Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Structural Loading Calculation

Caricato da

Amro Ahmad AliCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Structural Loading Calculation

Caricato da

Amro Ahmad AliCopyright:

Formati disponibili

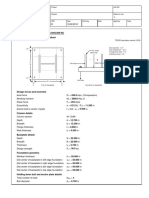

Structural Loading Calculations Of Wood Transmission Structures

Keith Malmedal P.E. Member IEEE

Senior Engineer/Project Manager

NEI Electric Power Engineering

Arvada, Colorado 80001

kmalmedal@neiengineering.com

P.K. Sen, Ph. D, P.E., Senior Member IEEE

Professor of Engineering

Colorado School of Mines

Golden, Colorado 80401

psen@mines.edu

II. NESC METHOD

Abstract: The most critical task in the design of

any structure is to determine the loads that the

structure must withstand.

In the case of

transmission line pole structures, currently there

are two available methods commonly utilized to

calculate the environmental loads: wind and ice.

The first method is suggested by the National

Electrical Safety Code (NESC). This is an ultimate

stress method where all factors of safety are

included in the loads. The second option,

recommended by the American Society of Civil

Engineers (ASCE), calculates the forces that must

be resisted by the structure and may be used in an

ultimate strength method, where wood is the pole

construction material. This later technique may also

be used in a load and resistance factor design

(LRFD) with other common materials. This paper

compares the advantages and limitations of the two

methods. Numerical examples will be provided

showing how the design may differ depending upon

which method is employed.

The NESC has traditionally been an ultimate stress

design method where all factors of safety are included

in the loading conditions by applying applicable

overload factors. Three cases for transverse loading

are considered.

1. General loading due to wind on wire and pole

with ice.

2. Extreme wind on all structures without

conductors or ice. This provision is new in the

2002 NESC.

3. Extreme wind on conductor and pole without

ice if the structure exceeds 60 ft in height.

Case 1:

The NESC defines three general loading areas in the

United States: heavy, medium, and light. Figure 1

defines these loading areas. For each of these loading

areas general wind and ice loads are also defined as

described in Table 1. Wind load is calculated

including ice on the conductor but not on the structure.

I. INTRODUCTION

There are two available options that may be used to

calculate the design loads for transmissions structures.

The minimum design requirements are provided by the

National Electrical Safety Code. The American

Society of Civil Engineers suggests an alternative

method. Even though, in the 2002 edition of the

NESC, efforts have been made to conform the two

loading methods, differences still exist. The two

methods result in differing design criteria for choosing

structures.

This paper focuses mainly on the transverse loading of

tangent type wood transmission structures due to ice

and wind loads and the numerical results illustrate the

differences between the two methods.

Figure 1: Loading Map [1]

Table 1: Loading Per District [1]

Heavy Medium Light

Radial Thickness

0.5

0.25

0

of ice (inch)

4

4

9

Horiz. Wind

Pressure (lb/ft2)

Temp.

0F

15F

30F

Hgt.

Cases 2 and 3:

Load cases 2 and 3 require the extreme wind pressure

to be calculated.

The method for making this

calculation is also new in the 2002 NESC. The

following equation is utilized to calculate the force due

to extreme wind.

Table 3: Gust Response Factor GRF

Structure

Wire GRF, Span Length (ft)

(ft)

GRF

<250

< 33

35-50

50-80

80-115

115-165

165-250

1.02

0.97

0.93

0.89

0.86

0.83

0.93

0.88

0.86

0.83

0.82

0.80

250500

0.86

0.82

0.80

0.78

0.77

0.71

500750

0.79

0.86

0.75

0.73

0.72

0.71

7501000

0.75

0.72

0.71

0.70

0.69

0.68

Loading in pounds =

0.00256(Vmi/h ) 2 k z G RF I C d A

(1)

Where:

Vmi/h = Basic Wind Speed at 33 ft above Ground

kz = Velocity Pressure Coefficient

GRF = Gust Response Factor

I = Importance factor (1.0 for utility structures)

Cd = Shape Factor 1.0 for circle or ellipse

A = Projected wind area in ft2

The basic wind speed Vmi/h is taken from Figures 2 or

3.

The thickness of ice is taken as 0 for extreme wind

loading. The velocity pressure coefficient (kz) is

dependent upon conductor height or pole height and is

found by using Table 2.

Table 2: Velocity Pressure Coefficient (kz) [1]

Height (ft)

Structure

Wire

< 33

0.92

1.00

35-50

1.00

1.10

50-80

1.10

1.20

80-115

1.20

1.30

115-165

1.30

1.40

165-250

1.40

1.50

Figure 2: Basic Wind Speed [1]

For final loading calculations, two different rules are

described in the NESC. Both rules require multiplying

the loads by an overload factor and multiplying the

ultimate pole strength by a strength factor.

For transverse wind loading and wood construction the

overload factors and strength factors to be used for the

first rule are shown in Table 4.

The gust response factor (GRF) is a function of height

and span length. It may be found from Table 3 for

span lengths of 250-1000 ft.

Table 5 shows the overload and strength factors if the

second allowed rule is applied.

2

The overload and strength factors may be combined

into a single overload-multiplying factor that will used

to multiply the load. Since the strength factors in rule

2 are all 1.0, the multiplying factor for rule 2 is the

same as the overload factors in Table 5. However, the

overload and strength factors from rule 1 may be

combined into the single set multipliers shown in Table

6.

Table 6

Rule 1 Overload Multipliers

Construction

Grade

B

C

Wind

3.85

2.59

Extreme Wind

1.33

1.33

The overload multipliers thus produced are comparable

to the rule 2 multipliers.

III. ASCE METHOD

The ASCE calculation technique is applied to an

ultimate stress method of design. It also lends itself to

a load and resistance factor design.

But for

comparison purposes the ultimate stress application is

only examined. For transverse loading due to wind

and ice, two loading calculations must be examined.

Figure 3: Basic Wind Speed [1]

Table 4

Rule 1 Overload and Strength Factors

(Transverse Loads)

Construction

Grade

B

C

Wind

2.5

2.2

Extreme Wind

1.0

1.0

Strength Factor (wind)

0.65

0.85

Strength Factor (extreme wind)

0.75

0.75

1. Calculated design wind on wire and structure

with no ice.

2. 40% of calculated design wind on structure

and wire with ice.

The following equation is suggested for calculation of

force due to wind loading [2].

Table 5

Rule 2 Overload and Strength Factors

(Transverse Loads)

Construction

Grade

B

C

Wind (at crossings)

4.0

2.67

(elsewhere)

4.0

2.0

Extreme Wind

1.33

1.33

Strength Factor (wind)

1.00

1.00

Strength Factor (extreme wind)

1.00

1.00

F = 0.00256(Z v V) 2 GC f A

(2)

Where:

F = Force in lbs

Zv = Terrain Factor

V = Fastest mile wind speed (from map) in mph

G = Gust Response

Cf = Force Coefficients (1.0 is recommended [2])

A = Area exposed normal to the wind direction in ft2

The fastest mile wind speed may be obtained from the

map in Figure 4.

There are two gust response factors, one for the

conductor and one for the structure. For exposure C

the gust response factor (Gw) for conductors is shown

in Figure 5.

Figure 4: Fastest Mile Wind Speed [2]

The terrain factor Zv is dependent upon the type of

terrain, which is divided into three exposure types.

Exposure B is urban, suburban, or wooded areas,

exposure C is flat open country, and exposure D is

country directly exposed to wind flowing over large

bodies of water. The NESC assumes exposure C for

all of its calculations. The value for Zv may be taken

from Table 7.

Figure 5:Conductor Gust Response Factor Gw [2]

The gust response factor (Gt) for structures is shown in

Figure 6.

Table 7: Terrain Factor Zv [2]

Height

Exposure

Exposure Exposure

above

B

C

D

Ground

(ft)

0-33

0.72

1.00

1.18

40

0.75

1.03

1.21

50

0.79

1.06

1.23

60

0.82

1.09

1.26

70

0.85

1.11

1.28

80

0.88

1.14

1.29

90

0.91

1.16

1.31

100

0.93

1.17

1.32

120

0.96

1.20

1.35

140

0.99

1.23

1.37

160

1.02

1.26

1.39

180

1.05

1.28

1.40

200

1.08

1.30

1.42

Note: Interpolation is acceptable

Figure 6: Gust Response Factor for Structures Gw[2]

The ice loading calculations used in design can be

found using the maximum 50-year ice load shown in

Figure 7.

2.0 (4)(114.87) = 918.96 pounds.

The corresponding force on the pole is:

2.0 (4)(55) = 440 pounds.

Assuming that the force on the pole is centered at a

distance 2/3 from the poles base [2], and all three

conductors are mounted 55 ft above ground, the pole is

required to resist a ground line moment of:

Figure 7: Maximum 50-Year Ice [2]

2

918.96 (55) + 440 (55) = 66.7 ft - kips

3

IV. COMPARISON OF NESC AND ASCE

LOADING

The second loading case for this example is for

extreme wind on the pole only. Using an overload

factor of 1.33 (from Table 5) for extreme wind loading

this produces a ground line moment of:

The first thing that becomes evident when comparing

the two methods is the difference in ice loading

calculations. The maximum design ice load for NESC

is 0.5 inch for heavy loading. Whereas, Figure 7,

adopted by ASCE, shows that most of the United

States is subject to ice loads between 1.0 to 2.2 inches

in radial thickness.

2

1.33(21.2)(55) (55) = 56.9 ft - kips

3

Load case 1 controls the design and according to the

NESC this pole would have to be designed to

withstand a ground line moment of 66.7 ft-kips.

The differences can be better illustrated by using

numerical examples. Consider a transmission line in

the central U.S. in the NESC heavy loading area where

the ASCE requires a design ice thickness of 1.0 inch.

Lets consider a line constructed with 55 ft. class 1

poles (average diameter 12 in.) and 250 ft. spans of

Hawk conductor (diameter 0.838 in.).

Using the ASCE method and equation (2) where

exposure C and grade C construction is assumed and

V= 90 mph, Zv = 1.075, Gw = 1.16 and Gt = 1.33, the

calculated pressure on the pole is 31.87 psf. The

pressure on the conductor is calculated to be 27.38 psf.

The area of 250 ft of Hawk conductor without ice is

17.45 ft2. The force acting on the three conductors is:

General NESC loading (Table 1) would be 4 psf on the

pole and the thickness of radial ice will be 0.5 in.

27.38 (3)(17.45) = 1433.34 pounds.

Extreme wind loading pressure is calculated from

equation (1) where V=90 mph, kz = 1.1 for the pole

and 1.2 for the conductor, and GRF = 0.93 for the pole

and 0.8 for the conductor.

The force acting on the pole is:

31.87(55) = 1752.85 pounds.

Using these values design pressures are calculated

yielding 21.2 psf for the pole and 19.9 psf for the

conductor. For this height of pole only extreme wind

on the pole (without conductors) need be considered.

The ground line moment needed for this load case is:

For this example a 250 ft. span of 3 hawk conductors

with 0.5 in. of radial ice results in an area of 114.87 ft2.

and the pole will have an area of 55 ft2. Assuming

grade C construction with an overload factor of 2.0, the

force due to wind on the conductors is:

For ASCE load case number two, 40% of the design

wind velocity (36 mph) is applied to both conductor

and ice. This results in a pressure of 4.4 psf for wind

on wire and ice and 5.1 psf for wind on the pole. For 1

inch of radial ice the area of the each conductor

2

1433.34 (55) + 1752.85 (55) = 143.1 ft - kips

3

becomes 59.1 ft2 which gives a total ground line

moment for this load case of:

Pressure of Wind on Pole (Ice Considered)

9

Load case one controls and according to the ASCE

method a design ground line moment of 143.1 ft-kips

is required. The required ground line moment as

calculated by the ASCE method is more than twice that

calculated by the NESC method. According to the

NESC a class 6 pole would be sufficient for this

example but the ASCE method would require a class 3

pole.

6

5

4

3

2

0

10

20

30

40

50

60

70

80

90 100 110 120 130 140 150 160 170 180 190 200

Pole Height (ft)

NESC

ASCE

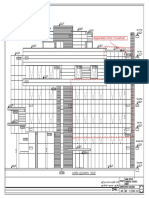

Figure 10: Comparison Between NESC and ASCE, Wind

Pressure on Pole (Ice Considered)

Pressure on Wire (psf)

Pressure of Wind on Wire (Ice Considered)

Pressure of Wind on Wire (No Ice Extreme Wind)

45

Pressure on Wire (psf)

Figures 8 through 11 show a comparison between

pressures calculated by the NESC and ASCE methods

on poles and wire for various pole heights, 250 ft. span

of Hawk conductor, 90 mph wind, and grade C

construction.

40

35

30

9

8

7

6

5

4

3

2

1

0

25

10

20 30 40

50 60

70 80 90 100 110 120 130 140 150 160 170 180 190 200

20

Pole Height (ft)

15

10

NESC

ASCE

Figure 11: Comparison Between NESC and ASCE, Wind

Pressure on Wire (Ice Considered)

Pole Height (ft)

19

0

17

0

15

0

13

0

11

0

90

70

50

30

10

It is seen from these figures that in load cases where

ice is not considered the ASCE values of pressure

always exceed the NESC values. However, when ice

is included in the load case the pressures calculated by

the NESC are greater then those calculated by the

ASCE method. It must be remembered that the NESC

ice loading is often half or less of the ice loading

recommended by the ASCE and the higher values of

pressure may be offset by the lighter ice loading used

for NESC calculations.

NESC

ASCE

Figure 8: Comparison Between NESC and ASCE, Wind

Pressure on Wire (No Ice)

Pressure of Wind on Pole (No Ice extreme wind)

45

Pressure on Pole (psf)

Pressure on Pole (psf)

2

4.4(3) (59.1) (55) + 5.1(55) (55) = 53.2 ft - kips

3

40

35

30

25

20

For comparison purposes, Figure 12 shows the

controlling ground line moment as calculated for

various pole heights by both methods. This is

calculated for a 250 ft. span of Hawk conductor on

Grade C construction, assuming an average pole

diameter of 12 inches and a wind speed of 90 mph.

15

10

5

0

10

20

30

40

50

60

70

80

90 100 110 120 130 140 150 160 170 180 190 200

Pole Height (ft)

NESC

ASCE

Figure 9: Comparison Between NESC and ASCE, Wind

Pressure on Pole (No Ice)

constructed using NESC loading would be expected to

suffer more structure failures than a transmission line

constructed using ASCE criteria. This must be weighed

against the additional cost of construction if the line

were built to withstand loads as calculated by ASCE

recommendations.

Groundline Moments

Groundline Moment (ftkips)

1600

1400

1200

1000

800

600

If minimizing structure failure is the primary design

criteria, caution should be exercised when using the

NESC methodology. Rather than relying on the values

of wind and ice loading recommended by the NESC a

more reliable design will be produced by using local

ice and wind records or by using the ASCE

recommendations in determining design loading.

400

200

Pole Height (ft)

19

0

17

0

15

0

13

0

11

0

90

70

50

30

10

NESC

ASCE

Figure 12: Required Ground Line Moments as calculated

by NESC Compared with ASCE Methods

Ice is calculated for NESC heavy loading and as

required by the ASCE.

All loading cases are

considered and Figure 12 displays the controlling

design case.

REFERENCES

[1]

National Electrical Safety Code, IEEE Std. C22002, Piscataway, New Jersey.

V. CONCLUSION

[2]

It is seen from this comparison that the ASCE method

of loading calculation results in more conservative

design, more wind and ice load, compared to the NESC

method. This is true even though NESC loads contain

overload factors presumably to include some factor of

safety.

Guidelines for Electrical Transmission Line

Structural Loading, ASCE Manual of Practice

No. 74, ASCE 1991, New York, New York.

[3]

Mechanical Design Manual for Overhead

Distribution Lines, REA Bulletin 160-2, US

Department of Agriculture, 1982, Washington

DC.

[4]

Design Manual for High Voltage Transmission

Lines, REA Bulletin 1724E-200, US Department

of Agriculture, 1992, Washington DC.

[5]

Reliability of Poles in NESC Grade C

Construction, H.J. Dagher, Proceedings of the

2001 IEEE Rural Electric Power Conference,

IEEE Catalog No. 01CH37214, Little Rock,

Arkansas, May 2001.

[6]

Methods of Transmission Line Structure Design,

Keith Malmedal, Masters Report, University of

Colorado at Denver, Denver, Colorado, May

2002.

[7]

American National Standard for Wood PolesSpecification and Dimensions, ANSI 05.1-1992,

New York, New York, 1991.

The ASCE calculated loads do not contain any factor

of safety and exceed the NESC loads. If a pole were

chosen so that the ultimate breaking moment of the

pole just equaled the loads calculated by this method it

is expected that some pole failures may result due to

variations in pole strengths if the design conditions

were ever actually applied to the transmission line. To

prevent pole failures under the design condition some

factor of safety should be applied. If load and

resistance factor design methodology were applied to

the design, the loads would be multiplied by some load

factor and the resistance of the pole would be

multiplied by a resistance factor to produce a design

that would prevent pole failures if the design

conditions were ever actually applied to the

transmission line.

The considerable disagreement between loads

calculated using NESC and ASCE data and

recommendations must be resolved by each designer.

Under design conditions a transmission line

Keith Malmedal received his BSEET degree from

Metropolitan State College of Denver in 1995, a MSEE

degree (Power Option) from the University of

Colorado at Denver in 1998, and a MSCE degree

(structural option) from the University of Colorado at

Denver in 2002. He has over ten years experience in

electrical power design and is presently a senior design

engineer and project manager at NEI Electric Power

Engineering, Arvada, Colorado, specializing in all

aspects of power system design. Mr. Malmedal is a

Registered Professional Engineer several states.

Pankaj K. Sen received his B.S.E.E degree (with

honors) from Jadavpur University, Calcutta, India, and

the M.Eng. and Ph.D. degrees in electrical engineering

from the Technical University of Nova Scotia, Halifax,

NS, Canada.

He is currently a Professor of

Engineering at Colorado School of Mines in Golden,

Colorado. His research interests include application

problems in electric machines, power systems, and

power engineering education. He has published more

than 55 articles in various archival journals and

conference proceedings. Dr. Sen is a Registered

Professional Engineer in the State of Colorado.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A 204 Elevation d1578487924094Documento1 paginaA 204 Elevation d1578487924094Amro Ahmad AliNessuna valutazione finora

- A 503 Window Schedule1699537950122Documento1 paginaA 503 Window Schedule1699537950122Amro Ahmad AliNessuna valutazione finora

- 5120544-Spo-A-5906-0 (T)Documento1 pagina5120544-Spo-A-5906-0 (T)Amro Ahmad AliNessuna valutazione finora

- Work in Progress: Dubai Creek ResidencesDocumento1 paginaWork in Progress: Dubai Creek ResidencesAmro Ahmad AliNessuna valutazione finora

- Large Moment ExampleDocumento5 pagineLarge Moment ExampleAmro Ahmad AliNessuna valutazione finora

- Aed130164 00 DD SD 0602 BDocumento1 paginaAed130164 00 DD SD 0602 BAmro Ahmad AliNessuna valutazione finora

- Ar-39 Wall SecDocumento1 paginaAr-39 Wall SecAmro Ahmad AliNessuna valutazione finora

- Window Schedule 13 11 2013-ModelDocumento1 paginaWindow Schedule 13 11 2013-ModelAmro Ahmad AliNessuna valutazione finora

- KWT NG 01 03 00Documento1 paginaKWT NG 01 03 00Amro Ahmad AliNessuna valutazione finora

- + Steel InsertDocumento1 pagina+ Steel InsertAmro Ahmad AliNessuna valutazione finora

- Partial Elevation: SCALE 1:20Documento1 paginaPartial Elevation: SCALE 1:20Amro Ahmad AliNessuna valutazione finora

- InsurancesDocumento1 paginaInsurancesAmro Ahmad AliNessuna valutazione finora

- 3A Alucobond PLUS SpecsDocumento8 pagine3A Alucobond PLUS SpecsyassdayshoumNessuna valutazione finora

- SHS 60x60x4 SHS 30x30x3.2Documento1 paginaSHS 60x60x4 SHS 30x30x3.2Amro Ahmad AliNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Chemical Resistance TableDocumento6 pagineChemical Resistance TableEdgarDavidDiazCamposNessuna valutazione finora

- Samsung Bd-p4600 SMDocumento101 pagineSamsung Bd-p4600 SMIonel CociasNessuna valutazione finora

- Part 66 B1 - MODULE 4 3 SERVOMECHANISMSDocumento26 paginePart 66 B1 - MODULE 4 3 SERVOMECHANISMSyaman91100% (1)

- UntitledDocumento300 pagineUntitledUnbox itNessuna valutazione finora

- Bar Tending TerminologyDocumento3 pagineBar Tending TerminologySiska WangNessuna valutazione finora

- Mohd Mopti Bin Yassin V Lembaga Kemajuan Perusahaan Pertanian Negeri Pahang (LKPP) Corp SDN BHD & AnorDocumento12 pagineMohd Mopti Bin Yassin V Lembaga Kemajuan Perusahaan Pertanian Negeri Pahang (LKPP) Corp SDN BHD & AnorA random humanNessuna valutazione finora

- Manual Elspec SPG 4420Documento303 pagineManual Elspec SPG 4420Bairon Alvira ManiosNessuna valutazione finora

- Know Thyself - Jnana Yoga - Par - Omraam Mikhael AivanhovDocumento314 pagineKnow Thyself - Jnana Yoga - Par - Omraam Mikhael AivanhovPedro Ribeiro100% (5)

- Steam Purity Considerations For New TurbinesDocumento46 pagineSteam Purity Considerations For New Turbinesomertrik100% (1)

- E11133 MB Pin Definition v2 Print Vendor Only PDFDocumento18 pagineE11133 MB Pin Definition v2 Print Vendor Only PDFLuciano MalancaNessuna valutazione finora

- Grocery GatewayDocumento2 pagineGrocery GatewayKumari Mohan0% (2)

- Pocket Book AGDocumento67 paginePocket Book AGsudiraharjaNessuna valutazione finora

- Squares and Square Roots Chapter Class ViiiDocumento24 pagineSquares and Square Roots Chapter Class ViiiManas Hooda100% (1)

- Maximum Influence at A Point Dueto A Series of Concentrated LoadsDocumento12 pagineMaximum Influence at A Point Dueto A Series of Concentrated LoadsAyad SlabyNessuna valutazione finora

- Hot Process Liquid SoapmakingDocumento11 pagineHot Process Liquid SoapmakingPanacea PharmaNessuna valutazione finora

- 5 - Oral Mucosa and Salivary Glands (Mahmoud Bakr)Documento115 pagine5 - Oral Mucosa and Salivary Glands (Mahmoud Bakr)MobarobberNessuna valutazione finora

- 06ESL37 Analog Electronics Lab MANUALDocumento70 pagine06ESL37 Analog Electronics Lab MANUALSan AngadiNessuna valutazione finora

- MIKE21BW Step by Step GuideDocumento124 pagineMIKE21BW Step by Step Guideflpbravo100% (2)

- Pottery Making May06 Poi0506dDocumento52 paginePottery Making May06 Poi0506dMadeleineNessuna valutazione finora

- A Review of Linear AlgebraDocumento19 pagineA Review of Linear AlgebraOsman Abdul-MuminNessuna valutazione finora

- The Fat CatsDocumento7 pagineThe Fat CatsMarilo Jimenez AlgabaNessuna valutazione finora

- Jerms B 2109 - 0BDocumento10 pagineJerms B 2109 - 0BNothing is ImpossibleNessuna valutazione finora

- 08 A330 Ata 35Documento32 pagine08 A330 Ata 35Owen100% (1)

- RocketsDocumento2 pagineRocketsAlin VoicuNessuna valutazione finora

- Macedonian KavalDocumento1 paginaMacedonian Kavalmikiszekely1362Nessuna valutazione finora

- The Lower Parts of The Lock Stitch Sewing MachineDocumento3 pagineThe Lower Parts of The Lock Stitch Sewing MachineHazelAnnCandelarioVitug20% (5)

- Glamour Secrets Prices For Products and ServicesDocumento1 paginaGlamour Secrets Prices For Products and ServiceslocalintheknowNessuna valutazione finora

- Indian Standard: Application Guide For Voltage TransformersDocumento16 pagineIndian Standard: Application Guide For Voltage TransformersGnanavel GNessuna valutazione finora

- CH Six Global Transportation Planning and ExecutionDocumento41 pagineCH Six Global Transportation Planning and ExecutionDsh ShNessuna valutazione finora

- Blank BPSU TemplateDocumento6 pagineBlank BPSU TemplateClarina Alviz BerganteNessuna valutazione finora