Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

04 - Data Sheet - Mech Seals-Cipf Inj Pump

Caricato da

isaac2408Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

04 - Data Sheet - Mech Seals-Cipf Inj Pump

Caricato da

isaac2408Copyright:

Formati disponibili

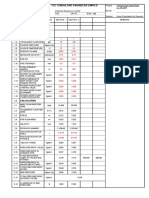

KOC ME-008 Part 2 - DATA SHEET

FOR PUMP:

DAS-1830-P-003 SITE:

CIPF

UNIT:

3

DAS-1830-MS-006 ITEM NO.

DATA SHEET NO.

REQUISITION / SPEC. NUMBER

/

BY

INQUIRY NUMBER

DATE

PURCH ORDER NUMBER

PAGE 1 OF 2

REVISION NO. 0

DATE

DATA SUPPLIED

CUSTOMARY UNITS

SI UNITS HARDWARE SUPPLIED

CUSTOMARY UNITS

SI UNITS

INDICATES DATA COMPLETED BY PURCHASER

BY SEAL VENDOR

BY SEAL VENDOR OR PURCHASER

DEFAULT SELECTION

SEAL SPECIFICATION - (REF CLAUSE 4.1, FIGURES 1 TO 6)

CATEGORY

MECHANICAL SEALS (CATEGORY 1 & 2)

FOR CENTRIFUGAL & ROTARY PUMPS

(API 682 3rd Edition)

S.I. UNITS

1

2

3

SEAL CATEGORY 1 (4.1.1)

SEAL CATEGORY 2 (4.1.1)

TYPE

TYPE A (3.72)

TYPE B (3.73)

(CODE-CW)

TYPE C (3.74)

ALTERNATIVE ROTATING (TYPE C)

ARR'G'T

1 (3.2)

DEFAULT CONFIGURATION

1CW-FX

2 (3.3)

13

14

15

3 (3.4)

16

17

BARRIER BUFFER

12

ALTERNATIVE STATIONARY (TYPE A & B)

SINGLE SPRING (TYPE A)

ALTERNATIVE DESIGN

1CW-FL

10

11

SEAL CODE (ANNEX D)

FLUSH PLANS (SEE ANNEX D)

DIST. FLUSH

01

11

14

23

32

50

61

ALTERNATIVE BUSH

02

13

21

31

41

51

62

FX

01

13

23

41

62

75

76

LIQUID

2CW-CW

TANGENTIAL LBO CONN'N

02

14

31

52

71

GAS

2CW-CS

2NC-CS

FX

11

21

32

61

72

LIQUID

3CW-FB

3CW-BB

FX

01

13

53A

54

3CW-FF

TANG. LBO

02

14

53B

61

3NC-FF

3NC-FB

11

32

53C

62

3NC-BB

GAS

SLEEVE-SHAFT DRIVE

DIST. FLUSH

SET-SCREW ONTO SHAFT

DIST. FLUSH

74

ALTERNATIVE (6.1.3.13) - SPECIFY

MATERIALS (REFERENCE 6.1.6 & ANNEX C)

18

19

SECONDARY SEALS

20

FKM

21

22

23

OTHER:

SEAL FACES

FFKM

METAL BELLOWS

SPRINGS

METAL PARTS

CARBON VS SIC

UNS N10276 (TYPE B)

UNS N10276

UNS S31600/ S31635

SPIRAL-W GASKET

SIC VS SIC

UNS N07718 (TYPE C)

OR N06455

UNS N10276

NBR

SS-SIC

UNS N08020

UNS S31600

UNS N08020

OTHER:

OR S31635

OTHERSuper Duplex SS

RB-SIC

VS

MECHANICAL SEAL DATA

24

25

SEAL VENDOR

ALTERNATIVE SEAL FOR PUMP PERFORMANCE TEST

26

DATA REQUIREMENTS FORM (ANNEX G)

DYNAMIC SEALING PRESSURE RATING (3.19)

bar (ga)

27

SIZE/TYPE

STATIC SEALING PRESSURE RATING (3.68)

bar (ga)

28

SEAL DRAWING NUMBER

MAXIMUM ALLOWABLE TEMPERATURE (3.38)

29

VENDOR'S SEAL CODE

MINIMUM DESIGN METAL TEMPERATURE (6.1.6.11.1)

30

MODIFIED FACES FOR PUMP PERFORMANCE TEST

SEAL CHAMBER DATA (REFERENCE 6.1.2.4)

31

32

ASME B73.1 & 2

CYLINDRICAL

TAPERED

ISO 13709

ISO 3069-C

OTHER, SPECIFY

Throttle Bushing

33

BOLT-ON CHAMBER (6.1.2.5)

SEAL CHAMBER FLUSH PORT REQ'D

SEAL CHAMBER VENT REQ'D

34

FLOATING THROAT BUSH

FIXED THROAT BUSH

CHAMBER HEATING REQ'D

PUMP DATA (Refer Pump Data Sheet)

35

36

PUMP DESIGN

37

PUMP OPERATING PRESSURE

MANUFACTURER

38

SEAL CHAMBER

NORMAL

39

SHAFT

HORIZONTAL

40

SHAFT DIRECTION (FROM DRIVER):

bar (ga)

MIN / MAX (3.40)

VERTICAL

DIA.

CW

CCW

PUMPED STREAM

HAZARDOUS

43

TYPE OR NAME

44

45

DISSOLVED CONTAMINANT

Cl2

ml/m3

OTHER

46

SOLID CONTAMINANT

47

FRAME/SIZE

bar (ga)

CASE MATERIAL

DISCHARGE PRESSURE

bar (ga)

bar (ga)

bar (ga)

MSSP (3.42)

mm

SHAFT SPEED

r/min

FLUID DATA - (FOR QUENCH, BUFFER AND BARRIER FLUID DATA, SEE PAGE 2) Refer Pump Data Sheet

41

42

MODEL

SUCTION PRESS. (RATED)

CONC'N

H2 S

ml/m3

WET

ml/m3

FLAMMABLE

FLUID SOLID @ AMBIENT

SOLIDIFIES @

POUR POINT

PUMPED STREAM CONTAINS AGENTS THAT POLYMERIZE

CONCENTRATION (MASS FRACTION)

SPECIFY AGENTS

@ TEMP

48

PUMPING TEMPERATURE

49

MIN

50

RELATIVE DENSITY (TO WATER @ 25C) AT REF. TEMP.

PUMPED STREAM IS REGULATED FOR FUGITIVE OR

51

@ NORMAL TEMP

OTHER EMISSIONS.

52

ABSOLUTE VAPOR PRESSURE AT REFERENCE TEMP.

53

NORMAL TEMP

bar

SPECIFY;

54

ATMOSPHERIC BOILING POINT.

ALTERNATIVE PROCESS FLUIDS & CONCENTRATION

55

VISCOSITY @ NORMAL PUMPING TEMP.

Pa.s

(INCL. COMMISIONING)

PUMPED STREAM SOLIDIFIES UNDER SHEAR

C

PUMPED STREAM CAN PLATE OUT OR DECOMPOSE:

NORMAL

MAX

@ MAX TEMP

bar

MAX TEMP

SPECIFY CONDITIONS

REGULATION LEVEL

ml/m3

SPECIAL PUMP CLEANING PROCEDURES

56

FLUSH FLUID (PLAN 32)

57

TYPE OR NAME

58

SEAL VENDOR REVIEW REQUIRED

NORMAL TEMP

59

FLUID TEMPERATURE

ATMOSPHERIC BOILING POINT.

60

MIN

61

RELATIVE DENSITY (TO WATER @ 25C) AT REF. TEMP.

FLOW RATE REQ'D MAX/MIN

l/min

62

@ NORMAL TEMP

PRESSURE REQ'D MAX/MIN

bar (ga)

If flush fluid is pumpage, then flush fluid data is not required.

CONC'N

NORMAL

MAX

@ MAX TEMP

ABSOLUTE VAPOR PRESSURE AT REFERENCE TEMP.

bar

MAX TEMP

bar

C

VISCOSITY @ NORMAL PUMPING TEMP.

Pa.s

KOC DATA SHEET- (CATEGORY 1 & 2 SEALS)

MECHANICAL SEAL DATA SHEET

FOR CENTRIFUGAL & ROTARY PUMPS

API 682 3rd EDITION

S.I. UNITS

REQUIRED FOR:

SITE:

UNIT:

JOB/PROJECT NO.

ITEM NO.

REQUISITION / SPEC. NUMBER

/

BY

INQUIRY NUMBER

DATE

PURCHASE ORDER NUMBER

REVISION NO. 0

DATE

BY SEAL VENDOR

BY SEAL VENDOR OR PURCHASER

PAGE 2 OF 2

(FLUID DATA, UTILITIES, ACCESSORIES, & INSP./TEST.)

1

INDICATES DATA COMPLETED BY PURCHASER

2

DEFAULT SELECTION

3

FLUID DATA - (QUENCH, BUFFER AND BARRIER FLUID DATA, LIQUID AND GAS)

4

5

6

QUENCH MEDIUM (PLAN 51, 62)

TYPE OR NAME

SUPPLY TEMPERATURE MAX/MIN

FLOW RATE REQ'D MAX/MIN

l/min

BUFFER/BARRIER MEDIUM

TYPE OR NAME

PURCHASER SELEC'N

SEAL VENDOR SELEC'N

@ NORMAL TEMP

SEAL VENDOR REVIEW

PURCHASER REVIEW

ABSOLUTE VAPOR PRESSURE AT REFERENCE TEMP.

10

FLOW RATE REQ'D MAX/MIN.

11

COOLING/HEATING REQUIRED (+ OR -)

12

SUPPLY PRESSURE MAX/MIN.

13

FLUID OPERATING TEMPERATURE

14

MIN

RELATIVE DENSITY (TO WATER @ 25C) AT REF. TEMP.

l/min

bar (ga)

NORMAL

110

CONTROL VOLTAGE

17

ELECTRICAL AREA

18

DESIGN AMBIENT MIN./MAX.

CL

MAX

VISCOSITY @ NORMAL TEMP (LIQUID)

Pa.s

PHASE

T3

FOR LIQUID @ NORMAL TEMPERATURE

SITE AND UTILITIES

COOLING H2O SUPPLY TEMP.

1 HERTZ

50

COOLING H2O PRESS. NORM./DES.

IIA

DIV

2

GR

/

ATEX (EC DIRECTIVE 94/9/EC)

GENERAL

NA

JOINT USER/VENDOR LAYOUT OF EQUIPMENT (8.1.4)

EQUIPMENT SUPPORT SUPPLIER

22

PIPE TAPER THREADS (8.1.9)

FILLING SYSTEM SUPPLIER

23

SPECIAL REQUIREMENTS FOR HAZARDOUS SERVICE

ISO 7

ASME B1.20.1

GR

RESERVOIR CAPACITY (8.5.4.3)

26

UTILITY MANIFOLD CONNECTIONS REQUIRED (8.4.4)

NLL TO GLAND PLATE HEIGHT (8.5.4.2)

27

TYPE AND SPEC. OF HEAT TRACING (8.6.5.8)

RESERVOIR MAWP (3.39)

THERMAL RELIEF VALVES REQUIRED (9.8.3)

EQUIPMENT REFERENCE/CODE

34

COOLING WATER LINES SUPPLIER

TUBING

37

SIGHT FLOW INDICATORS (8.4.3)

39

40

ISO 15649

Not Available

GALVANISED PIPING (8.4.2)

COOLING WATER FLOW RATE

bar (ga)

FALLING PRESSURE (ARR 3) SET @

bar (ga)

HIGH LEVEL ALARM REQUIRED (8.5.4.2.i)

EXTERNAL CIRCULATING PUMP (8.6.3.1)

OPEN

CLOSED

PLAN 72 AND 74 SYSTEM

EQUIPMENT SUPPLIER

Not Required

CONNECTING LINES SUPPLIER

RISING PRESSURE (ARR 2) SET @

TEST BASED H/Q CURVE FOR INTERNAL CIRC. DEVICE

l/min

PLAN 11, 13, 14, 21, 23, 31, 32 AND 41 SYSTEMS

TUBING

DAYS

PRESSURE SWITCH (8.5.4.2.h) TO ACTIVATE ON;

AIR COOLED

36

PIPING (8.5.2.2)

HIGH FLOW ALARM SWITCH (8.6.6.5)

PLAN 75 AND 76 SYSTEM

41

RESTRICTION ORIFICE NIPPLE IN FLUSH LINE (8.5.2.4)

EQUIPMENT SUPPLIER

42

CYCLONE SEPARATOR SUPPLIER

HIGH LEVEL ALARM SWITCH FOR PLAN 75 (8.6.5.3)

43

PLAN 32 EQUIPMENT SUPPLIER

44

PLAN 32 FLOW IND'R

45

46

47

TEST CONNECTION (8.6.5.4)

PLAN 32 TEMPERATURE IND'R

PLAN 52 AND 53 SYSTEMS

STANDARD (FIG D.27)

52

53

54

55

INSTRUMENTATION/CONTROLS

DIMENSIONAL VARIATIONS TO STANDARD (FIG D.27)

PRESSURE GAUGES (9.4);

DIMENSIONAL VARIATIONS TO ALTERNATIVE (FIG D.28)

PRESSURE SWITCHES (9.5.2);

TRANSMITTER (9.5.2.3)

LEVEL SWITCHES (9.5.3);

TRANSMITTER (9.5.3.2)

OIL FILLED PRESSURE GAUGES (9.4.3)

50

51

INSTRUMENTATION

USER SPECIFICATION REFERENCE FOR

ALTERNATIVE (FIG D.28)

48

49

C

bar (ga)

TEMPERATURE INDICATOR (PLAN 53B & 53C)

HEAT EXCHANGER SUPPLIER

WATER COOLED

SYSTEM HOLD-UP PERIOD (PLANS 53B & 53C)

COOLING SYSTEM (PLAN 21, 22, 23, 41, 53B, 53C)

33

38

m

bar (ga) @

SET PRESSURE RANGE, MAX/MIN

28

35

T CLASS

SPECIAL CLEANING AND DECONTAMINATION REQ'TS

32

CAT.

bar (ga)

EN 13445 OR OTHER CODE APPLICABLE

25

31

ml/m3

ASME CODE STAMP REQUIRED

24

30

Cl2

C

NA

PLAN 52 AND 53 SYSTEMS CONTINUED

21

29

J/Kg.K

ACCESSORIES (CLAUSES 8 AND 9)

19

20

bar

MAX TEMP

ATMOSPHERIC BOILING POINT (LIQUID)

SPECIFIC HEAT CAPACITY @ CONSTANT PRESSURE

15

16

bar

NORMAL TEMP

Kw

/

@ MAX TEMP

ALTERNATIVE FABRICATION STANDARD

PRIMARY EQUIPMENT SUPPLIER

SUPPLIER REFERENCE/CODE

CONNECTING LINES SUPPLIER

TUBING

HYDROSTATIC

CAPACITANCE

ULTRASONIC

LEVEL INDICATORS (9.6)

WELD PAD

FLOW INSTRUMENTS (9.7);

EXTERNAL, REMOVABLE (9.6.2)

TRANSMITTER (9.7.3)

SCH 80 PIPING (8.5.4.4.9)

INSPECTION AND TESTING

56

57

PURCHASER PARTICIPATION IN INSPECTION & TEST

58

SPECIFY;

MAGNETIC PARTICLE

LIQUID PENETRANT

59

INSPECTOR'S CHECK LIST (10.1.7 & ANNEX E)

RADIOGRAPHIC

ULTRASONIC

60

PURCHASER APPROVAL REQUIRED FOR WELDED

OPTIONAL QUALIFICATION TESTING REQ'D (10.3.1.1.2)

61

CONNECTION DESIGNS, (6.1.6.10.5)

MOD. FACES FOR PUMP TEST (10.3.5.1.1), SEE PG 1, LINE 30

62

HARDNESS TEST (10.2.3 k) REQUIRED FOR;

ALTERNATIVE SEAL PUMP TEST (10.3.5.1.2), SEE PG 1, LINE 25

63

100% INSPECTION OF ALL WELDS (6.1.6.10.5) USING;

Potrebbero piacerti anche

- TL140 Workshop Manual (CT9E004)Documento613 pagineTL140 Workshop Manual (CT9E004)kris75% (8)

- Intake Manifold Air Temperature Is High: TroubleshootingDocumento3 pagineIntake Manifold Air Temperature Is High: TroubleshootingPutra JawaNessuna valutazione finora

- Forged Steel Gate Valve CalculationsDocumento20 pagineForged Steel Gate Valve CalculationsMahendra PatilNessuna valutazione finora

- Pump HandbookDocumento257 paginePump Handbookisaac2408100% (12)

- Pocket API 682 4th Edition Piping Plans - EN Burgmann PDFDocumento131 paginePocket API 682 4th Edition Piping Plans - EN Burgmann PDFPoncho RmzNessuna valutazione finora

- Api 682 Mechanical Seal Data Sheet For Centrifugal and Rotary PumpsDocumento2 pagineApi 682 Mechanical Seal Data Sheet For Centrifugal and Rotary PumpsSakthikumar Chandrasekaran100% (3)

- ABC COSTING With Answers PDFDocumento13 pagineABC COSTING With Answers PDFShaira Rehj Rivera100% (1)

- Mechanical Data Sheet Pressure Vessel: GeneralDocumento2 pagineMechanical Data Sheet Pressure Vessel: GeneralEDUARDONessuna valutazione finora

- Input Data: Tce Consulting Engineers LimitedDocumento2 pagineInput Data: Tce Consulting Engineers Limitedsaptarshi samantaNessuna valutazione finora

- Data Sheet Ball ValveDocumento1 paginaData Sheet Ball ValveIkhsan Hj SiratNessuna valutazione finora

- API 674 Pump Data SheetDocumento5 pagineAPI 674 Pump Data SheetEason Ng100% (2)

- Well Pump Test Data Sheet: Subdivision/Site CondominiumDocumento2 pagineWell Pump Test Data Sheet: Subdivision/Site Condominiumisaac2408100% (2)

- API STD 676-2009 - Hoja de RequisiciónDocumento28 pagineAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNessuna valutazione finora

- Pump Test Data Sheet: Drawdown Data Recovery DataDocumento1 paginaPump Test Data Sheet: Drawdown Data Recovery Dataisaac2408100% (1)

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocumento9 pagine4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- Gas Generator Set G3516: Standby PowerDocumento4 pagineGas Generator Set G3516: Standby PowerGeneral-Turbos Machinery100% (4)

- Assembly Language 8086 Exercise Solution (Marut) PDFDocumento58 pagineAssembly Language 8086 Exercise Solution (Marut) PDFShaibal Ahmed56% (9)

- 62577A Calculation of Orifice Coefficient Si UnitsDocumento18 pagine62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioNessuna valutazione finora

- Vessel Calculation 200Documento37 pagineVessel Calculation 200Phát NguyễnNessuna valutazione finora

- SREBRSuperH Plug ValvesDocumento39 pagineSREBRSuperH Plug ValvesFAZUL412100% (1)

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocumento4 pagineToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocumento2 pagineE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNessuna valutazione finora

- Nozzle Load Calculation SpreadsheetDocumento10 pagineNozzle Load Calculation SpreadsheetMuthuNessuna valutazione finora

- Datasheets For Bucket Type StrainerDocumento2 pagineDatasheets For Bucket Type StrainerbecpavanNessuna valutazione finora

- Accident Case Studies On Lifting EquipmentDocumento21 pagineAccident Case Studies On Lifting EquipmentAremy Ibe100% (1)

- HD Api610Documento5 pagineHD Api610Venkat RanganNessuna valutazione finora

- Fsi Catalog Filter VesselsDocumento35 pagineFsi Catalog Filter VesselsarietilangNessuna valutazione finora

- 682 DatasheetDocumento2 pagine682 DatasheetHatem ShawkiNessuna valutazione finora

- Pipe Size Flange Rating Operating Condition: E F SFDocumento4 paginePipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- Basket Filter CalcDocumento17 pagineBasket Filter CalcRajesh NareNessuna valutazione finora

- Technical Specifications of Mechanical Seal S.NO. Description Specifications Eagle Poonawala Flowserve Sanmar Roto - Seals Hi - Fab Operating DetailsDocumento3 pagineTechnical Specifications of Mechanical Seal S.NO. Description Specifications Eagle Poonawala Flowserve Sanmar Roto - Seals Hi - Fab Operating Detailssushant_jhawerNessuna valutazione finora

- Mechanical Design Aspects For High-Performance Agitated ReactorsDocumento11 pagineMechanical Design Aspects For High-Performance Agitated ReactorsgpcshfNessuna valutazione finora

- Rupture Disk SizingDocumento2 pagineRupture Disk Sizingabhishek shindeNessuna valutazione finora

- c3 PDFDocumento29 paginec3 PDFHrithik IGNessuna valutazione finora

- Blind Flange Design Calculations - by Abdel Halim GalalaDocumento6 pagineBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- API 610 DatasheetDocumento7 pagineAPI 610 DatasheetagusnnnNessuna valutazione finora

- Check ValveDocumento1 paginaCheck ValveRoshanKuckianNessuna valutazione finora

- API 610 11th Ed DatasheetDocumento13 pagineAPI 610 11th Ed DatasheetHatem ShawkiNessuna valutazione finora

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocumento2 paginePolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Air Eliminator Datasheet PDFDocumento2 pagineAir Eliminator Datasheet PDFbecpavanNessuna valutazione finora

- Field HandbookDocumento72 pagineField Handbookisaac2408Nessuna valutazione finora

- Edutor Tank MixerDocumento2 pagineEdutor Tank MixerLeandro BuosiNessuna valutazione finora

- Welded Steel Pipe Design ManualDocumento93 pagineWelded Steel Pipe Design ManualfileseekerNessuna valutazione finora

- Power Transformer ENUDocumento32 paginePower Transformer ENUDaniel RizzoNessuna valutazione finora

- Wtm-058 Ut Procedure Aws d1.5 (2010)Documento9 pagineWtm-058 Ut Procedure Aws d1.5 (2010)Wisüttisäk Peäröön0% (1)

- Api 610 Datasheet PDF FreeDocumento7 pagineApi 610 Datasheet PDF FreeRisyda PutriNessuna valutazione finora

- Restriction Orifice Final CalculationDocumento1 paginaRestriction Orifice Final CalculationJasperTanNessuna valutazione finora

- Floating and Trunnion Ball Valves PDFDocumento15 pagineFloating and Trunnion Ball Valves PDFAlienshowNessuna valutazione finora

- Boss Ve-20 ManualDocumento144 pagineBoss Ve-20 ManualCarlo Mauricio González Parra100% (1)

- Data Sheet For Globe ValveDocumento4 pagineData Sheet For Globe ValveShaaban Noaman100% (1)

- ksb غاطسDocumento5 pagineksb غاطسGhassan ABO ALINessuna valutazione finora

- Cs Globe Valve 600#Documento1 paginaCs Globe Valve 600#Vijay GaikwadNessuna valutazione finora

- 10P87-D0003-046-R0-WHRU by TEPLDocumento23 pagine10P87-D0003-046-R0-WHRU by TEPLjigarNessuna valutazione finora

- BE-WI-248-01-F19 Datasheet Breather ValveDocumento3 pagineBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNessuna valutazione finora

- TEMA Shell Bundle Entrance and Exit AreasDocumento3 pagineTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNessuna valutazione finora

- Data Sheet For Silencer PDFDocumento3 pagineData Sheet For Silencer PDFAlvin Smith0% (1)

- API676 DatasheetDocumento2 pagineAPI676 DatasheetLuvys Garcia MartinezNessuna valutazione finora

- Roark Mast CalculationsDocumento1 paginaRoark Mast Calculationsjamil voraNessuna valutazione finora

- E 50B 4KG1 - Fire PDFDocumento2 pagineE 50B 4KG1 - Fire PDFdocrafiNessuna valutazione finora

- Needle ValveDocumento8 pagineNeedle ValveMuhammad Chilmi100% (1)

- Actuated Ball Valve 357 D - BDKDocumento4 pagineActuated Ball Valve 357 D - BDKfarhanakhtar ansariNessuna valutazione finora

- Ring Blower Vacuum Pump Catalog (Total) 2 PDFDocumento17 pagineRing Blower Vacuum Pump Catalog (Total) 2 PDFDSdds0% (1)

- Pressure Vessels (Project Standards and Specifications) : Page: 1 of 21Documento6 paginePressure Vessels (Project Standards and Specifications) : Page: 1 of 21Tafe AdamuNessuna valutazione finora

- Y-Strainer Spears DatasheetDocumento10 pagineY-Strainer Spears Datasheetmanoj_sitecNessuna valutazione finora

- 377 Series Trip Valves: Product BulletinDocumento3 pagine377 Series Trip Valves: Product BulletinIsmail AhmadNessuna valutazione finora

- Cast - Basket Strainers - 2nd EditionDocumento27 pagineCast - Basket Strainers - 2nd EditionmartinnovelNessuna valutazione finora

- 25nb y StrainerDocumento1 pagina25nb y StrainerKailas NimbalkarNessuna valutazione finora

- PVC Pipe Making Machine 01 PDFDocumento1 paginaPVC Pipe Making Machine 01 PDFabdul kareeNessuna valutazione finora

- Valve CV Sizing Liquids GasesDocumento24 pagineValve CV Sizing Liquids GasesRicardo RamosNessuna valutazione finora

- FOAMGLAS Cellular Glass InsulationDocumento18 pagineFOAMGLAS Cellular Glass InsulationermizeNessuna valutazione finora

- Crosby SizingDocumento89 pagineCrosby SizingNattapong Pongboot100% (1)

- Root BlowerDocumento1 paginaRoot Blowersushant_jhawerNessuna valutazione finora

- Product Date Sheet - Swagelok BrocureDocumento6 pagineProduct Date Sheet - Swagelok BrocurejulianpirahNessuna valutazione finora

- Htri Datasheet & Application Note - Datasheet ArchiveDocumento4 pagineHtri Datasheet & Application Note - Datasheet ArchiveShantanuNessuna valutazione finora

- Oil Cooler - Pre Design Data SheetDocumento3 pagineOil Cooler - Pre Design Data SheetSakthi VelNessuna valutazione finora

- Datasheet PompaDocumento8 pagineDatasheet PompaagusnnnNessuna valutazione finora

- 610 Datasheets SiDocumento7 pagine610 Datasheets SiHatem ShawkiNessuna valutazione finora

- Relationships Between CV KV and CDocumento30 pagineRelationships Between CV KV and Cisaac2408Nessuna valutazione finora

- API Standard 610 - Centrifugal Pumps For Petroleum, Petrochemical and Natural Gas IndustriesDocumento2 pagineAPI Standard 610 - Centrifugal Pumps For Petroleum, Petrochemical and Natural Gas Industriesisaac2408Nessuna valutazione finora

- Tri P10Documento10 pagineTri P10isaac2408Nessuna valutazione finora

- Pump. Demineralized Water (Spanish)Documento55 paginePump. Demineralized Water (Spanish)isaac2408Nessuna valutazione finora

- Piping Plan Pocket PalDocumento66 paginePiping Plan Pocket PalmflorespazosNessuna valutazione finora

- WOWLibrary TIG WeldingDocumento3 pagineWOWLibrary TIG Weldingisaac2408Nessuna valutazione finora

- API 6A Type 6B & 6BX FlangesDocumento28 pagineAPI 6A Type 6B & 6BX FlangesSajal KulshresthaNessuna valutazione finora

- Turbcomp Practicalguidelines DeerparkDocumento3 pagineTurbcomp Practicalguidelines Deerparkisaac2408Nessuna valutazione finora

- Procedimiento Encontrar ResonanciasDocumento2 pagineProcedimiento Encontrar Resonanciasisaac2408Nessuna valutazione finora

- Hoja Equilibrado DatosDocumento2 pagineHoja Equilibrado Datosisaac2408Nessuna valutazione finora

- HD Api610Documento10 pagineHD Api610isaac2408Nessuna valutazione finora

- Turbomachineryperformance DubaiDocumento4 pagineTurbomachineryperformance Dubaiisaac2408Nessuna valutazione finora

- Equivalencias de Normas Internacionales de Piping en PetroleoDocumento129 pagineEquivalencias de Normas Internacionales de Piping en PetroleoHernán H.Nessuna valutazione finora

- PSL 1 & 2Documento1 paginaPSL 1 & 2isaac2408Nessuna valutazione finora

- PSL 1 & 2Documento1 paginaPSL 1 & 2isaac2408Nessuna valutazione finora

- Tank Estimating ChartDocumento1 paginaTank Estimating Chartisaac2408Nessuna valutazione finora

- Dimensions, Sizes and Specification of ANSI ASME B 16.36 Orifice Flanges PDFDocumento8 pagineDimensions, Sizes and Specification of ANSI ASME B 16.36 Orifice Flanges PDFisaac2408Nessuna valutazione finora

- API 6A Type 6B & 6BX FlangesDocumento28 pagineAPI 6A Type 6B & 6BX FlangesSajal KulshresthaNessuna valutazione finora

- ChemicalDocumento5 pagineChemicalisaac2408Nessuna valutazione finora

- Recommended Ventilation For Various Sized TanksDocumento1 paginaRecommended Ventilation For Various Sized TanksBalasubramanian AnanthNessuna valutazione finora

- Safe ScaffoldingDocumento38 pagineSafe Scaffoldingisaac2408Nessuna valutazione finora

- Rendering An Exterior Scene - V-Ray 2.0 For SketchUp - Chaos Group HelpDocumento9 pagineRendering An Exterior Scene - V-Ray 2.0 For SketchUp - Chaos Group HelpRapha RachoNessuna valutazione finora

- Lecture 2Documento23 pagineLecture 2Sherif HelmyNessuna valutazione finora

- EMM 3514 - Numerical MethodDocumento33 pagineEMM 3514 - Numerical MethodAdhar GoodNessuna valutazione finora

- Five Masterworks by Louis Sauer - 9103559 PDFDocumento64 pagineFive Masterworks by Louis Sauer - 9103559 PDFAntonello Martinez GianfredaNessuna valutazione finora

- Document Feeder: (Machine Code: A662)Documento32 pagineDocument Feeder: (Machine Code: A662)servicerNessuna valutazione finora

- Cross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFDocumento22 pagineCross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFSiva KumarNessuna valutazione finora

- 3G Training Module-07 Nov-15Documento50 pagine3G Training Module-07 Nov-15technobrat_guy100% (1)

- Magnetic Abrasive Finishing A Review IJERTV2IS3010Documento9 pagineMagnetic Abrasive Finishing A Review IJERTV2IS3010Saketh ReddyNessuna valutazione finora

- On Windows Syscall Mechanism and Syscall Numbers Extraction MethodsDocumento26 pagineOn Windows Syscall Mechanism and Syscall Numbers Extraction MethodsqdwqdNessuna valutazione finora

- Chapter 13-Fire HoseDocumento138 pagineChapter 13-Fire HoseFadil Satrio PamungkasNessuna valutazione finora

- PW5 Basic Double Busbar Dis 20Documento12 paginePW5 Basic Double Busbar Dis 20Shanthiyaah ArumugamNessuna valutazione finora

- Loctite Instant Adhesives: Instant Solutions in Every DropDocumento9 pagineLoctite Instant Adhesives: Instant Solutions in Every DroptejassidhpuraNessuna valutazione finora

- Mbackpaper 18Documento6 pagineMbackpaper 18Aakash PathakNessuna valutazione finora

- F FiberglassDocumento66 pagineF Fiberglassosvald97Nessuna valutazione finora

- Aker Kvaerner Powergas Pvt. Ltd. Process Department: Checklist CL-PC-0012Documento4 pagineAker Kvaerner Powergas Pvt. Ltd. Process Department: Checklist CL-PC-001212mchc07Nessuna valutazione finora

- Deltascope FMP10 Isoscope FMP10 Dualscope FMP20: Operators ManualDocumento152 pagineDeltascope FMP10 Isoscope FMP10 Dualscope FMP20: Operators ManualMarcelino Navarrete EvaristoNessuna valutazione finora

- HVAC Dampers Installation Method StatementDocumento3 pagineHVAC Dampers Installation Method StatementDong VanraNessuna valutazione finora

- KatalogDocumento49 pagineKatalogYan BerliantinaNessuna valutazione finora

- Service Manual HP Ze4900 SchematicsDocumento39 pagineService Manual HP Ze4900 SchematicseduardosceNessuna valutazione finora

- Sony FDR AX1 - E ProDocumento68 pagineSony FDR AX1 - E ProTodorNessuna valutazione finora