Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flux Cored Wire

Caricato da

KentDemeterioCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flux Cored Wire

Caricato da

KentDemeterioCopyright:

Formati disponibili

Flux cored wire

Ideal combination of high quality and high

efficiency

Dipl.-Ing. IWE Michael Reimann

Product Manager

OERLIKON Switzerland

Welding conference Lima, Peru 25.11.2005

Arrangement of flux cored wires

Seamless flux cored wire

Metal cored wire

Basic flux cored wire

Rutil flux cored wire

Flux cored wire classification Fluxofil 14 HD

DIN EN 758

T 46 2 P M 1 H5

T

46

2

P

M

1

H5

: Flux cored wire

: Yield and tensile Strenght

: Toughness

: Slag fast freezing slag

: Mixed gas 82% Ar 18% CO2

: All welding position

: Diffusible hydrogen H2

ASME Code Sec.II/C

AWS SFA 5.20 E 71T-1 M H4

E

7

1

T-1M

H4

: Electrode

: Yield, tensile Strenght and toughness

: welding position H,F,VU,OH

: Slag characteristic, shielding gas

: Diffusible hydrogen H2

3

Welding project with Fluxofil 14 HD

Welding project with Fluxofil 14 HD

WPS Fluxofil 14 HD with weldycar

WPS Fluxofil 14 HD with weldycar

Root pass on ceramic backing

WPS Fluxofil 14 HD with weldycar

Front view on round ceramic backing

WPS Fluxofil 14 HD with weldycar

Fixation the weldycar

WPS Fluxofil 14 HD with weldycar

Root pass on ceramic backing

WPS Fluxofil 14 HD with weldycar

Cap welding

Current

I=225A

Voltage

U=24V

Welding speed

Vs=13cm/min

Wire speed

8,0m/min

Weld deposit

3,5 Kg/h

10

WPS Fluxofil 14 HD with weldycar

Joint preparation

Nahtvorbereitung

Schweiparameter

Layers set up

Lagenaufbau

Welding parameters

11

WPS Fluxofil 14 HD with weldycar

Weldycar fixed in transver position

12

WPS Fluxofil 14 HD with weldycar

Transver welding on ceramic in action

13

WPS Fluxofil 14 HD with weldycar

Joint preparation Nahtvorbereitung

Schweiparameter

Lagenaufbau

Layers set up

Welding parameters in transver position

14

Fluxofil 14 HD in project operation

15

Fluxofil 14 HD in project operation

16

Fluxofil 14 HD in project operation

17

Fluxofil 14 HD in project operation

18

Flux cored wire application tank building

19

Flux cored wire application tank building

Joint preparation

Vessel

20

Fluxofil 14 HD Application pipe junction

21

Flux cored wire application hall truss

22

Flux cored wire application exhibition hall

23

Fluxofil 14 HD in all welding position

24

Calculation comparison between solid and flux cored

wire

Schweiverfahren

MAG- Flldraht MAG- Massivdraht

Schweizusatz

Fluxofil 14 HD

Ausfhrungen

Nahtvorbereitung

Lagenaufbau

Halbmechanisiert

12

Lagenzahl/Raupenzahl

Schweiposition

(mm)

Drahtdurchmesser

I (mm)

Schweistrom

U (V)

Schweispannung

Schweigeschwindigkeit Vs (cm/min)

SG (Kg/h)

Abschmelzleistung

ED (%)

Schweizeitfaktor

LS (Euro/h)

Lohnsatz

SZP (Euro/Kg)

Schweizusatzpreis

SP (Euro/l)

Schutzgaspreis

Schutzgasmenge

SM (l/min)

GKF (%)

Gemeinkostenfaktor

Carbofil 1

Halbmechanisiert

90

3L/3R

3L/3R

PF

1,2

PF

1,2

210

140

23

18

26

13

3,0

45

1,5

45

13

13

3,3

0,93

0.01

0.01

15

300

15

300

25

Calculation comparison between solid and flux cored

wire

Schweiverfahren

MAG- Flldraht MAG- Massivdraht

Schweizusatz

Ausfhrungen

Nahtvorbereitung

Lagenaufbau

Fluxofil 14 HD

Halbmechanisiert

12

Carbofil 1

halbmechanisiert

90

Lagenzahl/Raupenzahl

Schweinahtgewicht

SNG (Kg/m)

3L/3R

1,20

3L/3R

1,20

Hauptzeit

Hauptzeit + Nebenzeit

Th ( min/m )

T ( min / m )

24,00

53,33

48,00

106,67

Schweizusatzkosten

Schutzgaskosten

KZ (Euro/m)

3,96

1,12

KS(Euro/m)

0,87

0,87

Lohnkosten

Gemeinkosten

Fertigungskosten

KL (Euro/m)

KG (Euro/m)

KF (Euro/m)

11,56

34,67

46,22

23,11

69,33

92,44

Gesamtkosten

KGe (Euro/m)

51,05

94,43

Ersparnis

Euro/m

43,38

Ersparnis

45,94

26

Fluxofil 14 HD - Data sheet FLUXOFIL 14 HD

Rutile tubular cored electrode for MAG-welding, with fastfreezing slag

Standards:

DIN EN 758

AW S/ASME SFA-5.20

T 46 2 P C 1 H5 / T 46 2 P M 1 H5

E71T-1 H4 / E71T-1M H4

Applications and properties :

The higher filling degree of FLUXOFIL 14 HD results in higher current carrying capacity and deposition rate. Welding

speed is thereby essentially increased which leads to a saving of time and reduction of costs. It can be used in all

positions with only one setting of welding parameters (2 4 volts, wire feed = 9m/min, wire dia. 1,2 mm). FLUXOFIL 14

HD is em ployed in manual welding, as well as in fully mechanized w elding by me ans of the orbital welding unit CITOTRACK OSG-O1 or the vertical welding set CITOTRACK VSG-O1. It is preferably used under mixed shield ing gas

and is characterized by low spatter loss, good slag removal and finely rippled, pore-free welds without undercutting

into the base metal.

Materials:

EN-Designation

S185

S235 to S355

P235

L210 to L415

L290, L320

DIN-Designation

EN-Designation

DIN-/AWS-Designation

St 33

S235 to S355

St 37.0 to St 52.0

St 37-2 to St 52-3

P235 to P355

St 37.4 to St 52.4

St 35.8

P265

St 45.8

StE 210.7 to StE 415.7

L360 to L485

StE 360.7 TM-StE 480.7 TM

StE 290.7TM, StE 320.7T M

P235GH, P265GH

HI, HII

X42 to X65

P295GH

17 Mn 4

StE 255

S(P)275 to S(P)460

StE 285to StE 460

A, B, D, E

AH 32 to EH 36

GS-38

GP240R

GS-45

Please observe admissible operating temperature for welding consumable and base material.

Qualification tests:

T V

Approvals:

DB, ABS, DNV, GL, LRS

Indications as to approvals, see appendix.

Analysis of all-weld metal (typical values in %):

C

0,05

Si

0,55

Mn

1,2

Mechanical properties of all-weld metal (single values are typical values):

Heat treatment

AW

AW = as-welded

Yield strength

[N/mm]

Tensile strength

[N/mm]

Elongation

A5 [%]

>460

550 650

>22

Impact energy ISO-V [Joule]

-20 C

>80

Chemical composition and mechanical properties apply to the use of shielding gas:

DIN EN 439 - M21 (82 Vol. % Ar + 18 Vol. % CO2 )

Shielding gas as to DIN EN 439:

Consumption:

M21 (ARCAL 21), C1 (carbon dioxide)

12 15 l/min for 1,6 mm

Welding parameters and deposition rate, see:

B 131

Form of delivery:

Wire diameters [mm]

Further forms of delivery on req uest.

Wire cage reel K300 (16 kg)

1,0

1,2

1,6

Type of current/Polarity/Welding positions:

27

Fluxofil 14 HD - advantages Easy handling in all welding position

-

High deposition rate in all welding position

To use in fully mechanized welding processes

One side welding on ceramic backing

Less spatter during the welding process

Easy slag removal

Very good penetration

Seamless wire

Less fume and less hydrogen content

High efficiency

28

Application

Metal cored wire

Fluxofil M8

29

Metal cored wire Fluxofil M8 - advantages -

Easy handling in H and F welding position

Seamless wire

Less fume and less hydrogen content

High deposition rate in H and F welding position

To use in fully mechanized welding processes

One side welding on ceramic backing

Less spatter during the welding process

Very good penetration

High efficiency

Very good ristriking

30

Application

Metal cored wire

Fluxofil M8

31

Application

Metal cored wire

Fluxofil M8

32

Application

Metal cored wire

Fluxofil M8

33

Application

Metal cored wire

Fluxofil M8

34

Application

Metal cored wire

Fluxofil M8

35

Variable applications with flux cored wires

36

Variable applications with flux cored wires

37

Variable applications with flux cored wires

38

Potrebbero piacerti anche

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesDa EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNessuna valutazione finora

- GM Aw and GT Aw ConsumablesDocumento118 pagineGM Aw and GT Aw Consumablessepe00Nessuna valutazione finora

- American Welding Society (AWS) Standards: Code DescriptionDocumento7 pagineAmerican Welding Society (AWS) Standards: Code DescriptionZainudinNessuna valutazione finora

- Weight Optimization of Tie Rod Using FEMDocumento4 pagineWeight Optimization of Tie Rod Using FEMInternational Journal of Innovations in Engineering and ScienceNessuna valutazione finora

- Top Down Master ModelDocumento6 pagineTop Down Master Modelarturojimenez72Nessuna valutazione finora

- ASSEMBLY, Layers, Parameters PPSXDocumento27 pagineASSEMBLY, Layers, Parameters PPSXPrateek ChakrabortyNessuna valutazione finora

- Part Modeling Best PracticesDocumento3 paginePart Modeling Best PracticesBryan BritoNessuna valutazione finora

- 21 Tutorial Bielle enDocumento10 pagine21 Tutorial Bielle enguilhermeNessuna valutazione finora

- Siemens NX11 Tutorials The Angled PartDocumento16 pagineSiemens NX11 Tutorials The Angled PartGonzalo AnzaldoNessuna valutazione finora

- NX Assign Material PropertiesDocumento54 pagineNX Assign Material PropertiesbiondavNessuna valutazione finora

- Böhler Folder Strip Cladding EN WEB PDFDocumento0 pagineBöhler Folder Strip Cladding EN WEB PDFCarlos Bermejo AlvarezNessuna valutazione finora

- Step by Step NX Open C++ Introduction - Cad Cam Development PDFDocumento6 pagineStep by Step NX Open C++ Introduction - Cad Cam Development PDFLuu Duc HopNessuna valutazione finora

- NX Programming NetDocumento3 pagineNX Programming NetAlfombras Lloveras100% (1)

- OneSteel Steel Pipe Final LoResDocumento24 pagineOneSteel Steel Pipe Final LoResPhilip TeakleNessuna valutazione finora

- Finite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Documento6 pagineFinite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Aswaja313Nessuna valutazione finora

- Index AwsDocumento1 paginaIndex AwsRaul2307Nessuna valutazione finora

- 3D FEA Simulations in MachiningDocumento95 pagine3D FEA Simulations in MachiningAyman TamimNessuna valutazione finora

- Stress Intensifiyer in Tanks 01Documento22 pagineStress Intensifiyer in Tanks 01gechaves1Nessuna valutazione finora

- ANSYS17.0 NCode Standard Online Training L2Documento11 pagineANSYS17.0 NCode Standard Online Training L2sergiogigiaNessuna valutazione finora

- Stellite 21 DatasheetDocumento2 pagineStellite 21 Datasheetapply19842371100% (3)

- Adams 2020 Adams View Command User GuideDocumento2.184 pagineAdams 2020 Adams View Command User GuideManoj SinghNessuna valutazione finora

- Alform 700 MCDocumento9 pagineAlform 700 MCCarlos Nombela PalaciosNessuna valutazione finora

- Abaqus Adaptive MeshingDocumento13 pagineAbaqus Adaptive MeshingpaivensolidsnakeNessuna valutazione finora

- CFD-ACE+ CFD View TutorialDocumento17 pagineCFD-ACE+ CFD View TutorialTiffany RileyNessuna valutazione finora

- NX Tutorial Drafting enDocumento4 pagineNX Tutorial Drafting enJag VrNessuna valutazione finora

- Design and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsDocumento7 pagineDesign and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsPradeep AdsareNessuna valutazione finora

- IRC5-Rapid Reference Part1B 3HAC16581-1 RevB en Part1b LibraryDocumento380 pagineIRC5-Rapid Reference Part1B 3HAC16581-1 RevB en Part1b Librarymauro_ricardo_sNessuna valutazione finora

- Superlite: Superlite Asbestos Free Gp-150Documento4 pagineSuperlite: Superlite Asbestos Free Gp-150blahblahNessuna valutazione finora

- Introduction To Abaqus Scripting (ABAQUS)Documento19 pagineIntroduction To Abaqus Scripting (ABAQUS)Mario AmellNessuna valutazione finora

- BoilerTubes - TechnitubeDocumento24 pagineBoilerTubes - TechnitubeMMPAPNessuna valutazione finora

- Analysis Methods For Fatigue of Welds: Jeff Mentley HBM - Ncode ProductsDocumento52 pagineAnalysis Methods For Fatigue of Welds: Jeff Mentley HBM - Ncode ProductsEvelin StefanovNessuna valutazione finora

- DM-Intro 15.0 WS-3.2 DesignModeler SketchingDocumento41 pagineDM-Intro 15.0 WS-3.2 DesignModeler SketchinghaziqNessuna valutazione finora

- NX Nastran Advanced Nonlinear - Solution 601-701Documento3 pagineNX Nastran Advanced Nonlinear - Solution 601-701Rubén GabrielNessuna valutazione finora

- Kitz Carbon and Stainless Steel Floating Ball ValvesDocumento160 pagineKitz Carbon and Stainless Steel Floating Ball ValvesAnonymous 1880JHcGNessuna valutazione finora

- Flexible Reporting: User'S Manual For Using The Protocoldesigner in Geopak and Cat1000SDocumento122 pagineFlexible Reporting: User'S Manual For Using The Protocoldesigner in Geopak and Cat1000Scmm5477Nessuna valutazione finora

- 3D FEM of Welding Process Using Element Birth & Element Movement TechniquesDocumento7 pagine3D FEM of Welding Process Using Element Birth & Element Movement TechniquesDebabrata PodderNessuna valutazione finora

- PADT Webinar Series: An Example of Moving Mesh Modeling of A ValveDocumento20 paginePADT Webinar Series: An Example of Moving Mesh Modeling of A ValvevahidssNessuna valutazione finora

- Plain Bearings Made From Engineering PlasticsDocumento44 paginePlain Bearings Made From Engineering PlasticsJani LahdelmaNessuna valutazione finora

- Canlin Castings - Cast Iron GradesDocumento2 pagineCanlin Castings - Cast Iron GradeshooijschuurNessuna valutazione finora

- IIW - International Institute of WeldingDocumento3 pagineIIW - International Institute of WeldingNilesh MistryNessuna valutazione finora

- Norme For WeldingDocumento3 pagineNorme For Weldingsirambo1Nessuna valutazione finora

- Air Flow Analysis For Defroster and Ventilation System of A Passanger CarDocumento4 pagineAir Flow Analysis For Defroster and Ventilation System of A Passanger CarSai PatilNessuna valutazione finora

- GS52Documento3 pagineGS52S.Hasan MirasadiNessuna valutazione finora

- Permas ContactDocumento14 paginePermas ContactvenkyNessuna valutazione finora

- 440C 1Documento4 pagine440C 1svk1234Nessuna valutazione finora

- FLOW 3D Cast Brochure PDFDocumento15 pagineFLOW 3D Cast Brochure PDFHamidAffandyNessuna valutazione finora

- Williamsons PluGDocumento3 pagineWilliamsons PluGSARATH KRISHNAKUMARNessuna valutazione finora

- Cost Reduction and Light Weighting (BIW)Documento25 pagineCost Reduction and Light Weighting (BIW)tran hungNessuna valutazione finora

- Numerical Analysis - I. Jacques and C. Judd PDFDocumento109 pagineNumerical Analysis - I. Jacques and C. Judd PDFMaria AquiseNessuna valutazione finora

- NX 10-Sheet Metal Design (Advanced) - Video TrainingTutorialsDocumento4 pagineNX 10-Sheet Metal Design (Advanced) - Video TrainingTutorialsSmartlearning TechnologyNessuna valutazione finora

- Code - Aster Application in The Oil&gas FieldDocumento17 pagineCode - Aster Application in The Oil&gas FieldSergio PluchinskyNessuna valutazione finora

- 2020 R1 Mechanical Overview PresentationDocumento60 pagine2020 R1 Mechanical Overview PresentationEmre ATAYNessuna valutazione finora

- Fluid Codes Training CatalogueDocumento44 pagineFluid Codes Training CatalogueMohamedJaberKutkutMjkNessuna valutazione finora

- 09MME020 Design and Analysis of 500 MT Wagon CarDocumento79 pagine09MME020 Design and Analysis of 500 MT Wagon CarJitendra PatelNessuna valutazione finora

- Packing Gasket Catalog enDocumento72 paginePacking Gasket Catalog enChristopherGunawanNessuna valutazione finora

- Example 02 (Linstatic Angle-Ply)Documento7 pagineExample 02 (Linstatic Angle-Ply)Luis HuayaneyNessuna valutazione finora

- Demonstration of SpringbackDocumento7 pagineDemonstration of SpringbackDan Wolf100% (1)

- Adiabatic Shear Localization: Frontiers and AdvancesDa EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNessuna valutazione finora

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Da EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNessuna valutazione finora

- Upgrading Skills For Pipe Fitters FabricatorsDocumento4 pagineUpgrading Skills For Pipe Fitters FabricatorsKentDemeterio0% (1)

- Weld DefectsDocumento38 pagineWeld DefectsJerry Man UtdNessuna valutazione finora

- Types WeldingDocumento66 pagineTypes WeldingRathnakraja50% (2)

- Weld Design SymbolsDocumento63 pagineWeld Design Symbolspriyoc6100% (15)

- Weld Defects TWIDocumento96 pagineWeld Defects TWISabir Shabbir100% (7)

- Weld-Consumable-Calculator Butt & Fillet WeldDocumento7 pagineWeld-Consumable-Calculator Butt & Fillet WeldKentDemeterioNessuna valutazione finora

- Weld Defects 2Documento78 pagineWeld Defects 2HskumarReddy KarriNessuna valutazione finora

- Welding PositionDocumento20 pagineWelding PositionKentDemeterioNessuna valutazione finora

- Welder Fitters Program NewDocumento9 pagineWelder Fitters Program NewKentDemeterioNessuna valutazione finora

- Welding Lecture Guide NewDocumento31 pagineWelding Lecture Guide NewKentDemeterioNessuna valutazione finora

- Weld Design SymbolsDocumento63 pagineWeld Design Symbolspriyoc6100% (15)

- Welding Competation GuideDocumento5 pagineWelding Competation GuideKentDemeterioNessuna valutazione finora

- Welding XXXXXDocumento25 pagineWelding XXXXXKentDemeterioNessuna valutazione finora

- Welding DefectsDocumento77 pagineWelding DefectsBalakumar100% (1)

- Welding Processes PresentationDocumento101 pagineWelding Processes PresentationKentDemeterio100% (1)

- Welding Metallurgy and Weldability of MetalsDocumento133 pagineWelding Metallurgy and Weldability of MetalsEfren Ibanez100% (2)

- Welding Super Duplex SSDocumento11 pagineWelding Super Duplex SSmuarabadak100% (1)

- Welding Inspection in ShipbuildingDocumento40 pagineWelding Inspection in ShipbuildingKentDemeterio0% (1)

- Welding-Training & InspectionDocumento46 pagineWelding-Training & InspectionKentDemeterio100% (3)

- Non Destructive TestingDocumento62 pagineNon Destructive Testingjoescribd55Nessuna valutazione finora

- Determination of The Solubility Product Constant of Silver AcetateDocumento8 pagineDetermination of The Solubility Product Constant of Silver AcetateSara Al AzemNessuna valutazione finora

- Curriculum Vitae: Augusto Javier Puican ZarpanDocumento4 pagineCurriculum Vitae: Augusto Javier Puican Zarpanfrank_d_1Nessuna valutazione finora

- Propeller DesignDocumento1 paginaPropeller DesignKeerthana MaheswarlaNessuna valutazione finora

- Receiving Material Procedure (Done) (Sudah Direvisi)Documento8 pagineReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangNessuna valutazione finora

- Module002 LaboratoryExercise002Documento2 pagineModule002 LaboratoryExercise002Joaquin SmithNessuna valutazione finora

- Teradata Installation: Installation Steps For WindowsDocumento4 pagineTeradata Installation: Installation Steps For WindowsjupudiguptaNessuna valutazione finora

- Mauser 98K - Model 48 Rifle ManualDocumento20 pagineMauser 98K - Model 48 Rifle ManualMeor Amri96% (28)

- Chapter 7 Notes Computer OrganizationDocumento20 pagineChapter 7 Notes Computer OrganizationsriNessuna valutazione finora

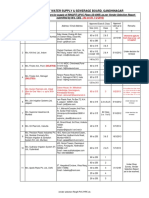

- GWSSB Vendor List 19.11.2013Documento18 pagineGWSSB Vendor List 19.11.2013sivesh_rathiNessuna valutazione finora

- 01 GeoStrucAnal Cylinder Elastic PDFDocumento12 pagine01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikNessuna valutazione finora

- Sec VlanaclsDocumento10 pagineSec VlanaclsTry FajarmanNessuna valutazione finora

- J.M. Hurst Cyclic AnalysisDocumento45 pagineJ.M. Hurst Cyclic AnalysisChristian Robinson80% (10)

- Quality Assurance Plan (1) ..Documento5 pagineQuality Assurance Plan (1) ..ARUNKUMARANNANBHEDANessuna valutazione finora

- High Integrity Aluminum (GENERAL)Documento140 pagineHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- 1 Xpower Safirus Owners Manual enDocumento8 pagine1 Xpower Safirus Owners Manual enMarianela MasyRubiNessuna valutazione finora

- Antikythera MechanismDocumento25 pagineAntikythera MechanismchetansergiurazvanNessuna valutazione finora

- PBLauncherDocumento50 paginePBLauncherborreveroNessuna valutazione finora

- Geotechnical Engineering 1 (RMIT) Course RevisionDocumento53 pagineGeotechnical Engineering 1 (RMIT) Course RevisionSaint123Nessuna valutazione finora

- V.K Jain-Advanced Machining Processes-Allied Publications PDFDocumento370 pagineV.K Jain-Advanced Machining Processes-Allied Publications PDFMayank Vyas100% (1)

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Documento7 paginePG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNessuna valutazione finora

- Compact 40/25Documento58 pagineCompact 40/25znim04Nessuna valutazione finora

- PIONEER AUTORADIO Deh-X4850bt Deh-X6850bt Operating Manual Ing - Esp - PorDocumento72 paginePIONEER AUTORADIO Deh-X4850bt Deh-X6850bt Operating Manual Ing - Esp - PorJesus NinalayaNessuna valutazione finora

- Comparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelDocumento12 pagineComparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelWaqqas ChaudhryNessuna valutazione finora

- D6489 PDFDocumento3 pagineD6489 PDFKalindaMadusankaDasanayakaNessuna valutazione finora

- Problems PDFDocumento9 pagineProblems PDFEduarGelvezNessuna valutazione finora

- Car DeerDocumento2 pagineCar DeerNEGameandParksNessuna valutazione finora

- BurnerDocumento4 pagineBurnerAhmed Mohamed KhalilNessuna valutazione finora

- Optimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanDocumento7 pagineOptimasi Blending Pertalite Dengan Komponen Reformate Di PT. XYZ BalikpapanFrizki AkbarNessuna valutazione finora

- ITP InstrumentationDocumento9 pagineITP InstrumentationzhangyiliNessuna valutazione finora