Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Finite Element Analysis of Corroded Steel Angles Under Compression

Caricato da

Erik Wahyu PradanaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Finite Element Analysis of Corroded Steel Angles Under Compression

Caricato da

Erik Wahyu PradanaCopyright:

Formati disponibili

Conference of Junior Researchers in Civil Engineering

163

Finite element analysis of corroded steel angles under compression

Katalin Oszvald

BME Department of Structural Engineering, e-mail: oszvaldkata@gmail.com

Abstract

Steel structures corrode almost in every environment. The measure of the corrosion can be especially significant if the

maintenance is insufficient. In practice it is necessary to determine the ultimate failure mode and estimate the resistance of the

corroded members to decide it should be replaced or it is enough to remove the corrosion and re-paint the structure. The subject of

this paper is a finite element study of corroded angle section members under centric compression. The joint influence of three

main corrosion parameters is analyzed on the buckling behaviour. The investigated basic elements have different cross-section

sizes and lengths. The behaviour is determined in the function of the parameters of the corrosion and the cross-section

characteristics.

Introduction

Single steel angles section members are used in many various structures as bridges, trusses and latticed

transmission towers. Every structure is exposed to the effects of different environmental influence. The

circumstances, which include the inadequate maintenance lead to corrosion on the structures. The rate of the

corrosion can be very significant and can cause failures in the structures. There are many various corrosion

types with different appearance forms like average, pitting, and crevice corrosion. Because of the diversity of

corrosion, it is difficult to describe it by only one parameter. Corrosion can occur anywhere along the

member length and has various size extensions and rarely extends to the whole member. The place of the

corrosion also can be various within the cross-section. The standards, as e.g. Eurocode [1], do not give any

suggestion [2] how to analyse the corroded members. In the practice the engineers apply an average crosssection decrease, what is supposed along the whole element. In some cases this assumption can be good

approach, but for example in case of localized corrosion it is not accurate enough to determine the behaviour.

In the current research a numerical model is developed and verified by experimental results. Geometrically

and material nonlinear analysis is used to follow the stability phenomena of the compressed angle section.

The resistance of the corroded members are determined, considering the cross-section classification of the

Eurocode. Three different corrosion parameters are studied: (i) cross-section reduction; (ii) extension of

corrosion and (iii) location of corrosion. The structural behaviour is determined in the function of the

corrosion parameters and the cross-section characteristics. In this paper the main focus is on the behaviour of

the corroded members, based on the finite element parametric study.

Previous research

The corrosion is a significant problem in the world, therefore many researcher analyze the effect of it on the

various members of the structures. All of the studies deal with the remaining capacity of the members and

give recommendation how can be assessed the influence of the corrosion. Numerical study was completed

on sheared plates with pitting corrosion by Paik at el. [3]. In the function of the corroded surface and the

plate thickness the ratio of the stress of the corroded and the non-corroded plates was determined. In other

study Rahgozar [4] developed residual capacity curves of corroded I-section on the basis of thickness

reduction. Corrosion on the lower flange and on the web was assumed. Effect of localized corrosion on

buckling plate was investigated by Sadovsy and Drdacky [5]. The influence of pitting corrosion on the hold

frames of bulk carrier was extensively analyzed by Nakai et al. [6, 7]. The research of Heinemeyer and

Feldman [8] focused on the influence of the corrosion on riveted connections. Angle section members, which

are investigated in this study too, were previously analyzed by Beaulieu et al. [2]. The specimens were

corroded by galvanic process and the tests results were compared to the analytical results which were

calculated according to Canadian and American standards. In the test set-up eccentric compression was

applied by gusset plate. Comprehensive study on corroded angle section members is not found in the

literature, where the effect of the main corrosion parameters on the buckling behaviour is analyzed.

Therefore, to determine the behaviour and the resistance decrease of the corroded members a numerical

study program is carried out.

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

164

Experimental and numerical background

In the first phase of the research compressive buckling tests were carried out on 24 specimens. The corrosion

was artificially created in the members; part of the leg thickness was eliminated by mechanical process.

During the test centric compression was applied and the obtained maximal load and the vertical and

horizontal displacements were measured. Details of the test can be found in [9]. In parallel with the tests, a

numerical model was developed using Ansys program [10]. The corroded angle section members and the

corrosion appearance in the model can be various by changing the different corrosion parameters. In the

linear and non-linear analyses the applied finite element is a brick element (SOLID 45 of [10]). The size of

the finite elements is half of the original thickness of the legs. The support is hinge connection in the center

of the gravity of the non-corroded elements. The model contains about 100000 elements. By the model the

experimental tests are simulated on the accuracy was verified. Based on the test results the equivalent

geometric imperfection was determined on every specimens of the test. The developed finite element model

is proved to be accurate and efficient to complete a parametric study on centric compression angle members.

Numerical study program

Design buckling resistance in the research is determined by numerical simulation; this process is a general

proposal in the Eurocode standard. In the finite element simulation the nominal yield stress and the

equivalent geometric imperfection are used. In the case of the corroded members the aim is to give a

recommendation based on the results of the numerical study, how can take into account the effect of the

corrosion in the design method. In the first step the behaviour must be determined. Therefore bifurcation

stability analysis is carried out on perfect corroded elements in order to find the critical compressive force

(geometric non-linear buckling analysis GNB). In the GNB analysis the first buckling mode (eigenvector)

is determined. The applied equivalent geometrical imperfection in the geometrically and material non-linear

analyses (GMNI) follows the shape of the determined first mode. In the simulations linear elastic plastic

material model is applied (steel grade of S235 with the nominal yield strength of fy = 235 N/mm2). In the

following parametric study three different cross-section sizes and three element lengths are applied, it means

nine different basic non-corroded elements are analyzed. Table 1 contains the cross-section sizes, the lengths

of the elements, the relative slendernesses and the legs initial b/t (width/thickness) ratios of the noncorroded elements.

ID

Cross-section

[mmmmmm]

Length

[mm]

Slenderness

b/t

RF-1

40404

510

0.7

10

RF-2

40404

840

1.15

10

RF-3

40404

1100

1.5

10

RF-4

60608

750

0.7

7.5

RF-5

60608

1250

1.15

7.5

RF-6

60608

1640

1.5

7.5

RF-7

10010012

1280

0.7

8.3

RF-8

10010012

2100

1.15

8.3

RF-9

10010012

2760

1.5

8.3

Table 1. Basic non-corroded elements

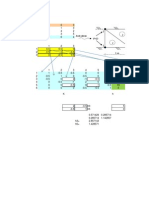

The thickness reduction (Tred), the extension of corrosion (Ext) and the position of the corrosion (pc) along

the whole element are the three main parameters which are considered in the analyses, as corrosion

parameters, defined in Eqs. (1) and (2). Two different basic corrosion patterns (A and B) are applied in the

analyses, as it is shown in Figs. 1 and 2. The crosshatched area marks the corrosion in the member.

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

165

L/2

0

Fig. 1. A pattern

Fig. 2. B pattern

pc =

Ext =

y

L/2

(1)

x

100

L

(2)

L [mm]: member length; x,y see Fig. 1.

Table 2 shows the applied parameters, in the table the corrosion is marked by black. The corrosion position

is calculated by the ratio of the centre of the corroded area and the half of the member length, Eq. (1). The

length of the corroded area is calculated by extension parameter Eq. (2).

The number of the studied members is about 2000; 238 different corroded cases are analyzed for each noncorroded members.

Pattern Cross - section Tred [%]Ext [%] Corrosion position (pc)

20

20

0.20, 0.47, 0.73, 1.00

30

30

0.30, 0.53, 0.77, 1.00

40

0.40, 0.70, 1.00

50

0.50, 0.75, 1.00

70

70

0.70, 1.00

80

100

1.00

40

50

60

B

Table 2. Corrosion parameters

GNB analyses equivalent geometric imperfections

The observed bucking around the weak axis is shown in Fig. 3. The width-to-thickness ratio of the legs is

changed due to thickness reduction by corrosion and it leads to change the buckling shape and failure mode.

For the relative slenderness of 1.15 and 1.5 the buckling modes follow the first buckling mode. This is also

valid if the thickness reduction is greater than 50%. If the relative slenderness is 0.7 the first mode is not the

same in every case as in the previous elements. Beside the global buckling shape a local buckling is

observed, as shown in Figs. 4 and 5. The length of the local buckling wave is approximately two times the

free width of the outstanding plates if the corrosion is on one leg (pattern A). In case of pattern B the length

of the buckling wave is the length of the corroded area, representing flexural-torsional buckling in the

corroded area, as it is shown in Fig. 6.

The buckling mode is very much dependent on the corrosion parameters. The reduced area can lead to

different modes of buckling due to the different b/t ratios. The reduced cross-section is in class 4 in all cases

if the thickness reduction is greater than 50%, but the b/t ratio is not the same on the studied elements. Table

3 presents the first mode of buckling of part of the studied elements. In RF-1 members with pattern A and

where the Tred is 80% the first buckling mode is local independently of the other two parameters. It is not

valid in case RF-4 and RF-7 members, because the p/t ratio is lower in these cases than in case of RF-1

elements. The position of corrosion also important parameter; if it is closer to the support (ID 171) local

buckling mode is observed by members with lower b/t ratio. But if the corrosion is in the middle (ID 174)

in the cases of RF-4 and RF-7 global bucking mode is observed. The extension of corrosion (Ext) is also an

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

166

important parameter. Having the same thickness reduction (Tred) and corrosion position (pc), but different

extension (Ext) causes different buckling mode, e.g. on RF-7 element in case of ID 175 and ID 182. This

is almost valid in cases of elements with corrosion pattern B. Local mode is observed already by 70%

thickness reduction, but the number of this type of mode is lower as in the cases of pattern A, beside the

same corrosion parameters.

The shape of the first mode of stability analysis is applied as equivalent geometrical imperfection in the

numerical simulation. The amplitude of the imperfection is L/200 in the analyses, following the

recommendation of the standard and the results of the model verification.

Fig. 3. Ext=20%, pc=0.47, Tred=80

Fig. 4. Ext=70%, pc=1.0, Tred=80

Fig. 5. Ext=70%, pc=1.0, Tred=80

Fig. 6. Ext=70%, pc=1.0, Tred=80

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

167

ID

Corrosion

pattern

Tred [%]

Ext [%]

pc

RF-1

RF-4

RF-7

171

80

20

0,20

Local

Local

Local

172

80

20

0,47

Local

Global

Local

173

80

20

0,73

Local

Global

Local

174

80

20

1,00

Local

Global

Global

175

80

30

0,30

Local

Global

Local

176

80

30

0,53

Local

Global

Local

177

80

30

0,77

Local

Global

Global

178

80

30

1,00

Local

Global

Global

179

80

40

0,40

Local

Global

Local

180

80

40

0,70

Local

Global

Global

181

80

40

1,00

Local

Global

Global

182

80

50

0,50

Local

Global

Global

183

80

50

0,75

Local

Global

Global

184

80

50

1,00

Local

Global

Global

185

80

70

0,70

Local

Global

Global

186

80

70

1,00

Local

Global

Global

187

80

100

1,00

Local

Global

Global

205

70

20

0,20

Local

Global

Global

209

70

30

0,30

Local

Global

Global

222

80

20

0,20

Local

Local

Local

223

80

20

0,47

Local

Global

Global

225

80

20

1,00

Local

Global

Global

226

80

30

0,30

Local

Global

Local

227

80

30

0,53

Local

Global

Global

228

80

30

0,77

Local

Global

Global

230

80

40

0,40

Local

Global

Global

233

80

50

0,50

Local

Global

Global

Table 3. Bucking modes in the function of corrosion parameters

GMNI analysis behaviour modes

The results of GMNI analyses are evaluated by the behaviour modes function of the different parameters.

Generally the observed failure mode is global flexural buckling about the weak axis on elements with 1.15

and 1.5 relative slenderness. The yield mechanism is developed at the half-length of the member according

to the expectation on the non-corroded members, but on corroded members it is shifted. In these cases the

buckling mode and the failure mode are same. In some cases, when the buckling mode is global, the

behaviour mode in the simulation is different. The observed behaviour is an elastic-plastic failure mode.

After an initial global behaviour the failure mode is local. A third type of behaviour mode is also observed,

in this case the first buckling mode and the failure mode are the same. This is valid if the corrosion is on one

or both of the legs. Figure 7 presents the deformed shape of three different behaviour modes. The first is the

global-global (RF-1-1), the second is global-local (RF-1-52) and the third is local-local (RF-1-222).The

second and the third type of failure modes are observed just on the element with 0.7 relative slenderness. In

two cases the behaviour is clearly global buckling around the y-y axis (the y-y axis is parallel with the leg).

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

168

The corrosion is on one leg and it is on the whole elements and the Tred is 60% and in the other case Tred is

70%.

RF-1-1

RF-1-52

RF-1-222

Fig. 7. Observed behaviour modes

The load and vertical displacement curve is similar in the case of the three modes. The curves are presented

on the right side of Fig. 8. On the left side of Fig. 8 the displacements of the middle point are shown (the

middle point is considered in the middle of the element length, in the corner edge of the cross-section). The

coordinate axes are the displacements in direction of x and y. The curve of RF-1-52 presents the behaviour;

in the initial phase the line goes together with RF-1-1 an in the moment of failure the direction changes,

because the reduced leg loses its stiffness.

60

4

3

50

2

1

30

RF-1-52

RF-1-1

RF-1-222

20

10

dy [mm]

Load [kN]

40

0

-2

-1 0

-2

RF-1-52

-3

RF-1-1

-4

0

0

0,5

1

Vertical displacement [mm]

1,5

-5

dx [mm]

Fig. 8. Behaviour curves

In GNB analyses the cases are determined when the first buckling is local, in GMNI analyses this statement

is also relevant. Table 4 contains some elements with the ID numbers and corrosion parameters, where the

first buckling mode and the failure mode are different in the GNB and GMNI analyses. The results show that

the b/t ratio is not negligible in the determination of the failure mode.

Changing the parameter b/t (modify Tred) and set to parameter of RF-1 the same behaviour occurs on the

examined RF-4 and RF-7 parameters. By more than 40% thickness reduction the second type of behaviour

mode appears if the b/t ratio is more or equal than 15. This is not a sufficient, but a necessary condition. The

position of the corrosion must be close to the support. As the Tred is getting greater the number of this type of

behaviour is increased; e.g. 70% thickness reduction just in one case the result is not the second mode. By

this scale of Tred the condition, corrosion close to the support, is not important. Necessary condition to local

failure mode is more than 80% thickness reduction and more or equal than 50 b/t ratio. If the thickness

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

169

reduction is on both of the legs, almost the same conditions are necessary to the various failure modes. In

these cases the second mode does not appear, because after the thickness reduction the symmetry of the

cross-section does not change. The local buckling failure mode is observed, however, by 70% thickness

reduction (more or equal than 35 b/t ratio). On the basis of the completed analyses the resistance of the

corroded members is determined, as a peak value of the applied compressive force.

ID

Cross-section

Tred

Ext

pc

b/t

RF-1-35

40404

40

20

0,2

16,67

RF-1-52

40404

50

20

0,2

20

RF-1-53

40404

50

20

0,47

20

RF-1-56

40404

50

30

0,3

20

RF-4-52

60608

50

20

0,2

15

RF-7-52

10010012

50

20

0,2

16,67

Table 4. Element parameters Global flexural buckling about strong axis

GMNI analysis resistances

1,20

1,20

1,00

1,00

0,80

0,80

Nb /Nb0

Nb /Nb0

The corrosion causes resistance reduction, but the measure of the decrease is different function of the

parameters. Results of RF-1 elements show the tendencies of the resistance decrease function of the different

parameters, as illustrated in Fig. 9. In the left side the horizontal axis is the whole cross-section reduction

(Cred [%]), what can be calculated from Tred. The tendency is almost linear, but there are some differences. In

the different cases the behaviour is the second and the third mode. If the results are plotted in the function of

the b/t ratio, the tendency is non-linear and there are no significant differences when the failure mode is

different. In Fig. 10 part of results are presented in the function of the b/t ratio. The corrosion parameters

what belongs to the plotted results are: Ext = 100% and pc = 1. In the case of the same b/t value the ratio of

the corroded and non-corroded element resistance can be different. The tendencies similar but the measure of

the decrease is greater if the initial b/t is lower.

0,60

0,60

0,40

0,40

0,20

0,20

0,00

0,00

0

50

C red [%]

100

20

40

60

b/t

Fig. 9. Resistances in the function of the Cred and b/t parameters

The development of a design method on the basis of the completed parametric study to determine the

buckling resistance of corroded angle section members is in process. In the method the application rule of

the Eurocode 3 is used with a cross-section dependent reduction factor.

Summary and conclusions

In the current research corroded compressed angle section elements are analysed. A numerical parametric

study is carried out on different corroded elements. In the completed numerical analyses, the effect of crosssection reduction, position and extension of corrosion are analyzed on the stability behaviour. On the basis of

the simulation results the first buckling modes and the failure modes are determined. On the basis of the

numerical study the following conclusions can be made:

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

170

1,2

RF-1

RF-4

Nb /Nbo

0,8

RF-7

0,6

0,4

0,2

0

5

10

15

b/t ratio

20

25

Fig. 10. Results of RF-1, RF-4 and RF-7 (Ext=100%, pc=1.0)

Three different failure modes are determined, as follows: first is global flexural buckling about weak

axis; second is an elastic-plastic failure mode (initial global behaviour with local failure mode); third is local

buckling. In the case of pattern A all of the modes are appeared, but in the case of pattern B just the first and

the third.

The knowledge of the corrosion parameters is not sufficient to determine the different buckling and

failure modes.

The width to remaining thickness ratio is important characteristic and it is a necessary but not

sufficient parameter to determine the first buckling and the ultimate failure modes.

The observed failure mode is global flexural buckling around the weak axis in the case of relative

slenderness greater than 1.15. Simulation results show that it is relevant in every corroded element,

irrespectively of the corrosion parameters.

The second behaviour mode is observed on the elements where, the b/t ratio is greater than 15 and the

corrosion is located close to the support, and the extension is around 20-30%.

Local failure mode can be observed on elements with greater than 35 b/t ratio. This is also a

necessary condition, but not sufficient.

Acknowledgement

This work is connected to the scientific program of the Development of quality-oriented and harmonized

R+D+I strategy and functional model at BME. This project is supported by the New Szchenyi Plan (Project

ID: TMOP-4.2.1/B-09/1/KMR-2010-0002).

References

[1] EN 1993-1-1:2005 Eurocode 3: Design of steel structures. Part 1-1: General rules and rules for buildings.

[2] Beaulieu LV, Legeron F, Langlois S, Compression strength of corroded steel angle members, Journal of Constructional

Steel Research, vol. 66, pp. 1366-1373, 2010.

[3] Paik JK, Lee JM, Ju Ko M, Ultimate shear strength of plate members with pit corrosion wastage, Thin-Walled Structures,

vol. 42, pp. 1161-1176, 2004.

[4] Rahgozar R, Remaining capacity assessment of corrosion damaged beams using minimum curves, Journal of

Constructional Steel Research, vol. 65, pp. 299-307, 2009.

[5] Sadovsky Z, Drdacky M, Buckling of plate strip subjected to localised corrosion a stochastic model, Thin-Walled

Structures, vol. 39, pp. 247-259, 2001.

[6] Nakai T, Matsushita H, Yamamoto N, Arai H, Effect of pitting corrosion on local strength of hold frames of bulk carrier

(1st report), Marine Structures, vol. 17, pp. 403-432, 2004.

[7] Nakai T, Matsushita H, Yamamoto N, Arai H, Effect of pitting corrosion on local strength of hold frames of bulk carrier

(2nd report) Lateral distortional buckling and local face buckling, Marine Structures, vol. 17, pp. 612-641, 2004.

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Conference of Junior Researchers in Civil Engineering

171

[8] Heinemeyer C, Feldman M, The influence of rivet corrosion on the durability of riveted connections, 6th European

Conference on Steel and Composite Structures, Budapest, Hungary, vol. C, pp. 2217-222, 2011.

[9] Oszvald K, Dunai L, Effect of corrosion on the buckling of steel angle elements. Proc. 8th International PhD Symposium

in Civil Engineering, pp. 549-554, Lyngby, Denmark, 2010.

[10] ANSYS v11.0, Canonsburg, Pennsylvania, USA.

Oszvald, K.: Finite element analysis of corroded steel angles under compression

Potrebbero piacerti anche

- Performance Based Seismic DesignDocumento154 paginePerformance Based Seismic DesignIp Siu Hei100% (5)

- Barry Isolators Selection GuideDocumento16 pagineBarry Isolators Selection GuideJason E. CortésNessuna valutazione finora

- Basis of Design Belmont Bridge REPORT 0328 ADADocumento17 pagineBasis of Design Belmont Bridge REPORT 0328 ADAErik Wahyu PradanaNessuna valutazione finora

- The Effect of Hole Shape On Fatigue LifeDocumento4 pagineThe Effect of Hole Shape On Fatigue LifeLukita Wahyu PermadiNessuna valutazione finora

- CE 370-Lecture-7 (Flexural Behavior of RC Beams - Ultimate Stage) (Read-Only) PDFDocumento24 pagineCE 370-Lecture-7 (Flexural Behavior of RC Beams - Ultimate Stage) (Read-Only) PDFJamal RkhNessuna valutazione finora

- Maurice Nicoll The Mark PDFDocumento4 pagineMaurice Nicoll The Mark PDFErwin KroonNessuna valutazione finora

- Design ThinkingDocumento29 pagineDesign ThinkingErik Wahyu PradanaNessuna valutazione finora

- NonLinearAnalysis SAP2000Documento11 pagineNonLinearAnalysis SAP2000Javier VidalNessuna valutazione finora

- Wind Load Based On SNI 1727 2013 and ASCDocumento78 pagineWind Load Based On SNI 1727 2013 and ASCeka putraNessuna valutazione finora

- Marc Mentat FEM PDFDocumento19 pagineMarc Mentat FEM PDFMahmud Kori EffendiNessuna valutazione finora

- Wave Optics QuestionDocumento6 pagineWave Optics QuestionMayank KumarNessuna valutazione finora

- Reinforcement-Concrete Bond Behavior - Experimentation in Drying Conditions and Meso-Scale ModelingDocumento46 pagineReinforcement-Concrete Bond Behavior - Experimentation in Drying Conditions and Meso-Scale ModelingfaridNessuna valutazione finora

- Corrosion and its Consequences for Reinforced Concrete StructuresDa EverandCorrosion and its Consequences for Reinforced Concrete StructuresNessuna valutazione finora

- TorsionalVibration PresentationDocumento20 pagineTorsionalVibration PresentationValentin JonovNessuna valutazione finora

- Catalogue GUNUNG GARUDADocumento40 pagineCatalogue GUNUNG GARUDAhendrobama50% (2)

- 1 s2.0 S0168874X98000572 MainDocumento13 pagine1 s2.0 S0168874X98000572 MainDevarajuNessuna valutazione finora

- Development of Forging Process Design To Close Internal VoidsDocumento8 pagineDevelopment of Forging Process Design To Close Internal VoidsAmir AmiriNessuna valutazione finora

- 1998 - Study of Stress Development in Axi-Symmetric Products Processed by Radial Forging Using A 3-D Non-Linear Finite-Element MethodDocumento9 pagine1998 - Study of Stress Development in Axi-Symmetric Products Processed by Radial Forging Using A 3-D Non-Linear Finite-Element MethodNguyen Hoang DungNessuna valutazione finora

- Thesis On Metal CuttingDocumento7 pagineThesis On Metal Cuttingaflodtsecumyed100% (1)

- Edd Fuel Tank ApplicationDocumento11 pagineEdd Fuel Tank ApplicationZubair AhmadNessuna valutazione finora

- Experiments On Stainless Steel Hollow Sections-Part 1: Material and Cross-Sectional BehaviourDocumento43 pagineExperiments On Stainless Steel Hollow Sections-Part 1: Material and Cross-Sectional BehaviourZim DausNessuna valutazione finora

- Tensile Notch Inconel 625Documento24 pagineTensile Notch Inconel 625多如Nessuna valutazione finora

- Characterising The Effect of Springback On Mechanically Formed Steel PlatesDocumento4 pagineCharacterising The Effect of Springback On Mechanically Formed Steel PlatespuneethudupiNessuna valutazione finora

- Numerical and Experimental Study of Frictional Behavior in Bending Under Tension TestDocumento9 pagineNumerical and Experimental Study of Frictional Behavior in Bending Under Tension Testsergio_rollaNessuna valutazione finora

- The Effect of Non-Local Approach in Simulating Cross-Weld Tensile Test SpecimenDocumento6 pagineThe Effect of Non-Local Approach in Simulating Cross-Weld Tensile Test SpecimenAnizahyatiNessuna valutazione finora

- Vehicle Structure Design & Material Selection: DR Meftah HrairiDocumento19 pagineVehicle Structure Design & Material Selection: DR Meftah Hrairi'Atif AliNessuna valutazione finora

- Numerical Study of Strain-Rate Effect in Cold Rolls Forming of SteelDocumento8 pagineNumerical Study of Strain-Rate Effect in Cold Rolls Forming of SteelVanganuru SunilNessuna valutazione finora

- Ms Tensile Refer ThisDocumento10 pagineMs Tensile Refer Thisddsiva402Nessuna valutazione finora

- Finite Element Model For The Effect of Heat Input & Speed On Residual Stress During WeldingDocumento6 pagineFinite Element Model For The Effect of Heat Input & Speed On Residual Stress During WeldingInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Engineering Structures: Cheng Shi, Hossein Karagah, Mina Dawood, Abdeldjelil BelarbiDocumento11 pagineEngineering Structures: Cheng Shi, Hossein Karagah, Mina Dawood, Abdeldjelil BelarbiIliuta FloreaNessuna valutazione finora

- Tolerance Transfer in Sheet Metal FormingDocumento21 pagineTolerance Transfer in Sheet Metal FormingMarvin GongNessuna valutazione finora

- Failure Analysis of A Bridge Crane Shaft-Version Online FinalDocumento8 pagineFailure Analysis of A Bridge Crane Shaft-Version Online FinaloazzambranoNessuna valutazione finora

- Non-Linear Elastic-Plastic Behaviour of Aluminium Sheet Metal Using Finite Element AnalysisDocumento10 pagineNon-Linear Elastic-Plastic Behaviour of Aluminium Sheet Metal Using Finite Element AnalysisTJPRC PublicationsNessuna valutazione finora

- Structures: Baofeng Zheng, Ganping Shu, Lianchun Xin, Ran Yang, Qinglin JiangDocumento12 pagineStructures: Baofeng Zheng, Ganping Shu, Lianchun Xin, Ran Yang, Qinglin JiangNasarKhanNessuna valutazione finora

- Elastic-Plastic Behaviour of A Nuclear Pipe Elbow With Axial Through Wall Crack at Crown Under In-Plane BendingDocumento9 pagineElastic-Plastic Behaviour of A Nuclear Pipe Elbow With Axial Through Wall Crack at Crown Under In-Plane BendingPeto FoteNessuna valutazione finora

- Fiber Reinforced Plastics VesselsDocumento5 pagineFiber Reinforced Plastics VesselsandreshuelvaNessuna valutazione finora

- Investigation of Springback of Metallic Sheets at Small StrainsDocumento17 pagineInvestigation of Springback of Metallic Sheets at Small Strainskhudhayer1970Nessuna valutazione finora

- Life Cycle Analysis of Steel Railway BridgesDocumento53 pagineLife Cycle Analysis of Steel Railway BridgesRaees MazharNessuna valutazione finora

- Ahmed H. Zubydan - Inelastic Large Deflection Analysis of Space Steel Frames Including H-Shaped Cross Sectional MembersDocumento11 pagineAhmed H. Zubydan - Inelastic Large Deflection Analysis of Space Steel Frames Including H-Shaped Cross Sectional MemberscosminducaNessuna valutazione finora

- Study On Sheet Metal BendingDocumento11 pagineStudy On Sheet Metal BendingmarcandreitraquenaNessuna valutazione finora

- Numerical Estimation and Analysis of Effective Width of Composite Beams With Ribbed SlabDocumento15 pagineNumerical Estimation and Analysis of Effective Width of Composite Beams With Ribbed SlabInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- The Behaviour of A Self-Piercing Riveted Connection Under Quasi-Static Loading ConditionsDocumento22 pagineThe Behaviour of A Self-Piercing Riveted Connection Under Quasi-Static Loading ConditionsShreehari HaridasanNessuna valutazione finora

- Factors Affecting On Springback in Sheet Metal Bending: A ReviewDocumento5 pagineFactors Affecting On Springback in Sheet Metal Bending: A Reviewkhudhayer1970Nessuna valutazione finora

- Simulation of Bolt Prestressing in Steel Shear Connections: Emistaki@Documento10 pagineSimulation of Bolt Prestressing in Steel Shear Connections: Emistaki@Anis SuissiNessuna valutazione finora

- 02Documento8 pagine02Nghiem QuocNessuna valutazione finora

- Materials Science and Engineering ADocumento10 pagineMaterials Science and Engineering ARodrigo MaiaNessuna valutazione finora

- Parametric Analysis of Steel Bolted End Plate Connections Using Finite Element ModelingDocumento20 pagineParametric Analysis of Steel Bolted End Plate Connections Using Finite Element Modelingbob8c5Nessuna valutazione finora

- Performance Criteria For Dissipative Steel Plate Shear Walls StructuresDocumento8 paginePerformance Criteria For Dissipative Steel Plate Shear Walls StructuresgiorgosantzelidisNessuna valutazione finora

- Experimental Study of The Effect of Triaxiality RatioDocumento4 pagineExperimental Study of The Effect of Triaxiality RatioEl Ehsan Abinya FatihNessuna valutazione finora

- Non-Linear Elastic-Plastic Behaviour of Aluminium Sheet Metal Using Finite Element AnalysisDocumento11 pagineNon-Linear Elastic-Plastic Behaviour of Aluminium Sheet Metal Using Finite Element AnalysisMarco ZanellaNessuna valutazione finora

- Full Text 01Documento33 pagineFull Text 01Zoric Bobby100% (1)

- Evaluation of In-Plane Shear Test Methods For Composite Material LaminatesDocumento6 pagineEvaluation of In-Plane Shear Test Methods For Composite Material Laminates3pherNessuna valutazione finora

- The Continuous Strength Method For The Design of Mono-Symmetric and Asymmetric Stainless Steel Cross-Sections in BendingDocumento12 pagineThe Continuous Strength Method For The Design of Mono-Symmetric and Asymmetric Stainless Steel Cross-Sections in BendingGogyNessuna valutazione finora

- 2014 - Failure Analysis of A Bridge Crane ShaftDocumento8 pagine2014 - Failure Analysis of A Bridge Crane ShaftOscar ZambranoNessuna valutazione finora

- Comparison Between Numerical Results and The Lab Results in Analyzing The Buckling Behavior of Plates Optimized by Longitude StiffenersDocumento9 pagineComparison Between Numerical Results and The Lab Results in Analyzing The Buckling Behavior of Plates Optimized by Longitude StiffenersMouhat OuadiaNessuna valutazione finora

- A Review On The Vibration Analysis For A Damage OccurrenceDocumento20 pagineA Review On The Vibration Analysis For A Damage OccurrenceSomNessuna valutazione finora

- CRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Documento16 pagineCRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Samir BoseNessuna valutazione finora

- Advanced Modelling of End Plate Joints: Lukas - Godrich@fsv - Cvut.cz, Wald@fsv - Cvut.cz, Sokol@fsv - Cvut.czDocumento6 pagineAdvanced Modelling of End Plate Joints: Lukas - Godrich@fsv - Cvut.cz, Wald@fsv - Cvut.cz, Sokol@fsv - Cvut.czbramo96Nessuna valutazione finora

- Analysis and Parametric Study of Reinforced Concrete Two-Way Ribbed Slabs by Using ANSYSDocumento21 pagineAnalysis and Parametric Study of Reinforced Concrete Two-Way Ribbed Slabs by Using ANSYSddNessuna valutazione finora

- Metals: Generation of A Layer of Severe Plastic Deformation Near Friction Surfaces in Upsetting of Steel SpecimensDocumento9 pagineMetals: Generation of A Layer of Severe Plastic Deformation Near Friction Surfaces in Upsetting of Steel SpecimensyesullenNessuna valutazione finora

- 10 1 1 685 4139 PDFDocumento6 pagine10 1 1 685 4139 PDFOvidiu Si Roxana IvascuNessuna valutazione finora

- 1-S2.0-S1877705817315205-Main (2017)Documento6 pagine1-S2.0-S1877705817315205-Main (2017)MAV2804Nessuna valutazione finora

- Effect of Forging On Micro-Hardness of Al7075 Based Al O Reinforced Composites Produced by Stir-CastingDocumento12 pagineEffect of Forging On Micro-Hardness of Al7075 Based Al O Reinforced Composites Produced by Stir-CastingPrasanna GubbiNessuna valutazione finora

- F 031032038Documento7 pagineF 031032038researchinventyNessuna valutazione finora

- Failure Analysis of Bridge ShaftDocumento19 pagineFailure Analysis of Bridge ShaftAhmad Abdul GhaniNessuna valutazione finora

- 1161-Article Text-2401-1-10-20180412Documento8 pagine1161-Article Text-2401-1-10-20180412Alessandro PalatellaNessuna valutazione finora

- Local Buckling Curves For The Design of FRPDocumento16 pagineLocal Buckling Curves For The Design of FRPfabianNessuna valutazione finora

- Structural Analysis Modeling of Unbonded Prestressing in Prestressed Concrete ContainmentsDocumento8 pagineStructural Analysis Modeling of Unbonded Prestressing in Prestressed Concrete ContainmentshemalcmistryNessuna valutazione finora

- Paris, A.J. (U. Alaska) DCBDocumento2 pagineParis, A.J. (U. Alaska) DCBalitcoNessuna valutazione finora

- Experimental Study of Residual Stresses in Thick Steel PlatesDocumento18 pagineExperimental Study of Residual Stresses in Thick Steel Plateshassnain iqbalNessuna valutazione finora

- Finite Element Modelling of Steel Beams With Web OpeningsDocumento29 pagineFinite Element Modelling of Steel Beams With Web Openingspsyko2099Nessuna valutazione finora

- Journals With No Article Processing ChargesDocumento14 pagineJournals With No Article Processing ChargesNurul Jami Bakti JayaNessuna valutazione finora

- Linear Analysis of RC Beam: Structural Analysis Lab Submission 4Documento20 pagineLinear Analysis of RC Beam: Structural Analysis Lab Submission 4Ping Fuan LeeNessuna valutazione finora

- Design and Development of Smart Campus System Based On BIM and GISDocumento4 pagineDesign and Development of Smart Campus System Based On BIM and GISErik Wahyu PradanaNessuna valutazione finora

- Failure Load Prediction of Castellated Beams UsingDocumento21 pagineFailure Load Prediction of Castellated Beams UsingErik Wahyu PradanaNessuna valutazione finora

- Three-Dimensional Non-Linear FE-analysis of Reinforced ConcreteDocumento148 pagineThree-Dimensional Non-Linear FE-analysis of Reinforced ConcreteErik Wahyu PradanaNessuna valutazione finora

- MDOT Research Report R1515 239284 7Documento40 pagineMDOT Research Report R1515 239284 7Erik Wahyu PradanaNessuna valutazione finora

- A New Method For CDP Input Parameter Identification of The ABAQUS Software Guaranteeing The Uniqueness and PrecisionDocumento23 pagineA New Method For CDP Input Parameter Identification of The ABAQUS Software Guaranteeing The Uniqueness and PrecisionErik Wahyu PradanaNessuna valutazione finora

- Linear Evaluation On Weak Story Medium Rise StructDocumento7 pagineLinear Evaluation On Weak Story Medium Rise StructErik Wahyu PradanaNessuna valutazione finora

- Experimental Test and Numerical Simulation of The Initial Crack Reinforced Concrete Beam in BendingDocumento6 pagineExperimental Test and Numerical Simulation of The Initial Crack Reinforced Concrete Beam in BendingErik Wahyu PradanaNessuna valutazione finora

- Steel Caracteristic Steel PortalDocumento20 pagineSteel Caracteristic Steel PortalIkhsan Fauzi GpNessuna valutazione finora

- 267 1015 1 PBDocumento7 pagine267 1015 1 PBErik Wahyu PradanaNessuna valutazione finora

- Blooms Taxonomy PDFDocumento13 pagineBlooms Taxonomy PDFhichem_nasroNessuna valutazione finora

- 267 1015 1 PB PDFDocumento7 pagine267 1015 1 PB PDFErik Wahyu PradanaNessuna valutazione finora

- Price2017 USD PDFDocumento1 paginaPrice2017 USD PDFErik Wahyu PradanaNessuna valutazione finora

- Jurnal Thesis S2 Tentang Gempa RS SardjitoDocumento6 pagineJurnal Thesis S2 Tentang Gempa RS SardjitoErik Wahyu PradanaNessuna valutazione finora

- Wartegg TestDocumento1 paginaWartegg TestErik Wahyu PradanaNessuna valutazione finora

- 03 - How To Design Timber BridgesDocumento41 pagine03 - How To Design Timber BridgesErik Wahyu PradanaNessuna valutazione finora

- Atasi Kelemahan Public Speaking Anda!Documento3 pagineAtasi Kelemahan Public Speaking Anda!Erik Wahyu PradanaNessuna valutazione finora

- Dinamika StrukturDocumento25 pagineDinamika StrukturErik Wahyu PradanaNessuna valutazione finora

- Full Text 01Documento148 pagineFull Text 01Erik Wahyu PradanaNessuna valutazione finora

- Kampung Inggris Pare Jawa TimurDocumento1 paginaKampung Inggris Pare Jawa TimurErik Wahyu PradanaNessuna valutazione finora

- FEM (Finite Element Method)Documento9 pagineFEM (Finite Element Method)Erik Wahyu PradanaNessuna valutazione finora

- Moczo Etal 2007a APSDocumento230 pagineMoczo Etal 2007a APSbiles1234Nessuna valutazione finora

- Aerodynamics - 1D Momentum Theory: Required To Pass: 60% or Higher You Can Retake This Quiz Up To 3 Times Every 8 HoursDocumento4 pagineAerodynamics - 1D Momentum Theory: Required To Pass: 60% or Higher You Can Retake This Quiz Up To 3 Times Every 8 HoursTarik AhasanNessuna valutazione finora

- UitmDocumento20 pagineUitmHaziq PazliNessuna valutazione finora

- Supersonic EjectorsDocumento202 pagineSupersonic Ejectorslokeshsharma4433Nessuna valutazione finora

- Answer The Following Question Model (A)Documento9 pagineAnswer The Following Question Model (A)Ahmed HassanNessuna valutazione finora

- Donikian Et Al (2012) 3D Ssi Analysis of Cut and Cover Tunnel Doyle Drive SF, CaDocumento10 pagineDonikian Et Al (2012) 3D Ssi Analysis of Cut and Cover Tunnel Doyle Drive SF, CaYuamar BasarahNessuna valutazione finora

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Documento8 pagine6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNessuna valutazione finora

- PhysicsDocumento5 paginePhysicsBrentNessuna valutazione finora

- Chem Ch4 NIE Premium NOtesDocumento19 pagineChem Ch4 NIE Premium NOtesAadil ShaikhNessuna valutazione finora

- FOUNDATION Isolated Square FootingDocumento15 pagineFOUNDATION Isolated Square FootingLoisse CabintoyNessuna valutazione finora

- CE 212 Mechanics of Solids Sessional Lab Manual: Department of Civil EngineeringDocumento87 pagineCE 212 Mechanics of Solids Sessional Lab Manual: Department of Civil Engineeringamtris406Nessuna valutazione finora

- BM8251 r17 EM For Biomedical EngineersDocumento2 pagineBM8251 r17 EM For Biomedical EngineersHOD AUTONessuna valutazione finora

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BQHXYNV96LV5B5Documento2 pagineETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BQHXYNV96LV5B5Rasec Otusgus ToNessuna valutazione finora

- Chapter 2 - Fluid Pressure and Its Measurement PDFDocumento52 pagineChapter 2 - Fluid Pressure and Its Measurement PDFrohit sharma100% (1)

- Describing Motion in Terms of Graphical RepresentationDocumento47 pagineDescribing Motion in Terms of Graphical RepresentationJohn Christian MejiaNessuna valutazione finora

- Newtons Laws of Motion NumericalsDocumento3 pagineNewtons Laws of Motion Numericalsdayanandan150% (2)

- Intz TankDocumento47 pagineIntz Tankyashfeen bakhshNessuna valutazione finora

- Bohrs Model For Hydrogen AtomDocumento36 pagineBohrs Model For Hydrogen AtomRekhashree H100% (1)

- 12 - Fluid Dynamics (CE and BE)Documento25 pagine12 - Fluid Dynamics (CE and BE)Yahiah HeshamNessuna valutazione finora

- Ib Phys DC ESQ B 231118 135653Documento25 pagineIb Phys DC ESQ B 231118 135653sammeaan khanNessuna valutazione finora

- Electromagnetic Theory - Unit 2 - EMT-Week 1 LecturesDocumento7 pagineElectromagnetic Theory - Unit 2 - EMT-Week 1 LecturesJignesh DesaiNessuna valutazione finora

- Basic Principles of SpectrosDocumento10 pagineBasic Principles of SpectrosAlexiss Chavez-De la MoraNessuna valutazione finora

- Pressure PrismDocumento28 paginePressure Prismmianismailkhan007Nessuna valutazione finora

- Mechanics: Physics 151Documento23 pagineMechanics: Physics 151nghaNessuna valutazione finora

- Paper 2Documento12 paginePaper 2Aisha ShaikhNessuna valutazione finora

- HW3 SolutionDocumento3 pagineHW3 Solutioniam0204Nessuna valutazione finora