Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Safety Relief Valves and Double Stop Valves,: Type SFVL and DSVL

Caricato da

Jason CampbellTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Safety Relief Valves and Double Stop Valves,: Type SFVL and DSVL

Caricato da

Jason CampbellCopyright:

Formati disponibili

Safety relief valves and

double stop valves,

type SFVL and DSVL

REFRIGERATION AND

AIR CONDITIONING

Technical leaflet

Technical leaflet

Safety relief valves and double stop valves, type SFVL and DSVL

Introduction

The SFVL safety valves are backpressure

dependent pressure relief valves. These are

designed for protection of vessels and other

components against excessive pressure. These

valves are recommended as an external and

internal safety relief valve in refrigeration plants.

These valves are manufactured according to

strict quality demands and safety requirements

for refrigeration installations, as specified

in many markets and comply with ASHRAE

Addendum15C-2000. These valves are

manufactured in accordance with the ASME

Quality Control Procedures and stamped with

the UV symbol. They are certified by the United

States National Board of Boiler & Pressure Vessel

Inspectors and are stamped with the NB symbol.

DSVL series 3-way valves are designed to

meet all industrial refrigeration application

requirements.

DSVL valves are designed specifically for use with

double safety valve systems. When used in such

applications, only one safety valve can be shut off

or isolated at any one time. Complete shut off of

one safety valve or the other can be obtained by

front seating or back seating of the valve spindle.

The valves are designed to give favourable flow

characteristics and are easy to dismantle for

servicing. The valve cone is designed to ensure

tight seal.

The 800 series safety relief valve:

Teflon seats mated with the stainless steel

multiple crown rings which provide a reliable

sealing. The triple crown sealing rings are

located at slightly different heights in order

to provide compound sealing ability with the

mating teflon ring.

Special extra lift, pop-open feature in order to

provide a high relief capacity.

A four-wing guided, stainless steel upper seat

provides an excellent guidance for the high

lift and reseating action.

A spring and seat design which provides for

a concentric and axial spring force, loads the

upper seat uniformly and maintains a tight

seal.

All relief valves come with an installation tag

and cable wire. Each valves identification

tag has information regarding the catalogue

number, month and year of manufacture, set

pressure, inlet pipe size and capacity for AIR in

units of SCFM. The tag is fastened with drive

rivets for security.

Relief valves are subject to 100% factory

testing through three separate test sequences

to verify quality and set pressure before being

factory sealed for security.

DSVL

The 843, 844, and 845 series stop valves feature:

A compact casted ductile iron valve body

which is painted with corrosion inhibiting

primer paint

Full port pipe threaded connections for easy

installation and disassembly. The connections

are marked for easy identification.

Stainless steel stems and seal caps

Teflon packing gland

Teflon valve seat

Danfoss A/S (RC-CMS / HBS), 12 - 2003

RD7FE102

Features

SFVL

Technical leaflet

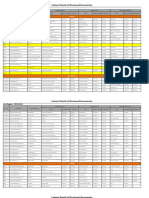

Technical data

SFVL

DSVL

Design

Safety relief valves and double stop valves, type SFVL and DSVL

The SFVL series relief valves are available

with pressure settings from 75 to 400 psi

and a maximum working pressure of 500

psi. Common set pressures of 150, 250 and

300 psi are available from stock or with short

lead-time. Other special pressure settings may

be ordered (see capacity charts in technical

information section.)

The SFVL series relief valves are suitable for

refrigerants R717 (ammonia NH3), HFC and

HCFC refrigerants.

The temperature range is 20F to +275F

(29C to 135C).

The valve body is made from ductile iron that

meets the ASME SA-395 specification grade

60-40-18.

All upper and lower valve seats, springs, and

spring guides are constructed from 304-grade

stainless steel.

Valve bodies are painted with a corrosion

inhibiting primer paint

The SFVL series relief valves are designed for

use with 800 series DSVL (843, 844, or 845).

The series relief valves are suitable for

refrigerants R717 (ammonia NH3), HFC and

HCFC refrigerants.

The 843, 844, and 845 DSVL valves are

approved:

Maximum working pressure of 400 psig.

Temperature range: 20F to +300 F

(29C to +149C)

To receive an updated list of certification

on the products please contact your local

Danfoss Sales Company.

Connections:

The valves are offered with threaded (NPT)

connections.

Housing and internal materials:

The valve body is made from cast ductile iron

that meets the ASME SA-395 specification

grade 60-40-18.

All upper and lower valve seats, springs, and

spring guides are constructed from 304-grade

stainless steel.

The upper valve seat is teflon.

RD7FE102

Danfoss A/S (RC-CMS / HBS), 12 - 2003

Technical leaflet

Safety relief valves and double stop valves, type SFVL and DSVL

Material specification

DSVL

SFVL

DSVL

SFVL

No.

Danfoss A/S (RC-CMS / HBS), 12 - 2003

Part

Material

Part

Material

Lower seat

Stainless steel

Stem / spindle

Stainless steel

Upper seat

Stainless steel

Packing nut

Stainless steel

Teflon ring

Teflon

Bonnet

Steel

Uniform load spring guide

Stainless steel

Housing

Ductile iron

Spring

Stainless steel

Upper and lower seat

Steel

Housing

Ductile iron

RD7FE102

No.

Technical leaflet

Safety relief valves and double stop valves, type SFVL and DSVL

Capacities

RD7FE102

Danfoss A/S (RC-CMS / HBS), 12 - 2003

Technical leaflet

Safety relief valves and double stop valves, type SFVL and DSVL

Dimensions and weights

DSVL

SFVL

Valve size

SFVL 803/813

SFVL 804/814

SFVL 805/815

DSVL 844

DSVL 845

Danfoss A/S (RC-CMS / HBS), 12 - 2003

RD7FE102

Weight

in.

1.77

5.24

1.77

1.65

2.83

3.2 lb

mm

45

133

45

42

72

1.4 kg

in.

1.97

6.06

1.97

1.97

3.31

5.3 lb

2.4 kg

mm

50

154

50

50

84

in.

2.36

7.09

2.36

2.36

3.94

7.9 lb

mm

60

180

60

60

100

3.5 kg

Weight

1.38

7.40

1.77

3.54

3.75 lb

1.7 kg

Valve size

DSVL 843

in.

mm

35

188

45

90

in.

1.73

9.37

2.01

4.13

6.5 lb

mm

44

238

51

105

2.9 kg

in.

1.97

11.34

2.20

4.72

10.25 lb

mm

50

288

56

120

4.6 kg

Technical leaflet

Safety relief valves and double stop valves, type SFVL and DSVL

Ordering

How to order

The table below is used to identify the valve

required.

Please note that the type codes only serve to

identify the valves, some of which may not form

part of the standard product range. For further

information please contact your local Danfoss

Sales Company.

Safety valves, type: SFVL

Double stop valves, type: DSVL

Type

Connections

Pressure setting

[psig]

Code no.

12 NFPT x 34 NFPT

150

148F8000

SFVL 803 12 NFPT x 34 NFPT

250

148F8001

12 NFPT x 34 NFPT

300

148F8002

12 NFPT x 1 NFPT

150

148F8003

SFVL 813 12 NFPT x 1 NFPT

250

148F8004

12 NFPT x 1 NFPT

300

148F8005

34 NFPT x 1 NFPT

150

148F8006

SFVL 804 34 NFPT x 1 NFPT

250

148F8007

34 NFPT x 1 NFPT

300

148F8008

34 NFPT x 1-14 NFPT

150

148F8009

SFVL 814 34 NFPT x 1-14 NFPT

250

148F8010

34 NFPT x 1-14 NFPT

300

148F8011

1 NFPT x 1-14 NFPT

150

148F8012

SFVL 805 1 NFPT x 1-14 NFPT

250

148F8013

1 NFPT x 1-14 NFPT

300

148F8014

1 NFPT x 1-12 NFPT

150

148F8015

SFVL 815 1 NFPT x 1-12 NFPT

250

148F8016

1 NFPT x 1-12 NFPT

300

148F8017

RD7FE102

Type

Connections

Code no.

DSVL 843

12 x 12 x 12 NFPT

148F8018

DSVL 844

34 x 34 x 34 NFPT

148F8019

DSVL 845

1 x 1 x 1 NFPT

148F8020

Danfoss A/S (RC-CMS / HBS), 12 - 2003

Potrebbero piacerti anche

- 3089.045 / Set C - Overhaul Set - SAB 283 S/L: Part No Designation Qty. Pos No. Item ImageDocumento3 pagine3089.045 / Set C - Overhaul Set - SAB 283 S/L: Part No Designation Qty. Pos No. Item ImageKevin ViaudNessuna valutazione finora

- Maquina Iqf 500 KG X HoraDocumento4 pagineMaquina Iqf 500 KG X Horamanuelgonzalez1984100% (1)

- OMEGA AIR-OMD - Dryers - EN - 950094 PDFDocumento2 pagineOMEGA AIR-OMD - Dryers - EN - 950094 PDFJunaid AhmedNessuna valutazione finora

- Ficha Tecnica ZS21KAE-PFV InglesDocumento2 pagineFicha Tecnica ZS21KAE-PFV InglesPascual DuqueNessuna valutazione finora

- Giro de MotorDocumento2 pagineGiro de Motorjose2525Nessuna valutazione finora

- Sprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFDocumento3 pagineSprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFsergirojasNessuna valutazione finora

- ASHRAE 15 - Reducing Toxic Leaks in HVAC Mechanical Equipment RoomsDocumento4 pagineASHRAE 15 - Reducing Toxic Leaks in HVAC Mechanical Equipment Roomspsn_kylmNessuna valutazione finora

- Tecumseh Guidelines For Utilization of R134aDocumento7 pagineTecumseh Guidelines For Utilization of R134aAnibal RiosNessuna valutazione finora

- Sabroe PAC Chillers: Packaged Ammonia Chillers Based On Screw Compressors, With A 100-6200 KW Capacity RangeDocumento2 pagineSabroe PAC Chillers: Packaged Ammonia Chillers Based On Screw Compressors, With A 100-6200 KW Capacity RangePreeti gulati100% (1)

- Technical Documentation: SAB 163 Screw Compressor UnitsDocumento2 pagineTechnical Documentation: SAB 163 Screw Compressor UnitsHenry100% (1)

- ECOSS IOM 102 V1.4 ENG 03 2018 WebDocumento34 pagineECOSS IOM 102 V1.4 ENG 03 2018 WebgbobadillaNessuna valutazione finora

- IIAR Ammonia Refrigeration Piping HandbookDocumento5 pagineIIAR Ammonia Refrigeration Piping HandbookALFONSO THAWENessuna valutazione finora

- Thermosyphon Oil Cooling Demonstration Projec1Documento1 paginaThermosyphon Oil Cooling Demonstration Projec1Raúl RiveraNessuna valutazione finora

- Apc Back Ups Bk300mi, Bk500mi - 3Documento1 paginaApc Back Ups Bk300mi, Bk500mi - 3Eduardo Lorenzetti Pellini100% (1)

- Bristol ScrollDocumento12 pagineBristol ScrollvickersNessuna valutazione finora

- ATC E Bulletin 153E Final LR PDFDocumento44 pagineATC E Bulletin 153E Final LR PDFMax JunghannsNessuna valutazione finora

- 4TTS Installer's GuideDocumento28 pagine4TTS Installer's GuideAlejandro OrdoñezNessuna valutazione finora

- AKV Valvulas Expansion ElectronicaDocumento16 pagineAKV Valvulas Expansion ElectronicaWilder VilcaNessuna valutazione finora

- SST Series Engineering Manual 413a-Sem 0Documento52 pagineSST Series Engineering Manual 413a-Sem 0Gerber GarciaNessuna valutazione finora

- RDB ManualDocumento160 pagineRDB ManualgamunozdNessuna valutazione finora

- 30rb 1wDocumento24 pagine30rb 1wmlozadabastNessuna valutazione finora

- Bristol H2234643DBLADocumento10 pagineBristol H2234643DBLAvickersNessuna valutazione finora

- Hankison H-Unit March06Documento40 pagineHankison H-Unit March06SAUL OSPINONessuna valutazione finora

- WorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRDocumento12 pagineWorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRpragnesh prajapati100% (1)

- FH GP Thermoline enDocumento8 pagineFH GP Thermoline enbegatruckvamNessuna valutazione finora

- AERCO Boiler Benchmark 3.0Documento129 pagineAERCO Boiler Benchmark 3.0hfdadl100% (1)

- Compresseur Danfoss Secop sc21cl PDFDocumento2 pagineCompresseur Danfoss Secop sc21cl PDFOscar MendozaNessuna valutazione finora

- LENNOX HS29 - 3phaseDocumento20 pagineLENNOX HS29 - 3phasedmoros100% (1)

- Catalogue Air Handling Unit DDW Without Frame PDFDocumento27 pagineCatalogue Air Handling Unit DDW Without Frame PDFFirman AnriNessuna valutazione finora

- Manual de Bomba Jockey Modelo 5sv12fg4f60Documento64 pagineManual de Bomba Jockey Modelo 5sv12fg4f60Deniss GálvezNessuna valutazione finora

- Wbh-Series Reciprocating Compressor: Exploded ViewDocumento7 pagineWbh-Series Reciprocating Compressor: Exploded ViewJose Antonio Yupa Medina100% (1)

- 157882189commissioning Checklist3.11.10Documento5 pagine157882189commissioning Checklist3.11.10kunta_kNessuna valutazione finora

- Fallas Compresor Copeland-DesbloqueadoDocumento16 pagineFallas Compresor Copeland-DesbloqueadoMabo MabotecnicaNessuna valutazione finora

- Ylaa0070 - Ylaa0175Documento194 pagineYlaa0070 - Ylaa0175dhcastanoNessuna valutazione finora

- Normas AriDocumento4 pagineNormas Ariotniel_davNessuna valutazione finora

- J Series ManualDocumento144 pagineJ Series ManualMaria DazaNessuna valutazione finora

- 1079Documento3 pagine1079Mahmoud MohamedNessuna valutazione finora

- Imagine Sustainable Power: Unparalleled Performance That's Environmentally FriendlyDocumento18 pagineImagine Sustainable Power: Unparalleled Performance That's Environmentally FriendlyMichel Giménez MéndezNessuna valutazione finora

- Secador de Aire Sullair SR 500Documento16 pagineSecador de Aire Sullair SR 500Darwin Santamaría CalderónNessuna valutazione finora

- Despiece DaewooDocumento58 pagineDespiece DaewoopericopepeNessuna valutazione finora

- Boiler Manual Updated 20131Documento50 pagineBoiler Manual Updated 20131api-251989125Nessuna valutazione finora

- Non-Electrical Auto-Purger (NEAP) : Operator Installation & Instruction ManualDocumento8 pagineNon-Electrical Auto-Purger (NEAP) : Operator Installation & Instruction ManualfriguzNessuna valutazione finora

- Parker Oil Cross ReferenceDocumento3 pagineParker Oil Cross ReferenceWarwick HolthamNessuna valutazione finora

- Tubos de CalorDocumento7 pagineTubos de CalorChristo AcostaNessuna valutazione finora

- Vertical and Horizontal Recirculator Packages: Form 120-200 IOM (MAR 2010)Documento44 pagineVertical and Horizontal Recirculator Packages: Form 120-200 IOM (MAR 2010)botaratoNessuna valutazione finora

- Prod e App - Catálogo EuropaDocumento41 pagineProd e App - Catálogo EuropaGleison PrateadoNessuna valutazione finora

- SC0501 01 - en UsDocumento3 pagineSC0501 01 - en Usalimoya13Nessuna valutazione finora

- LWN Operating Manual of FanDocumento20 pagineLWN Operating Manual of FanYogesh Badhe100% (1)

- Manual RWF II 100 - 1080Documento80 pagineManual RWF II 100 - 1080hunaldo100% (1)

- Model YK (Style H) Centrifugal Liquid ChillersDocumento56 pagineModel YK (Style H) Centrifugal Liquid ChillersAbdulSattarNessuna valutazione finora

- Carrier Serie 50TC (15-27.5 Ton) PDFDocumento98 pagineCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoNessuna valutazione finora

- HUSSMANN Line - Sizing - Refrig - Data - Guide - 101717 PDFDocumento32 pagineHUSSMANN Line - Sizing - Refrig - Data - Guide - 101717 PDFAnonymous 5moojwNessuna valutazione finora

- Filtro Culinario CSF16 PDFDocumento4 pagineFiltro Culinario CSF16 PDFluisNessuna valutazione finora

- SFVL & DSVL Data Sheet RD7FE102 PDFDocumento8 pagineSFVL & DSVL Data Sheet RD7FE102 PDFLuciano CaireNessuna valutazione finora

- Danfoss SFVLDocumento8 pagineDanfoss SFVLTorres Ivan100% (1)

- Crane - Series.rs Center LineDocumento23 pagineCrane - Series.rs Center LinenedwestNessuna valutazione finora

- ProductCatalog Cyrus Shank PSVDocumento95 pagineProductCatalog Cyrus Shank PSVmramos4191Nessuna valutazione finora

- Válvula DurcoDocumento12 pagineVálvula DurcoJames Henrry López EspejoNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- AspenONE Version 101 Press Release FINALDocumento2 pagineAspenONE Version 101 Press Release FINALJason CampbellNessuna valutazione finora

- 98 Analysis PDFDocumento7 pagine98 Analysis PDFgholiNessuna valutazione finora

- Ventiladores AC Hyblade PDFDocumento56 pagineVentiladores AC Hyblade PDFJason CampbellNessuna valutazione finora

- Tabela Deriv IntDocumento2 pagineTabela Deriv IntJoão AzevedoNessuna valutazione finora

- Thermal Properties of Some Oily Seeds: Raziye İNCE, Emin GÜZEL, Ahmet İNCEDocumento7 pagineThermal Properties of Some Oily Seeds: Raziye İNCE, Emin GÜZEL, Ahmet İNCEJason CampbellNessuna valutazione finora

- Xist PDFDocumento2 pagineXist PDFAgustin Gago LopezNessuna valutazione finora

- Pipe Shell Design ToolDocumento1 paginaPipe Shell Design Toolep_alfiNessuna valutazione finora

- Price List & Order FormDocumento2 paginePrice List & Order FormJason CampbellNessuna valutazione finora

- Stainless and Super Steel PlateDocumento2 pagineStainless and Super Steel PlateJason CampbellNessuna valutazione finora

- Finaldis2011 1Documento4 pagineFinaldis2011 1syaiful.idzwanNessuna valutazione finora

- Divisional Sec. Contact Details 2019-03-01-UpdateDocumento14 pagineDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Nessuna valutazione finora

- CodeDocumento2 pagineCodeJoao BatistaNessuna valutazione finora

- Gmu Unofficial TranscriptDocumento3 pagineGmu Unofficial Transcriptapi-491861804Nessuna valutazione finora

- International Journal On Cryptography and Information Security (IJCIS)Documento2 pagineInternational Journal On Cryptography and Information Security (IJCIS)ijcisjournalNessuna valutazione finora

- 2019 FTX2000S Course OutlineDocumento11 pagine2019 FTX2000S Course OutlineAhmed PatelNessuna valutazione finora

- Alex FordDocumento4 pagineAlex FordElectroventica ElectroventicaNessuna valutazione finora

- Social Studies 2014 Qu and AnsDocumento18 pagineSocial Studies 2014 Qu and AnsSaidu H SwarayNessuna valutazione finora

- Philippine Metal Foundries v. CADocumento2 paginePhilippine Metal Foundries v. CAMarcus AureliusNessuna valutazione finora

- Solar Electrical Safety Presentation 1PDFDocumento34 pagineSolar Electrical Safety Presentation 1PDFblueboyNessuna valutazione finora

- FDI and FIIDocumento17 pagineFDI and FIIsharathNessuna valutazione finora

- Agricultural Extension System in Sudan FinalDocumento52 pagineAgricultural Extension System in Sudan FinalMohamed Saad AliNessuna valutazione finora

- Arts Q1W3Documento44 pagineArts Q1W3LEILANI PELISIGASNessuna valutazione finora

- IT 118 - SIA - Module 1Documento9 pagineIT 118 - SIA - Module 1Kim Zyrene DominoNessuna valutazione finora

- 1LG4253-4AA60 Datasheet enDocumento1 pagina1LG4253-4AA60 Datasheet enanm bNessuna valutazione finora

- GNDDocumento16 pagineGNDDEAN TENDEKAI CHIKOWONessuna valutazione finora

- Science, Technology and SocietyDocumento2 pagineScience, Technology and SocietyHamieWave TVNessuna valutazione finora

- I Am Trying To Design A Bus Brace For A 3 Phase Busbar SyatemDocumento9 pagineI Am Trying To Design A Bus Brace For A 3 Phase Busbar SyatemSanjeewa HemaratneNessuna valutazione finora

- Catalogo de Partes Hero KarizmaDocumento98 pagineCatalogo de Partes Hero Karizmakamil motorsNessuna valutazione finora

- Manual of Infection Prevention and Control (PDFDrive)Documento399 pagineManual of Infection Prevention and Control (PDFDrive)அந்தோணி சாமி100% (1)

- 2000B - Row - Crop - Parts - F-247-0512 - 031214 Model 2000 SeriesDocumento48 pagine2000B - Row - Crop - Parts - F-247-0512 - 031214 Model 2000 SeriesvanchinatanyaNessuna valutazione finora

- Psar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0Documento183 paginePsar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0PhatNessuna valutazione finora

- Device Protocol - v2.2.4Documento81 pagineDevice Protocol - v2.2.4Aston MartinNessuna valutazione finora

- Difference Between Distinct and Group byDocumento1 paginaDifference Between Distinct and Group byPavelStrelkovNessuna valutazione finora

- 03 Pezeshki-Ivari2018 Article ApplicationsOfBIMABriefReviewADocumento40 pagine03 Pezeshki-Ivari2018 Article ApplicationsOfBIMABriefReviewAdanes1800Nessuna valutazione finora

- One For All Urc-8350 Instruction Manual PDF DownloadDocumento5 pagineOne For All Urc-8350 Instruction Manual PDF DownloademinaNessuna valutazione finora

- Performance Online - Classic Car Parts CatalogDocumento168 paginePerformance Online - Classic Car Parts CatalogPerformance OnlineNessuna valutazione finora

- BDA Guide To Successful Brickwor1kDocumento259 pagineBDA Guide To Successful Brickwor1kMudassar AhmadNessuna valutazione finora

- SAM3-P256 Development Board Users Manual: This Datasheet Has Been Downloaded From at ThisDocumento21 pagineSAM3-P256 Development Board Users Manual: This Datasheet Has Been Downloaded From at ThissunnguyenNessuna valutazione finora

- Batch 2 SEC Online Test AnswersDocumento5 pagineBatch 2 SEC Online Test AnswersBhairav YouthsNessuna valutazione finora