Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

User Manual T200A en V3.04

Caricato da

paru0509Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

User Manual T200A en V3.04

Caricato da

paru0509Copyright:

Formati disponibili

T200A Hardware Operation Manual

PONOVO POWER CO., LTD

2F, 4Cell, Tower C, In.Do Mansion

No.48A Zhichun Road, Haidian District

Beijing, China (Post Code 100098)

Office

TEL. +86 (10) 82755151 ext. 8887

FAX +86 (10) 82755257

Info@relaytest.com

Website

www.relaytest.com

T200A

OPERATION MANUAL

VERSION:

DATE:

T200A-AE-3.04

08/01/2013

This manual is the publisher of PONOVO POWER CO., LTD. To make any kind of copy of

this manual please contact PONOVO POWER CO., LTD in advance.

This manual represents the technical status for the moment of publishing. The product

information, description and specifications mentioned in the manual do not have any

contact binding force and PONOVO POWER CO., LTD remains the right to make

modifications to the technical specifications and configurations without prior notice.

PONOVO POWER does not take responsibility to the possible error/mistakes in this

manual.

1

T200A Hardware Operation Manual

Notes

In order to prevent accumulation of static electricity inside the running tester,

make reliable ground connection via its ground terminal before the test.

Be caution when output voltage is over 36V, this might cause some electric

accident. Keep safety and avoid this situation occurring.

When high current is being outputted, avoid personal injury and the equipment

damage, which is under test.

Never add external voltage and current onto the voltage/current output

terminals of the tester.

Since the tester is a kind of precision electronic equipment, keep a water-proof

and damp-proof environment for it.

Find any abnormal signs during the installation of the tester, please inform

factory immediately and dont fix it by yourself.

T200A Hardware Operation Manual

Content

1. General Introduction ................................................................................................. 5

2. Panel introduction ..................................................................................................... 8

3. Technique parameters ............................................................................................ 10

4. Operation guide ...................................................................................................... 14

4.1 How to select test item .................................................................................. 14

4.2 How to select variable ................................................................................... 15

4.3 How to set parameters .................................................................................. 15

4.4 How to control output .................................................................................... 15

4.5 Reports view and save ................................................................................. 16

4.5.1 Report view ......................................................................................... 16

4.5.2 Report save ......................................................................................... 16

4.6 System setting ............................................................................................... 17

5. Introduction to test function .................................................................................... 18

5.1. Aux DC ......................................................................................................... 18

5.2. Any test ......................................................................................................... 19

5.2.1 Manual &Meter.................................................................................... 19

5.2.2 ShotLinear RampPulses Ramp ................................................... 19

5.3 Relay test ...................................................................................................... 22

5.3.1 Trip time test, Trip time + pulse length test with I2 ............................. 22

5.3.2 Pick up test ......................................................................................... 24

5.3.3 Reclosing ............................................................................................ 25

5.3.4 Under freq test .................................................................................... 26

5.3.5 Differential test .................................................................................... 28

5.3.6 Harmonic ............................................................................................. 30

5.3.7 Synchronism test ................................................................................ 32

5.3.8 Directional test .................................................................................... 33

5.3.9 DC relay, mA level; AC & DC test ....................................................... 34

5.3.10 Motor overload test ........................................................................... 35

5.4 CT Test....................................................................................................... 36

5.4.1 Primary side injection .......................................................................... 36

5.4.2 Ratio test ............................................................................................. 37

5.4.3 Polarity test ......................................................................................... 38

5.4.4 Winding resistance test....................................................................... 39

5.4.5 Excitation curve test ............................................................................ 40

5.4.6 Secondary impedance test ................................................................. 41

5.5 DC test of operating loop .............................................................................. 42

3

T200A Hardware Operation Manual

5.6 Timer.............................................................................................................. 43

5.7 Voltage/current measuring function .............................................................. 44

6. T200A Accessories ................................................................................................. 45

6.1 Soft Bag for Test Leads ................................................................................. 46

6.2 Transportation Case ................................................................................. - 51 7. Appendix ............................................................................................................ - 53 -

T200A Hardware Operation Manual

1. General Introduction

The T500 series single phase relay test kits are designed for easy and safe test of

different type of relays. The powerful 250A/2000VA current source can be used to test all

kinds of current relays, including high burden relay and CT. The AC/DC current and/or

voltage sources allow phase angle and frequency to be adjusted smoothly. This makes it

possible to precisely test directional and frequency relay. The kit uses advanced switching

power amplifier to replace the traditional transformer, thus avoiding the dangerous high

voltage across the current output.

T500 series universal tester offers 2 types of products: T200A/T1000.

The following is the introduction of T200A.

Hardware configuration

High power AC current I1

0.2-250A

High power AC voltage U1

10-500V

High power DC voltage Udc

10-300V

High precision AC/DC current I2

0-20A

High precision AC/DC voltage U2

0-120V

High precision AC/DC low current I3

0-200mA

Auxiliary DC power supply

20-240V/55W110V/110W(220V)

AC/DC voltmeter

0-600V

AC/DC ammeter

0-6A

Binary input

Binary output

T200A Hardware Operation Manual

T200A Test Functions

SN.

Module

type

Functions

Application relay types

1.

Relay test

Users can select any of the

following test content to operate.

Trip time test, trip time and

pulse length test with I1, U1, I2,

U2, I3, Udc

Pick up test

Reclosing

Under frequency test

Differential test

Harmonics test

Synchronism test

Directional test

DC relay, mA level; AC & DC

test

Motor overload test

Overcurrent relays

Undercurrent relays

Overvoltage relays

Undervoltage relays

Motor overload protection (I2)

Automatic reclosing devices

Thermal relays

df/dt relay(U2&I2)

Time-delay relays (U2&I2)

Timer(Binary input)

Harmonic brake test

Differential relay

Synchronism relay

2.

Any Test

Manually control the amplitude,

phase of AC variables and also

high power Udc.

Shot, linear ramp, pulse ramp

start relay device test when

Udc being the power supply

low voltage operate test on trip

coil of intermedia\high voltage

breaker when Udc being the

control power resource

3.

Timer

Automatically test

4.

CT test

Action time measurement

Primary/secondary side

injectionUse manual control

Ratio test

Polarity test

Winding resistance test

Excitation curve test

Basic test functions for CT

T200A Hardware Operation Manual

5.

Report

Reviewing the report

6.

System

setting

Set rated voltage and frequency of

the system being tested

7.

Aux DC

Provide power supply

Provide power supply to relay or

other equipment

The test results can be transferred

to external PC via USB port.

Optional

8.

PC control

30 reports can be saved and 10

reports can be displayed in each

page.

T200A Hardware Operation Manual

2. Panel introduction

1)

2)

3)

4)

5)

6)

7)

8)

High power output (I1): its mainly applied for CT test and primary side injection.

High power output(UDC): 10300V, its mainly applied for DC act time testing

and low voltage operation test to the tripping coil on intermedia/high voltage

breaker.

High power output (U1): its mainly applied for CT test and primary side injection.

AC/DC voltmeter: they can be applied for measuring both internal and external

outputs. used for realizing the DC resistance and impedance measurement,

excitation characteristic test etc.

AC/DC ammeter: they can be applied for measuring both internal and external

outputs. used for realizing the DC resistance and impedance measurement,

excitation characteristic test etc.

Binary output: one pair, relay contacts

Binary input: two pairs with no polarity. It can not only receive protection acting

contacts, but be applied for timer test, pick up value test, with single channel and

double channels for options.

CT polarity test

Running lamp: its used for the equipment to output indications.

T200A Hardware Operation Manual

9)

10)

11)

12)

13)

14)

15)

16)

Overheat lamp: it will turn on the lamp, alarm and close the output, if the

operation temperature of the power module inside the equipment exceeds 80.

Overload lamp: it will turn on the lamp and close the output when an overload of

current and/or voltage occurs.

Open-circuit lamp: it will flame if an open circuit is detected at the current output .

Menu selection, parameter setting and adjustments output control areas.

USB port: it is applied for reading report and debugging the computer in high

level.

High precision voltage and current output: it gives high precision, adjusted angle

and frequency, good waveform and transient characteristic and is mainly applied

for protection tests, auto reclosing, under frequency, and directional power relay

etc.

Auxiliary DC power supply: its mainly used to provide power supply to protection

or relay with the load of 0.5A continuously.

High precision current AC/DC I3: DC relay, mA level, AC & DC test

Power socket: used for connecting the power supply cable, and with one

spared fuse

Earthed terminal: this is used for connecting the T series instrument to the rigid

grounded point

Breaker: used for controlling the power supply

T200A Hardware Operation Manual

3. Technique parameters

High power AC current output (I1)

Range

0.2A~20A

10A~250A

Accuracy

0.5%

Output voltage

130V~100V

10V~8V

Power

2000VA(20A)

2000VA(250A)

Output current

250A

100A

50A

<50A

Allowed output

time

120s

750s

3000s

continuous

High power AC voltage output (U1)

Range

10-500V

Accuracy

0.5%

Power

1200VA(400V)

Load

time

<1A

continuous

1-3 A

Max 60min

High power DC voltage output (Udc)

Range

10~300V

Accuracy

0.5%

Power(300V)

750W300V

Load

time

Output

<1A

>1A

Time

continuous

Max 60min

10

T200A Hardware Operation Manual

Auxiliary DC voltage output (Aux Udc)

Range

20~240V

Accuracy

1%

Power

55W at 110V/110W at 220V

Load time

continuous at 0.5A

AC/DC current output (I2)

Mode

AC output

DC output

Range

0~20A

0~20A

0.2~0.5A

0.5-20A

0.2-0.5A

0.5~20A

Accuracy

2.5mA

0.5%

2.5mA

0.5%

Power(20A)

200VA

300W

Frequency

20~100Hz

Phase angle

0~360

Phase angle accuracy

0.5

Distortion 1A~20A

<0.5%

Transient response

500s

500s

Load time

20A

60s

10A

240s

<10A

continuous

rd

1%

nd

Harmonics(2 , 3 ,

5th, 7th) accuracy

AC/DC voltage output (U2)

Mode

AC output

DC output

Range

0~120V

0~120V

1-5V

5-120V

1-5V

5-120V

Accuracy

25mV

0.5%

25mV

0.5%

Power(120V)

60VA

80W

Frequency

20~100Hz

Phase angle

0~360

Phase angle accuracy

0.5

Distortion 5V~120A

<0.5%

Transient response

500s

500s

11

T200A Hardware Operation Manual

High precision AC/DC current output (I3)

Mode

AC output

DC output

Range

0~200mA

0~200mA

Accuracy

0.5%

0.5%

Power(200mA)

3VA

3W

Frequency

20~100Hz

Ammeter & Voltmeter

Type

Ammeter

Voltmeter

Range

0~6A AC/DC

0~600V AC/DC

Accuracy

1%

1%

Binary inputs

Number

Input characteristics

30-250VDC, or dry contact

Time resolution

1 ms (0.01~1s) 0.1%

(1~9999.999s)

Max. measuring time

9999.999s

Binary output

Number

Type

Potential free relay contacts

Break capacity AC

Vmax :250V /Imax : 8A/ Pmax : 2000VA

Break capacity DC

Vmax : 250V /Imax : 8A/ Pmax : 150W

12

T200A Hardware Operation Manual

Power supply

Nominal input voltage

110/220Vac

Permissible tolerance

-20%~+15%

Nominal frequency

50/60Hz

Permissible frequency

45~65Hz

Others

Operation temperature

-5~+50C

Operation humidity

5~95%, non-condensing

Weight

23kg

Dimension (W*H*D)

440*255*255mm

PC connection

USB

Ground Socket

4 mm banana socket; front side

13

T200A Hardware Operation Manual

4. Operation guide

4.1 How to select test item

The tester has a test unit selection area on the right bottom of the equipment panel, where

gets 4 buttons: F1, F2, F3 and the menu. Press the MENU button in the area, you will

enter into the main menu directly.

In the main menu, rotate the ENTER button to select certain test item, and then press the

ENTER button to go into the interface of the test item you selected.

For sub-menu, you may press the F1 button to go back to last level menu.

14

T200A Hardware Operation Manual

4.2 How to select variable

In the test item interface, rotate the ENTER button (clockwise or counter clockwise) to

select the variable. The variable you selected will be displayed in white characters with

black background.

4.3 How to set parameters

When the variable was selected, press the ENTER button and rotate it clockwise or

counter-clockwise to change the magnitude of the variable. Select the step of parameter

changing by using the Fast/Fine adjustment button. You may switch the step between

0.001, 0.1, 1 and 10 by pressing the button.

The parameter setting of action unit and manual unit:

Both before and after test, you may select certain variable to set corresponding

parameters

Both before and after test, you may press the Fast/Fine adjustment button to

change the variable output.

Other units cant be changed with their parameters as soon as the test starts.

4.4 How to control output

The Run and Stop buttons are applied to control the tester of its output, or to stop it.

15

T200A Hardware Operation Manual

4.5 Reports view and save

4.5.1 Report view

Select the view option in the main menu to go into the report view interface, where you

may view all saved reports. Here, each page can display 10 reports. With total 3 pages, it

can save 30 reports at most. 1/3 denotes there have 3 pages and the current page is the

first page.

The report with cursor below has test items whose names are listed as following figure in

their item names.

4.5.2 Report save

After the test, you may save current item following the guide on the screen. Both date and

time will be saved in the report.

16

T200A Hardware Operation Manual

4.6 System setting

Select the system setting option in the main menu, and then go to its interface, where you

can set time, volt, freq., off delay.

Time can be represented by second or cycles.

Off delayWhen the tester receive a trip or reclose signal from the relay under test, the

tester will generate the voltage and current continually, until the delay time end.

Voltdenotes rated voltage value.

Freq: denotes rated frequency of high precision AC/DC I2, U2, according to rated

frequency setting codes of electric network.

17

T200A Hardware Operation Manual

5. Introduction to test function

5.1. Aux DC

Mainly provide power supply for protection or relay

Select the Aux DC menu as above figure shown.

Set the output voltage valuepress the Run button to output

The ON/OFF button on the panel can control the output voltage,

Note: a. The aux DC output can be controlled by the ON/OFF button, and be outputted

with other terminals at the same time.

b. The maximum output current is 0.5A.

18

T200A Hardware Operation Manual

5.2. Any test

5.2.1 Manual &Meter

This unit can output high power AC voltage/current, high power DC voltage, high

precision voltage/current and display the reading values of voltmeter and ammeter. It can

realize manual control on the amplitude, phase of AC variables or amplitude of DC

variables by the step.

5.2.2 ShotLinear RampPulses Ramp

It can output high power AC voltage/current, high power DC voltage, high precision

voltage/current, realize automatic control on amplitude, phase of AC variables and

amplitude of DC variables by the step, and record action values, action time automatically.

There have 3 test methods for your selection.

Shot

19

T200A Hardware Operation Manual

Select output variables from the menu: AC-I1 -250A, AC-I1-20A, AC-U1,

Udc-2.5A, Udc-0.5A, AC/DC-I2, AC/DC-U2, AC/DC-I3

Set the start value and duration time of variables.

Press the Run button to output. When the tester receives the binary input of

protection acting signal and finish recording the action time, the test will stop.

Linear ramp

Select output variables from the menu: Udc-0.5A , AC-I2, AC-U2, DC-I2, DC-U2,

AC-I3, DC-I3

Set variable, start value, stop value, step and step time.

Press the Run button to start output, shown as figure. The variable will gradually

increase on the step from the start value to the stop value. When the tester

receives the binary input of protection acting signal and finish recording the

action time, the test will stop.

20

T200A Hardware Operation Manual

Pulse ramp

Select output variables from the menu: AC-I2, DC-I2, AC-I3, DC-I3, AC-U2,

DC-U2

Set start value, stop value, step, step time and interval time.

Press the Run button to output as above figure shown. The variable will

gradually increase in the mode of pulse on the step from the start value to the

stop value. When the tester receives the binary input of protection acting signal

and finish recording the action time, the test will stop.

21

T200A Hardware Operation Manual

5.3 Relay test

5.3.1 Trip time test, Trip time + pulse length test with I2

There have two states for setting. You can set amplitude and phase for these two

states, and the tester will count time when entering into the 2nd state.

Perform tests on the action time in all kinds of over-voltage/current and

under-voltage/current relays.

Test process

1) Select test item.

2) Set voltage, current and current harmonics values.

Set the variable of offset to relay but no-action.

Set the variable of Test to reliable action of relay undertest.

Set the values of current harmonics (The 2nd and 3rd current

22

T200A Hardware Operation Manual

harmonics)

3) Test:

Press the Run button, the tester will start to output under the AC Test. Press the ENTER

button into the Test and start time counting at the same time. As soon as the tester

receives the binary input of protection acting signal, the tester will start to record the

action timepulse time.

This module can also test high power Udc-0.5A and high accuracy of Udc. The testing

method is the same.

Example: Time test of DC relay

1. Wiring

2. Test process

Select item Udc-0.5ASet parameterTest starts

23

T200A Hardware Operation Manual

5.3.2 Pick up test

a)

For high power output, you can manually control the amplitude to change on the

step.

b) Nominal voltage and current can manually control the amplitude, phase and

frequency of AC variables and amplitude of DC variables to change on the step.

Test process:

1) Select test item and then go into the action value test unit.

2) Set voltage and current values.

3) Press the Run button the tester starts to output based on the setting rotate

the ENTER button to control the output of the variable you selected as soon

as the tester receives the binary input of relay acting signal, the tester will start to

record the action time change the variable to make the relay equipment return

the record values, and automatically calculate the return coefficient at the same

time, and finally stop the test.

24

T200A Hardware Operation Manual

5.3.3 Reclosing

This unit can perform reclosing test .

There are two states for setting. You can set amplitude and phase for these two

states.

During test, you must connect the relays acting contacts and reclosing contacts

to the binary input terminals of the tester to make sure the correct logic for

output.

Time counting definition: pick up, denotes the time of first time tripping; reclosing,

denotes the time between binary input a and b after each fault;acctrip, denotes

the time of second time tripping.

Test process

1) Select test item, go into the reclosing unit..

2) Set voltage and current values of the two states.

3) Test:

Press the Run button, the tester will start to output under the Constant Fault. Press the

ENTER button into the Test and start time counting at the same time. As soon as the

tester receives the binary input of relay acting signal, it will record the acting timepulse

timeacc trip time

25

T200A Hardware Operation Manual

5.3.4 Under freq test

You can set end frequency, df/dt, frequency setting.

You can have a test on action value, action time, df/dt, under-voltage blocking

value in under-cycle load-shedding device:

1) Parameter setting

Voltage amplitude: it should be larger than the voltage blocking value of

the relay, unless the voltage blocking value of the protection is under

test.

Current amplitude: it should be larger than the current blocking value of

the relay, unless the current blocking value of the protection is under

test.

End frequency: it should be larger than the under-frequency blocking

value and is suggested to be no less than 45Hz;

df/dt: it should be less than the df/dt of the protection unless the df/dt of

relay is under test.

Frequency setting: it could be settled under-cycle action value, also

could be actual measuring action frequency.

2) Description of test process

Press the Run button, the tester will output the settled voltage and

current values with frequency of 50Hz of 5 seconds.

When the 5s end, the voltage and current frequencies will drop from

50Hz at df/dt to the end frequency. At the same time, the tester will start

26

T200A Hardware Operation Manual

to count time when the frequency has dropped to the frequency setting:

If the relay acts, while the action contacts are connected to the binary

inputs of tripping, the tester will stop to count time and show the action

time.

If the relay doesnt work, it will drop to the end frequency, hold for 30s

and then stop the test.

27

T200A Hardware Operation Manual

5.3.5 Differential test

This function is designed to test differential relay with independent restraint coil and

differential coil. The items, such as the trip value, time and differential current tripping

value under different restraint current, can be tested. Test results can be recorded.

Test process:

1) Action value:

Select test item, and then go into the differential test unit;

Set the amplitude and phase of I1 and I2. For example:

I1 for differential current; I2 for restraining current;

Press the Run button, the tester will start to output based on the settled I1, I2. Rotate the

ENTER button to change the magnitude of I1 (Id). As soon as the tester receives the

binary input of relay acting signal, press the Stop button to stop the test.

2) Action time:

Select test item, and then go into the differential test unit.

Set the amplitude and phase of I1 and I2 that can trigger the relay action.

28

T200A Hardware Operation Manual

Press the Run button, the tester will start to output based on the settled I1, I2. When the

tester receives the binary input of relay acting signal and finish recording the action time,

the test will stop.

29

T200A Hardware Operation Manual

5.3.6 Harmonic

This unit can have superposition of 2nd, 3rd, 5th,7th harmonics on the fundamental to

execute the harmonic surge blocking test and harmonic overflux blocking test of

transformers,

1) Select test item, and then go into the harmonic restrained unit;

2) Set parameters.

Rotate the ENTER button to set the amplitudes of fundamental current and

harmonic current.

Harmonic coefficient effective value of harmonic/effective value of

fundamental100;

Set U2 values of amplitude and phase

3) Test process

Press the Run button, and then the tester will output the recombination current of I2

fundamental and harmonic. Here, the ratio of harmonic to fundamental is larger than

the protections settled harmonic restrained coefficient, so the differential protection

wont work.

30

T200A Hardware Operation Manual

Rotate the ENTER button to decrease the harmonic currents amplitude value till the

differential relay act.

The tester will display the harmonic coefficient of acting moment.

31

T200A Hardware Operation Manual

5.3.7 Synchronism test

This function is for checking the performance of synchronism relay

Condition: power supply frequency, 50Hz or 60Hz.

Connect wires as above figure shown.

Select the synchronizing test menu as above figure shown.

Set amplitude and phase of voltages from the menu.

Press the Run button to output the voltage value, change the phase of voltage, if

the relay trips, record the corresponding phase angle difference.

32

T200A Hardware Operation Manual

5.3.8 Directional test

This function can be realized in the AC test of Pick Up.

This unit can make the boundary for power direction relay.

Connect wires as above figure shown.

Select high precision AC test menu as above figure shown.

Set amplitude and phase of voltage/current in the non-action zone of power

direction relay.

Press the Run button to output voltage and current values. Change the phase to

make the phase angle of voltage/current move from the non-action zone to the

action zone. During the protection acting period, mark the boundary I; then

change the moving direction of phase, which is also moving from non-action

zone to action zone, then marks the boundary II during the protection acting

period. Thus, calculate the sensitive angle with these measuring boundaries I

and II by the software automatically.

33

T200A Hardware Operation Manual

5.3.9 DC relay, mA level; AC & DC test

Connect wires as above figure.

Select Relay testPick upHigh precision DC-I3 test menu, shown as above

figure.

Set DC current value from the menu.

Press the Run button to output DC current, adjust DC current, and record

corresponding DC current values during protection acting.

34

T200A Hardware Operation Manual

5.3.10 Motor overload test

This unit can test trip time of motor.

The output current values can be set in two states, the tester will count time

when press the ENTER button.

There are two ways to record the action time. Firstly, as soon as the tester

receives a single from the relay under test; secondly, the current stop to output,

In this unit, the max output time of max output current is 120s.

Test process

1) Select test item.

2) Set current values.

3) The first state output current value should be smaller than trip current value of relay.

4) The second state output current value should be bigger than trip value of relay, and

makes the relay act.

Press the Run button, the tester will start to output the first state current value. Press

the ENTER button, the state will change into the second state and start time counting at

the same time. As soon as the tester receives the acting signal from relay or stops to

output, the tester will record the action time.

35

T200A Hardware Operation Manual

5.4 CT Test

5.4.1 Primary side injection

Connect wires as above figure, and connect the I1 output into the CT primary

side

Select high power AC current menu, shown as above figure.

Select a appropriate current output range

Set the current value for output

Press the Run button to output current, check the sampling of protection, or

action behaviors of relay and switching.

If the output current has insufficient power, the overload lamp will flame and the

output will be shut down at the same time.

36

T200A Hardware Operation Manual

5.4.2 Ratio test

Connect I1 output to the CT primary side and CT secondary side to the current

measuring terminal, shown as above figure. Dont make open circuit.

Select the Ratio 250A menu, shown as above figure.

Set the current for output, and CT secondary current rating. The software will

calculate the ratio by the CT secondary current rating automatically.

Press the Run button to output current. The tester will display the current it has

measured and the ratio that has been calculated.

37

T200A Hardware Operation Manual

5.4.3 Polarity test

Employ the method of inputting the pulse voltage at CT primary side to have the

CT polarity test.

Connect wires as above figure shown. Please connect the polarity terminals of

CT primary and secondary sides correctly.

Press the function button, then the tester will output a voltage pulse. Its not

necessary to press the function button for a longer time.

The positive and negative lamps will tell us the TA polarity.

If the report is needed to be saved, go to the CT Polarity menu and select the

CT polarity that has been measured out to save, shown as above figure.

38

T200A Hardware Operation Manual

5.4.4 Winding resistance test

Connect wires as above figure shown

Select the secondary DC Resistance test menu, shown as above figure.

Set the DC current values for output, and environment temperature.

Press the Run button to output the DC current, the tester will display the DC

voltage that has been measured and the secondary DC resistance that has been

calculated at 75

39

T200A Hardware Operation Manual

5.4.5 Excitation curve test

Connect wires as above figure shown

Select the Excitation Curve test menu, shown as above figure.

Set the start current value for output

Press the Run button to output the start current, elevate the current gradually

and record the corresponding voltages that have been measured and

corresponding series of test points.

Note: During the test, the current should be rise gradually and cant be swing up

and down, which might cause remanence. The existence of remanence will have

great effects on the measuring results. Once this situation happens, you should

re-elevate the current to be higher than the original value and then decrease it

gradually to zero. Repeat foregoing process for one or two times, thus the effect of

CT remanence can be cured.

40

T200A Hardware Operation Manual

5.4.6 Secondary impedance test

Connect wires as above figure shown. Disconnect the connecting sheet inside

the CT terminal box heading to CT winding.

Select the Manual&Meter menu, shown as above figure.

Set the current value for output, which is normally the secondary current rating.

Press the Run button to output current, and the tester will display the voltage

and secondary impedance value that have been measured.

41

T200A Hardware Operation Manual

5.5 DC test of operating loop

Connect wires as above figure shown.

Select the Manual&Meter menu, shown as above figure.

Select the DC voltage value from the menu.

Press the Run button to output the DC voltage, adjust DC voltage value, and

record the corresponding DC current value at the same time.

Operation loop test include 2 tests, one is the start performance test to

relay device, another is the low voltage operating test to trip coil of the

medium/high voltage breaker,

42

T200A Hardware Operation Manual

5.6 Timer

Single channel test

Double channels test

Connect wires as above figure shown

Select the Timer menu, shown as above figure.

Set single channel and/or double channels from the menu.

Press the Run button to start the test. The action time will be measured

automatically before the test has ended.

43

T200A Hardware Operation Manual

5.7 Voltage/current measuring function

Select the Manual& Meter menu, shown as above figure.

This unit could measure internal or external voltage and current, and when you

measure DC resistance or secondary impedance and CT ratio/excitation curve,

this measure part have to be in series with/ in parallel with the output

variable(current or voltage), or take it as a measurement tool to measure

external variable.

Press the Run button to start the test, and the test results will be displayed on

the screen directly.

44

T200A Hardware Operation Manual

6. T200A Accessories

This chapter describes the optional equipments and accessories for the T200A test set.

Please visit the PONOVO Web site www.relaytest.com for up-to-date information.

Standard accessories

Item

Part No.

Color coded current cables

SAW0001

Color coded voltage cables

SAW0002

Signal cables

SAW0003/4

Crocodile clips

SAW0005/6

U clamps

SAW0007

Pin clamps

SAW0008

Power cord

SAW0009

Earthing lead

SAW0018

Data cable (USB)

SAW0011

Transportation case

SAC0106

Color coded high current plier

SAW0023

45

T200A Hardware Operation Manual

6.1 Soft Bag for Test Leads

The T200A Wiring Accessory Package contains the following articles:

1.

Colour coded current cables

SAW0001 colour coded current cable

Amount:

1xred, 1xblack

The current cables to connect the T200A output to other safety sockets of, generally the

current parts, voltage and signal tripping.

46

T200A Hardware Operation Manual

2.

Color coded voltage cables

SAW0002 Colour coded voltage cable

Amount: 1x red, 1x yellow, 1x green, 1x black

The voltage cables to connect the T200A output to other safety sockets of, generally the

voltage parts, current and signal tripping.

3.

Signal Cable

SAW0003 Signal cables

Amount:

1xred, 1x yellow, 1x green, 1x blue, 1x brown, 1x purple

It connects the T200A with other different sockets, generally with signal tripping and

current/voltage testing.

47

T200A Hardware Operation Manual

4.

Crocodile Clips

SAW0005 Crocodile clips 10mm

SAW0006 Crocodile clips 20mm

Amount: 2xred, 2xblack, 2xyellow, 2xblue

1xred, 1xblack, 1xyellow, 1xblue

Crocodile clips for secondary side to connect to pins or screw types.

5.

U Clamps

SAW0007 U clamps

Amount: 1x red, 1x black

It is used to connect test leads with screw type terminals.

---------------------------------------------------------------------------------Notes: One end of the adapters have no

Users insert the non-safety into the

insulator, users should make sure there is

terminals and screw it firmly, then connect

no output during connecting the adapters.

the test lead with the other end.

----------------------------------------------------------------------------------48

T200A Hardware Operation Manual

6.

Pin clamps

SAW0008 Pin clamps

Amount: 2xred, 2xblack, 2x yellow, 2x green

It is used to connect test leads with screw type terminals.

7.

Power Cord

SAW0009 Power code

Amount:

1 piece

Power cord connects the T200A with power supply socket. PONOVO will provide relevant

plug socket according to different countries. For the plug socket information, please check

the Chapter 11. Appendix.

49

T200A Hardware Operation Manual

8.

Earthing Lead

T200A

SAW0018 Earthing lead

Specification: 2.5mm4m

Amount:

1 piece

Earthing lead connects the T200A with ground to ensure kit safety.

------------------------------------------------------------------------------ground reliably before testing.

Notes: In order to avoid static induction,

users should connect the T200A with

-------------------------------------------------------------------------------

50

T200A Hardware Operation Manual

9.

Data cable (USB)

SAW0011 Data cable (USB)

Amount: 1 piece

The data cable connects the T200A with PC for communications.

10. Color coded high current plier

SAW0023 Color coded high current plier

Amount: 1x red, 1x black

It is used to connect CT primary with T200A to make CT test.

6.2 Transportation Case

- 51 -

T200A Hardware Operation Manual

The large-size case with wheels is designed for heavy transport stress with folding hand it

is made of fireproof materials and smooth rolling rubber tires.

SAC0106 Transportation case

Dimension: 550x360x380mm (WxHxD)

Weight:

10Kg

- 52 -

T200A Hardware Operation Manual

7. Appendix

In order to assure PONOVO sockets are used smoothly in foreign countries, PONOVO

provides the plug sockets to our customers in different countries.

The followings are the sockets used in different countries.

1. Plug Type B

Type B adapter is mainly used in America, Canada and Taiwan etc.

- 53 -

T200A Hardware Operation Manual

2. Plug Type I Adapter

The UK type plug is mainly used in United Kingdom, India, Pakistan, Thailand, Malaysia,

Singapore, New Zealand and Hong Kong etc.

3. Plug Type L Adapter

Type L Adapter is mainly used in South Africa and British Standard 15A.

- 54 -

T200A Hardware Operation Manual

4. Plug Type N Adapter

This adapter is mainly used in Italy.

5. Type G Adapter

Type G Adapter is mainly used in German, Finland, France, Norway, Sweden, Poland,

South Korean, Austria, Spain, Hungary, Czech, Ukraine, Turkey, Brazil and Russia etc.

- 55 -

Potrebbero piacerti anche

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansDa EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansValutazione: 4 su 5 stelle4/5 (8)

- Project ReferenceeeeeeeeeeeeDocumento4 pagineProject Referenceeeeeeeeeeeeparu0509Nessuna valutazione finora

- LG 32LK330-DBDocumento63 pagineLG 32LK330-DBdoraemon007100% (2)

- VCB Manual ENG Ver.05 Dated 01.03.07Documento81 pagineVCB Manual ENG Ver.05 Dated 01.03.07mn090078dNessuna valutazione finora

- SLC 7015Documento1 paginaSLC 7015Дмитрий КопышевNessuna valutazione finora

- MV Trafo SB - SMC - STP TI US - en 10 PDFDocumento6 pagineMV Trafo SB - SMC - STP TI US - en 10 PDFVictor ToledanoNessuna valutazione finora

- Led TV: Service ManualDocumento127 pagineLed TV: Service ManualZigma FNessuna valutazione finora

- Samsung+UN32 40 46 50 F5000+series+ch.u86a PDFDocumento113 pagineSamsung+UN32 40 46 50 F5000+series+ch.u86a PDFelelolNessuna valutazione finora

- EnerVista UR Setup - Data Loggmotor2 Cv17Documento33 pagineEnerVista UR Setup - Data Loggmotor2 Cv17RodrigoCastilloAcostaNessuna valutazione finora

- Manual Relé GEDocumento16 pagineManual Relé GEPablo Briceño NavarroNessuna valutazione finora

- Vacuum Circuit-Breaker 12 - 24 KV ( 2500 A, 40 Ka) : Installation Operation MaintenanceDocumento32 pagineVacuum Circuit-Breaker 12 - 24 KV ( 2500 A, 40 Ka) : Installation Operation Maintenancesilviolima34Nessuna valutazione finora

- High Performances in Small Dimensions: InverterDocumento19 pagineHigh Performances in Small Dimensions: InverterСДММ ГЕВГЕЛИЈАNessuna valutazione finora

- SYLVANIA W6413tc - SMDocumento46 pagineSYLVANIA W6413tc - SMdreamyson1983100% (1)

- LG LCS500UN Manual Servicio PDFDocumento47 pagineLG LCS500UN Manual Servicio PDFaldo0% (1)

- Megmeet mp113 Led Power Supply PDFDocumento12 pagineMegmeet mp113 Led Power Supply PDFH S Mann100% (1)

- Daewoo xg-7283 725 726 727 728 SMDocumento49 pagineDaewoo xg-7283 725 726 727 728 SMFrancisco Orozco100% (1)

- Technical Data Fluokit m24 LengkapDocumento20 pagineTechnical Data Fluokit m24 LengkapAbdulhakk Agai100% (1)

- Ceramic Capacitor: TC / Hik High Voltage Ceramic CapacitorsDocumento4 pagineCeramic Capacitor: TC / Hik High Voltage Ceramic CapacitorsIdajet ProjkoNessuna valutazione finora

- 20mu14 PDFDocumento24 pagine20mu14 PDFOmar Cuellar BNessuna valutazione finora

- SD8 ManualDocumento4 pagineSD8 ManualWaqar AhmedNessuna valutazione finora

- KVGCDocumento46 pagineKVGCLê Văn PhúNessuna valutazione finora

- U4J - Diodo SMDDocumento5 pagineU4J - Diodo SMDedgarlibanioNessuna valutazione finora

- LG 42PJ250-SA Chassis PB02ADocumento70 pagineLG 42PJ250-SA Chassis PB02AamaralfassNessuna valutazione finora

- L24D10 MT23-AP Service ManualDocumento44 pagineL24D10 MT23-AP Service Manualunexpoyap100% (2)

- Diesel Engine Fire Pump Controllers (Firetrol)Documento4 pagineDiesel Engine Fire Pump Controllers (Firetrol)Shibu ThomasNessuna valutazione finora

- Neosat SX1600 Plus & SX1100 Alpha-MDocumento28 pagineNeosat SX1600 Plus & SX1100 Alpha-MJawad Hassan NiaziNessuna valutazione finora

- Varlogic Power Factor Controller - 51213Documento2 pagineVarlogic Power Factor Controller - 51213Prashanth KandulaNessuna valutazione finora

- DB Eletronica KE 20 R 2.3.2Documento70 pagineDB Eletronica KE 20 R 2.3.2carlosNessuna valutazione finora

- Elite 440: Technical Reference ManualDocumento80 pagineElite 440: Technical Reference ManualHung Cuong Pham100% (1)

- LG 42LC46 Ld73a (SM)Documento47 pagineLG 42LC46 Ld73a (SM)Jose Maria Cambero100% (1)

- 32LC818 Lcd26v88amDocumento53 pagine32LC818 Lcd26v88amDaniel AvecillaNessuna valutazione finora

- 1 - Susol VCB - E - 1611Documento248 pagine1 - Susol VCB - E - 1611cuongnv_19100% (1)

- Samsung PS43D490A1XZN F83A PDFDocumento68 pagineSamsung PS43D490A1XZN F83A PDFoppa BaruNessuna valutazione finora

- HIPASE-E 001-AB-310 Application Board ExcitationDocumento3 pagineHIPASE-E 001-AB-310 Application Board ExcitationChi PhamNessuna valutazione finora

- Samsung Ln19a450c1d, Ln22a450c1dDocumento153 pagineSamsung Ln19a450c1d, Ln22a450c1dMichael Jackson0% (1)

- LG LCD TV 42lb9rt Lp7bbDocumento53 pagineLG LCD TV 42lb9rt Lp7bbremobrNessuna valutazione finora

- 3ADW000196R0101 DCS800 12-Pulse Manual e ADocumento96 pagine3ADW000196R0101 DCS800 12-Pulse Manual e ADeepak Jain100% (1)

- Rele G60Documento776 pagineRele G60Omar Iván Rozas GuzmánNessuna valutazione finora

- Manual Service MT56B-LADocumento52 pagineManual Service MT56B-LAArturo ZacariasNessuna valutazione finora

- QJ71C24N PDFDocumento358 pagineQJ71C24N PDFalbertoNessuna valutazione finora

- V Series Temperature Controllers User's Manual: (21) Specifications (22) WiringDocumento4 pagineV Series Temperature Controllers User's Manual: (21) Specifications (22) WiringluisNessuna valutazione finora

- Sansui HDLCD-3700 Flat Panel Television User ManualDocumento48 pagineSansui HDLCD-3700 Flat Panel Television User Manualschroeder76Nessuna valutazione finora

- Trivector MeterDocumento2 pagineTrivector MeterTarun AhujaNessuna valutazione finora

- LG 42LS3400 Chassis LD21CDocumento53 pagineLG 42LS3400 Chassis LD21CLoscarzinos LoscarzinosNessuna valutazione finora

- 3 Phase 4 Wire LT Operated CT Dual Source Meter: User ManualDocumento8 pagine3 Phase 4 Wire LT Operated CT Dual Source Meter: User ManualIshwar ranawatNessuna valutazione finora

- Samsung WD2 WD4Documento76 pagineSamsung WD2 WD4André Frota PaivaNessuna valutazione finora

- Manual TX-NR626 enDocumento140 pagineManual TX-NR626 enalex_heavy100% (1)

- LG Bh9520twDocumento147 pagineLG Bh9520twdanielradu27100% (1)

- ADR244ADocumento36 pagineADR244AVirender RanaNessuna valutazione finora

- FA334694 - Set 64 REF Protection in SepamDocumento4 pagineFA334694 - Set 64 REF Protection in SepamThức VõNessuna valutazione finora

- RCA - 40SMARTR30 - Manual Service PDFDocumento60 pagineRCA - 40SMARTR30 - Manual Service PDFjose4445Nessuna valutazione finora

- BB Series User Manual V0 (2) .0Documento28 pagineBB Series User Manual V0 (2) .0a.elwahabNessuna valutazione finora

- BLDC 5015aDocumento5 pagineBLDC 5015aroozbehxoxNessuna valutazione finora

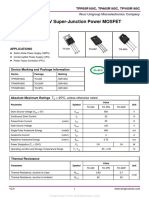

- 650V Super-Junction Power MOSFET: FeaturesDocumento9 pagine650V Super-Junction Power MOSFET: FeaturesAdalbertoRoque100% (1)

- Curvas CooperDocumento13 pagineCurvas CooperRoh OJ100% (1)

- Ccum 21Documento4 pagineCcum 21Hari Krishna.MNessuna valutazione finora

- B43876S9478M 1 - Ed5Documento3 pagineB43876S9478M 1 - Ed5Mauricio BaronNessuna valutazione finora

- Power Flex Multistage ControllerDocumento4 paginePower Flex Multistage ControllerNguyễn Phi TriềuNessuna valutazione finora

- Manual PDFDocumento100 pagineManual PDFAnonymous hPxR0SNessuna valutazione finora

- Delixi 9200 Inverter ManualDocumento114 pagineDelixi 9200 Inverter Manualmushtaq246100% (1)

- PMAC735 User Manual V8.2Documento98 paginePMAC735 User Manual V8.2jesankingNessuna valutazione finora

- Generic Keyboard ChordDocumento1 paginaGeneric Keyboard Chordparu0509Nessuna valutazione finora

- Inggirs Time FBDocumento27 pagineInggirs Time FBparu0509Nessuna valutazione finora

- Burndy TerminalDocumento13 pagineBurndy Terminalparu0509Nessuna valutazione finora

- 150KV Grounding BrosurDocumento7 pagine150KV Grounding Brosurparu0509Nessuna valutazione finora

- Product: Advanced Test Equipment For High Voltage Proof and Preventive Maintenance Testing of Electrical ApparatusDocumento1 paginaProduct: Advanced Test Equipment For High Voltage Proof and Preventive Maintenance Testing of Electrical Apparatusparu0509Nessuna valutazione finora

- Mikroommetras RMO200 enDocumento4 pagineMikroommetras RMO200 enparu0509Nessuna valutazione finora

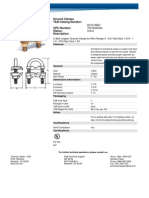

- Ground Clamps T&B Catalog Number: UPC Number: Status: DescriptionDocumento1 paginaGround Clamps T&B Catalog Number: UPC Number: Status: Descriptionparu0509Nessuna valutazione finora

- User Manual T200A en V3.04Documento55 pagineUser Manual T200A en V3.04paru0509Nessuna valutazione finora

- 1 KV Tester Insulation: 500 V and 1000 V Test Voltage. It Is A Portable, Hand-Held, Battery-PoweredDocumento2 pagine1 KV Tester Insulation: 500 V and 1000 V Test Voltage. It Is A Portable, Hand-Held, Battery-Poweredparu0509Nessuna valutazione finora