition information provided by the Aluminum Association and is not for design.

Key Words: UNS A95083; ISO AlMg4.5Mn; Aluminium 5083-H112; AA5083-H112

Component

Wt. %

Component

Wt. %

Component

Wt. %

Al

92.4 - 95.6

Mg

4 - 4.9

Si

Max 0.4

Cr

0.05 - 0.25

Mn

0.4 - 1

Ti

Max 0.15

Cu

Max 0.1

Other, each Max 0.05

Zn

Max 0.25

Fe

Max 0.4

Other, total Max 0.15

Material Notes:

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

Physical Properties

Metric

English

Comments

2.66 g/cc

0.0961 lb/in

AA; Typical

Hardness, Brinell

81

81

500 kg load with 10 mm ball. Calculated value.

Hardness, Knoop

104

104

Converted from Brinell Hardness Value

Hardness, Rockwell B

50

50

Converted from Brinell Hardness Value

Hardness, Vickers

91

91

Converted from Brinell Hardness Value

Tensile Strength, Ultimate

300 MPa

43500 psi

Tensile Strength, Yield

190 MPa

27600 psi

16 %

16 %

In 5 cm; Sample 1.6 mm thick

Modulus of Elasticity

70.3 GPa

10200 ksi

In Tension

Compressive Modulus

71.7 GPa

10400 ksi

Poisson's Ratio

0.33

0.33

Shear Modulus

26.4 GPa

3830 ksi

Shear Strength

180 MPa

26100 psi

5.9e-006 ohm-cm

5.9e-006 ohm-cm

Density

Mechanical Properties

Elongation at Break

Estimated from trends in similar Al alloys.

Calculated value.

Electrical Properties

Electrical Resistivity

06/07/11 10:11

ASM Material Data Sheet

2 de 2

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA508...

Thermal Properties

CTE, linear 68F

CTE, linear 250C

Specific Heat Capacity

Thermal Conductivity

Melting Point

23.8 m/m-C

13.2 in/in-F

AA; Typical; Average over 68-212F range.

26 m/m-C

14.4 in/in-F

Average over the range 20-300C

0.9 J/g-C

0.215 BTU/lb-F

117 W/m-K 812 BTU-in/hr-ft-F

591 - 638 C

1095 - 1180 F AA; Typical range based on typical composition for wrought

products 1/4 inch thickness or greater

Solidus

591 C

1095 F

AA; Typical

Liquidus

638 C

1180 F

AA; Typical

413 C

775 F

holding at temperature not required

316 - 482 C

600 - 900 F

Processing Properties

Annealing Temperature

Hot-Working Temperature

References for this datasheet.

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistant format. Users

requiring more precise data for scientific or engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We

advise that you only use the original value or one of its raw conversions in your calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and

terms of use regarding this information. MatWeb data and tools provided by MatWeb, LLC.

06/07/11 10:11

Potrebbero piacerti anche

- Aerospace Material Specification: AMS5709 REV. HDocumento6 pagineAerospace Material Specification: AMS5709 REV. Hfelipe jurema100% (1)

- Ams 81200Documento29 pagineAms 81200BacksniperNessuna valutazione finora

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDa EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNessuna valutazione finora

- A580A580M-15 Standard Specification For Stainless Steel WireDocumento5 pagineA580A580M-15 Standard Specification For Stainless Steel Wiretjt4779Nessuna valutazione finora

- A565A565M-10 Standard Specification For Martensitic Stainless Steel Bars For High - Temperature ServiceDocumento4 pagineA565A565M-10 Standard Specification For Martensitic Stainless Steel Bars For High - Temperature Servicetjt47790% (1)

- Ams 4928Documento8 pagineAms 4928REKHA100% (3)

- Engineering Welding Handbook99 PDF TigDocumento48 pagineEngineering Welding Handbook99 PDF TigSorin Stanescu100% (1)

- Check List For Site Construction WorksDocumento65 pagineCheck List For Site Construction WorksUmar Farooq91% (11)

- Astm A890-A890m-12Documento4 pagineAstm A890-A890m-12Sankar Ganesh100% (3)

- Gas Cutting WLDNG Process - 06 - Module 6Documento100 pagineGas Cutting WLDNG Process - 06 - Module 6sskiitb100% (1)

- Pec Ifica Tion .PW: Surface Vehicle InformationDocumento11 paginePec Ifica Tion .PW: Surface Vehicle InformationCelso100% (1)

- A 297 Heat Resistant Casting SteelDocumento60 pagineA 297 Heat Resistant Casting SteelIr FankovicNessuna valutazione finora

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesDa EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNessuna valutazione finora

- Specs ColdRoomDocumento6 pagineSpecs ColdRoommdalt9180Nessuna valutazione finora

- Recent Advances in Concrete TechnologyDocumento18 pagineRecent Advances in Concrete TechnologyGokul KrishnanNessuna valutazione finora

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualDa EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNessuna valutazione finora

- Packaging DesignDocumento33 paginePackaging DesignAkhilendra PratapNessuna valutazione finora

- Aluminio 6061-T6 6061-T651Documento2 pagineAluminio 6061-T6 6061-T651leroniusNessuna valutazione finora

- AISI 4140 - 42Cr4Mo2Documento2 pagineAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- DS Din 11864-3 Iso 1127Documento7 pagineDS Din 11864-3 Iso 1127dinamitero_1985Nessuna valutazione finora

- AISI 8620 SteelDocumento2 pagineAISI 8620 SteelVinit AhluwaliaNessuna valutazione finora

- Din en 12517 - 2006Documento17 pagineDin en 12517 - 2006marcelogf74Nessuna valutazione finora

- Aluminum 5052 H38Documento2 pagineAluminum 5052 H38Vishal VaishnavNessuna valutazione finora

- ASM Material Data SheetDocumento3 pagineASM Material Data SheetrenjithaeroNessuna valutazione finora

- Asm A2024-O PDFDocumento2 pagineAsm A2024-O PDFjbaldenebroNessuna valutazione finora

- 7178-T6511 Property - ASM Material Data SheetDocumento2 pagine7178-T6511 Property - ASM Material Data SheetptrfmNessuna valutazione finora

- ASM Material Data SheetDocumento3 pagineASM Material Data SheetMadhu MithaNessuna valutazione finora

- Aluminum 413 FDocumento2 pagineAluminum 413 Ftanto_deep_15Nessuna valutazione finora

- Al 7075 T651Documento2 pagineAl 7075 T651Michael HarrellNessuna valutazione finora

- Aluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocumento3 pagineAluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum Alloyrezaeibehrouz100% (1)

- Zamak 5Documento1 paginaZamak 5san moedanoNessuna valutazione finora

- Astm A351 A351m 18Documento4 pagineAstm A351 A351m 18Milady OyuelaNessuna valutazione finora

- ASM Material Data SheetDocumento2 pagineASM Material Data SheetShankar PranavNessuna valutazione finora

- 6061 Vs 6063Documento9 pagine6061 Vs 6063SrRonNessuna valutazione finora

- Valbruna Grade Steel TypeDocumento3 pagineValbruna Grade Steel TypeLebasNessuna valutazione finora

- 7050Documento1 pagina7050yasvanth_m1493Nessuna valutazione finora

- Steel AISI S7Documento1 paginaSteel AISI S7edraelmxNessuna valutazione finora

- ASM Material Data Sheet (Aluminium Beam)Documento2 pagineASM Material Data Sheet (Aluminium Beam)Mohammed AdnanNessuna valutazione finora

- Aluminum 356.0-F, Sand Cast: Metal Nonferrous Metal Aluminum Alloy Aluminum Casting AlloyDocumento1 paginaAluminum 356.0-F, Sand Cast: Metal Nonferrous Metal Aluminum Alloy Aluminum Casting AlloyNabil RidwanNessuna valutazione finora

- Aco AISI 1020 PDFDocumento1 paginaAco AISI 1020 PDFIbsonhNessuna valutazione finora

- Alluminium SheetsDocumento7 pagineAlluminium SheetsVaibhav ShuklaNessuna valutazione finora

- Eastman 2197 Turbo-Oil TDS - SkySupplyUSADocumento2 pagineEastman 2197 Turbo-Oil TDS - SkySupplyUSASkySupplyUSANessuna valutazione finora

- Special Metals NIMONIC® Alloy 90: Categories: Material NotesDocumento3 pagineSpecial Metals NIMONIC® Alloy 90: Categories: Material NotesDragomirescu AlinaNessuna valutazione finora

- Data Sheet Res PDFDocumento5 pagineData Sheet Res PDFToufani Rizal AlfarisiNessuna valutazione finora

- Free-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM RodDocumento2 pagineFree-Cutting Brass, UNS C36000, H02 (Cold Drawn 20%) Temper 25 MM Rodkahutzed666Nessuna valutazione finora

- Aisi 5140 PDFDocumento2 pagineAisi 5140 PDFTasha AnaNessuna valutazione finora

- MaterialData - Aço 1045Documento2 pagineMaterialData - Aço 1045Victhor AraujoNessuna valutazione finora

- MaterialData 11916 2Documento1 paginaMaterialData 11916 2Muhammad Shena GumilangNessuna valutazione finora

- Aluminum 6061 Data SheetDocumento2 pagineAluminum 6061 Data SheetASHOK100% (1)

- Din 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnDocumento3 pagineDin 1652-3 Grade 16Mncr5 Treated To Ferritic-Pearlite Structure and Cold-DrawnairkadNessuna valutazione finora

- TDS AI Understanding A Coolant Analysis ReportDocumento1 paginaTDS AI Understanding A Coolant Analysis Reportjuanmanuel_4615958Nessuna valutazione finora

- Steel AISI O2Documento1 paginaSteel AISI O2edraelmxNessuna valutazione finora

- Apmr 2023 05 31 - 08 55 46Documento3 pagineApmr 2023 05 31 - 08 55 46triggs1971Nessuna valutazione finora

- Aluminum A380Documento4 pagineAluminum A380syuepiNessuna valutazione finora

- An Overview of The API Section 10Documento18 pagineAn Overview of The API Section 10api-3855165100% (1)

- Minfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Documento3 pagineMinfm32202 Din 17445 Grade G X5crni13 4 Quenched and Tempered qt1Biraj SahooNessuna valutazione finora

- ALPEMA Standards Rev1Documento8 pagineALPEMA Standards Rev1nattusharanNessuna valutazione finora

- ASTM A573 Steel, Grade 70: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelDocumento1 paginaASTM A573 Steel, Grade 70: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelNenad NedeljkovicNessuna valutazione finora

- Aluminum 6061-O: To View All Available Suppliers For This MaterialDocumento2 pagineAluminum 6061-O: To View All Available Suppliers For This MaterialAlonso ReynaNessuna valutazione finora

- Hot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsDocumento3 pagineHot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsBielXDNessuna valutazione finora

- Material AlSiDocumento2 pagineMaterial AlSidoanthanh88Nessuna valutazione finora

- A 488A 488M - 01 Welding, Qualifications of Procedures and PersonnelDocumento16 pagineA 488A 488M - 01 Welding, Qualifications of Procedures and Personnelamitanshu01482100% (1)

- Metallic Material Specifications: Title: CMS-Z28GN.0, 2-1/4 Cr-1Mo, Q&T, 90 KSI YS 1. ScopeDocumento4 pagineMetallic Material Specifications: Title: CMS-Z28GN.0, 2-1/4 Cr-1Mo, Q&T, 90 KSI YS 1. ScopeReginaldo SantosNessuna valutazione finora

- ASM Material Data SheetDocumento3 pagineASM Material Data SheetAscanio BarbosaNessuna valutazione finora

- Astm f1537-07 - Standard Specification For Wrought Cobalt-28chromium-6molybdenum Alloys For Surgical ImplantsDocumento4 pagineAstm f1537-07 - Standard Specification For Wrought Cobalt-28chromium-6molybdenum Alloys For Surgical ImplantsJohnBMurleyNessuna valutazione finora

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationDa EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNessuna valutazione finora

- MFL Tank Bottom Scanner PDFDocumento2 pagineMFL Tank Bottom Scanner PDFmarcelogf74Nessuna valutazione finora

- Dacromet Coating: World Class Corrosion ProtectionDocumento6 pagineDacromet Coating: World Class Corrosion Protectionmarcelogf74Nessuna valutazione finora

- Lgeil YashDocumento3 pagineLgeil YashYash RoxsNessuna valutazione finora

- IJPR2016 Lacerda Xambre Alvelos 2Documento14 pagineIJPR2016 Lacerda Xambre Alvelos 2Finda Bangkit WidiartoNessuna valutazione finora

- C Triple LokDocumento32 pagineC Triple LokSpectrumRaijinNessuna valutazione finora

- Ucm03 038939 CrusherDocumento1 paginaUcm03 038939 CrusherEndro SuhadiNessuna valutazione finora

- Part208 Catalog Elmark 2015 WebDocumento1 paginaPart208 Catalog Elmark 2015 WebGoran PanticNessuna valutazione finora

- Masina Whirlpool Awt 2250Documento2 pagineMasina Whirlpool Awt 2250mark pavlovic100% (3)

- P&GDocumento7 pagineP&GAli Jibran100% (1)

- Square PipeDocumento2 pagineSquare PipeWijayanto BekasiNessuna valutazione finora

- Fanuc 2019 Robots Product Line BrochureDocumento2 pagineFanuc 2019 Robots Product Line Brochureapi-545777494Nessuna valutazione finora

- 12-Exhibit 8 - Subcontractors and Vendors - Offshore Integrated Works - Rev GleDocumento6 pagine12-Exhibit 8 - Subcontractors and Vendors - Offshore Integrated Works - Rev GleIdara OkopidoNessuna valutazione finora

- ILO - ASEAN Transformation - Electrical and Electronics On and Off The GridDocumento52 pagineILO - ASEAN Transformation - Electrical and Electronics On and Off The GridThiru YoNessuna valutazione finora

- RHI MagnesitaDocumento11 pagineRHI MagnesitaOscar Rodrigo Andrade SilvaNessuna valutazione finora

- Lokring Refrigeration and Air Conditioning enDocumento62 pagineLokring Refrigeration and Air Conditioning enYen NguyenNessuna valutazione finora

- A Casa SaddleDocumento2 pagineA Casa SaddlesalamrefighNessuna valutazione finora

- Bangladesh New Gen PLanDocumento4 pagineBangladesh New Gen PLanRVaranasiNessuna valutazione finora

- Differentiate Between HCV and LCVDocumento5 pagineDifferentiate Between HCV and LCVhamza jelaniNessuna valutazione finora

- Mjengo Magazine November 2017Documento40 pagineMjengo Magazine November 2017Lwifunyo MangulaNessuna valutazione finora

- Obtained From SQA Difference Between Iso 9001 and As 9100Documento44 pagineObtained From SQA Difference Between Iso 9001 and As 9100Kristian GarcidueñasNessuna valutazione finora

- Bulk Deformation ProcessesDocumento71 pagineBulk Deformation ProcessesHavenesh HaveNessuna valutazione finora

- 3 ConduitsDocumento9 pagine3 ConduitsAlsayed Rabiea MiesalamNessuna valutazione finora

- of Supply ChainDocumento21 pagineof Supply ChainPriyanka KashyapNessuna valutazione finora

- This Is Hatch 2011Documento56 pagineThis Is Hatch 2011alibaba011Nessuna valutazione finora

- Managerial Economics Cap 4Documento17 pagineManagerial Economics Cap 4Eractnod100% (1)

- Katalog LincolnaDocumento612 pagineKatalog LincolnaHaris TrešnjoNessuna valutazione finora