Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Typical Damages On New Structures

Caricato da

Gerasopoulos Tasos0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni6 pagineAddresses typical damages found on concrete structures

Titolo originale

Typical Damages on New Structures

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoAddresses typical damages found on concrete structures

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni6 pagineTypical Damages On New Structures

Caricato da

Gerasopoulos TasosAddresses typical damages found on concrete structures

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

1.

2. Typical Damages on new Structures

Typical damages encountered on new concrete structures usually are the result of

one or a combination of the following actions.

(a) Crazing of concrete

Incorrect placement of steel can result in insufficient cover, leading to corrosion of

the reinforcement. If the bars are placed grossly out of position or in the wrong

position, collapse can occur when the element is fully loaded.

(b) Inadequate cover to reinforcement

Inadequate cover to reinforcement permits ingress of moisture, gases and other

substances and leads to corrosion of the reinforcement and cracking and spalling of

theconcrete.

(c) Incorrectly made construction joints

The main faults in construction joints are lack of preparation and poor compaction.

The old concrete should be washed and a layer of rich concrete laid before pouring

is continued. Poor joints allow ingress of moisture and staining of the concrete face.

(d) Grout leakage

Grout leakage occurs where formwork joints do not fit together properly. The result

is a porous area of concrete that has little or no cement and fine aggregate. All

formwork joints should be properly sealed.

(e) Poor compaction

If concrete is not properly compacted by ramming or vibration the result is a portion

of porous honeycomb concrete. This part must be hacked out and recast. Complete

compaction is essential to give a dense, impermeable concrete.

(f)

Segregation

Segregation occurs when the mix ingredients become separated. It is the result of

1. dropping the mix through too great a height in placing (chutes or pipes should be

used in such cases)

2. using a harsh mix with high coarse aggregate content

3. large aggregate sinking due to over-vibration or use of too much plasticizer

Segregation results in uneven concrete texture, or porous concrete in some cases.

(g) Poor curing

A poor curing procedure can result in loss of water through evaporation. This can

cause a reduction in strength if there is not sufficient water for complete hydration of

the cement. Loss of water can cause shrinkage cracking. During curing the concrete

should be kept damp and covered.

(h) Too high a water content

Excess water increases workability but decreases the strength and increases the

porosity and permeability of the hardened concrete,which can lead to corrosion of

the reinforcement. The correct water-to-cement ratio for the mix should be strictly

enforced.

Examples of damages created by the above actions are given below as reference:

Figure 1. Crazing damage example

Figure 2. Pour Contraction Joint Damage

Figure 3. Segregation

Figure 4. Plastic Settlement

Figure 5. Plastic shrinkage Damages

Figure 6. Pour Vibration Damages

3. Types of repairs

(a) Concrete replacement

-The concrete replacement method consists of replacing defective concrete with

machine-mixed concrete of suitable proportions and consistency, so that it will

become integral with the base concrete.

Concrete replacement is the desired method if there is honeycomb in new

construction or deterioration of old concrete which goes entirely through the wall or

beyond the reinforcement, or if the quantity is large. For new work, the repairs should

be made immediately after stripping the forms.

Considerable concrete removal is always required for this type of repair. Excavation

of affected areas should continue until there is no question that sound concrete has

been reached.

Additional chipping may be necessary to accommodate the repair method and

shape the cavity properly.

Concrete for the repair should generally be similar to the old concrete in maximum

size of aggregate and water-cement ratio.

Forming will usually be required for large repairs in vertical surfaces.

(b) Dry pack

The dry pack method consists of ramming a very stiff mix into place in thin layers. It

is suitable for filling form tie-rod holes and narrow slots, and for repairing any cavity

which has a relatively high ratio of depth to area.

Practically no shrinkage will occur with this mix, and it develops a strength equalling

or exceeding that of the parent concrete. The method does not require any special

equipment, but cement finishers must be trained in this type of repair if the results

are to be satisfactory.

(c) Preplaced aggregate:

Concrete-Preplaced aggregate concrete may be used advantageously for certain

types of repairs. It bonds well to concrete and has low drying shrinkage. It is also

well adapted to underwater repairs. This is a specialized process which is described

elsewhere.

(d) Shotcrete

Shotcrete has excellent bond with new or old concrete and is frequently the most

satisfactory and economical method of making shallow repairs. It is particularly

adapted to vertical or overhead surfaces where it is capable of supporting itself

(without a form) without sagging or sloughing. Shotcrete repairs generally perform

satisfactorily where recommended procedures are followed." Simplified equipment

has been developed for use in small repairs.

4. Preparations for repair

All deteriorated or defective concrete must be removed; in the case of slabs,

suitable mechanical scarification equipment should be used. Next, the surfaces of

the concrete must be thoroughly cleaned.

The bonding surface should have been previously wet down, but should be dry at

the time of patching. The dry surface should be carefully coated with a layer of

mortar about 3 mm thick, or with another suitable bonding agent. The bonding agent

that will be used should be approved by the Engineer. The repair should proceed

immediately.

5. Appearance

In concrete where appearance is important, particular care should be taken to

insure that the texture and colour of the repair will match the surrounding concrete. A

proper blend of white cement with the job cement will enable the patch to come close

to matching the colour of the original concrete. A patch on a formed concrete surface

should never be finished with a steel trowel, since this produces a dark colour which

is impossible to remove.

6. Curing

All patches (except where epoxy mortar or epoxy concrete is used) must be

properly cured to assure proper hydration of the cement and durable concrete or

mortar. The recommendations of Part 7.3 of this MS should be followed or specific

instructions given by the supplier of the repair material.

The decision of whether a crack should be repaired to restore structural integrity or

merely sealed is dependent on the nature of the structure and the cause of the

crack, and upon its location and extent. If the stresses which caused the crack have

been relieved by its occurrence, the structural integrity can be restored with some

expectation of permanency. However, in the case of working cracks (such as cracks

caused by foundation movements, or cracks which open and close from temperature

changes), the only satisfactory solution is to seal them with a flexible or extensible

material.

Thorough cleaning of the crack is essential before any treatment takes place. All

loose concrete, oil joint sealant, and other foreign material must be removed. The

method of cleaning is dependent upon the size of the crack and the nature of the

contaminants. It may include any combination of the following: compressed air, wire

brushing, sandblasting, routing, or the use of picks or similar tools.

Restoration of structural integrity across a crack has been successfully

accomplished using pressure and vacuum injection of low viscosity epoxies and

other monomers which polymerize in situ and rebond the parent concrete.

Sealing of cracks without restoration of structural integrity requires the use of

materials and techniques similar to those used in sealing joints.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ibps RRB Po Scale - I Prelims Model Mock Test - 8Documento7 pagineIbps RRB Po Scale - I Prelims Model Mock Test - 8Sanjay DasNessuna valutazione finora

- Manufacturing Finance With SAP ERP Financials: Subbu RamakrishnanDocumento33 pagineManufacturing Finance With SAP ERP Financials: Subbu RamakrishnanKhalifa Hassan100% (1)

- Lesson 5 Flight of Projectile, Air Resistance Neglected: OverviewDocumento7 pagineLesson 5 Flight of Projectile, Air Resistance Neglected: OverviewNadjer C. AdamNessuna valutazione finora

- ECE3073 P4 Bus Interfacing Answers PDFDocumento3 pagineECE3073 P4 Bus Interfacing Answers PDFkewancamNessuna valutazione finora

- TTC 1000Documento2 pagineTTC 1000svismaelNessuna valutazione finora

- Serie10 ElecDocumento75 pagineSerie10 Elecmealier severineNessuna valutazione finora

- Principles of Public ExpenditureDocumento1 paginaPrinciples of Public ExpenditureNikhil Shenai100% (1)

- Phil. Hist. SyllabusDocumento7 paginePhil. Hist. SyllabusCarl Angelo MartinNessuna valutazione finora

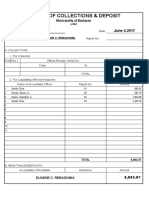

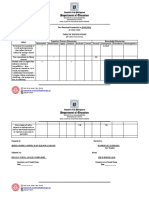

- RCD - SEF (Liquidating)Documento40 pagineRCD - SEF (Liquidating)Chie NemzNessuna valutazione finora

- Booklet The 8th JAKINUDocumento20 pagineBooklet The 8th JAKINUsamuelionardiNessuna valutazione finora

- LoratadinaDocumento3 pagineLoratadinapapaindoNessuna valutazione finora

- Webinar WinCC SCADA NL 29052018Documento62 pagineWebinar WinCC SCADA NL 29052018AlexNessuna valutazione finora

- Technical Sheet Vacuum Tube Collectors CVTDocumento2 pagineTechnical Sheet Vacuum Tube Collectors CVTgonzalez2678Nessuna valutazione finora

- Vững vàng nền tảng, Khai sáng tương lai: Trang - 1Documento11 pagineVững vàng nền tảng, Khai sáng tương lai: Trang - 1An AnNessuna valutazione finora

- Triangular Short Crested Weir. Local Geometry ? Discharge CoefficientsDocumento7 pagineTriangular Short Crested Weir. Local Geometry ? Discharge CoefficientsTI Journals PublishingNessuna valutazione finora

- Irregular Verbs Lesson PlanDocumento13 pagineIrregular Verbs Lesson Planapi-311868026Nessuna valutazione finora

- Case For Overhead and DistributionDocumento2 pagineCase For Overhead and DistributionBhargav D.S.Nessuna valutazione finora

- 007: The Stealth Affair ManualDocumento11 pagine007: The Stealth Affair Manualcodigay769Nessuna valutazione finora

- Mucic Acid Test: PrincipleDocumento3 pagineMucic Acid Test: PrincipleKrizzi Dizon GarciaNessuna valutazione finora

- The London SchoolDocumento3 pagineThe London SchoolKhawla Adnan100% (5)

- MSDS Potassium DichromateDocumento8 pagineMSDS Potassium DichromateAyu Lakshemini OkaNessuna valutazione finora

- TOS 1st QuarterDocumento6 pagineTOS 1st QuarterQuerisa Ingrid MortelNessuna valutazione finora

- The Definitive Guide On How To Build A High Status Social CircleDocumento46 pagineThe Definitive Guide On How To Build A High Status Social CircleCecilia Teresa Grayeb SánchezNessuna valutazione finora

- 3rd Year. PunctuationDocumento14 pagine3rd Year. PunctuationmawarNessuna valutazione finora

- Internal Audit, Compliance& Ethics and Risk Management: Section 1) 1.1)Documento6 pagineInternal Audit, Compliance& Ethics and Risk Management: Section 1) 1.1)Noora Al ShehhiNessuna valutazione finora

- Landis+Gyr Model EM5300 Class 0.5 Electricity Meter 14-2-63Documento5 pagineLandis+Gyr Model EM5300 Class 0.5 Electricity Meter 14-2-63kulukundunguNessuna valutazione finora

- Standard CellDocumento53 pagineStandard CellShwethNessuna valutazione finora

- FM Assignment 17-M-518 MMM - Eicher MotorDocumento33 pagineFM Assignment 17-M-518 MMM - Eicher MotorTrilokNessuna valutazione finora

- Raw:/storage/emulated/0/download/1623980378472 - 1623980347729 - PE 4 Module 2Documento11 pagineRaw:/storage/emulated/0/download/1623980378472 - 1623980347729 - PE 4 Module 2Marvin Espenocilla EspeñoNessuna valutazione finora

- BAFINAR - Quiz 2 ColarDocumento3 pagineBAFINAR - Quiz 2 ColarRonalyn ColarNessuna valutazione finora