Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Seminar Report (Roll No. 143040044) - Structural Health Monitoring of Concrete Structures

Caricato da

Souradeep SenCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Seminar Report (Roll No. 143040044) - Structural Health Monitoring of Concrete Structures

Caricato da

Souradeep SenCopyright:

Formati disponibili

Structural Health Monitoring of Concrete Structures

Submitted for CE694 (Seminar)

Master of Technology

in

STRUCTURAL ENGINEERING

Submitted by

Souradeep Sen

(Roll No. 143040044)

Under the supervision

of

Prof. Sauvik Banerjee

Department of Civil Engineering

Indian Institute of Technology Bombay

November, 2014

Abstract

Structural Health Monitoring is the field where the health of structures are assessed, monitored

and evaluated from time to time, for the improvement in serviceability of these structures. In this

seminar report, a basic understanding of the meaning, need, and methods of structural health

monitoring (SHM) has been presented. Also, the SHM of concrete structures have been

mentioned and case studies regarding these have been presented in a concise manner.

Methods regarding the uses of piezoceramic based sensors, Interferometric methods of frequency

evaluation and self-diagnosis materials for structural health monitoring have been presented

case-wise from the works of various authors. The results from the experiments conducted for the

respective methods have been shown and discussed.

Acknowledgement

My indebtedness to Prof. Sauvik Banerjee is unlimited for his kind guidance, cooperation and help in selection of the topic, describing the topic in detail and

presenting a large number of study materials which helped me in completion of

this seminar report.

Souradeep Sen

Roll No. 143040044

Structural Health Monitoring of Concrete Structures

Table of Contents

Introduction to Structural Health Monitoring........................................................................... 3

Case Studies ................................................................................................................................... 5

1) Wen-I Liao et al. (Structural health monitoring of concrete columns subjected to seismic

excitations using piezoceramic-based sensors). .......................................................................... 5

Introduction ............................................................................................................................. 5

The Specimen .......................................................................................................................... 6

Method of measuring the Energy and Damage Index used in the experiment ........................ 9

Results after the shake table test ............................................................................................ 10

2) F.C. Ponzo et al. (Structural Health Monitoring of Reinforced Concrete Structures using

Nonlinear Interferometric Analysis). ........................................................................................ 12

Introduction ........................................................................................................................... 12

The Simplified Method Proposal Method Proposed by Ponzo et al...................................... 13

Frequency and Damping Cofficient by IRF, Interferometric and S-transform Methods ...... 14

3) H. Inada et al. (Improvement on Health Monitoring System Using Self-diagnosis Materials

for Practical Application). ......................................................................................................... 19

Introduction ........................................................................................................................... 19

Self-Diagnosis Materials and their Production ...................................................................... 20

Displacement measuring device using the Self-Diagnosis Materials .................................... 22

Conclusions .................................................................................................................................. 25

References .................................................................................................................................... 27

Structural Health Monitoring of Concrete Structures

Lists of Figures

Figure 1 Configuration of the tested column specimen in lateral view and front view. ................ 6

Figure 2 Test setup of the shake table test. .................................................................................... 7

Figure 3 TCU078 seismogram of the 1999 .................................................................................... 8

Figure 4 Location of the smart aggregates ..................................................................................... 8

Figure 5 Damage Pattern of PGA 600 gal and 900 gal ................................................................ 10

Figure 6 Sinusoidal wave response after the earthquake excitation at different PGA levels ...... 10

Figure 7 Damage index matrix of sensors after the earthquake excitation at different PGA levels

....................................................................................................................................................... 11

Figure 8 (a) Results obtained by using the station located at the top floor as a reference station

(b) Impulse Response Function obtained by using the bottom floor as a reference station (from

Snieder and Safak (2006)) ............................................................................................................ 14

Figure 9 (Left) Numerical Model (Right) Input used for the analyses ........................................ 15

Figure 10 IRFs evaluated using the bottom floor as a reference station ...................................... 16

Figure 11 Nonlinear Interferometric Analysis performed on the top floor accelerometric

recording and S-Transform evaluated on the single IRF .............................................................. 18

Figure 12 Schematic drawing of materials. ................................................................................. 20

Figure 13 Two types of sensors. .................................................................................................. 20

Figure 14 Result of tensile test and regression ............................................................................ 21

Figure 15 Manufacturing Process ................................................................................................ 22

Figure 16 Displacement of measuring device .............................................................................. 23

Figure 17 Measurement of Displacement during Shake-Table Tests .......................................... 24

Figure 18 Examples of test results. .............................................................................................. 24

Structural Health Monitoring of Concrete Structures

Chapter 1

Introduction to Structural Health Monitoring

The process of implementing a damage detection and characterization strategy for engineering

structures is referred to as Structural Health Monitoring (SHM). Here damage is defined as

changes to the material and/or geometric properties of a structural system, including changes to

the boundary conditions and system connectivity, which adversely affect the systems

performance. The SHM process involves the observation of a system over time using

periodically sampled dynamic response measurements from an array of sensors, the extraction of

damage-sensitive features from these measurements, and the statistical analysis of these features

to determine the current state of system health. For long term SHM, the output of this process is

periodically updated information regarding the ability of the structure to perform its intended

function in light of the inevitable aging and degradation resulting from operational environments.

After extreme events, such as earthquakes or blast loading, SHM is used for rapid condition

screening and aims to provide, in near real time, reliable information regarding the integrity of

the structure

Structural Health Monitoring (SHM) aims to give, at every moment during the life of a structure,

a diagnosis of the state of the constituent materials, of the different parts, and of the full

assembly of these parts constituting the structure as a whole. The state of the structure must

remain in the domain specified in the design, although this can be altered by normal aging due to

usage, by the action of the environment, and by accidental events. Thanks to the time-dimension

of monitoring, which makes it possible to consider the full history database of the structure, and

with the help of Usage Monitoring, it can also provide a prognosis(evolution of damage, residual

life, etc.).

If we consider only the first function, the diagnosis, we could estimate that Structural Health

Monitoring is a new and improved way to make a Non- Destructive Evaluation. This is partially

true, but SHM is much more. It involves the integration of sensors, possibly smart materials, data

transmission, computational power, and processing ability inside the structures. It makes it

Structural Health Monitoring of Concrete Structures

possible to reconsider the design of the structure and the full management of the structure itself

and of the structure considered as a part of wider systems.

In this seminar report, the methods of Structural Health Monitoring for Concrete Structures will

be discussed, via various case studies accomplished by various institutes and people across the

globe. The various methods have been successfully tested to be useful for the health monitoring

of structures and have been presented in a compact manner.

Structural Health Monitoring of Concrete Structures

Chapter 2

Case Studies

1) Wen-I Liao et al.

Structural health monitoring of concrete columns subjected to seismic

excitations using piezoceramic-based sensors

Introduction

Throughout the life cycle of a concrete structure, important issues have to be addressed properly

to ensure the safe operation of these structures. It becomes essential to perform structural health

monitoring on these structures that can detect the amount of damage on these structures. After

earthquake, it becomes very essential to monitor the health of the structure due to the

earthquakes catastrophic nature. In recent years, piezoelectric materials have been successfully

applied to the structural health monitoring of concrete structures due to their advantages of active

sensing, low cost, quick response, availability in different shapes, and simplicity in

implementation.

There are two major categories of piezoelectric-based health monitoring.

The first includes the impedance-based approach, in which the impedance of piezoelectric

transducers can be applied to the health monitoring of structures. Although, it is difficult to

identify the distribution and severity of a large damaged region, the advantage of the impedancebased approach is that it does not require knowledge of the modal parameters or other failure

information of the structure.The second approach is the wave-based health monitoring approach

(Okafor et al 1996, Saafi and Sayyah 2001), in which the wave-propagation properties are

studied to detect and evaluate the cracks and damages inside concrete structures. Wang et al

(2001) studied the debonding behaviors between steel rebar and concrete by using PZT (lead

zirconate titanate) patches fixed on the rebar. Sun et al (2008) used a PZT patch transducer to

Structural Health Monitoring of Concrete Structures

initiate and receive elastic waves in the concrete, and obtained the modulus of elasticity by

utilizing the wave-propagation characteristics.

Song et al (2004, 2007, 2008) developed smart aggregate (SA), an innovative multifunctional

piezoceramic-based device, to perform structural health monitoring for concrete structures. The

smart aggregates have been successfully utilized in the structural health monitoring of a twostory concrete frame structure (Gu et al 2007).

The piezoceramic based smart aggregates were distributed at strategic location prior to the

casting of the column for the formation of an active sensing system for the health monitoring of

the column. A shake table was used to simulate the earthquake ground motion recorded in the

Taiwan 1999 earthquake. The acceleration was increased gradually upto failure of the column.

During the tests, the distributed smart aggregates and PZT patches embedded in the concrete

columns were utilised to perform the structural health monitoring. One of the PZTs was used as

an actuator for generating and propagating of waves and the others were used as sensors to detect

the waves. If the propagation energy was attenuated at certain portions, it meant that the portion

had cracks or voids. The decreased value of the transmission energy is proportional to the

severity and extent of the damage.

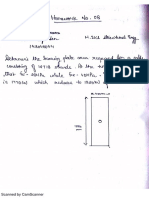

Figure 1 Configuration of the tested column specimen in lateral view and front view.

The Specimen

Structural Health Monitoring of Concrete Structures

A flexural governed reinforced concrete

column was tested on a shake table (Figure

2). The height and cross section of the

column were 80 cm and 20 20 cm2,

respectively. The rebar arrangement of the

test columns was 4#3 longitudinal steel

rebars with #3@10 cm stirrup. The average

concrete strength was 210 kg cm2 and the

Figure 2 Test setup of the shake table test.

average yielding stresses for #3 rebar was

4100 kg cm2. The size of the top concrete

plate

was

160

160

20 cm3 and the size of the reinforced concrete foundation was 120 50 40 cm3. The

foundation was designed to remain elastic when the failure of the reinforced concrete column

occurred. The horizontal displacements and response accelerations of the column were measured

by linear variable displacement transducers (LVDTs) and accelerometers.

A total mass of 1000 kg was put on the top plate in order to increase the inertia force. Two load

cells were placed underneath the foundation to measure the vertical load and base shear during

the test. Furthermore, in order to prevent the abrupt falling of the top concrete plate and

additional lead blocks due to failure of the reinforced concrete column, four steel columns were

provided in the four corners of concrete mass block for support. The input acceleration time

history for all shake table tests is the E-W component of the record at TCU078 station of the

1999 Taiwan Chi- Chi earthquake (denoted as TCU078EW). Figure 3 below shows the

seismogram of the acceleration time history. Corresponding to the input ground motion, the test

protocol is sequentially the peak ground acceleration (PGA) of 50 gal, 200 gal, 400 gal, 600 gal,

and

900

gal,

and

the

specimen

failed

at

the

test

run

of

PGA=900gal.

Structural Health Monitoring of Concrete Structures

Figure 3 TCU078 seismogram of the 1999

In this test, PZT-type piezoceramic patches were embedded in a 1 inch cube of concrete (called

smart aggregate). The piezoelectric strain constat d33 and piezoelectric voltage constants g33 of

the PZT patches are 390 1012 C N1 and 24 103 V mN1, respectively. Piezoceramic patches

are usually fragile and can be easily damaged by the vibrations subjected to the column. To

protect the peizeoelectric transducers, the patch is coated with insulation in order to prevent

moisture related damages. Only then it is embedded in the concrete block as a smart aggregate.

Figure 4 Location of the smart aggregates

The sensors were kept at the specific locations as it was speculated that damage would most

likely occur at the places which have a tendency of formation of a plastic hinges. The actuator

was kept at the centre of the column. (Figure 4)

8

Structural Health Monitoring of Concrete Structures

Method of measuring the Energy and Damage Index used in the experiment

Wavelet packet analysis was used as a signal processing tool in order to analyse the signals

detected by the smart aggregates. The sensor signal (say S) was decomposed by an n-level

wavelet packet decomposing into 2n signal sets{X1, X2,., X2n }. If Eij is the energy of the

decomposed signal, here i stands for time index and j for the frequency band XJ = [xj,1, xj,2, . .

. , xj,m ] where m is the sampling data.

The energy vector at time index i can be given as

Ei = [Ei,1, Ei,2, . . . , Ei,2n ].

Root-mean-square deviation (RMSD) is a commonly used damage index to compare the

difference between the signatures of the healthy state and damaged state. In the proposed

approach, the damage index is formed by calculating the RMSD between the energy vectors of

the healthy state and the damaged state. The energy vector for healthy data is Eh = [Eh,1, Eh,2, . . .

, Eh,2n ]. The energy vector Ei for the damaged state at time index i is defined as Ei = [Ei,1, Ei,2, . .

. , Ei,2n ]. The damage index (DI) at time i is defined as:

The proposed damage index represents the transmission energy loss portion caused by damage.

When the damage index is close to 0, it means that the concrete structure is in a healthy state.

The greater the damage index, the more serious the damage is.

Structural Health Monitoring of Concrete Structures

Results after the shake table test

Figure 5 Damage Pattern of PGA 600 gal and 900 gal

The shake table test causes the column to crack at the bottom and top. Figure 5 shows the failure

pattern of the column specimen after the PGA runs near 600 to 900 gal. After this, the smart

aggregates were removed for the structural health monitoring during and after the shake table

test. From the sensor voltage graph (Figure 6) of the PZT-S2 used as the smart aggregate, it was

seen that the peak of the peak sensor voltage decreased as the ground acceleration of the shake

table kept increasing. This means that the propagated energy kept getting attenuated higher as the

cracks in the column kept increasing in size and number.

Figure 6 Sinusoidal wave response after the earthquake excitation at different PGA levels

10

Structural Health Monitoring of Concrete Structures

The plot of the damage index matrix of sensors is shown in figure , and the values are

demonstrated in Table 1 with the measured drift ratio of the column for comparison, where the

drift ratio is defined as the relative displacement at the column top to the column bottom divided

by the column height. After each test run of the shake table test, the sensor signals for health

monitoring have been measured twice by the same sweep sine excitation. The damage indices

shown in Table 1 were the mean values of the first and second measuring. The value shown in

brackets after the damage index was the relative error between each measuring.

Figure 7 Damage index matrix of sensors after the earthquake excitation at different PGA levels

11

Structural Health Monitoring of Concrete Structures

2) F.C. Ponzo et al.

Structural Health Monitoring of Reinforced Concrete Structures using

Nonlinear Interferometric Analysis

Introduction

The maintenance of a huge number of aged structures and infrastructures require a huge effort

and present a huge task to accomplish, if a detailed analysis of seismic risk is to be done

properly. It was seen that periodic visual inspection was rendering to be more and more

ineffective. A specific task of the Italian research RELUIS-DPC 2010-2013 project, funded by

the Department of Italian Civil Protection (DPC), dealt with the devising and implementing of a

fast procedure (Ponzo et al., 2010) to obtain useful information about the damage evolution in a

large number of strategic buildings during and after seismic events, by the help of just a few

sensors. The two most important goal which to be obtained regarding the usage of sensors was

feasibility and cost optimisation, so that it could be used in a more widespread manner.

Significant research in the field of Non-destructive Damage Evaluation (NDE) methods has been

done which have made use of the dynamic response changes in the structure. (Chen et al., 1995;

Capecchi and Vestroni, 1999; Ponzo et al., 2010)

NDE methods are classified into Four Levels, depending on the amount of data that can be

retrieved from the sensors.

(i)

Level I methods, i.e. those methods that only identify if damage has occurred.

(ii)

Level II methods, i.e. those methods that identify if damage has occurred and

simultaneously determine the location of damage.

(iii)

Level III methods, i.e. those methods that identify if damage has occurred, determine

the location of damage as well as estimate the severity of damage.

(iv)

Level IV methods, i.e. those methods that identify if damage has occurred, determine

the location of damage, estimate the severity of damage and evaluate the impact of

damage on the structure.

With the increase in level, the amount of data and algorithm required became more sophisticated.

And so did the cost. Ponzo et al. (2010) had proposed an innovative approach for a simplified

12

Structural Health Monitoring of Concrete Structures

structural damage detection. Due to this, it was easier to obtain information about the health of

the structure minutes after a seismic activity. The method includes the acquisition of structural

dynamic response by a three-directional accelerometer which is to be installed on top floor of a

structure. From the data, maximum acceleration, frequency variation and equivalent viscous

damping can be obtained and hence be used to find the maximum inter-storey displacement.

The paper focused on the interferometric analyses (Snieder and Safak, 2006; Picozzi et al., 2011)

useful to obtain the dynamic response of the monitored structure. Particularly, the Impulse

Response Function (IMF) obtained by mean the interferometric analysis, applied on the data

recorded on the monitored structure, was combined with the S-Transform (Stockwell et al.,

1996)

to

perform

pseudo

time-frequency analysis with the aim to automatize the procedure to evaluate both frequency

and damping variation during earthquakes.

The Simplified Method Proposal Method Proposed by Ponzo et al.

The method by Ponzo et al. (2010) began from a limited number of records obtained from the

accelerometer on the top floor of the structure. It overcame certain limitations of Level I

methods. The method considers some parameters evaluated by the recorded signals: (i)

Maximum Absolute Top Acceleration (MATA); (ii) variations of the fundamental frequency (iii)

variation of the equivalent viscous damping, and provides a combination of these parameters to

estimate the maximum interstorey drift by means of an empirical relationship. All signals are

filtered with band-pass filter centred on the fundamental frequency of the monitored structure.

The Maximum Absolute Top Acceleration represents the first instrumental parameter. It was

evaluated directy by the filtered signal (filtered by band filter) recorded by the accelerometer. An

appropriate arrangement of recording sensors on the structure permits to reconstruct all

displacement and rotation components of the floor. The other two instrumental parameters

13

Structural Health Monitoring of Concrete Structures

considered in the method are the percent variations (f1) between the fundamental frequency of

the building before the seismic event finit and the minimum one fmin, corresponding to the

maximum non linear behaviour of the building and the percent variations (f2) between initial

and final frequency (ffin)

The frequencies were evaluated by using a STFT (Short Time Fourier Transform) applied to the

signals. The final instrumental parameter considered is the variation of the equivalent structural

viscous damping related to the first mode of vibration of the structure. For non-stationary

signals, the damping can be found by the semi-probabilistic approach elaborated by Mucciarelli

and Gallipoli (2007).

Frequency and Damping Cofficient by IRF, Interferometric and S-transform

Methods

The structure which was selected is as shown in Figure 9. It had 5 storeys, with inter-storey

height of 3m, representative of Italian Standard Buildings. The building considered had a plan of

12 m x 15m.In order to take into account the presence of infill panels within the structural R/C

frames and their interaction with the columns, both the masonry strength and stiffness

contribution had been considered by inserting two equivalent structural elements in the models.

The mechanical characteristics of these elements were evaluated considering the Mainstone

model (Mainstone, 1974).

Figure 8 (a) Results obtained by using the station located at the top floor as a reference station

(b) Impulse Response Function obtained by using the bottom floor as a reference station (from

Snieder and Safak (2006))

14

Structural Health Monitoring of Concrete Structures

It was noted that using the top floor as a reference station it was possible to retrieve information

about the wavefield propagated into the building while using the bottom floor as a reference

station it was possible to extract the impulse response function of the building.( After

deconvolution of the response in frequency domain)

Figure 9 (Left) Numerical Model (Right) Input used for the analyses

The damping can be evaluated before and after earthquake using the IRF (Impulse Response

Function). Figure 10 shows the example of an IRF evaluated with bottom floor as reference. By

using logarithmic decrement method, the viscous damping can be evaluated.

15

Structural Health Monitoring of Concrete Structures

Figure 10 IRFs evaluated using the bottom floor as a reference station

It was noted that from the IRFs evaluated at the top floor it was also possible to extract

interesting information related to the fundamental frequency of the structure. In fact, comparing

the results obtained from the fundamental frequency of the structure before and after the

earthquake it was possible to note a shift of the frequency from 2.0Hz (before the earthquake) to

1.10Hz (after the earthquake). Applying the logarithm decrement method on the evaluated IRFs

before and after the earthquake it was seen that the equivalent viscous damping factor varied

from 5.22% (before the earthquake) to 9.40% (after the earthquake).

Picozzi et al. (2011) showed that it was possible to evaluate the IRF also from a windowed signal

acting on a single time-window. It was seen that the time-varying behavior of the structure of the

structure could be represented as frequency variation using both the IRFs evaluated from

windowed signals and the related S-transform.

As discussed in the previous section, the method proposed by Ponzo et al. (2010) was based also

on the frequency evaluation before, during and after an earthquake. In the method, a partially

solved problem is the possibility to automatic evaluation of the fundamental frequency changes

during the strong motion phase. Here a new approach for the automatic evaluation of the

fundamental frequency over it is be shown. The fundamental frequency is constant for linear

structural behavior. It can get lowered only by non-linear behavior. Hence, an upper bound for

the frequency domain is maintained.

16

Structural Health Monitoring of Concrete Structures

When the frequency domain upper bound is established, just using ambient noise recordings, it is

possible to use a limited domain for the interferometric analyses and for the S-Transform of the

IRFs evaluated at the top level (using the windowed signal). At this purpose it is important to

decide how is the length of the selected moving time-window and the related overlap. Generally,

the time-window length is fixed as a function of the fundamental period of the structure:

w 10 T

where w (in seconds) is the moving time-window length and T is the fundamental period of the

monitored structure. With regards to the moving time-window overlap, basing on the results

obtained in this work, a good rule seems to be 50% of the considered time-window length.

In the following it is possible to find an example of application of the proposed procedure to

automatic evaluate the fundamental frequency variation of the structure before, after and during

the earthquake. The elastic starting frequency of the structure, as mentioned before, is equal to

2.0Hz with a period equal to 0.5sec. Using the rule established before it is necessary to use a

moving time-window length greater than 5sec. It is worth noting that during the earthquake, if

the structure exhibits a nonlinear

17

Structural Health Monitoring of Concrete Structures

Figure 11 Nonlinear Interferometric Analysis performed on the top floor accelerometric

recording and S-Transform evaluated on the single IRF

It is worth noting from Figure 11 that the instantaneous fundamental frequency of the structure

changes over time starting from a value equal to 2.0Hz, reaching a minimum frequency equal to

0.85Hz and concluding with a fundamental frequency equal to 1.10Hz.

For each time-window the fundamental frequency can be automatically evaluated considering

the S-Transform results. In fact, the fundamental frequency corresponds, for each time-window,

to the frequency related to the maximum value of the S-Transform for.

18

Structural Health Monitoring of Concrete Structures

3) H. Inada et al.

Improvement on Health Monitoring System Using Self-diagnosis Materials

for Practical Application

Introduction

Programming of sensors to memorise peak values of deformation of strain caused by the

catastrophic disasters of earthquakes and other such calamities in Structural Health Monitoring is

essentially required. Also, the ability of the sensors to retain this experienced information makes

it possible to remove the need for continuous monitoring of the structures. In previous studies,

the conductive fiber reinforced composite, the glass fiber reinforced plastics containing carbon

black particles, has been confirmed to respond sensitively against applied strain and memorise

the peak value. Because the percolation structure formed by carbon black causes irreversible

change in resistance, the sensor maintains the electrical resistance value corresponding to the

applied peak strain.

Research has been conducted by the authors of the paper using the carbon materials as electrical

conductive sensors. Earlier, conductive fibre reinforced composites, glass fibre reinforced

concrete containing carbon black particles were tested and had responded positively. Due to the

percolation structure formed by the carbon black, it leads to an irreversible change in the

resistance. Hence, it can memorise the changed resistance values and hence the deformation

can be extracted from the value of the changed resistance. These have been used on reinforced

concrete structures with positive results.

19

Structural Health Monitoring of Concrete Structures

Self-Diagnosis Materials and their Production

Characteristics of materials

The schematic drawing of self-diagnosis materials is shown in Figure 12. The rod-shaped FRP is

composed of glass fibers and matrix phase consisting of thermoset epoxy. High-structure carbon

black is dispersed into resin as conductive particles. The particle volume fraction is typically set

at 5.8%. After being cured at 160C for 90min, the materials are carbonized through a pyrolysis

process at 500C in N2 ambient. The carbonized composites were found to acquire high

sensitivity and distinguished ability to memorize peak strain. The composite is utilized as a

sensor by attaching grips and electrodes at both ends. In this study, two sizes of sensors as shown

in Figure 13 are applied. As shown in the figure, two pairs of cables, connecting to outer current

electrodes and inner voltage electrodes, are attached.

Figure 12 Schematic drawing of materials.

Figure 13 Two types of sensors.

Tensile tests were conducted on the sensors in order to evaluate its performance as strain sensors.

A relation between the applied strain and the electrical resistance of the sensor was deduced as

follows:

= ab ; a = 6.86103 , b = 0.384

20

Structural Health Monitoring of Concrete Structures

The resistance is represented as = (RR0) / R0 where R0 is the initial resistance value. The

values of a and b were found by regression of the observed data.

The example of results obtained by tensile test and estimated relation by the above equation is

shown in figure 14. As shown in the figure, sensor shows a distinguished memory function, but

has lower detectivity against small strain under 1000.

Figure 14 Result of tensile test and regression

Development of production method of materials

Due to the non-uniformity of the cross sectional shape and dispersion of carbon black in the

resin, there is variability in the tensile tests performed on the materials. Initially, the materials

were manufactured one at a time, thus leading to the variation in the properties. In later stages,

the materials are made in continuous batches to maintain equal quality throughout. Also by

continuous manufacturing, the production costs also reduce. The production system using

pultrusion process has been employed, with the mass production line as shown in the figure.

Carbon black is dispersed into resin and warmed well in temperature controlled bath of 80C in

order to accelerate uniform impregnation into glass fiber. The composites are gradually shaped

into rod and cured at the same time, by passing them through a heated die with inner Tefloncoating. As a result, two rod shaped materials with different diameters for two types of sensors

are formed simultaneously as shown. The diameters of each composite are 1.5mm and 0.9mm,

respectively.

21

Structural Health Monitoring of Concrete Structures

Figure 15 Manufacturing Process

Displacement measuring device using the Self-Diagnosis Materials

Development of device

The developed measuring device is as shown in Figure 16. The device is composed of small

sized sensor with helical compression spring, aluminum cylinder and tensile rod, which are all

set coaxially. The rod and the cylinder are connected to two fix points, and slides from side to

side smoothly with each other. The sensor is installed in the cylinder for protection and made

watertight. Both ends of the sensor are clamped to cylinder and rod via spring, and relative

displacement caused between two fix positions are distributed to sensor (SE) and spring (SP)

allocated according to their stiffness. Setting the gauge length and stiffness of the sensor LSE and

EASE, the constant of spring kSP, relation between displacement X and strain of sensor SE is

represented as follows:

X = (EASE + LSE kSP ) . SE kSP

22

Structural Health Monitoring of Concrete Structures

Therefore, sensitivity and allowable displacement of the device can be controlled by

specification of spring. Experimental results shown below have been obtained by specifying

allowable displacement as 10cm using spring with constant of 28.3N/mm.

Figure 16 Displacement of measuring device

.

Vibration tests of displacement measuring device

Vibration tests were conducted on shake tables where only one-directional excitation was

applied. The aim was to evaluate the applicability and performance of the displacement

measuring devices.

Because the peak memory sensor is applied to static post-event

measurement, its performance is generally evaluated through static tests. However, in the real

world scenario, sensors are required to record the response of the target structures against

dynamic loading such as earthquakes.

Figure 17 gives the outline of shake table experiments conducted. One fixed part of device is

mounted on the fixed table with the other end on the shaking table, vibrating in the horizontal

direction (unidirectional vibration). The frequencies used in the sine sweep were 1, 2 and 5 Hz

with amplitudes of 10, 10 and 5 cm respectively. After oscillating in constant amplitude during

certain period, amplitude is decreased gradually. Number of specimens for each frequency is three.

Relative displacement of shaking table is measured by laser displacement meter for comparison.

23

Structural Health Monitoring of Concrete Structures

Figure 17 Measurement of Displacement during Shake-Table Tests

Figure 18 Examples of test results.

The examples of obtained time waveforms of displacement and electrical resistance of the

sensors are shown in Figure 18. Variation of resistance is represented as above-mentioned

variation ratio . In all test condition, the sensor increases its resistance value only against the

displacement in tensile direction, and keeps peak value corresponding to the maximum

displacement. Therefore, the sensor is confirmed to show the expected performance as peak

memory measuring device even against dynamic loading. The sensor also shows apparent

resistance variation up to the maximum frequency of 5Hz in the tests, which demonstrates

enough capability to follow the response of general structures against external excitations such as

earthquakes. In the result of higher frequency, slight phase delay in response of the sensor

against displacement has been observed. The mechanism and the effect on the sensing accuracy

are being investigated in foregoing studies.

24

Structural Health Monitoring of Concrete Structures

Chapter 3

Conclusions

Structural health monitoring including the dynamic identification techniques is getting a firm

foothold in both the scientific as well as the civil community. The need for the assessment of the

aged and important structures health has been on the rise for better longetivity of the structures

and better serviceability. Various methods are being developed to assess the various properties of

the structures which include concrete structures predominantly, given that most structures in the

world are made of reinforced concrete.

The meaning of structural health monitoring, its needs and its objective were discussed initially.

The various processed of structural health monitoring were mentioned along a few newly

developed methods of assessing the health of a structure after an earthquake and similar

phenomena were henceforth discussed.

In the first case study, a piezoelectric-based sensor system was described and developed for the

structural health monitoring of concrete columns under seismic loadings. From the experimental

results of the shake table test and the in situ cyclic loading test, the DI (damage index) obtained

which were proposed for the specific sensing mechanism increased as the damage levels

increased. Also the drift ratio of the columns had a similar variation as the damage indices. The

proposed process of health monitoring can be used to predict the health of the structure and the

level of damage after earthquakes and similar calamities.

In the second case study discussed, it was seen that techniques based on Fourier transform

provide good results when the response of the system is stationary, but fail when the system

exhibits a non-stationary, time-varying behaviour.

In 1996, Stockwell introduced a new

powerful tool for the signals analysis: the S-Transform. Compared with the classical techniques

for the time-frequency analysis, this transformation shows a much better resolution and also

offers a range of fundamental properties such as linearity and invertibility. The ability to

investigate the non-stationary response of structures opens new scenarios, giving the opportunity

to explore new possibilities. The paper dealt with the combination of this S-transform and

25

Structural Health Monitoring of Concrete Structures

Interferometric Approaches in determining the change in the fundamental frequencies of the

structure and the displacement from column to column on different stories.

In the third case study described, newly developed damage detection devices using self-diagnosis

materials have been described. Their usage for damage detection for various structures is

discussed. However, it had shown variation in quality due to absence of mass production lines.

By the advent of pultrusion methods, the variational aspect of the sensors has been significantly

reduced. The memory aspect of the sensors helps in the retention of the data after certain

catastrophic events like earthquakes.

26

Structural Health Monitoring of Concrete Structures

References

Inada, H., Inada, Y. Okuhara, Y., Hayashi, Y. (2009). Improvement on Health Monitoring

System Using Self-diagnosis Materials for Practical Application.

Hayashi, Y, Miyamoto, M, Nii, A, Suzuki, Y, and Morii, A. (2005). Structural health monitoring

of hugetimber structures in Japan. Proc. International Conference on Structural Health

Monitoring ofIntelligent Infrastructures. 1043-1048.

Inada, H, Kumagai, H, and Okuhara, Y. (2005). Development of monitoring techniques for

concretestructures using self-diagnosis materials and wireless measurement systems. Proc.

InternationalConference on Structural Health Monitoring of Intelligent Infrastructures. 619-626.

Inada, H, Kumagai, H, and Okuhara, Y. (2007). Health monitoring techniques to detect damage

to concretestructures using self-diagnosis materials. Proc. International Conference on

Structural HealthMonitoring of Intelligent Infrastructures.

Carkhuff B. and Cain R. (2003). Corrosion sensors for concrete bridges IEEE Instrum. Meas.

Mag. 6 1924

Tseng K K and Wang L (2004). Smart piezoelectric transducers for in situ health monitoring of

concrete

Wang C S, Wu F and Chang F K (2001). Structural health monitoring from fiber-reinforced

composites to steel reinforced concrete Smart Mater. Struct. 10 54852

Liao, W., Wang, J., Song, G., Gu, H., Olmi, C., Mo, Y., Chang, K. and Loh, C. (2011).

Structural health monitoring of concrete columns subjected to seismic excitations using

piezoceramic-based sensors. Smart Mater. Struct., 20(12), p.125015

Ponzo,F. C., Ditommaso, R. & Auletta, G. (2012). Structural Health Monitoring of Reinforced

Concrete Structures using Nonlinear Interferometric Analysis

27

Potrebbero piacerti anche

- Simulating Distributional Impacts of Macro-dynamicsDa EverandSimulating Distributional Impacts of Macro-dynamicsNessuna valutazione finora

- Seminar Report On Analysis of Cable Stayed BridgeDocumento31 pagineSeminar Report On Analysis of Cable Stayed BridgeSijan Shrestha100% (1)

- Six Month Training Report On Construction of Railway Overbridge PDFDocumento49 pagineSix Month Training Report On Construction of Railway Overbridge PDFGurpreet SinghNessuna valutazione finora

- A Mini Project ReportDocumento37 pagineA Mini Project ReportChintuu Sai100% (2)

- PMC-18CV733 Notes Module-2Documento8 paginePMC-18CV733 Notes Module-2Girish Haragon100% (1)

- De Report 2021Documento23 pagineDe Report 2021Unknown SoulNessuna valutazione finora

- Basic Structural Analysis by C.S. ReddyDocumento4 pagineBasic Structural Analysis by C.S. ReddyArif Ahmed Laskar0% (6)

- Summer Training ReDocumento23 pagineSummer Training ReWalid AdnanNessuna valutazione finora

- Major Project ReportDocumento49 pagineMajor Project ReportMohini BhartiNessuna valutazione finora

- "Pervious Concrete": Gujarat Technological UniversityDocumento26 pagine"Pervious Concrete": Gujarat Technological UniversityRutvikNessuna valutazione finora

- Internship Report On Construction Management and RMCDocumento19 pagineInternship Report On Construction Management and RMCAnnaiah Revanth100% (1)

- Internship ReportDocumento30 pagineInternship ReportAbhishek SengarNessuna valutazione finora

- Civil Seminar TopicsDocumento13 pagineCivil Seminar TopicsKaran AvadNessuna valutazione finora

- Final Project Report Batch 4Documento44 pagineFinal Project Report Batch 4Manu P SNessuna valutazione finora

- Ganesh InternshipDocumento65 pagineGanesh InternshipArjunRathod100% (2)

- An Internship Project Report On Residential BuildingDocumento14 pagineAn Internship Project Report On Residential Buildingrupesh singhNessuna valutazione finora

- Disuniting of StructureDocumento15 pagineDisuniting of StructureJohn MathewNessuna valutazione finora

- Building Construction ReportDocumento38 pagineBuilding Construction ReportAnantPawarNessuna valutazione finora

- Civil Engineering Training College ReportDocumento23 pagineCivil Engineering Training College ReportabhishekNessuna valutazione finora

- Old Tank CivilDocumento15 pagineOld Tank CivilnaveenNessuna valutazione finora

- DE Sem 5Documento24 pagineDE Sem 5Yamin Devgadhwala100% (1)

- Dinesh InternshipDocumento39 pagineDinesh InternshipDinesh Gowda100% (3)

- REPORT FINAL PROJECT-KKI Group 3-Underpass PDFDocumento45 pagineREPORT FINAL PROJECT-KKI Group 3-Underpass PDFRadifan HalifNessuna valutazione finora

- VACCUM DEWATERED FLOORING-1-converted FinalDocumento20 pagineVACCUM DEWATERED FLOORING-1-converted FinalSachin50% (2)

- Final Project ReportDocumento65 pagineFinal Project ReportVikas Dalal75% (4)

- Seminar Report On Reactive Powder Concrete (Civil Engineering)Documento20 pagineSeminar Report On Reactive Powder Concrete (Civil Engineering)Siddhartha Siddhu87% (31)

- 152.prefabricated Multistory Structure Exposure To Engineering Seismicity by UsingDocumento6 pagine152.prefabricated Multistory Structure Exposure To Engineering Seismicity by UsingVishvajit KohakadeNessuna valutazione finora

- Major Project PPT GGBSDocumento20 pagineMajor Project PPT GGBSNaReN KumarNessuna valutazione finora

- A Study On Water AbsorbingDocumento2 pagineA Study On Water AbsorbingInternational Journal of Innovative Science and Research Technology100% (1)

- Partially Replacing of Aggregate by Wall and Floor Tile in ConcreteDocumento69 paginePartially Replacing of Aggregate by Wall and Floor Tile in ConcreteprotenelllyNessuna valutazione finora

- To Find The Strength of Concrete Block Using Waste Material Project ReportDocumento49 pagineTo Find The Strength of Concrete Block Using Waste Material Project ReportSahil Bali100% (1)

- Technical Seminar Report On PAPERCRETE FINALDocumento8 pagineTechnical Seminar Report On PAPERCRETE FINALaditya100% (3)

- Ijetae 1014 72Documento8 pagineIjetae 1014 72Charan ReddyNessuna valutazione finora

- Iternship ReportDocumento40 pagineIternship Reportpavan coorgNessuna valutazione finora

- Internship Report 111111111Documento27 pagineInternship Report 111111111shivakumar100% (3)

- Stabilization of Black Cotton Soil by Using Fly AshDocumento52 pagineStabilization of Black Cotton Soil by Using Fly AshManohar ManuNessuna valutazione finora

- Seismic Analysis of High-Rise Buildings (G+30) by Using ETABSDocumento9 pagineSeismic Analysis of High-Rise Buildings (G+30) by Using ETABSHema Chandra Reddy KarimireddyNessuna valutazione finora

- M60 Self Compacting ConcreteDocumento42 pagineM60 Self Compacting ConcreteAsif HussainNessuna valutazione finora

- Development of Robotic BridgeDocumento34 pagineDevelopment of Robotic BridgeNikesh Ram67% (9)

- Internship Report On 120 Mens Hostel ConstructionDocumento47 pagineInternship Report On 120 Mens Hostel ConstructionApollyon A100% (3)

- PP20063 InternshipDocumento22 paginePP20063 InternshipGaurav Dhembare100% (2)

- Plastic Pavement Mtech Dissertation Nit Rourkela 211CE3244 PDFDocumento106 paginePlastic Pavement Mtech Dissertation Nit Rourkela 211CE3244 PDFTora ZaraNessuna valutazione finora

- Pile Foundation: An Industrial Training Report Submitted in The Partial Fulfillment of The Requirement of The Degree ofDocumento24 paginePile Foundation: An Industrial Training Report Submitted in The Partial Fulfillment of The Requirement of The Degree ofGagan NagpalNessuna valutazione finora

- Box Pushing Tech SeminarDocumento20 pagineBox Pushing Tech SeminarVaishnavi Hallikar75% (4)

- InternshipDocumento32 pagineInternshipPurna Chowdary Vootla50% (4)

- Mini Project PDFDocumento54 pagineMini Project PDFTrZure Kukz80% (5)

- Advantages and Disadvantages of Rigid PavementDocumento1 paginaAdvantages and Disadvantages of Rigid PavementGelo Dizon100% (1)

- Forensic Case Study of Retaining Wall Failure in GoaDocumento4 pagineForensic Case Study of Retaining Wall Failure in GoaIanNessuna valutazione finora

- Plastic Roads Seminar ReportDocumento8 paginePlastic Roads Seminar ReportShahid Bhat0% (1)

- Bituminous (Asphalt) Road: Bachelor of TechnologyDocumento22 pagineBituminous (Asphalt) Road: Bachelor of TechnologyBirjesh KumarNessuna valutazione finora

- Seminar ReportDocumento26 pagineSeminar ReportSana Loni100% (2)

- Alternatives of Sand PDFDocumento27 pagineAlternatives of Sand PDFRaviteja100% (1)

- Sulphur Infiltrated ConcreteDocumento10 pagineSulphur Infiltrated ConcreteRishi Ramakrishnan0% (1)

- Summer Internship ReportDocumento17 pagineSummer Internship ReportSiddh NayakNessuna valutazione finora

- A Mini Project Report On CONCRETEDocumento9 pagineA Mini Project Report On CONCRETEsuresh nenavathNessuna valutazione finora

- Final Project Flat Slab 2 160215151248Documento111 pagineFinal Project Flat Slab 2 160215151248Mark Lester Ogot80% (10)

- Internship Report On CC PavementsDocumento39 pagineInternship Report On CC PavementsPrakashNessuna valutazione finora

- Summer Internship ReportDocumento46 pagineSummer Internship ReportNeel KurreyNessuna valutazione finora

- Sad Ass22222222222222Documento71 pagineSad Ass22222222222222Joseph Justeen LavarinthanNessuna valutazione finora

- Project 1Documento19 pagineProject 1Mohammad NajiNessuna valutazione finora

- CKYC Form Fillable FormDocumento4 pagineCKYC Form Fillable Formt_syamprasadNessuna valutazione finora

- TotalDocumento9 pagineTotalSouradeep SenNessuna valutazione finora

- f1076496360 New Doc 28Documento4 paginef1076496360 New Doc 28Souradeep SenNessuna valutazione finora

- Internet JanuaryDocumento1 paginaInternet JanuarySouradeep SenNessuna valutazione finora

- Dice SquareDocumento1 paginaDice SquareSouradeep SenNessuna valutazione finora

- Pratik Mahesh C.: PrathmeshDocumento1 paginaPratik Mahesh C.: PrathmeshSouradeep SenNessuna valutazione finora

- Trishil Aditya K.: Amit ShawDocumento1 paginaTrishil Aditya K.: Amit ShawSouradeep SenNessuna valutazione finora

- FSDJKFHFSKDJF SDFDSFDSFDDFSFDSDFSsdkjhfsdkfdsDocumento1 paginaFSDJKFHFSKDJF SDFDSFDSFDDFSFDSDFSsdkjhfsdkfdsSouradeep SenNessuna valutazione finora

- Day After Is Wednesday PDFDocumento1 paginaDay After Is Wednesday PDFSouradeep SenNessuna valutazione finora

- Cardholder's Dsipute Form - Axis BankDocumento1 paginaCardholder's Dsipute Form - Axis BankSouradeep SenNessuna valutazione finora

- CHAUSARDocumento2 pagineCHAUSARSouradeep SenNessuna valutazione finora

- HeheheDocumento1 paginaHeheheSouradeep SenNessuna valutazione finora

- CHAUSARDocumento2 pagineCHAUSARSouradeep SenNessuna valutazione finora

- Missing: Have You Seen This Charger?Documento2 pagineMissing: Have You Seen This Charger?Souradeep SenNessuna valutazione finora

- Important Note Before Opening Music FilesDocumento1 paginaImportant Note Before Opening Music FilesSouradeep SenNessuna valutazione finora

- 'Matrix Should Be Square' 'Matrix Should Be Symmertic': %%to Find The Eigen Vector and Eigen Value of A Symmetric MatrixDocumento1 pagina'Matrix Should Be Square' 'Matrix Should Be Symmertic': %%to Find The Eigen Vector and Eigen Value of A Symmetric MatrixSouradeep SenNessuna valutazione finora

- Tutorial 6Documento1 paginaTutorial 6Souradeep SenNessuna valutazione finora

- Where Is The Trigger PDFDocumento1 paginaWhere Is The Trigger PDFSouradeep SenNessuna valutazione finora

- Madness Is Like Gravity PDFDocumento1 paginaMadness Is Like Gravity PDFSouradeep SenNessuna valutazione finora

- Semi LogScaledDocumento1 paginaSemi LogScaledEmily WongNessuna valutazione finora

- Dskjdkdukfcds PDFDocumento1 paginaDskjdkdukfcds PDFSouradeep SenNessuna valutazione finora

- Harvey Dent PDFDocumento1 paginaHarvey Dent PDFSouradeep SenNessuna valutazione finora

- Tomorrow Is Tuesday PDFDocumento1 paginaTomorrow Is Tuesday PDFSouradeep SenNessuna valutazione finora

- HIP No. Transition Length (M) Y X Curve Radius (M)Documento5 pagineHIP No. Transition Length (M) Y X Curve Radius (M)Souradeep SenNessuna valutazione finora

- Cover Page III PDFDocumento1 paginaCover Page III PDFSouradeep SenNessuna valutazione finora

- Seminar Cover Page PDFDocumento7 pagineSeminar Cover Page PDFSouradeep SenNessuna valutazione finora

- Semi LogScaledDocumento1 paginaSemi LogScaledEmily WongNessuna valutazione finora

- GATE 2014 Syllabus PDFDocumento3 pagineGATE 2014 Syllabus PDFSouradeep SenNessuna valutazione finora

- Sieve Analysis Hydrometer Test (Wet Analysis) : Total Weight of Sample (GM)Documento6 pagineSieve Analysis Hydrometer Test (Wet Analysis) : Total Weight of Sample (GM)Souradeep SenNessuna valutazione finora

- CVP LicenseDocumento7 pagineCVP LicenseWaqar KhanNessuna valutazione finora

- SCHLEICH - Advanced Test Technologies - GLP1-e - PE+IR+HVAC PDFDocumento4 pagineSCHLEICH - Advanced Test Technologies - GLP1-e - PE+IR+HVAC PDFRakesh Kumar VermaNessuna valutazione finora

- Turning Five Student Progress ReportDocumento2 pagineTurning Five Student Progress ReportBryan Peterson100% (2)

- English Practice 1: C. Carried D. Sugar B. Underline A. Danger A. CharacterDocumento3 pagineEnglish Practice 1: C. Carried D. Sugar B. Underline A. Danger A. CharacterKeisaNessuna valutazione finora

- Indirectness and Euphemism PDFDocumento30 pagineIndirectness and Euphemism PDFmgar10Nessuna valutazione finora

- Active CitizenshipDocumento2 pagineActive CitizenshiprachidNessuna valutazione finora

- Sounds EverywhereDocumento6 pagineSounds EverywhereNieyfa RisyaNessuna valutazione finora

- A Study On Green Supply Chain Management Practices Among Large Global CorporationsDocumento13 pagineA Study On Green Supply Chain Management Practices Among Large Global Corporationstarda76Nessuna valutazione finora

- Digitel SignatureDocumento21 pagineDigitel Signatureapi-3746880Nessuna valutazione finora

- BlahDocumento5 pagineBlahNaz KierbeyNessuna valutazione finora

- W3: Assess 2 On Self-PerceptionDocumento2 pagineW3: Assess 2 On Self-PerceptionGielyn Camilo100% (1)

- 1 Lesson Plan in Formulating AssertionsDocumento6 pagine1 Lesson Plan in Formulating AssertionsGenelyn TimolaNessuna valutazione finora

- User fc20 PDFDocumento34 pagineUser fc20 PDFjesus diasNessuna valutazione finora

- (One Village One Product) Berbasis KoperasiDocumento11 pagine(One Village One Product) Berbasis KoperasiIndah Kumala SariNessuna valutazione finora

- Guide To Information Technology Security ServicesDocumento84 pagineGuide To Information Technology Security ServicesSecurity Face to FaceNessuna valutazione finora

- Enterprise Exam Style QuestionsDocumento2 pagineEnterprise Exam Style Questionsapi-301785352Nessuna valutazione finora

- An Inspector Calls Character Notes Key Quotations Key Language & Structural Features Priestley's IdeasDocumento8 pagineAn Inspector Calls Character Notes Key Quotations Key Language & Structural Features Priestley's IdeasPNessuna valutazione finora

- Course Outlines For CA3144 Sem A 2014-15Documento3 pagineCourse Outlines For CA3144 Sem A 2014-15kkluk913Nessuna valutazione finora

- 458M Parr 6755 Solution Calorimeter InstDocumento56 pagine458M Parr 6755 Solution Calorimeter InstWilo JaraNessuna valutazione finora

- What Is Engineering SurveyingDocumento5 pagineWhat Is Engineering SurveyingHui EdroxNessuna valutazione finora

- Frankel 1991 PDFDocumento17 pagineFrankel 1991 PDFFábio SilvaNessuna valutazione finora

- Strut & Tie ModelDocumento67 pagineStrut & Tie Modelahmed adel100% (9)

- Anomaly Detection Time Series Final PDFDocumento12 pagineAnomaly Detection Time Series Final PDFgong688665Nessuna valutazione finora

- Glimpses of Vedic MicrobiologyDocumento3 pagineGlimpses of Vedic MicrobiologybluestriateNessuna valutazione finora

- Rules Engine Deep DiveDocumento63 pagineRules Engine Deep Divevinoth4iNessuna valutazione finora

- Grade 8 Science Unit 1 Force, Motion and EnergyDocumento68 pagineGrade 8 Science Unit 1 Force, Motion and EnergyKeil Morada73% (26)

- 6 1Documento19 pagine6 1Zubair AhmedNessuna valutazione finora

- Sample of PHD Thesis Content Format USIM - Computer ScienceDocumento6 pagineSample of PHD Thesis Content Format USIM - Computer ScienceKhirulnizam Abd RahmanNessuna valutazione finora

- Direct 3 DDocumento406 pagineDirect 3 Dxlam99Nessuna valutazione finora