Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thermosets & Thermoplastics

Caricato da

Manjunath Keshav D MDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thermosets & Thermoplastics

Caricato da

Manjunath Keshav D MCopyright:

Formati disponibili

1/19/2011

Course: B.E (EEE) Part Time Subject: APPLIED SCIENCE Unit: V

PLASTICS

Dr. K. SIVAKUMAR

Dept. of Chemistry, SCSVMV University

Syllabus: Plastics

Thermoplastics

Thermosetting plastics

Processing of plastics

Injection moulding

Blow moulding

Extrusion processes

1

THERMOPLASTICS

&

THERMOSETTING PLASTICS

1/19/2011

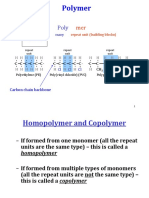

Thermoplastics (resins): Thermoplastics soften when

heated and subsequently melt. When cooled they

become hard and rigid once again.

Example: Polyethylene, PVC, Nylon

Uses: Bags, Mugs, Toys

Thermosetting plastics (resins): Thermosetting resins

do not become softy on heating & they never melt

once set.

Example: Bakelite

Uses: Electric switches, Telephone parts, Cooker

handles

3

Moulding constituents of plastic:

Higher polymer material is mixed with 4 to 10

ingredients each of which imparts some useful

property to the moulded products.

Some are,

Resins: Holds the different constituents together

Example: Linear polymers with low molecular

weights.

Resins form 40-50% of moulding mixture

Plasticisers: To increase the plasticity and flexibility

Example: Castor oil, Dibutylphthalate, Alkyl & Aryl

Phosphate etc.,

4

1/19/2011

Fillers: To impart valuable service properties such as

strength, resistance, finish and workability.

Reducing cost, shrinkage on setting and brittleness.

Example: Wood flour, asbestos, china clay, talc,

gypsum, saw dust.

Fillers form 60% of plastics

Lubricants: To facilitate the moulding operations.

Gives glossy finish

Example: Waxes, soaps, Oleates, stearates

Catalyst/accelerators:

To

accelerate

the

polymerisation (added only in thermosetting resins)

Example: Hydrogen peroxide, Benzoyl peroxide,

Metals (Ag, Cu & Pb)

5

Difference between Thermoplastics & Thermosetting plastics

S.No.

THERMOPLASTICS

THERMOSETTING PLASTICS

1.

Formed by addition Polymn.

Formed by condensation Polymn.

2.

Long chain linear polymers

Three dimensional network

structure joined by strong covalent

bonds

3.

Soften on heating and stiffen on

cooling

Do not soften on heating

4.

Can be remoulded

Cannot be remoulded

5.

Usually soft, weak & less brittle

Usually hard, strong & more brittle

6.

Can be reclaimed from wastes

Cannot be reclaimed from wastes

7.

Soluble in organic solvents

Insoluble in organic solvents

6

1/19/2011

INJECTION MOULDING (for Thermoplastics):

Materials of definite quantity at Hi Temp. is injected into a cold mould under P

In cold mould, the polymer solidifies

Polymer is fed as granules, pellets / powder through hopper

Polymer get softened in horizontal cylinder

Hydraulic piston pushes the molten material into mould

Uniform spreading inside the hot cylinder is ensured by torpedo

Molten plastic is injected through a nozzle into moulded cavity

Mould:

Consists of movable & stationary parts

Molten plastic is injected at a P of

15000kg/cm2

Proper flow of material is ensured by

preheating the mould to appropriate T

Mould is cooled by circulating water

and then opened to eject the moulded

article

7

BLOW MOULDING (for thermoplastics); [for hollow plastic articles]

To produce soft drink bottles, containers using Polyethylene, PVC, Polystyrene

PARISON hot softened thermoplastic made by injection / extrusion moulding

Parison is placed inside a two piece hollow mould (as 2 halves)

Parison kept between two halves encloses a blowing pin at one end

Other end pinches and closes

Parison is blown using pressurized air through the blow pin

1/19/2011

BLOW MOULDING: Continued

Parison kept under hot condition is inflated and expands until it comes in

contact with inner area of the cold hollow mould

Under pressure

Parison acquires the shape of hallow cavity of mould

Mould is cooled and the thermoplastic article is removed from the mould by

opening the mould

EXTRUSION MOULDING:

For producing common plastic materials

eg: films, filaments, hoses, sheets & coating wires and cables with PVC

Plastic material as powder / granules is fed into a cylinder thru hopper

Cylinder is with the provision for heating

Hot plastic is pushed thru cylinder by helically revolving screw

Due to friction the Temperature increases

10

1/19/2011

EXTRUSION MOULDING: (Continues.)

Plastic material passes through three zones

1. Feed zone

2. Compression zone

3. Metering zone

11

EXTRUSION MOULDING: (Continues.)

In compression zone, powder charge is melted by heating element

It is compressed by revolving screw

Polymer flows at a constant rate due to helical movement of screw

Pressure in this zone enables plastic to be in melted stage & enters the die

12

1/19/2011

EXTRUSION MOULDING: (Continues.)

From die moulded plastic is coming out in desired profile

Extrudated material from die is hot and hence it is cooled rapidly to

avoid any deshaping

Cooling by passing extrudate over a conveyor belt through which

tubes of cold water/cold air are passed

13

Potrebbero piacerti anche

- MAE250LPlastics ProcessingDocumento40 pagineMAE250LPlastics ProcessingLuckyLokeShNessuna valutazione finora

- Unit-6 Plastic MouldingDocumento12 pagineUnit-6 Plastic MouldingManav Patel100% (1)

- Ceramic Plastics CompositesDocumento45 pagineCeramic Plastics Compositesዘረአዳም ዘመንቆረርNessuna valutazione finora

- 1.0 Mould Intro On PlasticsDocumento17 pagine1.0 Mould Intro On Plasticsnurul ainiNessuna valutazione finora

- 6 Plastic Processing ReducedDocumento16 pagine6 Plastic Processing Reducedhb8btk4s8cNessuna valutazione finora

- Plastics ProcessingDocumento19 paginePlastics ProcessingAnonymous mRBbdopMKfNessuna valutazione finora

- Processing of PolymersDocumento105 pagineProcessing of PolymersAftaab AlamNessuna valutazione finora

- Thermoplastic and ThermosetDocumento8 pagineThermoplastic and ThermosetRenzo Cadag MacasilNessuna valutazione finora

- Unit 4 (BCHE-602)Documento14 pagineUnit 4 (BCHE-602)Garima TamtaNessuna valutazione finora

- Polymer Processing TechniquesDocumento9 paginePolymer Processing TechniquesShalini VirdiNessuna valutazione finora

- Fabrication of Plastics, Ceramics, and Composites: (Review)Documento34 pagineFabrication of Plastics, Ceramics, and Composites: (Review)Joshua StrykrNessuna valutazione finora

- 202004032240236827nksingh Polymer ProcessingDocumento9 pagine202004032240236827nksingh Polymer ProcessingMuhammad Umair Akbar GujjarNessuna valutazione finora

- Manufacturing of PlasticsDocumento39 pagineManufacturing of PlasticsShivani MedarapuNessuna valutazione finora

- Plastic Processing: Extrusion Compression MouldingDocumento19 paginePlastic Processing: Extrusion Compression MouldingMohsen SaidiNessuna valutazione finora

- Unit v-mt1Documento22 pagineUnit v-mt1Mareeswaran Maruthamuthu MNessuna valutazione finora

- Plastic Moulding ProcessDocumento28 paginePlastic Moulding ProcessQUAZI ADYAN AHMAD 160419736049Nessuna valutazione finora

- Polymers PPT PDFDocumento47 paginePolymers PPT PDFShivani RajeevNessuna valutazione finora

- POLYMER PROCESSING HandoutDocumento4 paginePOLYMER PROCESSING HandoutAmabelle SantosNessuna valutazione finora

- Plasting ProcessingDocumento19 paginePlasting Processingnethumini GunawardanaNessuna valutazione finora

- Gear Type Injection Moulding MachineDocumento4 pagineGear Type Injection Moulding MachineJeya KumarNessuna valutazione finora

- EAT227-Lecture 8 - Shaping ProcessDocumento18 pagineEAT227-Lecture 8 - Shaping ProcessQim SvNessuna valutazione finora

- Unit-5 - Plastic Processing (51-94)Documento44 pagineUnit-5 - Plastic Processing (51-94)jasvinder singhNessuna valutazione finora

- Blowmolding 120209032429 Phpapp01Documento16 pagineBlowmolding 120209032429 Phpapp01luan_baNessuna valutazione finora

- Production Methods BiopolymersDocumento22 pagineProduction Methods BiopolymersAdamNessuna valutazione finora

- Processing of Ceramics, Glass and PlaticsDocumento23 pagineProcessing of Ceramics, Glass and Platicsabhist singhNessuna valutazione finora

- Injection Moulding MachineDocumento4 pagineInjection Moulding MachinescbrajaNessuna valutazione finora

- Injection MouldingDocumento23 pagineInjection MouldingPrathmeshBhokari100% (1)

- Processing of PolymersDocumento36 pagineProcessing of Polymerssaadahmedkalidaas100% (1)

- MouldingDocumento18 pagineMouldingNabin BaskotaNessuna valutazione finora

- ThermoplasticDocumento3 pagineThermoplasticsumankumariNessuna valutazione finora

- Unit Vi. Polymeric Materials: Topic OutlineDocumento7 pagineUnit Vi. Polymeric Materials: Topic OutlineIvyy Joyce BuanNessuna valutazione finora

- Manufacturing Process of Bubble WrapDocumento2 pagineManufacturing Process of Bubble WrapAreeb AbidNessuna valutazione finora

- Polymer Notes 2014 Parts 8-11 PDFDocumento42 paginePolymer Notes 2014 Parts 8-11 PDFRadhiNessuna valutazione finora

- UntitledDocumento61 pagineUntitledDr. Sharad GaikwadNessuna valutazione finora

- FilmsDocumento2 pagineFilmsElisya DiantyNessuna valutazione finora

- Manufacturing of Plastic ComponentsDocumento50 pagineManufacturing of Plastic ComponentsrameshwarmaNessuna valutazione finora

- Lecture 6Documento25 pagineLecture 6Ishtiaq AhmedNessuna valutazione finora

- Processing of PolymersDocumento15 pagineProcessing of PolymersK Sruti RaniNessuna valutazione finora

- VisteonDocumento34 pagineVisteonAmbareesh NarayanpetNessuna valutazione finora

- Polymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeDocumento26 paginePolymer Processing (Molding) : D. Jim Livingston Faculty of Chemistry, St. John's CollegeJim LivingstonNessuna valutazione finora

- Part 4 - 2 - Polymers Processing TechsDocumento42 paginePart 4 - 2 - Polymers Processing TechsAlemu MergaNessuna valutazione finora

- Unit 1Documento26 pagineUnit 1vaishnavi ChamartiNessuna valutazione finora

- Plastics ManufacturingDocumento39 paginePlastics ManufacturingSparsh KatiyarNessuna valutazione finora

- Plastic ProcessesDocumento27 paginePlastic Processesnitouch3564Nessuna valutazione finora

- ManufacturingDocumento29 pagineManufacturingAbel BatuNessuna valutazione finora

- Plastic Processing TechniquesDocumento8 paginePlastic Processing TechniquesSohail Anwar KhanNessuna valutazione finora

- Manufacturing Processes: ME 335 432 Lecture #16Documento36 pagineManufacturing Processes: ME 335 432 Lecture #16abdullah sulimanNessuna valutazione finora

- MODULE I Injection Molding ProcessDocumento40 pagineMODULE I Injection Molding ProcessAntonius PrakosaNessuna valutazione finora

- Injection Permanent Molding and Extrution Machine: Case StudyDocumento7 pagineInjection Permanent Molding and Extrution Machine: Case StudyBrown MeshNessuna valutazione finora

- Blow Moulding: BY-Jai Talwar Jigisha K Kaushika Kartik Kartik Kedia Khushi SharmaDocumento11 pagineBlow Moulding: BY-Jai Talwar Jigisha K Kaushika Kartik Kartik Kedia Khushi SharmaKartik KediaNessuna valutazione finora

- Polymer and Ceramic ProcessingDocumento43 paginePolymer and Ceramic ProcessingnvemanNessuna valutazione finora

- 2.4 Fabrication Process of PolymerDocumento10 pagine2.4 Fabrication Process of Polymersalmie_77Nessuna valutazione finora

- Polymer MFGDocumento51 paginePolymer MFGPranav KaushikNessuna valutazione finora

- Mold Design PDFDocumento17 pagineMold Design PDFjahir khanNessuna valutazione finora

- Plastics and Related ProductsDocumento74 paginePlastics and Related ProductsRoland CepedaNessuna valutazione finora

- Manufacturing Rocesses - I - Unit III - Plastic ProcessingDocumento22 pagineManufacturing Rocesses - I - Unit III - Plastic ProcessingPramod WadateNessuna valutazione finora

- Moulding TechniquesDocumento24 pagineMoulding TechniquesBubbleNessuna valutazione finora

- Clear and Plastic Danger: The Alien in your KitchenDa EverandClear and Plastic Danger: The Alien in your KitchenValutazione: 4 su 5 stelle4/5 (1)

- Sci Worksheet W2 Act 2Documento5 pagineSci Worksheet W2 Act 2Mae GuerreroNessuna valutazione finora

- Performance Analysis of Locally Design Plastic Crushing Machine For Domestic and Industrial Use in NigeriaDocumento6 paginePerformance Analysis of Locally Design Plastic Crushing Machine For Domestic and Industrial Use in NigeriaRishokNessuna valutazione finora

- Full Thesis Diah Nazirah Binti Roma (F16A0050) PDFDocumento89 pagineFull Thesis Diah Nazirah Binti Roma (F16A0050) PDFhmossNessuna valutazione finora

- Reading Comprehension SPM2020Documento3 pagineReading Comprehension SPM2020cherry mie'aNessuna valutazione finora

- Passive VoiceDocumento2 paginePassive Voicebrenda servinNessuna valutazione finora

- Science For Life 9: VELS Chapter GridsDocumento58 pagineScience For Life 9: VELS Chapter GridsSAMMARNessuna valutazione finora

- Horizontal Boundary of RFL Plastic LTDDocumento8 pagineHorizontal Boundary of RFL Plastic LTDMohammed Zahidul IslamNessuna valutazione finora

- BykDocumento5 pagineByksamratsamudraguptaNessuna valutazione finora

- Design StuffDocumento3 pagineDesign StuffSaskaNessuna valutazione finora

- Order Form: Shipping Sub-Total Sub-TotalDocumento1 paginaOrder Form: Shipping Sub-Total Sub-TotalTheodore LiwonganNessuna valutazione finora

- Intensification of Yam-Starch Based Biodegradable Bioplastic Film With Bentonite For Food Packaging Application (2022)Documento12 pagineIntensification of Yam-Starch Based Biodegradable Bioplastic Film With Bentonite For Food Packaging Application (2022)Mahmoud BelabbassiNessuna valutazione finora

- Class 17-25Documento716 pagineClass 17-25Parvez khanNessuna valutazione finora

- The Plastic ProblemDocumento5 pagineThe Plastic ProblemCJ LayosaNessuna valutazione finora

- Dielectric Materials Types and ApplicationsDocumento34 pagineDielectric Materials Types and ApplicationspkumarmysNessuna valutazione finora

- Science Vi: Values: Appreciation of Household Materials Draw Neatly and Accurately CooperationDocumento11 pagineScience Vi: Values: Appreciation of Household Materials Draw Neatly and Accurately CooperationElizerNessuna valutazione finora

- ADB 154 - AdbustersDocumento80 pagineADB 154 - AdbustersTerceiro NeurônioNessuna valutazione finora

- W9 ScienceDocumento10 pagineW9 ScienceLeny GanalonNessuna valutazione finora

- DBL 5404 - 2014Documento38 pagineDBL 5404 - 2014Mateo BanzanNessuna valutazione finora

- Enhancing The Bio Plastic Produced Out of Potato Starch Using The Calcium Carbonate Content of Eggshells MANUSCRIPT FINAL 5TH FILE 1Documento21 pagineEnhancing The Bio Plastic Produced Out of Potato Starch Using The Calcium Carbonate Content of Eggshells MANUSCRIPT FINAL 5TH FILE 1Cristine Angela BattungNessuna valutazione finora

- Chisorb 519: Light StabilizerDocumento3 pagineChisorb 519: Light StabilizerHai NguyenNessuna valutazione finora

- Characterization of Municipal Solid Waste in Sunder Nagar, Himachal Pradesh, IndiaDocumento8 pagineCharacterization of Municipal Solid Waste in Sunder Nagar, Himachal Pradesh, Indiazohain sethNessuna valutazione finora

- Correlation of Test Methods To Evaluate The Thermal Stability of Neat PVC ResinDocumento20 pagineCorrelation of Test Methods To Evaluate The Thermal Stability of Neat PVC ResinlouisNessuna valutazione finora

- ReduceDocumento33 pagineReduceAnonymous PyRIcWNessuna valutazione finora

- The Possibility of Making An Umbrella and Raincoat in A Plastic WrapperDocumento15 pagineThe Possibility of Making An Umbrella and Raincoat in A Plastic WrapperMadelline B. TamayoNessuna valutazione finora

- Industrial Training Report 19ME559 (PARTH MALDHURE)Documento23 pagineIndustrial Training Report 19ME559 (PARTH MALDHURE)Parth MaldhureNessuna valutazione finora

- A Brief Literature Review On Optimization of Plastic Injection Moulding Process Parameters For Various Plastic Materials by Using Taguchi's TechniqueDocumento9 pagineA Brief Literature Review On Optimization of Plastic Injection Moulding Process Parameters For Various Plastic Materials by Using Taguchi's TechniqueAnand BhiseNessuna valutazione finora

- Testing Methods of Chemical Resistance For Plastic Parts: Nissan Engineering StandardDocumento13 pagineTesting Methods of Chemical Resistance For Plastic Parts: Nissan Engineering StandardjenwitbunjongsatNessuna valutazione finora

- Paper vs. PlasticDocumento29 paginePaper vs. PlasticCari BalboaNessuna valutazione finora

- Sample ResearchDocumento2 pagineSample ResearchAngelica DacuycuyNessuna valutazione finora

- Synthesis of PolymersDocumento4 pagineSynthesis of PolymersYana AnguloNessuna valutazione finora