Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Long-Term Effectiveness of Liquid Anti-Stripping Agents in Asphalt Mixes

Caricato da

gouravgoelshinuDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Long-Term Effectiveness of Liquid Anti-Stripping Agents in Asphalt Mixes

Caricato da

gouravgoelshinuCopyright:

Formati disponibili

Laboratory Evaluation of Long Term Effectiveness of Liquid Antistripping

Agents

By Tejash S. Gandhi1*, Kathryn P. Copeland1, Bradley J. Putman2, and Serji N.

Amirkhanian3

1*

Corresponding author

Graduate Research Assistants

Asphalt Rubber Technology Services

2002, Hugo Drive

Clemson University, Clemson, SC, 29634

Phone: 864-650-5685

Fax: 864-656-6186

eMail: tgandhi@clemson.edu

Assistant Professor, Department of Civil Engineering

110 Lowry Hall, Clemson University

Clemson, SC 29634

Phone: 864-656-0374

eMail: putman@clemson.edu

and

3

Professor, Department of Civil Engineering

110 Lowry Hall, Clemson University

Clemson, SC 29634

Phone: 864-656-3316

eMail: kcdoc@clemson.edu

Total Words (6919): Abstract (250) + Text (4169) + Table (3 * 250) + Figures (7 * 250)

Gandhi, et. al.

ABSTRACT

The use of hydrated lime or other liquid anti-stripping agents (ASA) is the most common method

to improve the moisture susceptibility of asphalt mixes. However, most laboratory test conditions

used to evaluate the moisture susceptibility of the mixes are only for a short duration of time.

This might not be a good representation of the field conditions (i.e., several months or years of

service). Thus, a study to evaluate the effects of conditioning the mixes for longer duration was

initiated. Also, another problem with the use of the liquid anti-stripping agents is their heat

storage capability. This paper addresses these two issues, by preparing and testing mixtures made

with fresh binder for indirect tensile strengths after conditioning the samples for 1, 7, 28, 90 and

180 days, and samples prepared from binder stored for 3 days at 163C after conditioning them

for 1, 28 and 90 days. The results of this limited study indicated that hydrated lime and the liquid

anti-stripping agents were equally effective for the mixes used in this research when conditioned

beyond 1 day. In case of samples prepared from stored binder, there was no significant

difference in the effectiveness of hydrated lime and the liquid anti-stripping agents even after

conditioning for 1 day. Though it was observed that none of the ASA treatments performed

better than others in case of samples prepared with stored binder, it was also observed that

almost all mixes gave significantly similar wet ITS and TSR values as samples prepared from

fresh binder.

Key Words: Antistrip additives, hydrated lime, moisture susceptibility, long term conditioning,

hot mix asphalt stripping.

Gandhi, et. al.

INTRODUCTION

The bond between the aggregate surface and the binder can be considered one of the most

important factors influencing the integrity of a pavement. The bond between the aggregate and

the binder should not only form in the initial states, but should also last the entire life of the

pavement. Several mechanisms such as intrusion of water, hydraulic scouring due to tire

pressure, and pore pressure within the matrix, film rupture, spontaneous emulsification, etc. can

weaken and break the bond between the aggregate and the binder (1). This phenomenon of

breaking the bond between the aggregate and the binder is known as stripping. Stripping usually

begins at the bottom of the pavement layer, and travels upwards gradually. A typical situation is

the gradual loss of strength over the years, which causes many surface manifestations like

rutting, corrugations, shoving, raveling, cracking, etc. (2). This makes identification of stripping

very difficult. Also, it may take many years for the surface indicators to show up. To prevent

moisture susceptibility, proper mix design is essential. However, even with a proper mix design,

if the mix is not compacted properly, it may still be susceptible to moisture. Thus, hot mix

asphalt (HMA) should be tested in a situation where moisture can infiltrate into the air voids of

the mixture. For this reason, the tests for moisture susceptibility are done on mixes containing 7

1 percent air voids (3). Of the many ways to prevent stripping in a pavement, the use of antistripping agents (ASAs) is the most common (4). One of the most commonly used ASAs in the

United States is hydrated lime (5). Others include liquids like amines, di-amines, liquid

polymers, and solids like Portland cement, fly-ash, flue dust, etc. Pavement contractors usually

prefer liquid ASAs as they are relatively easy to use (6). However, ASAs from an approved list

of sources should not be blindly added as some ASAs are aggregate and asphalt specific, and

therefore, may not be effective to be used in all mixes; they could even be detrimental at times.

Thus, a proper study of the mix should be done by systematically testing the mix for moisture

susceptibility using tests like indirect tension testing (ITS), Lottmans test, and boiling water test

in the laboratory or other tests.

Several studies have been conducted to evaluate the effectiveness of hydrated lime as

well as liquid ASAs (6,7,8,9). However, most lab tests that are done to assess the moisture

susceptibility of mixes assess only the short term effect of moisture on the mix. The ITS test, for

instance, tests the moisture susceptibility of mixes after conditioning the samples in water for

only 24 hours. This may not always be representative of the actual field conditions, and thus

might be, in some cases, a misrepresentation of the actual moisture susceptibility of the

pavement itself. In a previous study conducted by Lu and Harvey (10), the long term effects of

moisture on the effectiveness of the ASAs were studied. From the study, it was observed that

most of the detrimental effects of moisture occurred in the first four months.

Another commonly reported problem associated with the liquid ASAs is their ability to

be stored with hot binder over longer durations (8,11,12). Typically, when amine based liquid

ASAs are stored with bitumen at 140C to 190C, the nitrogen based functional groups of the

ASAs react with the polar group of the bitumen to form compounds that do not have any antistripping capabilities. Another issue regarding the use of liquid ASAs is the possibility of being

oxidized in the bitumen, and thus losing its anti-stripping capabilities (12).

This research project evaluated the long term effects of moisture on the moisture

susceptibility of several mixes. Some of the storage stability issues of the ASAs also have been

investigated. Indirect tensile strength (ITS) tests were performed on samples conditioned in

water for 1 day, 7 days, 28 days, 90 days, and 180 days, and the results were compared. A total

Gandhi, et. al.

of 600 samples were prepared and tested. To address the heat storage capability of the ASAs, the

binder containing the ASAs was stored at 163C for 3 days, and was then used to prepare ITS

samples that were tested after conditioning in water for 1 day, 28 days, and 90 days. A total of

360 samples were prepared with the stored binder.

OBJECTIVES

The main objective of the research was to determine the feasibility of using certain liquid ASAs

in HMA mixtures and determine their effectiveness over longer durations. The specific

objectives were as follows.

Determining the physical properties of asphalt concrete specimens containing no

ASAs, hydrated lime, or liquid ASAs.

Comparing and analyzing, statistically, the physical properties of asphalt concrete

containing particular ASAs to the other mixes.

Comparing the effects of the physical properties of three aggregate sources and two

binder sources containing particular ASAs.

Comparing the effects of the physical properties of samples of a particular mix

conditioned in water for 1 to 180 days.

Compare the effects of storing the binder on the physical properties of the asphalt

concrete specimens.

METHODOLOGY

The Superpave method of mix design was followed to determine the optimum binder content for

each mix design. A total of 30 mix designs (2 binder sources 3 aggregate sources 5 different

ASA treatments) were conducted. In the mixes containing hydrated lime as the ASA, 1%

hydrated lime, by weight of the aggregate, was added in a slurry form. In the mixes containing

liquid ASAs, 0.5% liquid ASA, by weight of the binder, was added to the binder. This ASA

content selected based on the 0.25% - 0.75% recommended by the suppliers. The bulk specific

gravity, maximum specific gravity, voids in mineral aggregate (VMA) and voids filled with

asphalt (VFA) were obtained or calculated to determine the optimum asphalt content of all the 30

mixes.

For the moisture susceptibility study, a total of 960 samples were prepared. The samples

were 150 mm in diameter and 95 5 mm in height. These samples were subjected to SC-T-70

Laboratory Determination of Moisture Susceptibility testing procedures to obtain wet and dry

ITS and tensile strength ratio (TSR) at ages of 1 day, 7 days and 28 days, 90 days and 180 days

for mixes with fresh binder, and ages of 1 day, 28 days, and 90 days for mixes with stored binder

(13). The SC-T-70 is similar to AASHTO T283, the only difference being that the samples are

not subjected to any freezing. The Statistical Analysis Systems (SAS) computer program was

used to analyze the results.

MATERIALS AND EXPERIMENTAL PROCEDURES

The Superpave method of mix design for a 12.5 mm mix was followed for this study. Figure 1

illustrates the flowchart of the experimental design used in this laboratory investigation.

Gandhi, et. al.

Binder Source

Binder I

(PG 64 -22)

Control

Binder II

(PG 64 -22)

Hydrated lime

Liquid ASA 1

Liquid ASA 2

Aggregate A

Aggregate B

Aggregate C

Liquid ASA 3

Same as

Binder I

Mix Design

(12.5 mm)

ITS Test

1 day curing

(8 samples)

7 days curing

(4 samples)

28 days curing

(8 samples)

90 days curing

(8 samples)

180 days curing

(4 samples)

FIGURE 1 Experimental design.

The aggregates used in this study were obtained from three sources, denoted as A, B, and

C. The types of aggregate received from each quarry consisted of #57, #789, Regular Screenings

(RS), and Manufactured Sand (MS). Each type of the aggregate was randomly obtained from

quarry stockpiles and transported to the laboratory. Aggregate A is prone to stripping, and

Aggregate B is known to perform well against stripping.

The aggregates obtained were then tested for gradation as per the ASTM C 136, Method

for Sieve Analysis for Fine and Coarse Aggregate. Table 1 contains the gradation properties of

the aggregates used, and the percentage of each aggregate type used. Figure 2 shows the

combined gradation of the three aggregate sources used.

Gandhi, et. al.

TABLE 1 Aggregate Properties

Sieve Size

(mm)

Gradation Range

38

25

19

12.5

9.5

4.75

2.36

0.150

0.075

Stone Type

#57

#789

RS

MS

100

100

98 100

90 100

74 90

46 62

25 41

4 12

28

Combined Gradation (% Passing)

Agg. A

100

100

99

94

89

49

30

6.6

3.34

% Used in the mix

9

61

20

10

Properties

Micaceous Granite

2.700

0.77

52

Aggregate Type

Bulk Specific Gravity

% Absorption, %

Los Angelis Abration Loss, %

Agg. B

100

100

100

94

84

49

39

8.5

5.12

Agg. C

100

100

100

94

85

51

32

8.1

5.01

11

46

17

26

30

32

20

18

Marble Schist

2.830

0.49

23

Granite

2.610

0.62

26

100

90

80

% Passi ng

70

60

50

40

30

20

10

0

0.075 0.150

2.36

4.75

9.5

12.5

19

25

38

Sieve Size, mm

UL

FIGURE 2 Aggregate Gradation.

LL

Sieve Agg.

Size, Amm

Agg. B

Agg. C

Gandhi, et. al.

Two different sources of binder were used in this project, both PG 64 -22, denoted as I (a

mixture of crude sources that could not be determined) and II (a Venezuelan crude source). The

binders were transported to the laboratory in sealed 5 gallon containers to prevent oxidation and

premature aging. Table 2 gives the properties of the binder sources. Four different anti-stripping

agents were used in the project. They were commercially available hydrated lime, three liquid

ASAs denoted as 1, 2 and 3 respectively. The fifth treatment was the Control, no ASAs, denoted

by 0 in this paper.

TABLE 2 Binder Properties

Property

Original Binder

Viscosity, Pa-s (135C)

G*/sin , kPa (64C)

RTFO Residue

Mass Change, % (163C)

G*/sin , kPa (64C)

PAV Residue

G*/sin , kPa (25C)

Stiffness (60), MPa (-12C)

m-Value (60) (-12C)

PG Grade

Mixing Temperature+, C

Compaction Temperature+, C

+

Information provided by supplier

Binder I

Binder II

0.405

1.207

0.626

1.801

-0.02

2.815

-0.24

4.608

2970

183

0.311

64 -22

150 155

139 - 144

2420

129

0.345

64 -22

163 170

150 155

In this paper, each of the mixes is given a unique code containing 3 parts. The first part is

the aggregate (A, B or C); the second part represents the binder source; (I or II), and the third

part for the ASAs; (0, 1, 2, 3 or L). The age of the samples is denoted by the number before the

mix code. For example, 180AIIL denotes a 180 day sample prepared by mixing aggregate A with

binder II and Hydrated lime as the ASA treatment.

RESULTS AND DISCUSSIONS

The Superpave method of mix design was used to determine the optimum binder contents of

various mixtures. Table 3 gives the results of the mix design for the 30 mixes. Knowing the

optimum binder content for each of the mix designs, ITS samples were made for each of the mix

type. Four samples for each age (e.g., 1 day, 90 days, etc.) were prepared to test the ITS. Two of

which were stored as dry samples at 25 1C, and two were stored as wet samples. If the

samples were to be broken after 1 day, the wet samples were submerged in water at 60 1C for

24 hours followed by submersion in water at 25 1C for 2 hours before breaking. For

conditioning durations of more than 1 day, the wet samples were submerged in a water bath at 25

Gandhi, et. al.

1C for one day short of that specific duration (e.g., 6 days, 27 days, etc.) and then they were

submerged in a water bath (60 1C) for 24 hours followed by submersion in water at 25 1C

for 2 hours before breaking. All the wet samples were vacuum saturated to a saturation level of

70% to 80% before immersing in water.

The wet ITS and the TSR were used as the measure of stripping for each of the mixes. To

study the effects of ASAs and aggregates on the mixes, a Randomized Complete Block Design

(RCBD) was developed with the ASAs as the treatment variables and the aggregate source as the

block variables. Similarly, a RCBD was developed with the binder source as the block variable

to study the effects of the binder sources. Analysis of variance (ANOVA) was then performed to

test the null hypothesis which was the mean ITS (or TSR) of each treatment and block variables

are not significantly different from each other at the 5% level of significance.

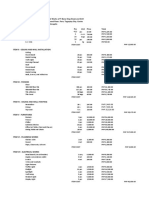

TABLE 3 Mix Design Results

Mix Type

AI0

AI1

AI2

AI3

AIL

AII0

AII1

AII2

AII3

AIIL

BI0

BI1

BI2

BI3

BIL

BII0

BII1

BII2

BII3

BIIL

CI0

CI1

CI2

CI3

CIL

CII0

CII1

CII2

CII3

CIIL

Optimum AC

(%)

5.8

5.9

5.9

5.9

5.7

5.8

5.8

5.8

5.8

5.4

4.6

4.6

4.6

4.6

4.4

4.6

4.5

4.5

4.5

4.4

5.8

5.8

5.8

5.8

5.2

5.8

5.7

5.7

5.7

5.3

VMA

(%)

17.5

17.7

17.7

17.7

16.8

17.3

17.6

17.6

17.6

16.2

15.1

15.2

15.2

15.2

14.5

15.0

14.8

14.8

14.8

14.5

17.2

16.8

16.8

16.8

14.6

17.1

16.6

16.6

16.6

15.2

VFA

(%)

76

77

77

77

77

77

77

77

77

76

74

72

72

72

76

73

73

73

73

73

76

77

77

77

76

76

77

77

77

76

Air Voids

(%)

4.0

3.9

3.9

3.9

3.8

3.9

3.9

3.9

3.9

3.4

3.4

3.7

3.7

3.7

3.5

3.4

3.5

3.5

3.5

3.5

3.9

3.9

3.9

3.9

3.3

4.0

3.6

3.6

3.6

3.4

Gandhi, et. al.

After conditioning the samples for 1 day and 7 days, mixes with hydrated lime gave the

highest wet ITS. They were followed by mixes with the liquid ASAs. The control treatment was

the least effective. After 28 days of conditioning, no general trend was observed. It was observed

that certain aggregate/ASA or binder/ASA or aggregate/binder/ASA combinations work better

than others. In general, hydrated lime seemed to be the most effective ASA. For longer durations

of conditioning, namely 90 days and 180 days, mixes with hydrated lime and the liquid ASAs

were equally effective, and performed better than mixes with no treatment. A similar set of

ANOVA tests, at the 5% significance level, were performed on the TSR values of the samples.

Based on these results, it was observed that mixes with hydrated lime and the liquid ASAs gave

similar TSR values when conditioned in water for durations beyond 1 day. After conditioning the

samples for 1 day, mixes with hydrated lime gave the highest TSR values, followed by the liquid

ASAs with no significant difference in their effectiveness, then followed by the control

treatment.

For mixes prepared with stored binders, there were no significant differences in the ITS

values of mixes with different ASA treatments. This was observed at 1 day, 28 days and 90 days

of conditioning. The only exception was mixes with binder source II after 90 days of

conditioning, where the use of hydrated lime seemed to be effective, statistically, in improving

the wet ITS. The TSR values also showed a similar trend, where none of the anti-stripping

treatments performed significantly different from the others after 1 day, 28 days and 90 days of

conditioning.

Effect of Aggregate Sources

In most cases, it was observed that mixes with aggregate source B gave the highest wet ITS after

all conditioning durations. Mixes with aggregate source A and C followed with no significant

difference in their mean wet ITS values after all conditioning durations. Figure 3 (a e) shows

the effects of aggregate source on the wet ITS of the mixes at different conditioning durations.

As far as the effect of the aggregate source on the TSR of mixes was concerned, there was no

significant difference in the values of the mean TSR for mixes with different aggregate sources.

This was the case at 1 day as well as at 7 days. However, at 28 days, mixes with aggregate

source B showed significantly lower TSR values compared to the other aggregate sources. This

may be explained due to the reason that mixes with aggregate source B showed exceptionally

higher dry ITS compared to the mixes with other aggregate sources. After longer durations of

conditioning (90 and 180 days), there was no significant difference in the TSR values of the

mixes with different aggregate sources.

Gandhi, et. al.

160

WET ITS (psi)

140

120

100

80

60

40

20

0

0

Binder I

Binder II

Agg. A

Agg. B

Agg. C

(a)

160

Wet ITS (psi)

140

120

100

80

60

40

20

0

0

Binder I

Agg. A

Agg. B

Binder II

Agg. C

(b)

160

Wet ITS (psi)

140

120

100

80

60

40

20

0

0

Binder I

Agg. A

Agg. B

Binder II

Agg. C

(c)

Figure 3 Effects of conditioning duration on wet ITS (a - 1 day conditioning; b - 7 days conditioning;

c - 28 days conditioning; d - 90 days conditioning; e - 180 days conditioning).

Gandhi, et. al.

10

160

Wet ITS (psi)

140

120

100

80

60

40

20

0

0

Binder I

Binder II

Agg A

Agg B

Agg C

(d)

160

Wet TIS (psi)

140

120

100

80

60

c

40

20

0

0

Binder I

Agg A

2

Binder II

Agg B

Agg C

(e)

FIGURE 3 Continued.

Even when stored binder was used to prepare the samples, mixes with aggregate source B

gave the highest wet ITS after 1 day of conditioning. However, after 28 and 90 days of

conditioning, the mean wet ITS of mixes with different aggregate sources were significantly

similar, at the 5% level. When the TSR values of the mixes were compared after 28 days of

conditioning, mixes with aggregate source B gave the highest TSR values.

Effect of Binder Source

The ANOVA performed to check the effect of binder source on the wet ITS of mixtures showed

that the mixes with fresh binder I generally gave higher wet ITS at 1 day, except in the case of

mixes with aggregate source B, where the mean strengths of mixes with both binders were not

significantly different. After other conditioning durations, there was no significant difference in

Gandhi, et. al.

11

the mean wet ITS of the mixes with either binder source. Also, the binder source did not seem to

have any effect on the TSR values of the mixes used in this research after all conditioning

durations. Similar trends were observed when stored binder was used to prepare the samples.

None of the binder sources used in the research showed significantly different wet ITS or TSR

values. Figures 4 (a c) and 5 (a c) show the effects of binder source on the wet ITS and TSR

values of the mixes at different conditioning durations.

160

Wet ITS(psi)

140

120

100

80

60

40

20

0

0

Agg. A

Agg. B

Binder II

Binder I

Agg. C

(a)

160

Wet ITS(psi)

140

120

100

80

60

40

20

0

0

Agg. A

Agg. B

Binder II

Binder I

2

Agg. C

Wet ITS(psi)

(b)

160

140

120

100

80

60

40

20

0

0

2

Agg. A

Agg. B

Binder I

2

Agg. C

Binder II

(c)

FIGURE 4 Effects of binder source on wet ITS (a 1 day conditioning; b 28 days conditioning; c

90 days conditioning).

Gandhi, et. al.

12

120

TSR (%)

100

80

60

40

20

0

0

Agg. A

Agg. B

Binder II

Binder I

Agg. C

(a)

120

TSR (%)

100

80

60

40

20

0

0

Agg. A

Agg. B

Binder II

Binder I

2

Agg. C

(b)

120

TSR (%)

100

80

60

40

20

0

0

2

Agg. A

Agg. B

Binder I

Binder II

2

Agg. C

(c)

FIGURE 5 Effects of binder source on TSR (a 1 day conditioning; b 28 days conditioning; c 90

days conditioning).

Gandhi, et. al.

13

Effect of conditioning duration

To check the effect of moisture on the samples over a long duration of time, the mean wet ITS

and the TSR values of the samples were compared for different conditioning durations. The

comparison revealed that all mixes prepared from fresh binder yielded significantly higher wet

ITS values after shorter durations of conditioning (1 and 7 days) compared to higher durations of

conditioning (90 and 180 days). However, most of the mixes prepared from stored binder yielded

significantly similar wet ITS values after conditioning for 1, 28 and 90 days. Figures 6 ( a b)

and 7 (a b) show the wet ITS and TSR of mixes with aggregate source C and binder source I.

Other mixes also followed similar trends.

130

Wet ITS (psi)

110

90

70

50

30

0

50

100

150

200

Conditioning Duration (Days)

ASA '0'

ASA '1'

ASA '2'

ASA '3'

ASA 'L'

(a)

Wet ITS (psi)

130

110

90

70

50

30

0

20

40

60

80

100

Conditioning Duration (Days)

ASA '0'

ASA '1'

ASA '2'

ASA '3'

ASA 'L'

(b)

FIGURE 6 Effects of conditioning durations on wet ITS (aggregate C; a fresh binder I; b stored

binder I).

Gandhi, et. al.

14

120

TSR (%)

100

80

60

40

20

0

50

100

150

200

Conditioning Duration (Days)

ASA '0'

ASA '1'

ASA '2'

ASA '3'

ASA 'L'

(a)

120

TSR (%)

100

80

60

40

20

0

20

40

60

80

100

Conditioning Duration (Days)

ASA '0'

ASA '1'

ASA '2'

ASA '3'

ASA 'L'

(b)

FIGURE 7 Effects of conditioning durations on TSR (aggregate C; a fresh binder I; b stored

binder I).

In addition, it was observed that all the mixes prepared with stored binders, and with

hydrated lime as the ASA, showed significantly similar strengths after 1, 28 and 90 days of

conditioning. Whereas, mixes prepared from fresh binder, and with hydrated lime as the ASA,

showed significantly higher strengths after 1 and 7 days of conditioning compared to strengths

obtained after 90 and 180 days of conditioning.

Gandhi, et. al.

15

Comparison of Fresh and Stored Binder Mixes

To determine the heat storage stability of the liquid ASAs, the mean wet ITS and TSR values of

samples prepared from fresh binder were compared with that of stored binder after each

conditioning duration. A simple t-test was used to make this comparison. From the comparison,

it was observed that although none of the ASA treatments were significantly better performing

when stored binder was used to prepare the samples, almost all the mixes showed significantly

similar wet ITS and TSR values when compared to fresh binder. This was observed after 1, 28

and 90 days of conditioning in water. Thus, it could be concluded that the liquid ASAs, used in

this research project, do not appear to lose their effectiveness when stored in the oven for 3 days

at 163C.

SUMMARY AND CONCLUSIONS

This research was conducted to study the effectiveness of liquid ASAs over longer durations of

conditioning. Some of the storage stability issues related to the use of liquid ASAs were also

investigated. A total of 30 mixtures including three aggregate sources, two binder sources, and

five anti-stripping treatments (including control treatment no ASA) were used in this

investigation. ITS samples were prepared and tested after conditioning them in water for 1, 7, 28,

90 and 180 days. To study the storage stability issue, samples were prepared from binders stored

for 3 days at 163C and then tested after conditioning in water for 1, 28 and 90 days.

From the study conducted, the following could be concluded.

After one and seven days of conditioning in water, hydrated lime seemed to be the

most effective ASA treatment. Hydrated lime was followed by the three liquid ASAs, which

were followed by the control treatment (no ASA). However, after longer durations of

conditioning (90 and 180 days) none of the ASA treatments were significantly different from the

others.

When stored binders were used to prepare the samples, none of the ASA treatments

showed any significant improvement in the wet ITS or the TSR values of the mixes. Thus, it

could be concluded that none of the ASA treatments used in this research were effective after

longer durations of conditioning.

Although aggregate source B showed higher ITS values after conditioning for 1 and 7

days, its TSR values were similar to mixes with other aggregate sources. Also, after higher

conditioning durations, the wet ITS and TSR values of mixes with all aggregate sources were

significantly similar. Thus, it can be concluded that the aggregate sources used in this research

work had no significant effect on the effectiveness of the ASA treatments.

Similar to the aggregate source, the binder source also did not seem to have any

significant effect on the effectiveness of the ASA treatments. None of the binder sources showed

significantly higher wet ITS or TSR values compared to others.

Certain aggregate/binder combinations yielded higher wet ITS and TSR values

compared to others. It could be hypothesized that each aggregate/binder combination is unique,

and that each combination has to be individually examined for moisture susceptibility. It should

be noted that the liquid ASAs added were 0.5% by weight of binder. This was based on the

0.25% - 0.75% recommended by the suppliers. Thus, if more liquid ASA was added to the

aggregate/binder combinations that did not work, different results could have been obtained.

Gandhi, et. al.

16

For mixes prepared from fresh binder, the conditioning duration has a significant

influence. The wet ITS and the TSR values of the mixes reduced significantly after longer

conditioning durations. However, for mixes prepared from stored binders, the conditioning

durations did not have any significant influence. The wet ITS and the TSR values were

significantly similar after 1, 28 and 90 days of conditioning.

Since the wet ITS and the TSR values of the samples prepared from stored binders

were significantly similar to the wet ITS and TSR values of the samples prepared from fresh

binder, it is concluded that the liquid ASAs used in this study do not break down under the heat

when stored for 3 days at 163C.

REFERENCE

1. Kiggundu, B.,M., and Kandhal, P.S. (1988), Stripping in HMA Mixtures: State of

the Art and Critical Review of Test Methods, Publication NCAT Report No. 88-02,

National Center for Asphalt Technology, Auburn, USA.

2. Roberts, F.L., Kandhal, P.S., Brown, E.R., Lee, D.Y., and Kennedy, T.W. (1996), Hot

Mix Asphalt Materials, Mixture Design, and Construction, Second Edition, National

Asphalt Pavement Association Research and Education Foundation.

3. Hunter, E.R., and Ksaibati, K. (2002), Evaluating Moisture Susceptibility of Asphalt

Mixes, Department of Civil and Architectural Engineering, University of Wyoming.

http://www.ndsu.nodak.edu/ndsu/ugpti/MPC_Pubs/html/MPC02-138/index.html.

4. Huang, Y.H. (1993), Pavement Analysis and Design, Prentice Hall Inc.

5. Little, D.N., and Epps, J.A. (2001), The Benefits of Hydrated Lime in Hot Mix

Asphalt, Technical Report Prepared for National Lime Association.

6. Kennedy, T.W., and Ping, W.V. (1991), Comparison of Moisture Damage Test

Methods for Evaluating Antistripping Treatments in Asphalt mixtures,

Transportation Research Record 1323, Transportation Research Board, Washington

DC.

7. Kim, K. W., and Amirkhanian, S. (1991), Evaluation of Effectiveness of Antistrip

Additives Using Fuzzy Set Procedures, Transportation Research Record 1323,

Transportation Research Board, Washington DC.

8. Busching, H.W., Burati, J.L., and Amirkhanian, S.N. (1986), An Investigation of

Stripping in Asphalt Concrete in South Carolina, Publication FHWA-SC-86-02.

FHWA, U.S. Department of Transportation.

9. Busching, H.W., Amirkhanian, S.N., and Burati, J.L. (1986), Effects of Selected

Asphalts and Antistrip Additiveson Tensile Strength of Laboratory Compacted

Marshall Specimens A Moisture Susciptibility Study, Proceedings, Association of

Asphalt Paving Technologists Technical Sessions, Volume 55.

10. Lu. Q, and Harvey, J.T., (2006), Laboratory Evaluation of Long-term Effectiveness

of Antistripping Additives, TRB 2006 Annual Meeting CD ROM.

11. Yoon, H.R., Tarrer, A. R., and Wagh, V. P. (1993), Thermal Degradation of

Antistripping Agents and Enhanced Performance by Curing, Journal of Materials in

Civil Engineering, Volume 5, Issue 1.

12. Castano, N., Ferre, P., Fossas, F., and Punet, A. (2004), A Real Heat Stable Bitumen

Antistripping Agent, 8th Conference on Asphalt pavements for Southern Africa, Sun

City, South Africa.

Gandhi, et. al.

17

13. South Carolina Department of Transportation, Office of Materials and Research

Laboratory Procedures Manual

http://www.scdot.org/doing/pdfs/OMR_LabProceduresManual.pdf, accessed July

2006.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Structural Design of Swimming PoolsDocumento12 pagineStructural Design of Swimming Poolsale hopeju200975% (20)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 15cv741 (Design of Bridges)Documento129 pagine15cv741 (Design of Bridges)mohan80% (20)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Ad Dec 22Documento1 paginaAd Dec 22gouravgoelshinuNessuna valutazione finora

- MNIT Faculty RecruitmentDocumento14 pagineMNIT Faculty RecruitmentgouravgoelshinuNessuna valutazione finora

- National Highway Authority of IndiaDocumento4 pagineNational Highway Authority of IndiagouravgoelshinuNessuna valutazione finora

- National Highway Authority of IndiaDocumento5 pagineNational Highway Authority of IndiagouravgoelshinuNessuna valutazione finora

- Fun Numbertracing 1 PDFDocumento1 paginaFun Numbertracing 1 PDFjayonline_4uNessuna valutazione finora

- Design of Bridg PDFDocumento2 pagineDesign of Bridg PDFgouravgoelshinuNessuna valutazione finora

- Soma-Isolux Nh-One Tollway PVT LTD: Page 1 of 1Documento1 paginaSoma-Isolux Nh-One Tollway PVT LTD: Page 1 of 1gouravgoelshinuNessuna valutazione finora

- Ad05 2022Documento1 paginaAd05 2022gouravgoelshinuNessuna valutazione finora

- NATIONAL HIGHWAY ACCIDENT DATADocumento4 pagineNATIONAL HIGHWAY ACCIDENT DATAgouravgoelshinuNessuna valutazione finora

- NATIONAL HIGHWAY ACCIDENT DATA AT NIGHTDocumento3 pagineNATIONAL HIGHWAY ACCIDENT DATA AT NIGHTgouravgoelshinuNessuna valutazione finora

- Information For AuthorsDocumento7 pagineInformation For AuthorsgouravgoelshinuNessuna valutazione finora

- LS-283 R171Documento13 pagineLS-283 R171gouravgoelshinuNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento14 pagineDisclosure To Promote The Right To InformationgouravgoelshinuNessuna valutazione finora

- BME311-Reading Assignment-2 Stress Strain1Documento11 pagineBME311-Reading Assignment-2 Stress Strain1gouravgoelshinuNessuna valutazione finora

- BME311-Reading Assignment-2 Stress Strain1Documento11 pagineBME311-Reading Assignment-2 Stress Strain1gouravgoelshinuNessuna valutazione finora

- Flakiness and Elongation IndexDocumento4 pagineFlakiness and Elongation IndexChandan RpNessuna valutazione finora

- Adhesive and Cohesive Properties of ASP... Avement Design - Volume 11, Issue Sup1Documento7 pagineAdhesive and Cohesive Properties of ASP... Avement Design - Volume 11, Issue Sup1gouravgoelshinuNessuna valutazione finora

- stp204 22 PDFDocumento2 paginestp204 22 PDFgouravgoelshinuNessuna valutazione finora

- Aggreg-bitumen bond refsDocumento4 pagineAggreg-bitumen bond refsgouravgoelshinuNessuna valutazione finora

- Sample ThesisDocumento7 pagineSample ThesisgouravgoelshinuNessuna valutazione finora

- A Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. General Arangement, Bill of Materials, Notes, Isometric ViewDocumento1 paginaA Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. General Arangement, Bill of Materials, Notes, Isometric ViewMD26Nessuna valutazione finora

- IS Code of Cement & ConcreteDocumento8 pagineIS Code of Cement & ConcreteKuldeep UpadhyayNessuna valutazione finora

- Advantages of Bubble Deck Slab Over RCC Slab: Presentation On Project Review - IIDocumento25 pagineAdvantages of Bubble Deck Slab Over RCC Slab: Presentation On Project Review - IIsumitNessuna valutazione finora

- Socketweldspacerrings SoluGapBrochureDocumento2 pagineSocketweldspacerrings SoluGapBrochureRamzi BEN AHMEDNessuna valutazione finora

- Protek Etl: Technical Data SheetDocumento1 paginaProtek Etl: Technical Data SheetArnel G. PetalioNessuna valutazione finora

- EPP Surface Preparation NetDocumento5 pagineEPP Surface Preparation Netumunera2997Nessuna valutazione finora

- Building Technology (ALE Review 5)Documento1 paginaBuilding Technology (ALE Review 5)Jehan MohamadNessuna valutazione finora

- Portland Cement Plaster - SpecDocumento7 paginePortland Cement Plaster - Speclinga2014Nessuna valutazione finora

- Interior Fitting Out Works Bill of MaterialsDocumento15 pagineInterior Fitting Out Works Bill of MaterialsAnn MoralesNessuna valutazione finora

- 38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsDocumento7 pagine38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsMarjan SubanNessuna valutazione finora

- General Specification - Roads and BridgesDocumento165 pagineGeneral Specification - Roads and BridgesEnea BogdanNessuna valutazione finora

- Protection of Reinforcement With Corrosion Inhibitors, PhaseDocumento137 pagineProtection of Reinforcement With Corrosion Inhibitors, Phasealwan61Nessuna valutazione finora

- HS PDFDocumento11 pagineHS PDFSawa Zayia MichaelNessuna valutazione finora

- Effect of Superplasticizer Type On The PerformanceDocumento14 pagineEffect of Superplasticizer Type On The PerformanceKevin ChumánNessuna valutazione finora

- OMV Pipe ClassDocumento160 pagineOMV Pipe Classliviu_dovaNessuna valutazione finora

- JZ LSR Catalog AllDocumento27 pagineJZ LSR Catalog AllJZ HuangNessuna valutazione finora

- Introduction To GlassDocumento25 pagineIntroduction To GlassankithaNessuna valutazione finora

- Foundations in Building ConstuctionDocumento95 pagineFoundations in Building ConstuctionDivya Tadepalli100% (2)

- Pmi Louis Proserv 3Documento6 paginePmi Louis Proserv 3Ebit TrisnoNessuna valutazione finora

- Technical Datasheet: ENGUARD™ BP 75 ARF Multi Purpose Bonding Paste With FibresDocumento2 pagineTechnical Datasheet: ENGUARD™ BP 75 ARF Multi Purpose Bonding Paste With FibresFernando Cesar PérezNessuna valutazione finora

- Multi-Use Product: Technical DataDocumento2 pagineMulti-Use Product: Technical Datacorsini999Nessuna valutazione finora

- Piping Class - DC11Documento2 paginePiping Class - DC11Дмитрий РыбаковNessuna valutazione finora

- Report by KKParthiban On Boiler Explosion of A Shell Type High PR BoilerDocumento97 pagineReport by KKParthiban On Boiler Explosion of A Shell Type High PR Boilerparthi20065768100% (1)

- 07 DITO Rebar Inspection Report Template v2Documento6 pagine07 DITO Rebar Inspection Report Template v2AndeeCrisNessuna valutazione finora

- Dortech Direct Product CatalogueDocumento29 pagineDortech Direct Product CatalogueAdam YatesNessuna valutazione finora

- DR Area Drain Saudi CastDocumento38 pagineDR Area Drain Saudi CastMohamad NohayliNessuna valutazione finora

- Mic Full m12x1.75px45l b7 Blackodising Mi0000000011Documento1 paginaMic Full m12x1.75px45l b7 Blackodising Mi0000000011GauravNessuna valutazione finora

- Material Conversion Chart: Steel Grades and StandardsDocumento8 pagineMaterial Conversion Chart: Steel Grades and StandardsChuan SwtsNessuna valutazione finora

- Bill of MaterialDocumento11 pagineBill of MaterialMuhammad FikriNessuna valutazione finora