Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ideal On Site Produced Fuel

Caricato da

SteveKeller0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni5 pagineTechnical Library / Additional Information /

Titolo originale

Ideal on Site Produced Fuel

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTechnical Library / Additional Information /

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni5 pagineIdeal On Site Produced Fuel

Caricato da

SteveKellerTechnical Library / Additional Information /

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

The Ideal On-site Produced Fuel

Simple process for on-site production

Engines easily modified to use fuel

Uses locally available raw materials

High Specific Energy (kWhr/kg)

High Energy Density (kWhr/liter)

Low Cost

Easily Transported, Stored and Handled

Flammability Low

Toxicity low

Synergistic with solution of other problems

Hydrogen as On-site Produced Fuel

Simple process for on-site production - YES

Engines easily modified to use fuel - YES

Uses locally available raw materials - YES

High Specific Energy (kWhr/kg) - YES

High Energy Density (kWhr/liter) - NO

Low Cost - YES

Easily Transported, Stored and Handled - NO

Flammability Low - NO

Toxicity low - YES

Synergistic with solution of other problems - NO

Major show stopper for hydrogen is the extreme difficulty of storage both on and off vehicle.

The Department of Energy FreedomCAR program has devoted major resources to the solution of

this problem without success

Hydrocarbons as On-site Produced Fuel

Simple process for on-site production - NO

Engines easily modified to use fuel - YES

Uses locally available raw materials - YES

High Specific Energy (kWhr/kg) - YES

High Energy Density (kWhr/liter) - YES

Low Cost - NO

Easily Transported, Stored and Handled - YES

Flammability Low - NO

Toxicity low - NO

Synergistic with solution of other problems - YES

Fischer-Tropsch technology used in South Africa for over 50 years to produce fuel from coal.

Requires significant carbon to produce mixture of CO and H2 (stores ~ 2.3 H per C)

Complex process with catalyst sensitive to poisoning

Ammonia as On-site Produced Fuel

Simple process for on-site production - Moderate

Engines easily modified to use fuel - YES

Uses locally available raw materials - YES

High Specific Energy (kWhr/kg) - YES

High Energy Density (kWhr/liter) - YES

Low Cost - Moderate

Easily Transported, Stored and Handled - YES

Flammability Low - YES

Toxicity low - NO

Synergistic with solution of other problems - YES

Uses N2 from air and H2 to produce fuel using Haber-Bosch process

Fuel chosen by U.S. Army in 1960s for on-site production using nuclear energy in

Energy Depot Concept

Norsk Hydro started producing ammonia using hydrogen from water electrolysis in 1928

Primary disadvantage is toxicity

Ammonia Toxicity

Energy Density (theoretical max.) of Stored Ammonia as a Fuel - 3.5 kWhr/L

Specific Energy (theoretical max.) of Stored Ammonia as a Fuel - 5.2 kWhr/kg

Storage - Ammonia requires pressure tank ~ 10 bar

Toxicity time-weighted average (TWA) = 25 ppm

short-term exposure limit (STEL) = 35 ppm

concentration immediately dangerous to life or health (IDLH) = 500 ppm

Ammonia as Diesel Engine Fuel

Diesel engines are easily adapted to use ammonia as the primary

energy source by:

a) Introducing ammonia gas into the air intake

(The low boiling point (-33 C, 1 atm) of ammonia assists

operation at low temperatures)

b) Using fuel injectors to supply a small amount of diesel fuel (~ 1-2%

w/w of ammonia consumed, reducing diesel consumption by

~40x) to ignite the ammonia cylinder charge

13% higher

thermal efficiency

32% higher power

output

Ref: Pearsall, T.J., Garabedian, C. G.

Combustion of Anhydrous Ammonia in

Diesel Engines SAE Paper 670947

I.M.E.P. = Indicated Mean Engine Pressure

Ammonia as Otto Cycle Fuel

Spark Ignition can be used in Otto cycle and diesel engines to

eliminate the need for any diesel fuel by:

a) Partially dissociating the ammonia using exhaust heat or

electrical resistance heating prior to introduction into the

air intake

b) Using long-reach, spark plugs with a high-energy ignition

system

Experimental Engine Performance

Comparative performance in a

spark ignition engine

Higher fuel consumption due to

the lower energy content of

ammonia compared to gasoline

(isooctane)

Ref: Starkman, E. S., et. al.. Ammonia as a Spark Ignition Engine Fuel

SAE Paper 660155

Small Electrolysers Commercially Available

(303 kW power input)

Potrebbero piacerti anche

- Performance Analysis of An Engine Using Producer GasDocumento53 paginePerformance Analysis of An Engine Using Producer GasKIRAN CHERIYANNessuna valutazione finora

- IGCC: Integrated Gasification Combined Cycle Power GenerationDocumento33 pagineIGCC: Integrated Gasification Combined Cycle Power GenerationRoop KumarNessuna valutazione finora

- Dual Fuel EnginesDocumento51 pagineDual Fuel EnginesAhmed shawkyNessuna valutazione finora

- Alternative Fuels Seminar: Biodiesel, Hydrogen, Electricity and MoreDocumento30 pagineAlternative Fuels Seminar: Biodiesel, Hydrogen, Electricity and MoreSatish HS0% (1)

- YggjDocumento11 pagineYggjSaldrie Abhirama NohanNessuna valutazione finora

- Alternative Fuels For SI Engines: by K C Karthik 2 Sem, M.Tech (A.E)Documento25 pagineAlternative Fuels For SI Engines: by K C Karthik 2 Sem, M.Tech (A.E)محمد السنوسيNessuna valutazione finora

- Lecture - (Unit-5) - Rating and Convetional-Alternative FuelsDocumento41 pagineLecture - (Unit-5) - Rating and Convetional-Alternative FuelsraviNessuna valutazione finora

- Hydrogen As A Fuel For Ic EngineDocumento23 pagineHydrogen As A Fuel For Ic Enginerahulthapa403Nessuna valutazione finora

- Alternate Fuels For CI Engine 2003Documento22 pagineAlternate Fuels For CI Engine 2003Vaman ShenoyNessuna valutazione finora

- Carbon Neutral Green Energy Solutions - Rev 0Documento50 pagineCarbon Neutral Green Energy Solutions - Rev 0lojiaxuanNessuna valutazione finora

- Production of Urea Through ACES Process: Advanced Cost and Energy Saving ProcessDocumento13 pagineProduction of Urea Through ACES Process: Advanced Cost and Energy Saving ProcessEngnrXaifQureshiNessuna valutazione finora

- Hydrogen Fuel Cell Tech ExplainedDocumento61 pagineHydrogen Fuel Cell Tech ExplainedSyed Ñąveed HąįdeŕNessuna valutazione finora

- Fuel CellsDocumento107 pagineFuel CellsKapil Reddy100% (1)

- 2019 06 18 Hydrofuel Hydrogen Conference PresentationDocumento22 pagine2019 06 18 Hydrofuel Hydrogen Conference PresentationGarip GerçeklerNessuna valutazione finora

- Plasma HHO To FuelDocumento30 paginePlasma HHO To FuelmikrovoltNessuna valutazione finora

- Hydrogen EngineDocumento4 pagineHydrogen EnginerajmehaNessuna valutazione finora

- Scope For Development in I. C. Engine Design: Means To Move Towards Ideal Cycle Performance Limits !!!Documento8 pagineScope For Development in I. C. Engine Design: Means To Move Towards Ideal Cycle Performance Limits !!!Auto DeptNessuna valutazione finora

- The Evolution of The Internal Combustion Engine and Future Design Challenges: Performance, Efficiency, EmissionsDocumento26 pagineThe Evolution of The Internal Combustion Engine and Future Design Challenges: Performance, Efficiency, EmissionschikulenkaNessuna valutazione finora

- Training on Waste Heat Recovery & CogenerationDocumento26 pagineTraining on Waste Heat Recovery & CogenerationPhani KumarNessuna valutazione finora

- Coal Gasification – Today's Technology of Choice and Tomorrow's Bright PromiseDocumento44 pagineCoal Gasification – Today's Technology of Choice and Tomorrow's Bright Promisestavros7Nessuna valutazione finora

- Urea 6Documento28 pagineUrea 6Pragati Kshatriya100% (1)

- Catalytic Converter - Wikipedia, The Free EncyclopediaDocumento11 pagineCatalytic Converter - Wikipedia, The Free EncyclopediaazamrashdiNessuna valutazione finora

- Petcoke in Cement Industry - Global Cement Conference - MumbaiDocumento28 paginePetcoke in Cement Industry - Global Cement Conference - MumbairsvasanrssNessuna valutazione finora

- Hydrogen generation design for modern refineriesDocumento4 pagineHydrogen generation design for modern refineriesJosiph BukairNessuna valutazione finora

- Greem Ammonia Business Model Rev 1 - 1 - 2022 - JanDocumento6 pagineGreem Ammonia Business Model Rev 1 - 1 - 2022 - JanPrashant DeshmaneNessuna valutazione finora

- Hydrogen Fuel Cell TechnologyDocumento107 pagineHydrogen Fuel Cell TechnologyShriniketh Chandrashekhar67% (3)

- I. C. Engines 1Documento53 pagineI. C. Engines 1Avi4hireNessuna valutazione finora

- Hydraulic Cylinder Engine OptimizationDocumento15 pagineHydraulic Cylinder Engine Optimizationkuttu SureshNessuna valutazione finora

- YMEH0002 s3Documento52 pagineYMEH0002 s3api-3697097Nessuna valutazione finora

- Teknologi Energi Hidrogen 31-03-2020Documento81 pagineTeknologi Energi Hidrogen 31-03-2020erniNessuna valutazione finora

- Section2 3 Wang LiuqiDocumento35 pagineSection2 3 Wang Liuqitsar_philip2010Nessuna valutazione finora

- 3 Minchener Undp CFBCDocumento20 pagine3 Minchener Undp CFBCfaqdaniNessuna valutazione finora

- Svendsen CATO Amsterdam June 2014Documento43 pagineSvendsen CATO Amsterdam June 2014jiangshencaoNessuna valutazione finora

- Solar and Fuel Cell Development 2005Documento31 pagineSolar and Fuel Cell Development 2005ali aminNessuna valutazione finora

- Ormat Technologies Inc. - Organic Rankine Cycle Power Plant For Waste Heat Recovery - 2013-05-09Documento5 pagineOrmat Technologies Inc. - Organic Rankine Cycle Power Plant For Waste Heat Recovery - 2013-05-09Anonymous Cxriyx9HIX100% (1)

- Catalytic Converters Reduce PollutionDocumento20 pagineCatalytic Converters Reduce PollutionHussain AhmedNessuna valutazione finora

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDocumento70 pagineEncon Thermal Engineers: Answer To The Continued Need For Energy ConservationAtul SaxenaNessuna valutazione finora

- Thermal Treatment of Solid WasteDocumento63 pagineThermal Treatment of Solid WastePongphong PhornngamNessuna valutazione finora

- Presentations Oil Refinery ProcessesDocumento36 paginePresentations Oil Refinery ProcessesGururaj SreepatharaoNessuna valutazione finora

- Hydrogen As Engine FuelDocumento19 pagineHydrogen As Engine FuelThameem AbbasNessuna valutazione finora

- Sabroe PPDocumento28 pagineSabroe PPGPNessuna valutazione finora

- Boilers and Thermic Fluid HeatersDocumento54 pagineBoilers and Thermic Fluid HeatersAmit ChauhanNessuna valutazione finora

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsDa EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNessuna valutazione finora

- Comparison of Diesel and Petrol EnginesDa EverandComparison of Diesel and Petrol EnginesValutazione: 2.5 su 5 stelle2.5/5 (3)

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyDa EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNessuna valutazione finora

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementDa EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNessuna valutazione finora

- Renewable Energy Engineering: Solar, Wind, Biomass, Hydrogen and Geothermal Energy SystemsDa EverandRenewable Energy Engineering: Solar, Wind, Biomass, Hydrogen and Geothermal Energy SystemsNessuna valutazione finora

- Hydrogen Production TechnologiesDa EverandHydrogen Production TechnologiesMehmet SankirNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Underground Gas Storage Facilities: Design and ImplementationDa EverandUnderground Gas Storage Facilities: Design and ImplementationNessuna valutazione finora

- Innovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987Da EverandInnovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D A ReayNessuna valutazione finora

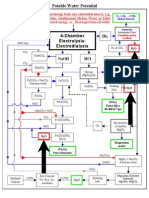

- Comparison Chart Electrodialysis Vs Chlor AlkaliDocumento2 pagineComparison Chart Electrodialysis Vs Chlor AlkaliSteveKellerNessuna valutazione finora

- Four Chambered Electrolysis Calculations 1mw PowerDocumento2 pagineFour Chambered Electrolysis Calculations 1mw PowerSteveKellerNessuna valutazione finora

- Potable Water PotentialDocumento1 paginaPotable Water PotentialSteveKellerNessuna valutazione finora

- Food Security - AgricultureDocumento2 pagineFood Security - AgricultureSteveKellerNessuna valutazione finora

- Wind Energy Cost Original Javv 2009Documento1 paginaWind Energy Cost Original Javv 2009SteveKellerNessuna valutazione finora

- Audio Session Text With GraphicsDocumento5 pagineAudio Session Text With GraphicsSteveKellerNessuna valutazione finora

- Electrolysis Option DiagramDocumento8 pagineElectrolysis Option DiagramSteveKellerNessuna valutazione finora

- Comparison Chart Electrodialysis Vs Chlor AlkaliDocumento2 pagineComparison Chart Electrodialysis Vs Chlor AlkaliSteveKellerNessuna valutazione finora

- Wind Energy Cost Original Javv 2009Documento1 paginaWind Energy Cost Original Javv 2009SteveKellerNessuna valutazione finora

- 4-Chamber Electrolysis-ElectrodialysisDocumento1 pagina4-Chamber Electrolysis-ElectrodialysisSteveKellerNessuna valutazione finora

- DRRR Q2 Module 4Documento11 pagineDRRR Q2 Module 4Jana Mae Catot AcabalNessuna valutazione finora

- Introduction To Fire Behaviour Course SummaryDocumento22 pagineIntroduction To Fire Behaviour Course SummaryAyodeji OyelamiNessuna valutazione finora

- ThorCon International Molten Salt Reactor DesignDocumento4 pagineThorCon International Molten Salt Reactor DesignFahdila RahmaNessuna valutazione finora

- Combined Heat and Power Systems: Reference Manual ForDocumento284 pagineCombined Heat and Power Systems: Reference Manual ForKamyab PakistanNessuna valutazione finora

- Varanasi BrickDocumento73 pagineVaranasi Brickrajesh laddhaNessuna valutazione finora

- Dry Low NOxDocumento28 pagineDry Low NOxRiza Agung NugrahaNessuna valutazione finora

- UKG EVS exam questionsDocumento19 pagineUKG EVS exam questionsYaseer PashaNessuna valutazione finora

- A060631 - 00E FuelsDocumento39 pagineA060631 - 00E Fuelslawternay stevaneli de britoNessuna valutazione finora

- Striking an Equilibrium Between Consumer and Energy Providers InterestDocumento50 pagineStriking an Equilibrium Between Consumer and Energy Providers InterestTerence LaiNessuna valutazione finora

- How Climate Change Affects Our LivesDocumento9 pagineHow Climate Change Affects Our LivesJohn Rey LayderosNessuna valutazione finora

- Nuclear-Reactor - Working and ConstructionDocumento15 pagineNuclear-Reactor - Working and Constructionprince arora80% (5)

- ch8 Mbe4000Documento10 paginech8 Mbe4000Duy KhaNessuna valutazione finora

- A Proposal of A Hydrogen Injection SystemDocumento16 pagineA Proposal of A Hydrogen Injection Systemtashkek556Nessuna valutazione finora

- 5A. Gas TurbinesDocumento4 pagine5A. Gas TurbinesKathlyn Kyle MoralesNessuna valutazione finora

- LPG Vaporizer Reduces Costs & EmissionsDocumento9 pagineLPG Vaporizer Reduces Costs & Emissionsatripathi2009Nessuna valutazione finora

- CESC TrainingDocumento34 pagineCESC TrainingShangarab Bera100% (1)

- 10ta - Brochure - Flypartsguy - Com - 8.2019Documento5 pagine10ta - Brochure - Flypartsguy - Com - 8.2019Kurd SkorvskiNessuna valutazione finora

- Assignment English Group 8Documento14 pagineAssignment English Group 8Zeroos TargenNessuna valutazione finora

- 03-Fossil FuelsDocumento85 pagine03-Fossil FuelsUsama Ahmed100% (1)

- Content-Assessment Unit Test Answer KeyDocumento2 pagineContent-Assessment Unit Test Answer KeyceciNessuna valutazione finora

- Onluyen.vn - đề Thi Tuyển Sinh Vào Lớp 10 Có Đáp Án Môn Tiếng AnhDocumento41 pagineOnluyen.vn - đề Thi Tuyển Sinh Vào Lớp 10 Có Đáp Án Môn Tiếng AnhRyan MathProNessuna valutazione finora

- Physical Science: Quarter 4 - Module 2: How Energy Is Produced and ManagedDocumento19 paginePhysical Science: Quarter 4 - Module 2: How Energy Is Produced and ManagedDelson Son100% (1)

- ĐỀ ĐỌC ĐIỀN 4Documento6 pagineĐỀ ĐỌC ĐIỀN 4Mai LeNessuna valutazione finora

- 7 Urea Synthesis Using Chemical Looping ProcessDocumento10 pagine7 Urea Synthesis Using Chemical Looping ProcessNeyda Flores VasquezNessuna valutazione finora

- Beyond BeefDocumento54 pagineBeyond BeefGuvvala RavikiranNessuna valutazione finora

- Selections From C. E. Goering and A. C. Hansen. 2014. Engine and Tractor Power. 4th Ed. ASABEDocumento11 pagineSelections From C. E. Goering and A. C. Hansen. 2014. Engine and Tractor Power. 4th Ed. ASABErobin nandaNessuna valutazione finora

- Climate Change: The Fork at The End of NowDocumento28 pagineClimate Change: The Fork at The End of NowMomentum Press100% (1)

- Eaton's 36kw Liquid Cooled Owner's Manual With Nexus)Documento157 pagineEaton's 36kw Liquid Cooled Owner's Manual With Nexus)OmarColonNessuna valutazione finora

- How To Turn Plastic Waste Into Diesel Fuel CheaplyDocumento25 pagineHow To Turn Plastic Waste Into Diesel Fuel CheaplyJeno Zsolt DudasNessuna valutazione finora

- Energy Resources (G-7) Lesson PlanDocumento7 pagineEnergy Resources (G-7) Lesson PlanKatrinaNessuna valutazione finora