Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chemical Engineering Progress: An Publication

Caricato da

goalgoal0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni1 paginaSeals

Titolo originale

0405 Cep Aesseal

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSeals

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

49 visualizzazioni1 paginaChemical Engineering Progress: An Publication

Caricato da

goalgoalSeals

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Ma y 2 0 0 4

Chemical

Engineering

Progress

An AIChE Publication

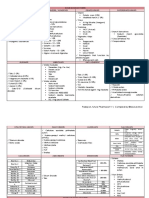

AESSEAL, Inc. (Rotherham,

U.K.; www.aesseal.com) has unveiled a double-face mechanical seal

for bearing isolation, that corrects the

shortcomings of the widely used lip

and labyrinth seals, and costs less to

operate. Called the MagTecta-II

(Figure 1), the cartridge unit is said to

be the only commercially available

double-face seal that provides hermetic bearing isolation in both static

and dynamic rotating equipment for

vertical or horizontal shafts. This is

particularly useful in API sealing applications, as it complies with

European ATEX and API 610 v9

specifications for use in explosive areas and in centrifugal pump components where absolute containment of

lubricating fluids is required, says

Chris Rehmann, general manager of

AESSEAL, Inc.s MagTecta Div.

A combination of the MagTecta

seals and synthetic lubricants can

reduce the frequency of oil changes

in pumps and gearboxes by a minimum of 4:1 under ideal conditions,

and by as much as 50:1 under adverse conditions.

Unlike a lip seal, the MagTecta-II

does not rub against the shaft, so

there is no mechanical wear or shaft

damage. Furthermore, the design

does not include a labyrinth arrangement, which could seize parts with

close radial and axial running clearances and which allows moisture

ingress due to bearing-chamber

breathing. Instead, it hermetically

seals the bearing chamber by using

magnets to pull two stationary faces

(antimony-carbon and bronze-filled

Teflon) against a tungsten-carbide

rotary (Figure 2 and Table). These

faces are polished to 2.0 105 in.

so as to prevent fluid movement

across the moving face, using standard mechanical-seal technology.

CEP

www.cepmagazine.org

Figure 1. The MagTecta-II is a magnetically

energized, double-cartridge seal that can fit into

the space occupied by a lip seal.

The MagTecta-II can be installed

in physical spaces that were previously occupied by labyrinth or lip

seals. It is designed to fit shafts

ranging in size from 5/8-in. to 11-in.

dia. with peripheral speeds up to 20

m/s (equivalent to a 4.25-in. shaft at

3,600 rev/min) and is inventoried in

1/16-in. and metric increments.

The MagTecta-II costs about

$100150/in. of shaft dia. vs.

$10/in. for a similar-sized lip seal.

But the high maintenance costs of

the latter due to shaft damage, frequent replacement and lubricant

leakage will often result in total lip

seal operating costs that are 35

times higher than that of the

MagTecta-II, says Rehmann.

One Michigan-based paper manufacturer was spending over $5,000

every 34 months to repair leak-induced damage to rectifier-roll bearing

housings furnished with lip seals,

says Bruce McCartney, president of

ProSeal, Inc., a rotating-equipment

consulting firm in Madison Heights,

MI (www.prosealsg.com). Four

months after being rebuilt with firstgeneration MagTecta seals, no measurable water entry into the bearings

has occurred. Payback for the

MagTecta retrofit has already been realized, he adds.

Component

1. Rotary seal face

2. Rotary elastomer

3. Stationary seal face

4. Stationary elastomer

5. Outer body

6. Outer body elastomer

7. Shroud

8. Magnet

9. Stationary seal face

10. Stationary elastomer

11. Circlip

* Ethylene propylene rubber

Construction

Tungsten carbide

Viton

Antimony carbon

Viton/EPR*

Stainless steel

Viton/Atlas/Kalrez

Phosphor bronze

Ni-plated rare earth

Bronze-filled Teflon

Viton/EPR

Stainless steel

Figure 2. Cross section of the MagTecta-II

shown in normal orientation.

Reproduced with permission from CEP

(Chemical Engineering Progress) May 2004.

Copyright 2004 AIChE. All rights reserved.

CEP

May 2004

www.cepmagazine.org

Potrebbero piacerti anche

- LN Uk Magtecta 01Documento8 pagineLN Uk Magtecta 01denizarazNessuna valutazione finora

- Ku Reprint Ps April2007Documento2 pagineKu Reprint Ps April2007keyur1109Nessuna valutazione finora

- Labtecta 04Documento10 pagineLabtecta 04sanjeevvangeNessuna valutazione finora

- Tuthil Gear Pump Performance CurveDocumento6 pagineTuthil Gear Pump Performance CurveLuis R MartínezNessuna valutazione finora

- Blower Testing StandardsDocumento13 pagineBlower Testing StandardsChokri ChakiirNessuna valutazione finora

- Schroedahl ArvDocumento19 pagineSchroedahl ArvfadzilharmanNessuna valutazione finora

- Defect Elimination From A CMMS Perspective - Reliabilityweb - A Culture of ReliabilityDocumento17 pagineDefect Elimination From A CMMS Perspective - Reliabilityweb - A Culture of ReliabilityAugusto RezendeNessuna valutazione finora

- Troubleshooting Centrifugal Pumps July04!28!34Documento7 pagineTroubleshooting Centrifugal Pumps July04!28!34ho-faNessuna valutazione finora

- Pitfalls of Pump PipingDocumento3 paginePitfalls of Pump PipingChris PeramunugamaNessuna valutazione finora

- Performance AnalysisDocumento10 paginePerformance AnalysisHimanshu RanjanNessuna valutazione finora

- Tilting Pad Journal Bearing Starvation EffectsDocumento10 pagineTilting Pad Journal Bearing Starvation EffectsFarzadNessuna valutazione finora

- Pump Life Cycle Cost 8 Energy Cost ReductionDocumento31 paginePump Life Cycle Cost 8 Energy Cost ReductionRafael OrjuelaNessuna valutazione finora

- Is Rod Drop The Right Measurement For My Reciprocating Compressor?Documento4 pagineIs Rod Drop The Right Measurement For My Reciprocating Compressor?Sagar MishraNessuna valutazione finora

- Gear Guide 060817Documento0 pagineGear Guide 060817Anonymous oAbjbl4HNessuna valutazione finora

- Ch9 ToleranceDocumento18 pagineCh9 TolerancewissamhijaziNessuna valutazione finora

- Up-Stream Pumping - Presentation1Documento46 pagineUp-Stream Pumping - Presentation1Chozha RajanNessuna valutazione finora

- Syn Gas Compressor Oil Tank ExplosionDocumento6 pagineSyn Gas Compressor Oil Tank Explosionarunanshu palNessuna valutazione finora

- Pumps Vibrations Limits As Per International Standards: EnggcyclopediaDocumento10 paginePumps Vibrations Limits As Per International Standards: Enggcyclopediasantosh kumarNessuna valutazione finora

- Asset Management Plant PDFDocumento42 pagineAsset Management Plant PDFJose Antonio100% (1)

- Rotary Vane PumpDocumento7 pagineRotary Vane PumpSanny HamdaniNessuna valutazione finora

- ACHE Windmill DraftguardDocumento5 pagineACHE Windmill DraftguardTIKSHALANessuna valutazione finora

- 2016 Vol-2 3 OCTDocumento12 pagine2016 Vol-2 3 OCTsppramNessuna valutazione finora

- Sundyne Prospekt Int Geared PDFDocumento16 pagineSundyne Prospekt Int Geared PDFrohituchaniNessuna valutazione finora

- Coupling TypeDocumento8 pagineCoupling Typerajiv_ramachandranNessuna valutazione finora

- CMVA2010 Pump Cavitation PresentationDocumento30 pagineCMVA2010 Pump Cavitation PresentationHéctor RiveraNessuna valutazione finora

- Improve Operational Availability of CCR ReformersDocumento20 pagineImprove Operational Availability of CCR Reformersshivakumar_ammaNessuna valutazione finora

- Turbogrupo Pni1: Vibrotest 60 Bruel & Kjaer VibroDocumento16 pagineTurbogrupo Pni1: Vibrotest 60 Bruel & Kjaer VibroNestor Lopez100% (1)

- Ebara Horizontal Multistage PumpDocumento27 pagineEbara Horizontal Multistage PumpYohanes KrisNessuna valutazione finora

- FSD101eng FSG Seals Catalog A4Documento64 pagineFSD101eng FSG Seals Catalog A4ASHOKNessuna valutazione finora

- Compressor Turbo-Air API a4-IRDocumento12 pagineCompressor Turbo-Air API a4-IRMachineryengNessuna valutazione finora

- F2489Documento13 pagineF2489msbarretosNessuna valutazione finora

- Sealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?Documento3 pagineSealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?madairkifNessuna valutazione finora

- Dawson Downie Lamont LTDDocumento2 pagineDawson Downie Lamont LTDwarehouse cikalongNessuna valutazione finora

- Centrifugal Pump Set Failure ModesDocumento70 pagineCentrifugal Pump Set Failure ModesArif WidyatamaNessuna valutazione finora

- Compressor Choke: by TMI Staff & Contributors On August 27, 2019Documento5 pagineCompressor Choke: by TMI Staff & Contributors On August 27, 2019Tusar KoleNessuna valutazione finora

- EagleBurgmann DGSDocumento8 pagineEagleBurgmann DGSdfNessuna valutazione finora

- 2 How To Make A Pump Selection - Intro To PumpsDocumento7 pagine2 How To Make A Pump Selection - Intro To PumpsMohammed MustafaNessuna valutazione finora

- Explosive DecompressionDocumento11 pagineExplosive DecompressionAndrey EkkertNessuna valutazione finora

- Why EagleBurgmann 29.03.2011Documento15 pagineWhy EagleBurgmann 29.03.2011ybozbasNessuna valutazione finora

- Mechanical Seals According To StandardsDocumento6 pagineMechanical Seals According To StandardsSunit MishraNessuna valutazione finora

- Canned PumpDocumento1 paginaCanned Pumpvk1234Nessuna valutazione finora

- PumpsDocumento45 paginePumpsMehmood Ul Hassan100% (1)

- Integrated Test Systems With Hot Gas Generator For The Development of Turbocharger ApplicationsDocumento7 pagineIntegrated Test Systems With Hot Gas Generator For The Development of Turbocharger ApplicationsravigobiNessuna valutazione finora

- Root Cause Analysis: Motivation, Process, Tools, and PerspectivesDocumento15 pagineRoot Cause Analysis: Motivation, Process, Tools, and PerspectivesMohamed HamdallahNessuna valutazione finora

- Advantages of High Speed Balancing - ToshibaDocumento3 pagineAdvantages of High Speed Balancing - ToshibaJessica SandersNessuna valutazione finora

- 2020 Style 688 Split SealtekDocumento8 pagine2020 Style 688 Split SealtekdiamsamNessuna valutazione finora

- Machinery Component Maintenance and RepairDocumento2 pagineMachinery Component Maintenance and Repairapi-3723333100% (1)

- Failure Mode and Effects Analysis1Documento6 pagineFailure Mode and Effects Analysis1VLASTARNessuna valutazione finora

- Trane SemiHermetic CompressorsDocumento169 pagineTrane SemiHermetic CompressorsGerson RomeroNessuna valutazione finora

- Mechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocusDocumento21 pagineMechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocuspratapNessuna valutazione finora

- Flowserve Reg PumpDocumento66 pagineFlowserve Reg Pumpshaad_ksi100% (1)

- Pressurized Mech Seals Piping PlansDocumento9 paginePressurized Mech Seals Piping PlanssachinumaryeNessuna valutazione finora

- John Crane Gas Seals: Gas Seals and Their Application For Maximum ReliabilityDocumento41 pagineJohn Crane Gas Seals: Gas Seals and Their Application For Maximum ReliabilityDoctorObermanNessuna valutazione finora

- Mechanical Seals Often Fail As A Consequence of Prior Bearing DistressDocumento4 pagineMechanical Seals Often Fail As A Consequence of Prior Bearing DistressMagical RiyaNessuna valutazione finora

- Mechanical Seal AramcoDocumento18 pagineMechanical Seal AramcoMohamed AbdelsalamNessuna valutazione finora

- PMP800 Mechanical Seals PDFDocumento91 paginePMP800 Mechanical Seals PDFsagar1503100% (3)

- MASTER - Publications 47Documento1 paginaMASTER - Publications 47gioNessuna valutazione finora

- Exhaust Valve Main EngineDocumento7 pagineExhaust Valve Main EngineMandeep Singh Kahlon100% (1)

- SPE/IADC 85338 New Performance Motors Set New Benchmarks in Drilling PerformanceDocumento6 pagineSPE/IADC 85338 New Performance Motors Set New Benchmarks in Drilling PerformanceJohnSmithNessuna valutazione finora

- c2 - Static Load Case EditorDocumento22 paginec2 - Static Load Case EditorEsapermana RiyanNessuna valutazione finora

- Corrosion Resistant Guide Plastics & MetalsDocumento32 pagineCorrosion Resistant Guide Plastics & MetalsKen ValencianoNessuna valutazione finora

- UFED 5.0 ReleaseNotes Unblock Phones CellebriteDocumento13 pagineUFED 5.0 ReleaseNotes Unblock Phones CellebritegoalgoalNessuna valutazione finora

- 06-010504.012 Compressed Air Storage PDFDocumento8 pagine06-010504.012 Compressed Air Storage PDFAgung Pramu AjiNessuna valutazione finora

- CRN PipingDocumento12 pagineCRN PipinggoalgoalNessuna valutazione finora

- FlangesDocumento2 pagineFlangesgoalgoalNessuna valutazione finora

- Ufed 5.0Documento13 pagineUfed 5.0goalgoalNessuna valutazione finora

- Hdpe Pipe ChartsDocumento2 pagineHdpe Pipe ChartsgoalgoalNessuna valutazione finora

- Manhole Brochure InteractiveDocumento16 pagineManhole Brochure InteractiveIsmail IbrahimNessuna valutazione finora

- Revision Test-1, 12th ChemistryDocumento4 pagineRevision Test-1, 12th ChemistryVasanthakumar shanmugamNessuna valutazione finora

- European Patent Application C11D 17/00: Production Process For Detergent TabletDocumento19 pagineEuropean Patent Application C11D 17/00: Production Process For Detergent Tabletshadi elhagNessuna valutazione finora

- Nutraceutical-Based Therapeutics and Formulation Strategies Augmenting Their Efficiency To Complement Modern Medicine: An OverviewDocumento18 pagineNutraceutical-Based Therapeutics and Formulation Strategies Augmenting Their Efficiency To Complement Modern Medicine: An OverviewSERGIO ANDRES VERGARA GALLARDONessuna valutazione finora

- Gastro Retentive Drug Delivery SystemDocumento20 pagineGastro Retentive Drug Delivery SystemokNessuna valutazione finora

- E Proceedings - GTSD 2021 - SPP PaperDocumento22 pagineE Proceedings - GTSD 2021 - SPP PaperProf. S. P. Parmar CL Dept.Nessuna valutazione finora

- Universal Cable UC2000 CT-A NG ..: FO Cables With Loose Tube U-DQZN) BH 1500NDocumento2 pagineUniversal Cable UC2000 CT-A NG ..: FO Cables With Loose Tube U-DQZN) BH 1500NDragan ŽivkovićNessuna valutazione finora

- ASTM Volume 08.02, June 2018: Plastics (II) : D3222-D5083Documento9 pagineASTM Volume 08.02, June 2018: Plastics (II) : D3222-D5083s0n1907Nessuna valutazione finora

- Oral Allylestrenol A Pregnancy-Supporting ProgestogenDocumento7 pagineOral Allylestrenol A Pregnancy-Supporting Progestogenjefri efendiNessuna valutazione finora

- (VC60) Natural Derived Fullerene CatalogDocumento4 pagine(VC60) Natural Derived Fullerene CatalogcantuscantusNessuna valutazione finora

- Research Architectural: Tech VDocumento6 pagineResearch Architectural: Tech VMark DanielNessuna valutazione finora

- Chemical Resistance of Epoxy To Common ProductsDocumento4 pagineChemical Resistance of Epoxy To Common ProductsBoro TerakolNessuna valutazione finora

- Reaksi Metatesis JurnalDocumento9 pagineReaksi Metatesis JurnalLatifah SariNessuna valutazione finora

- JMB 28 314 PDFDocumento9 pagineJMB 28 314 PDFkenneth ogocNessuna valutazione finora

- A Review On Engineered Cementitious Composite - Final - IJARESMDocumento13 pagineA Review On Engineered Cementitious Composite - Final - IJARESMPartha SahaNessuna valutazione finora

- Additives For Drilling FluidsDocumento3 pagineAdditives For Drilling FluidsGeorge Liberty0% (1)

- Polunuclear Hydrocarbon: Napthalene: As Per PCI Curriculum Pharmaceutical Chemistry-II Second Year B. Pharmacy (Sem-III)Documento21 paginePolunuclear Hydrocarbon: Napthalene: As Per PCI Curriculum Pharmaceutical Chemistry-II Second Year B. Pharmacy (Sem-III)Ronak Modi100% (1)

- Manual For The Implementation of Gots: Based On The Global Organic Textile Standard (Gots) Version 6.0Documento39 pagineManual For The Implementation of Gots: Based On The Global Organic Textile Standard (Gots) Version 6.0SMART CERTNessuna valutazione finora

- Thinner EN PDFDocumento1 paginaThinner EN PDFLHYT NTUANessuna valutazione finora

- PolymersDocumento1 paginaPolymersqishyNessuna valutazione finora

- Basics of Lubrication - TrainingDocumento35 pagineBasics of Lubrication - TrainingsatfasNessuna valutazione finora

- Chemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionDocumento80 pagineChemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionMagin Idelfonso TorreblancaNessuna valutazione finora

- Recent Advances in Transdermal Drug Delivery Systems: A ReviewDocumento15 pagineRecent Advances in Transdermal Drug Delivery Systems: A ReviewMayang AprilianiNessuna valutazione finora

- FM-200 Alpha Series SystemsDocumento6 pagineFM-200 Alpha Series SystemsGurusumiNessuna valutazione finora

- EWG SkinDeep WalletGuideDocumento2 pagineEWG SkinDeep WalletGuidedaph777Nessuna valutazione finora

- Solid Dosage Forms Diluents Binders / Adhesives Disintegrants SuperdisintegrantsDocumento4 pagineSolid Dosage Forms Diluents Binders / Adhesives Disintegrants SuperdisintegrantsMargaret RNessuna valutazione finora

- Sport TechDocumento4 pagineSport Techila03100% (1)

- FF e Schedule Sheet1Documento3 pagineFF e Schedule Sheet1api-377472062Nessuna valutazione finora

- What Is PlasticDocumento2 pagineWhat Is PlasticJunaidahMubarakAliNessuna valutazione finora

- DULUXDocumento12 pagineDULUXsellamuthuNessuna valutazione finora

- Jurnal Jefry Hutasoit 20769Documento16 pagineJurnal Jefry Hutasoit 20769sayjugigaNessuna valutazione finora