Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

04 - Buttweldfitt Ellbows Din2605 PDF

Caricato da

Jacob HarrisDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

04 - Buttweldfitt Ellbows Din2605 PDF

Caricato da

Jacob HarrisCopyright:

Formati disponibili

S TA I N L E S S S T E E L

Butt-Weld Fittings

RO-FI Precision in Stainless Steel

Zuverlssigkeit

durch Qualittsmanagement

Reliability

by quality

management

Reliability by quality management - ISO 9001

Butt-Weld Fittings

Elbows DIN 2605

measures in mm

1 Coverage

This norm consider to seamless (S) and welded (W)

sure. (Reduced utilisation, see table 1 and chapter 5.) The

elbows of steel whose wall thickness are resemble to the

elbows will be used as fittings to weld in.

to welding tubes, but they allow just a lower inside pres-

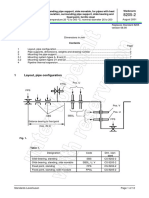

2 Type of design, description

elbow 90

elbow 180

s

da

da

da

www.rofi.de

11.2007_1.000

elbow 45

2b

The dimensions e and r are auxiliary

type 2:

r 1,0 da

dimensions for the constructions

type 3:

r 1,5 da

type 5:

r 2,5 da

type 10:

r 5,0 da

type 20:

r 10,0 da

The description of a elbow according to this

norm part 1 (1), type 90 (90), of the type 3 (3)

with a external diameter da = 88,9 mm and

wall thickness s = 2,3 mm (88,9 x 2,3), seamless = S (S), of a material of the group of

materials G (G) according to DIN 2609:

Elbow DIN 2605-1-90-3-88,9 x 2,3 S-G

RO-FI Precision in Stainless Steel

4/11

Butt-Weld Fittings

Elbows DIN 2605

3 dimensions

Table 1.

extern. condiametr. strucof the

tion

tube

wall thickness s

line

DN

15

d a 1)

1

1,6

3

2,0

4

3,2

5

4,0

1,6

2,3

3,2

4,0

2,0

2,6

3,2

4,0

2,0

2,6

3,6

4,0

2,0

2,6

4,0

5,0

2,0

2,9

4,5

5,6

2,3

2,9

5,0

7,1

2,3

3,2

5,6

8,0

2,6

3,6

6,3

8,8

2,6

4,0

6,3

10,0

2,6

4,0

4,5

7,1

11,0

21,3

20

26,9

25

33,7

32

42,4

40

48,3

50

60,3

65

76,1

80

88,9

100

114,3

125

139,7

150

168,3

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

acceptable utilisation leven

in %

at wall thickness lines

1

53

74

85

59

67

86

52

70

86

52

70

86

51

72

87

56

74

87

92

96

55

74

87

92

96

57

75

87

93

96

60

76

88

93

96

61

77

88

93

97

60

77

87

93

97

61

77

87

93

97

3

54

75

85

60

68

86

53

70

86

52

70

86

52

72

87

56

74

87

93

96

55

74

87

92

96

57

75

87

93

96

60

76

88

93

96

61

77

88

93

97

61

77

87

93

97

4

57

75

85

61

68

86

54

70

86

54

71

87

53

73

87

57

75

87

93

96

56

75

87

92

96

58

75

87

93

96

61

76

88

93

96

61

77

88

93

97

61

77

87

93

97

5

59

76

85

62

69

86

55

71

86

54

71

87

54

73

87

58

75

87

93

96

57

75

87

93

96

59

75

88

93

96

61

77

88

93

96

62

77

88

93

97

62

77

88

93

97

r

17,5

28,0

42,5

25,0

29,0

57,5

25,0

38,0

72,5

32,0

48,0

92,5

38,0

57,0

107,5

51,0

76,0

135,0

254,0

508,0

63,0

95,0

175,0

318,0

635,0

76,0

114,0

205,0

381,0

762,0

102,0

152,0

270,0

508,0

1016,0

127,0

190,0

330,0

635,0

1270,0

152,0

229,0

390,0

762,0

1524,0

b

28

38

53

39

43

71

42

56

90

53

69

114

62

82

132

81

106

165

284

538

102

133

213

356

673

121

159

250

425

806

159

210

327

565

1073

197

260

400

705

1340

237

313

474

846

1608

1) The tubes- and external diameters da are retained of line 1 of ISO 4200. (This line is the line of the diameter for all

attachments which are necessary for the construction an which is standardised.)

2) The wall thickness of line 2 consider till DN1000 of the normal wall thickness line according to DIN 2458. Dimensions

which are marked with lines in the tables are not standardised.

4/12

RO-FI Precision in Stainless Steel

e

7

12

18

10

12

24

10

16

30

13

20

38

16

24

45

21

32

56

105

210

26

39

73

132

263

32

47

85

158

316

42

63

112

210

421

53

79

137

263

526

63

95

162

316

631

11.2007_1.000

nominal

width

Butt-Weld Fittings

Elbows DIN 2605

nominal

width

extern.

diametr.

of the

tube

DN

200

d a 1)

250

273,0

300

323,9

350

355,6

400

406,4

450

457,0

500

508,0

600

610,0

700

711,0

800

813,0

219,1

construction

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

wall thickness s

line

1

2,9

2

4,5

2,9

5,0

6,3

2,9

5,6

7,1

3,2

acceptable utilisation leven

in %

at wall thickness lines

4

6,3

8,0

5

12,5

8,8

10,0

5,6

8,0 11,0

3,2

6,3

8,8

12,5

4,0

6,3

10,0

4,0

6,3

11,0

5,0

6,3

12,5

5,0

7,1

12,5

5,6

8,0

12,5

1

62

77

87

93

97

62

78

88

93

97

63

78

88

93

97

66

79

88

94

97

66

79

88

94

97

66

79

88

94

97

66

79

88

94

97

66

79

88

94

97

62

75

83

88

91

61

74

82

87

90

2

62

78

87

93

97

62

78

88

93

97

63

78

88

93

97

66

79

88

94

97

66

79

88

94

97

66

79

88

94

97

66

79

88

94

97

66

79

88

94

97

61

73

81

86

89

60

73

81

86

89

3

62

78

87

93

97

63

78

88

93

97

63

78

88

93

97

66

79

88

94

97

66

79

88

94

97

66

80

88

94

97

66

80

88

94

97

66

80

88

94

97

60

72

81

85

88

60

72

81

85

88

4

63

78

88

93

97

62

78

88

93

97

63

78

88

93

97

66

80

88

94

97

66

80

88

94

97

5

63

78

88

93

97

r

203

305

510

1016

2032

254

381

650

1270

2540

305

457

775

1524

3048

356

533

850

1778

3556

406

610

970

2032

4064

457

686

1122

2286

4572

508

762

1245

2540

5080

610

914

1525

3050

6100

711

1067

1778

3555

7110

813

1219

2033

4065

8130

b

e

313

84

414

126

620

211

1126

421

2142

842

391

105

518

158

787

269

1407

526

2677

1052

467

126

619

189

937

321

1686

631

3210

1263

533

148

711

221

1028

352

1956

737

3734

1473

610

168

813

253

1173

402

2235

842

4267

1683

686

189

914

284

1350

465

2515

947

4801

1894

762

210

1016

316

1500

516

2794

1052

5334

2104

914

253

1219

379

1830

632

3355

1263

6405

2527

1066

295

1422

442

2133

737

3911

1473

7466 2945

1220

337

1626

505

2439

842

4472

1684

8537 3368

www.rofi.de

11.2007_1.000

Table 1.

1) and 2) see page 4/12

Dimensions which are marked with lines in the tables are not standardised.

RO-FI Precision in Stainless Steel

4/13

Butt-Weld Fittings

Elbows DIN 2605

Table 1.

extern.

diametr.

of the

tube

DN

900

d a 1)

1000

1016,0

1200

1220,0

1400

1420,0

1600

1620,0

914,0

construction

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

2

3

5

10

20

wall thickness s

line

acceptable utilisation leven

in %

at wall thickness lines

1

6,3

2

3

10,0 12,5

6,3

10,0 12,5

6,3

12,5

6,3

12,5

6,3

12,5

1

61

74

82

87

90

61

74

82

87

90

61

74

82

87

90

61

74

82

87

90

61

74

82

87

90

2

60

72

80

85

88

60

72

80

85

88

60

72

81

85

88

60

72

81

85

88

60

72

81

85

88

1) and 2) see page 4/12

Dimensions which are marked with lines in the tables are not standardised.

4/14

RO-FI Precision in Stainless Steel

3

60

72

81

85

88

60

72

81

85

88

r

914

1372

2285

4570

9140

1016

1524

2540

5080

10160

1220

1830

3050

6100

12200

1420

2130

3550

7100

14200

1620

2430

4050

8100

16200

b

1371

1829

2742

5027

9597

1524

2032

3048

5588

10668

1830

2440

3660

6710

12810

2130

2840

4260

7810

14910

2430

3240

4860

8910

17010

e

379

568

947

1893

3786

421

631

1052

2104

4208

505

758

1263

2527

5053

588

882

1471

2941

5882

671

1007

1678

3355

6710

11.2007_1.000

nominal

width

Butt-Weld Fittings

Elbows DIN 2605

The in the following table 2 named elbows with an external

tube diameter which deviate from table1, can be order according

to the agreement of this norm too. This elbows was need and

will be need for tubes according to DIN 2448 and DIN 2458.

Elbows according to table 2 should not be provide for new constructions.

construction

da

25,0

30,0

31,8

38,0

44,5

11.2007_1.000

57,0

63,5

70,0

82,5

101,6

108,0

127,0

133,0

152,4

159,0

177,8

193,7

244,5

2,6

2,6

2,6

2,6

2,6

2,9

2,9

2,9

3,2

3,6

3,6

4,0

4,0

4,5

4,5

5,0

5,0

6,3

r

27,5

52,5

33,5

62,5

35,0

67,5

45,0

82,5

51,0

97,5

63,5

115,0

72,0

127,5

82,5

142,5

65,0

92,0

160,0

77,5

107,5

190,0

95,0

133,5

237,5

100,0

142,5

252,5

117,5

175,0

300,0

125,0

181,0

312,5

142,5

215,0

357,5

150,0

216,0

375,0

170,0

250,0

430,0

180,0

270,0

455,0

235,0

340,0

580,0

nominal width

DN

all

wall thickness

lower

limiting-size

-12,5 %

all

b

40

65

48

77

51

83

64

101

73

120

88

140

100

156

114

174

100

127

195

119

149

231

146

184

288

154

196

306

181

238

364

192

247

379

219

291

434

230

294

454

259

340

519

277

367

552

357

462

702

nominal width

DN

elbow 45

15 to 65

80 to 100

125 to 200

250

300 to 450

500 to 600

700

limiting-size

b

elbow 90

6,0

7,0

8,5

9,5

12,0

14,5

14,5

b

elbow 180

2,5

3,0

3,5

4,0

5,0

6,0

6,0

800

19,0

8,0

2b

8,0

9,0

10,0

14,0

14,0

16,0

by

appointment

by

appointment

3) The limiting-size for the dimension b consider for the constructions 2,3

and 5. For the constructions 10 and 20 the limiting-sizes have to be

arrange.

3) The dimension b have to measured at the external diameter of the

weld seam

5 Acceptable utilisation and basis of

the calculation

www.rofi.de

51,0

3

5

3

5

3

5

3

5

3

5

3

5

3

5

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

2

3

5

wall

thickness

s

2,0

Table 3. lower limiting-size of the wall thickness

Table 4. limiting-size for dimension b 3), 4)

Table 2. dimensions: not for new constructions

tube external

diameter

4 Acceptable dimension variations

As acceptable utilisation, in %, you have to act up the relation of

the (lower) acceptable elbow internal pressure to the acceptable internal pressure of the tube.

The maximal demands is calculated according to TRD 301. The

calculation result against the internal pressure of the acceptable internal pressure of the tube with following assumptions:

lower limiting-size of the tube wall thickness

da 610 mm: - 12,5%

da > 610 mm: s 10 mm: - 0,35 mm

s > 10 mm: - 0,50 mm

lower limiting-size of the tube wall thickness according to

table 3

same material

same longitudinal seam-weld factor

same external diameter

without corrosions allowance

6 Differing wall thickness

Elbows with wall thickness for the order which differing from

the wall thickness of table 1, can be order to the agreement of

this norm.

RO-FI Precision in Stainless Steel

4/15

Butt-Weld Fittings

Elbows DIN 2605

7 Manufacturing

Manufactured may be produced the dimension of the

pipe connection by chamfer of the inner edge with a

Further norms

DIN 2605 part 2 fittings for welding, elbows;

full utilisation factor

angle of 15 till 18 and/or of the outer edge with a angle

of 27 till 30, based of the current axis.

Earlier editions

DIN 2606: 07.65

8 Technical conditions of delivery

DIN 2605: 11.53, 09.62

See DIN 2609

Modifications

At DIN 2605/09.62 and DIN 2606/07.65 were made folloDIN 2448

Seamless steel tubes, dimensions

DIN 2458

Welded steel tubes, dimensions

DIN 2609

Fitting for welding, technical conditions

of delivery

ISO 4200

Plain and steel tubes, welded and

seamless General tables of dimensions

wing changes:

a) Contents of both norms consolidated and amplify of

constructions 2,10 and 20

b) Elbow 45 affiliated

c) Area adjusted till DN 1600.

*) to referring by: Beuth Verlag GmbH/Berlin

and masses per unit length

International patent classification

B 23 K

F 16 L 43/00

4/16

RO-FI Precision in Stainless Steel

11.2007_1.000

Cited norms and other basics

S TA I N L E S S S T E E L

www.rofi.de

S TA I N L E S S S T E E L

South

www.rofi.de

Karl-Arnold-Strae 7

D-73230 Kirchheim/Teck

Tel. +49 (0) 70 21 94 35-0

Fax +49 (0) 70 21 5 60 31

kirchheim@rofi.de

North Export

South

Mittelgnrather

Strae

Karl-Arnold-Strae

7 15

D-42655 Kirchheim/Teck

Solingen

D-73230

2 12

3235-0

54-0

Tel. +49 (0) 70

21294

Fax +49 (0) 70

2 12

212532

6054-11

31

solingen@rofi.de

kirchheim@rofi.de

North

MiddleExport

Mittelgnrather

Ostendstrae 3 Strae 15

D-42655

D-63110 Solingen

Rodgau-Niederroden

Tel. +49 (0) 2

6112

062232

8554-0

79-30

Fax +49 (0) 2

6112

062232

2254-11

08

solingen@rofi.de

rodgau@rofi.de

Middle

East

Ostendstrae

Reuterstrae 23

D-63110

D-99867 Rodgau-Niederroden

Gotha

Tel. +49 (0) 61

36 06

21 2

7 85

33 79-30

97-0

Fax +49 (0) 61

36 06

21 2

7 22

33 08

97-10

rodgau@rofi.de

gotha@rofi.de

RO-FI Precision in Stainless Steel

East

Reuterstrae 2

D-99867 Gotha

Tel. +49 (0) 36 21 7 33 97-0

Zuverlssigkeit

durch Qualittsmanagement

Reliability

by quality

management

Fax +49 (0) 36 21 7 33 97-10

Reliability by quality management - ISO 9001

gotha@rofi.de

Potrebbero piacerti anche

- DIN-2605-2-95 StandartDocumento9 pagineDIN-2605-2-95 StandartGürolNessuna valutazione finora

- Din 2394-1Documento5 pagineDin 2394-1sharrrstar826Nessuna valutazione finora

- Din 2391Documento16 pagineDin 2391rgi178Nessuna valutazione finora

- DIN 2605 2 Steel Butt Welding Pipe Fittings 2 Elbows and Bends For Use at Full Service PressureDocumento9 pagineDIN 2605 2 Steel Butt Welding Pipe Fittings 2 Elbows and Bends For Use at Full Service Pressureocean12Nessuna valutazione finora

- Pipe DesignDocumento6 paginePipe DesignmaneeshmsanjagiriNessuna valutazione finora

- Din 1615Documento5 pagineDin 1615David FonsecaNessuna valutazione finora

- 3408 AGMWS Vol1 TA2 CleanDocumento8 pagine3408 AGMWS Vol1 TA2 CleanWong AlexNessuna valutazione finora

- Technical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsDocumento10 pagineTechnical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsMunishNessuna valutazione finora

- Steel Supply Sub-Grades To EC3Documento22 pagineSteel Supply Sub-Grades To EC3Anonymous iS33V5Nessuna valutazione finora

- AVM Pipes Fittings CatalogueDocumento41 pagineAVM Pipes Fittings CataloguebinunalukandamNessuna valutazione finora

- 53 - Butt-Weld Pipe FittingsDocumento13 pagine53 - Butt-Weld Pipe Fittingsjoni_capelletoNessuna valutazione finora

- COLD FORMED STEEL MEMBERS AND DESIGNDocumento14 pagineCOLD FORMED STEEL MEMBERS AND DESIGNMihai MariusNessuna valutazione finora

- Steel Supply Sub-Grades To EC3Documento22 pagineSteel Supply Sub-Grades To EC3Huy Rathana100% (2)

- Din 8570-1987Documento8 pagineDin 8570-1987Kike Silva100% (2)

- Flange Selection GuideDocumento11 pagineFlange Selection GuidebandithaguruNessuna valutazione finora

- Global Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsDocumento7 pagineGlobal Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsHoangNessuna valutazione finora

- Weld Pipe FittingsDocumento21 pagineWeld Pipe FittingsRanjit SinghNessuna valutazione finora

- 1729Documento52 pagine1729praj24083302Nessuna valutazione finora

- 200: Shell Cassettes Corner Node - Type 230-60Documento8 pagine200: Shell Cassettes Corner Node - Type 230-60sasikumarNessuna valutazione finora

- Specification For Carbon Steel Piping MaterialsDocumento8 pagineSpecification For Carbon Steel Piping MaterialsAmro HarasisNessuna valutazione finora

- Special Steel Structures - Courses - 2013Documento253 pagineSpecial Steel Structures - Courses - 2013Largu George DanielNessuna valutazione finora

- Victaulic DimensionsDocumento2 pagineVictaulic DimensionsSH1961Nessuna valutazione finora

- DIN 2080-1-1978 Conos ISODocumento3 pagineDIN 2080-1-1978 Conos ISOdanielk3267% (3)

- DIN 2460 Steel Pipes WaterDocumento5 pagineDIN 2460 Steel Pipes WaterAhmed BoussoffaraNessuna valutazione finora

- Hot RolledDocumento16 pagineHot Rolledlbo33Nessuna valutazione finora

- Piping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDocumento52 paginePiping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDesmond Chang100% (1)

- RTA - Concrete DetailingDocumento9 pagineRTA - Concrete DetailingPanca AtmajatamaNessuna valutazione finora

- Steel Penstocks - 11 ManufactureDocumento10 pagineSteel Penstocks - 11 ManufactureRicardo MartinezNessuna valutazione finora

- Design For Hot Dip GalvanisingDocumento9 pagineDesign For Hot Dip GalvanisingSreedhar Patnaik.MNessuna valutazione finora

- DSR PuneDocumento7 pagineDSR PunedigvijayjagatapNessuna valutazione finora

- GHGGFHJDocumento13 pagineGHGGFHJAllswell ElleNessuna valutazione finora

- Explosion Resistant EquipmentDocumento3 pagineExplosion Resistant EquipmentAndrewrzeNessuna valutazione finora

- Minimum Dimension of Piping Components and AssembliesDocumento43 pagineMinimum Dimension of Piping Components and AssembliesRagerishcire Kanaalaq100% (1)

- Jis G 3444 - 2010Documento17 pagineJis G 3444 - 2010ZSZ GAMINGNessuna valutazione finora

- Design of SHSDocumento56 pagineDesign of SHSRobertBayley100% (1)

- Jis G3452Documento7 pagineJis G3452Bahtiar Anak LaNangNessuna valutazione finora

- TS-03 Air Distribution WorksDocumento14 pagineTS-03 Air Distribution WorksPraveen KumarNessuna valutazione finora

- Designation B 828 - 002Documento11 pagineDesignation B 828 - 002Raron1Nessuna valutazione finora

- Weld ToleranceDocumento1 paginaWeld ToleranceNirav DesaiNessuna valutazione finora

- Ch1.1.3.3.3.5sect2 - Tensile TestsDocumento6 pagineCh1.1.3.3.3.5sect2 - Tensile Testsalinox chapaNessuna valutazione finora

- Asme Sec Viii D1 Ma App 2 Part2 PDFDocumento21 pagineAsme Sec Viii D1 Ma App 2 Part2 PDFjuanfco1965Nessuna valutazione finora

- Composite SlabDocumento13 pagineComposite Slabkosithuag50% (2)

- 6935 2011Documento13 pagine6935 2011Tufan Ünal100% (4)

- Iwl-Rmm-D Fa@W'I: Ti-Wn'M-Afati-RalDocumento8 pagineIwl-Rmm-D Fa@W'I: Ti-Wn'M-Afati-Raldrjonesg19585102Nessuna valutazione finora

- 8202 2Documento10 pagine8202 2Yang WuNessuna valutazione finora

- IRC 24-2010 Ammendment (Nov-17)Documento3 pagineIRC 24-2010 Ammendment (Nov-17)avisek_basuNessuna valutazione finora

- Curved Heads DIN 28011/cap Form: 1 CoverageDocumento6 pagineCurved Heads DIN 28011/cap Form: 1 CoverageE Santosh KumarNessuna valutazione finora

- Ford Spot Weld SpecDocumento12 pagineFord Spot Weld SpecJonathan Davies0% (1)

- 1 Layout, Pipe ConfigurationDocumento12 pagine1 Layout, Pipe ConfigurationYang WuNessuna valutazione finora

- Is 2830 1992Documento9 pagineIs 2830 1992Sunny SaparNessuna valutazione finora

- Piping Elbows and Bends PDFDocumento4 paginePiping Elbows and Bends PDFaap1100% (2)

- Tubes and PipesDocumento40 pagineTubes and PipesAran ChandranNessuna valutazione finora

- Ductile Cast IronDocumento30 pagineDuctile Cast IrontribleprinceNessuna valutazione finora

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDa EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Sarma Tub Inox Certificat PDFDocumento1 paginaSarma Tub Inox Certificat PDFJacob HarrisNessuna valutazione finora

- Certificate Material PDFDocumento6 pagineCertificate Material PDFJacob HarrisNessuna valutazione finora

- O Pressure Controls Brochure 5L PDFDocumento12 pagineO Pressure Controls Brochure 5L PDFJacob HarrisNessuna valutazione finora

- Iso 2768-1: 1989Documento7 pagineIso 2768-1: 1989jferreiraNessuna valutazione finora

- Iso 2768-1: 1989Documento7 pagineIso 2768-1: 1989jferreiraNessuna valutazione finora

- Quality Data Registration Ex. G Control PDFDocumento7 pagineQuality Data Registration Ex. G Control PDFJacob HarrisNessuna valutazione finora

- SSAB Hardox-Guarantees PDFDocumento6 pagineSSAB Hardox-Guarantees PDFJacob HarrisNessuna valutazione finora

- Din en Iso 9013 2002 PDFDocumento27 pagineDin en Iso 9013 2002 PDFJacob HarrisNessuna valutazione finora

- Recommendations for welding low alloy steel materials from AIR LIQUIDEDocumento1 paginaRecommendations for welding low alloy steel materials from AIR LIQUIDEJacob HarrisNessuna valutazione finora

- Cert 1185-Cert 1186-Ped PDFDocumento4 pagineCert 1185-Cert 1186-Ped PDFJacob HarrisNessuna valutazione finora

- Weldingguide ENGDocumento518 pagineWeldingguide ENGBoris Kozjan0% (1)

- En 12062 (Iso 17635)Documento18 pagineEn 12062 (Iso 17635)qsd1q2123rd100% (3)

- Fisa 7.past Continuous DocumentDocumento2 pagineFisa 7.past Continuous DocumentJacob HarrisNessuna valutazione finora

- P9521 000 e - 08 11 PDFDocumento25 pagineP9521 000 e - 08 11 PDFJacob HarrisNessuna valutazione finora

- P9521 000 e - 08 11 PDFDocumento25 pagineP9521 000 e - 08 11 PDFJacob HarrisNessuna valutazione finora

- Tee STD SCH XS Din 2615 PDFDocumento8 pagineTee STD SCH XS Din 2615 PDFJacob HarrisNessuna valutazione finora

- Iso 2768-1: 1989Documento7 pagineIso 2768-1: 1989jferreiraNessuna valutazione finora

- P9521 000 e - 08 11 PDFDocumento25 pagineP9521 000 e - 08 11 PDFJacob HarrisNessuna valutazione finora

- 04 - Buttweldfitt Ellbows Din2605 PDFDocumento8 pagine04 - Buttweldfitt Ellbows Din2605 PDFJacob HarrisNessuna valutazione finora

- Weldinghuide Eng BohlerDocumento515 pagineWeldinghuide Eng BohlerJorge VasquezNessuna valutazione finora

- 04 Robinson CrusoeDocumento59 pagine04 Robinson CrusoeJacob HarrisNessuna valutazione finora

- Weldingguide ENGDocumento518 pagineWeldingguide ENGBoris Kozjan0% (1)

- Alice's Adventures in Wonderland SummaryDocumento47 pagineAlice's Adventures in Wonderland SummaryJacob Harris100% (1)

- Catalog Parweld PDFDocumento321 pagineCatalog Parweld PDFJacob HarrisNessuna valutazione finora

- NPT Threaded and Socket Welding Fittings ANSI Standard 3000lbsDocumento10 pagineNPT Threaded and Socket Welding Fittings ANSI Standard 3000lbsdandan29Nessuna valutazione finora

- 04 Buttweldfitt Tee Din2615Documento7 pagine04 Buttweldfitt Tee Din2615ivanmatijevicNessuna valutazione finora

- Tee STD SCH XS Din 2615 PDFDocumento8 pagineTee STD SCH XS Din 2615 PDFJacob HarrisNessuna valutazione finora

- 04 - Buttweldfitt Ellbows Din2605 PDFDocumento8 pagine04 - Buttweldfitt Ellbows Din2605 PDFJacob HarrisNessuna valutazione finora

- 04 Buttweldfitt Tee Din2615Documento7 pagine04 Buttweldfitt Tee Din2615ivanmatijevicNessuna valutazione finora

- Mechanical Engineer Muhammad Ibtisam's ResumeDocumento1 paginaMechanical Engineer Muhammad Ibtisam's ResumeshoaibNessuna valutazione finora

- TIMBER BEAM DESIGNDocumento144 pagineTIMBER BEAM DESIGNweng paraleNessuna valutazione finora

- BMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)Documento2 pagineBMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)YeisonNessuna valutazione finora

- VOLVO AT2412D IshiftDocumento16 pagineVOLVO AT2412D IshiftSaray Aljure Ospino100% (1)

- Slip and Crystallographic TexturesDocumento34 pagineSlip and Crystallographic TexturesSunkulp GoelNessuna valutazione finora

- A Study of Liquid Metal AtomizationDocumento22 pagineA Study of Liquid Metal AtomizationAlisha Allison0% (1)

- Anexo 1 - Generac SG625-PG563 PDFDocumento6 pagineAnexo 1 - Generac SG625-PG563 PDFJuly E. Maldonado M.Nessuna valutazione finora

- Protection, Monitoring and ControlDocumento22 pagineProtection, Monitoring and ControlSarah FrazierNessuna valutazione finora

- Acknowledgement: Mechanical DesignDocumento72 pagineAcknowledgement: Mechanical DesignEyob KetemaNessuna valutazione finora

- Structural Mechanics 2-Lesson 4-Buckling (Complete Note)Documento27 pagineStructural Mechanics 2-Lesson 4-Buckling (Complete Note)Janith amarawickramaNessuna valutazione finora

- Harley-Davidson P&a 2020 en WebOptimisedDocumento103 pagineHarley-Davidson P&a 2020 en WebOptimisedAmanNessuna valutazione finora

- ASME Technical Presentation 2013Documento152 pagineASME Technical Presentation 2013Siraj KhanNessuna valutazione finora

- Two Rotor CDocumento3 pagineTwo Rotor CmuralidharanNessuna valutazione finora

- Tubular Bowl CentrifugeDocumento22 pagineTubular Bowl CentrifugeTouhid Islam100% (1)

- 2002 Yamaha FZS1000 Service Repair Manual PDFDocumento30 pagine2002 Yamaha FZS1000 Service Repair Manual PDFjhjnsemmemNessuna valutazione finora

- UG-6th - Online Class TTDocumento6 pagineUG-6th - Online Class TTFOODIE USNessuna valutazione finora

- MAB 103B-24 - Parts - 2011Documento60 pagineMAB 103B-24 - Parts - 2011Centrifugal SeparatorNessuna valutazione finora

- View thousands of Crane Specifications on FreeCraneSpecs.comDocumento64 pagineView thousands of Crane Specifications on FreeCraneSpecs.comD Rider Casanova100% (1)

- Cup 04 HSP Uk Web PDFDocumento2 pagineCup 04 HSP Uk Web PDFcasda73Nessuna valutazione finora

- Asme Questions and Answers Part ViDocumento22 pagineAsme Questions and Answers Part ViAshwani DograNessuna valutazione finora

- Driller Controller User ManualDocumento12 pagineDriller Controller User ManualYahya BA100% (1)

- Chapter 1 FrictionDocumento20 pagineChapter 1 FrictionSherif Yehia Al Maraghy100% (1)

- 6 Cylinder MBE906: Engine PerformanceDocumento2 pagine6 Cylinder MBE906: Engine Performanceguillermo meza huamanNessuna valutazione finora

- Electrical System in AENDocumento21 pagineElectrical System in AENNilesh PatilNessuna valutazione finora

- DIESEL CYCLE With ExplantionDocumento5 pagineDIESEL CYCLE With ExplantionEES StudyNessuna valutazione finora

- Ninja Part PDFDocumento105 pagineNinja Part PDFErlangga AlamNessuna valutazione finora

- BT DT Rev 5Documento37 pagineBT DT Rev 5Anonymous 7pJU2NFhANessuna valutazione finora

- Analisa Water Hammer Pada Pipa Condensate PLTUDocumento6 pagineAnalisa Water Hammer Pada Pipa Condensate PLTUamrullah100% (1)

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDocumento16 pagineAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456Nessuna valutazione finora

- Question Bank - HMTDocumento5 pagineQuestion Bank - HMTSUNDARAMAHALINGAM ANessuna valutazione finora