Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Condition Monitoring of Machinery Is Through FFT of Field Current, Voltage, Stator Current and Shaft Current

Caricato da

shobhan19840 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaLITERATURE ON CONDITION MONITORING THROUGH FFT

Titolo originale

Condition Monitoring of Machinery is Through FFT of Field Current,Voltage,Stator Current and Shaft Current

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLITERATURE ON CONDITION MONITORING THROUGH FFT

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni1 paginaCondition Monitoring of Machinery Is Through FFT of Field Current, Voltage, Stator Current and Shaft Current

Caricato da

shobhan1984LITERATURE ON CONDITION MONITORING THROUGH FFT

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Condition monitoring of machinery is the analysis & measurement of various

parameters related to the mechanical condition of the machinery which makes it

possible to determine whether the machinery is in good or bad mechanical

condition. The philosophy of conditional monitoring has been extended over now

to analyze and understand even the winding and insulation thus propagating itself

to electrical healthiness of the machines. This has been a significant move to

realize not only the state and operation of a machine but also to predict its

healthiness and condition attributing to save a lot of unwanted/unprecedented and

forced outage. If the mechanical condition is bad, then condition monitoring

makes it possible to deter- mine the cause of the problem. The result is the

maximization of the machine availability and maximum utilization of its

components.

Conditional monitoring has been limited to mechanical parameter supervision

generally owing its understanding over the mechanical aspects of the machine. In

this paper we would like to understand especially electrical parameters and its

effect over electrical insulation , winding condition and also mechanical

healthiness of machine. In the initial section we would devote our understanding of

FFT analyses of field current directly or through as search coil, stator current,

ground voltage through a NGT and then the shaft ground voltage and current

components and understand and compare its signature spectrum over a normal

operating condition to a various simulated fault conditions and a large number of

operating severity conditions such as surge , unbalance load and distinguish it with

faulty condition. This would help us keep a trace of probable developing failures

and their understanding helping us to plan and rectify the above. Lastly we would

study the vibration signature spectrum over generator stator frame and transformer

body and analyse it to understand the healthiness of insulation core and winding

with respect to vibration spectrum over the frame or body.

The results and test would be simulated over a DFIG and also a case study over a

operating hydro station would be done and its various results and simulations shall

be presented to analyze and predict the healthiness of a machine. The above

aspects of conditional monitoring would require precise understanding of various

faults and hazards and their dedifferentiation over normal conditions hence helping

to form a effective tool to reduce and help in regular and effective periodic

maintenance.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Quality Our CommitmentDocumento3 pagineQuality Our Commitmentshobhan1984Nessuna valutazione finora

- Report of Unchahar Unit 2 Bearing 6 VibrationDocumento8 pagineReport of Unchahar Unit 2 Bearing 6 Vibrationshobhan1984Nessuna valutazione finora

- Phrasal Verbs List PDFDocumento20 paginePhrasal Verbs List PDFNelly Vicky CruzNessuna valutazione finora

- 501 Sentence Completion QuestionsDocumento194 pagine501 Sentence Completion QuestionsSapna Ludhani100% (4)

- Small Hydro AnalysisDocumento52 pagineSmall Hydro Analysisapi-26947710100% (2)

- Bar Chart Anpara U#2 PDFDocumento1 paginaBar Chart Anpara U#2 PDFshobhan1984Nessuna valutazione finora

- Presentation of RSC Varanasi EdittedDocumento27 paginePresentation of RSC Varanasi Edittedshobhan1984Nessuna valutazione finora

- Hydrogen Sensor Fabrication FlowchartDocumento2 pagineHydrogen Sensor Fabrication Flowchartshobhan1984Nessuna valutazione finora

- Rule Based Sensor Fault IdentificationDocumento1 paginaRule Based Sensor Fault Identificationshobhan1984Nessuna valutazione finora

- Hydrogen Gas SensorsDocumento21 pagineHydrogen Gas Sensorsshobhan1984Nessuna valutazione finora

- Hydrogen Gas SensorsDocumento21 pagineHydrogen Gas Sensorsshobhan1984Nessuna valutazione finora

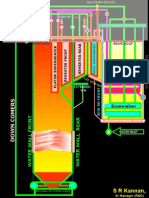

- Boiler Flow DiagramDocumento1 paginaBoiler Flow Diagramshobhan1984Nessuna valutazione finora

- Hydrogen Leakage in LMW Set (Thrust Seal)Documento2 pagineHydrogen Leakage in LMW Set (Thrust Seal)shobhan1984Nessuna valutazione finora

- Bhel RSC VaranasiDocumento29 pagineBhel RSC Varanasishobhan1984Nessuna valutazione finora

- Corruption in IndiaDocumento1 paginaCorruption in Indiashobhan1984Nessuna valutazione finora

- Threshold LogicDocumento8 pagineThreshold Logicshobhan1984Nessuna valutazione finora

- Neural LogicDocumento43 pagineNeural Logicshobhan1984Nessuna valutazione finora

- Tnerc CodesDocumento84 pagineTnerc CodesBala SubramanianNessuna valutazione finora

- Design of Multi-Channel and Distributed Wireless Communication Network in Under Water VehicleDocumento27 pagineDesign of Multi-Channel and Distributed Wireless Communication Network in Under Water Vehicleshobhan1984Nessuna valutazione finora

- Bhel RSC VaranasiDocumento30 pagineBhel RSC Varanasishobhan1984Nessuna valutazione finora

- Pros and Cons of Democracy in India and Abroad Comparison of Democracy With Other Modes of GovernmentDocumento1 paginaPros and Cons of Democracy in India and Abroad Comparison of Democracy With Other Modes of Governmentshobhan1984Nessuna valutazione finora

- Calculation of Circulating Bearing Currents in MACHINESDocumento7 pagineCalculation of Circulating Bearing Currents in MACHINESshobhan1984Nessuna valutazione finora

- Liberalized Economy Differences From State-Controlled One Which One Is BetterDocumento1 paginaLiberalized Economy Differences From State-Controlled One Which One Is Bettershobhan1984Nessuna valutazione finora

- Vibration PDFDocumento74 pagineVibration PDFshobhan1984Nessuna valutazione finora

- 19-AC Motor ProtectionDocumento16 pagine19-AC Motor ProtectionSristick100% (7)

- Overspeed Protection Device & Coincidence Limit SwitchDocumento1 paginaOverspeed Protection Device & Coincidence Limit Switchshobhan1984Nessuna valutazione finora

- 1-Turbine Operation & MaintenanceDocumento17 pagine1-Turbine Operation & Maintenanceshobhan1984Nessuna valutazione finora

- 4 A Large Steam TurbineDocumento22 pagine4 A Large Steam TurbineabhikaushikNessuna valutazione finora

- Monitoring OF Power Plant OperationDocumento9 pagineMonitoring OF Power Plant Operationshobhan1984Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Full Text of "Waterproofing EngineeringDocumento966 pagineFull Text of "Waterproofing Engineeringmazharul43Nessuna valutazione finora

- Answers & Solutions: For For For For For NTSE (Stage-I) 2017-18Documento20 pagineAnswers & Solutions: For For For For For NTSE (Stage-I) 2017-18Manish GoyalNessuna valutazione finora

- FuelDocumento172 pagineFuelImtiaz KhanNessuna valutazione finora

- Lecture 02 - Acoustics + Psychoacoustics PDFDocumento115 pagineLecture 02 - Acoustics + Psychoacoustics PDFpaolokboardNessuna valutazione finora

- Claim The Sky Preview 2021-10-04 G9r9eoDocumento16 pagineClaim The Sky Preview 2021-10-04 G9r9eoAlexandre AmorimNessuna valutazione finora

- Fan 7316Documento21 pagineFan 7316sontuyet82Nessuna valutazione finora

- Report 2012 - DPT - Chemical - Engineering - USC PDFDocumento57 pagineReport 2012 - DPT - Chemical - Engineering - USC PDFJuberthArmandoBuitragoNessuna valutazione finora

- Virtual Reality Technology and Applications-Springer Netherlands (2014)Documento236 pagineVirtual Reality Technology and Applications-Springer Netherlands (2014)Keyser SozeNessuna valutazione finora

- ECBC Implementation Experience Case StudyDocumento16 pagineECBC Implementation Experience Case StudysiddharthaNessuna valutazione finora

- Raksasa CVDocumento5 pagineRaksasa CVLydia Febriana SimanjuntakNessuna valutazione finora

- Assignment 1Documento2 pagineAssignment 1sanjana.gummuluruNessuna valutazione finora

- CHEM 212 - RecrystallizationDocumento16 pagineCHEM 212 - RecrystallizationkristaNessuna valutazione finora

- Gas BookDocumento202 pagineGas Bookomiitg67% (3)

- Banner Details: STABILIZED MUD CONCRETE BLOCK (SMCB) Is Where We Replace CoarseDocumento3 pagineBanner Details: STABILIZED MUD CONCRETE BLOCK (SMCB) Is Where We Replace Coarsemohd sohailNessuna valutazione finora

- E 126 - 92 R98 Rteyng - PDFDocumento6 pagineE 126 - 92 R98 Rteyng - PDFLuis Alberto Cristo GallegoNessuna valutazione finora

- Murray Leinster - Sidewise in TimeDocumento25 pagineMurray Leinster - Sidewise in Timemiquester50% (2)

- Ricoh mpc307 407 Parts ManualDocumento244 pagineRicoh mpc307 407 Parts Manualmark adams50% (2)

- NOTES Genchem 2 Lesson 6 Phase Diagram of Water and Carbon DioxideDocumento8 pagineNOTES Genchem 2 Lesson 6 Phase Diagram of Water and Carbon DioxidestephniedayaoNessuna valutazione finora

- Indian Engineering Services (IES) : Reference BooksDocumento6 pagineIndian Engineering Services (IES) : Reference BooksKapilNessuna valutazione finora

- Heat Transfer ProDocumento7 pagineHeat Transfer ProBorse RajNessuna valutazione finora

- Hilbert Transform and Empirical Mode Decomposition As Tools For Data Analysis - SuzDocumento18 pagineHilbert Transform and Empirical Mode Decomposition As Tools For Data Analysis - Suzjoy4riverNessuna valutazione finora

- Thermalrock S Data Sheet - inDocumento2 pagineThermalrock S Data Sheet - inlac ngoNessuna valutazione finora

- White Pigments For Flexible Packaging InksDocumento8 pagineWhite Pigments For Flexible Packaging InksHOANGVUNL1988Nessuna valutazione finora

- Prefixes and SuffixesDocumento15 paginePrefixes and SuffixesRita Otero100% (1)

- Presentation Dr. Fahmida Gulshan 1Documento30 paginePresentation Dr. Fahmida Gulshan 1Vishal SharmaNessuna valutazione finora

- Chapter 1 Smith and Van NessDocumento41 pagineChapter 1 Smith and Van NessJohn Raymart RaferNessuna valutazione finora

- Conics 2Documento8 pagineConics 2Boy ShahNessuna valutazione finora

- Air Pollution by Grade 6Documento4 pagineAir Pollution by Grade 6Eljay VinsonNessuna valutazione finora

- SPHL Sample ProblemsDocumento20 pagineSPHL Sample ProblemsĐức TiếnNessuna valutazione finora

- Electric Power Steering - An Overview of Dynamics Equation and How It - S Developed For Large VehicleDocumento8 pagineElectric Power Steering - An Overview of Dynamics Equation and How It - S Developed For Large VehiclecieloNessuna valutazione finora