Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cathodic Protection - Quality Control Procedure

Caricato da

Ahmed GomaaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cathodic Protection - Quality Control Procedure

Caricato da

Ahmed GomaaCopyright:

Formati disponibili

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

SE-003-QCP-PRC-021

Discipline: QCP

SEPOC/ENG-2009.0002.1:

YLNG Upstream Facilities:

Phase-II Construction Work

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

1 of 7

HAWK BERKSAN

Joint Venture

QUALITY CONTROL PROCEDURE

CATHODIC PROTECTION SYSTEM

IFA

13-Mar-10

Issue For

Approval

Prem CP

J.John

S.Jetti

UK Sikdar

Rev.

Status

Date

Revision memo

Issued by

HBJV

Checked by

HBJV

Approved by

HBJV

Approved by

SEPOC

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

TABLE OF CONTENTS

Discipline: QCP

SE-003-QCP-PRC-021

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

2 of 7

PAGE NO

.1

INTRODUCTION

.2

PURPOSE AND SCOPE

.3

REFERENCES

.4

DEFINITIONS / ABBREVIATIONS

.5

ORGANIZATIONS AND RESPONSILITIES

4-5

.6

SEQUENCE OF PROCEDURE/METHODS

5-7

.7

DOCUMENT

ITP forms

3-4

4

7

Pages 4

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

Discipline: QCP

SE-003-QCP-PRC-021

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

3 of 7

1. INTRODUCTION

This project Quality Control Procedure is established for the Quality control of the

CATHODIC PROTECTION SYSTEM INSTALLATION for YLNG Upstream Facilities

Phase II construction work. This applies to all HBJV employees who are working for these

particular activities

2. SCOPE and PURPOSE

The Quality Control Procedure explains the minimal requirement of the Quality system for

various activities involved in CATHODIC PROTECTION SYSTEM INSTALLATION

Method implemented for these particular activities.

Maintain the workmanship for the entire work period

Closely Monitoring during performance of each activity

Proper documentation is to be maintained upon completion of each activity

Within the scope of works at YLNG Upstream Facilities-Phase II Construction Work Contract

in accordance with EXHIBIT A: Scope of Work & Services to Company as per project

specification

The purpose of the procedure is to control the quality requirement, closely monitoring all

activities related to CATHODIC PROTECTION SYSTEM INSTALLATION and to ensure that

works comply with Project Specifications and Technical Standards related to YLNG Upstream

Facilities-Phase-II Construction Work Contract in accordance with EXHIBIT A: Scope of Work &

Services to Company.

3. REFERENCES

3.1 PROJECT SPECIFICATIONS

3.2 EXHIBIT A Scope of Works

3.3 PROJECT REFERENCE DOCUMENTS/DRAWINGS

3.4 METHOD OF STATEMENT

3.5 INSPECTION AND TEST PLAN

4. DEFINITIONS / ABBREVIATIONS

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

TERM

Method Statement

Company

Const. Contractor

YLNG

ITP

IFC

QA/QC

E&I

HSE

PPE

MCT

MCC

CP

QCP

Discipline: QCP

SE-003-QCP-PRC-021

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

4 of 7

DESCRIPTION

A Written document that explains the planned execution method to control

the work at various stages and assure quality

Safer Exploration & Production Operation Company. (SEPOC)

HAWK BERKSAN Joint Venture.(HBJV)

Yemen Liquid Natural Gas

Inspection Test Plan

Issued for Construction

Quality Assurance and Quality Control

Electrical And Instrumentation

Health, Safety and Environment

Personal Protection Equipment

Mechanical Transit

Motor Control Center

Cathodic Protection

Quality Control Procedure

5. RESONSIBILITIES

QA/QC Manager is responsible to organize resources to perform QC systems, QC

Supervisors, QC Inspectors to monitor Cathodic Protection System Installation

activities including HSE requirements for the particular activity. He will be responsible

to monitor and control the activities and report to the Project Manager

E&I Construction Manager is responsible to ensure that Cathodic Protection System

Installation activities are executed according to the relevant project specifications and

in compliance with quality assurance and HSE requirements within his area and

discipline. Before starting any activity he is responsible for conducting a toolbox talks

with his crews. He will be reporting to Deputy Project Manager regarding detailed

activities of each day and co-ordinate with QC documentation

E&I QA/QC Superintendent is responsible for all the Quality Control during Cathodic

Protection System Installation activities are executed according to the IFC drawings

and QCP & ITP with required quality system. He will be reporting to E & I QA/QC

Manager regarding the particular activities daily wise.

E & I QA/QC Engineers / Inspectors is the overall responsible to ensure that quality

requirements of the Cathodic Protection System Installation like are met and record

all the activities in the specified form and He will be reporting to E & I QA/QC

Superintendent daily wise

E & I Supervisor/Foreman will be responsible for the complete E & I crews performing

the job at site as per the approved procedure IFC Drwgs. They are also responsible

for the Safety of the crews and meet the Quality requirements for the projects and will

be reporting E & I Superintendent daily wise

E & I Technicians/Electricians will be responsible to ensure that the Cathodic

Protection System Installation are carried out as per the instruction of the

Supervisor/foreman. They are also responsible to maintain the Quality system and

workmanship as per the project requirements. During performing the work all the

safety regulation should be followed strictly.

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

Discipline: QCP

SE-003-QCP-PRC-021

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

5 of 7

HSE will responsible to ensure that all the works are performed safely as per the

HSE requirements. E&I Supervisor/Foremen must make sure proper works permits

are issued for the particular activities and works permit should be kept at work area.

It is the duty of the HSE officers to monitor any unsafe activities of the crew during

site performance of the crews under him and house keeping is mandatory every end

of working days. Job Description of HSE Officer is attached.

6. SEQUENCE OF PROCEDURE AND METHODS

6.1 MANPOWER

The Electrical & Instrumentation QA/QC Inspectors will control the Inspection and Testing

activities and he will be directly reporting to the E & I QA/QC Superintendent. The E & I

Supervisor will perform the test and E & I QA/QC Representative from HBJV and SEPOC will

witness the test. The basic manpower under E & I Supervisor will consist of the following

5.1 E & I Foreman

5.2 E & I Technician

5.3 E & I Helpers

5.4 Safety Officer/Safety Watcher

6.2 TOOLS AND EQUIPMENT

Tools and Equipment should be in good condition and must be checked by E & I supervisor

prior to use. The E & I QA/QC representative from HBJV and SEPOC will check the Third party

calibration certificate, Date of Validity and Due date of all the Test equipment of These includes

but not limited to:

6.2.1 EXECUTION

Hand Tools

Transformer Oil tester

Torque wrench

Multi Meter with test leads

Mega Ohm Meter with test leads

Insulation flange tester

6.2.2 HSE

Safety Coverall

Safety Helmet

Safety Boot

Safety Goggles

Safety Gloves

Full body Harness (If required)

Dust Mask (If required)

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

6.3

Discipline: QCP

SE-003-QCP-PRC-021

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

6 of 7

Ear Protection (If Required)

INITIAL SET UP:

6.4

Work shall be started only after getting a valid work permit as applicable

Safety line should be used when working at height as required.

All personnel performing works should wear basic PPE such as Safety Shoes,

goggles, hand gloves, hard-hat and cover all.

Toolbox talk shall be conducted to keep all the personnel aware of job activity

involved.

Make sure all the elevated scaffolds are inspected and tagged green. Before wearing

the safety harness a thorough check-up should be carried out for the worn out parts

and satisfy.

CATHODIC PROTECTION SYSTEM

Verify the Method of Statement /Procedure preparation and it meeting the project

specification, Project standards and IFC drawings

Verify all the Test Equipment third party calibration certificate, Date of validity,

Calibration Due date and the working condition of the equipments prior to start the

activity

Verify the material test certificate against the data sheets and confirm it is meeting the

project specification and requirements

Verify the construction is following the steps which have mentioned in approved

procedure during Cathodic Protection system installation

During the inspection of the Transformer-Rectifier installation, check the location as per

the IFC layout drawing, Civil foundation is installed as per the IFC drawing and project

standards, civil is provided enough conduit sleeves for cabling as per the electrical

standard installation details and completed the QC documentation, approved by the

COMPANY

Check the fabrication of the base frame (If applicable) for good workmanship, painting

and installation methods are matching with the standard installation details drawing

After installation of the Transformer-Rectifier check the orientation, alignment, fixing

methods etc...

Check the transformer for the internal damages, Breaker/Fuse rating, internal wiring,

marking, tightness of the connections etc....

Check for the external damages, oil level, oil leakages, breather installation, indicators

etc...

After the visual inspection carry out the winding continuity, resistance test and

insulation resistance test and record all the test results in the respective ITP forms.

Check the transformer-rectifier for the gland plate penetrations as per the cable

schedule and all the spare entries are plugged with certified plugs as per the area

classification, ready for cabling, glanding and termination

After the installation of the Reference anode and reference electrode junction box

check the Support fabrication, painting and installation as per the standard installation

details drawing. And Junction box installation, bolting as per the standard drawing

Reference Anode and reference electrode Junction box check for the internal and

external damages, internal wiring, marking, tightness of the connections etc...

Reference Anode and reference electrode Junction Box check for gland plate

penetrations as per the cable schedule and all the spare entries are plugged with

certified plugs as per the area classification, Ready for glanding and termination.

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Document Number:

CATHODIC PROTECTION SYSTEM

Document Type: PRC

Contractor Number : SEPOC-ENGG-2009-0002.1

Discipline: QCP

SE-003-QCP-PRC-021

Revision A

Status : IFA

Rev Date :13-Mar-2010

Page

7 of 7

After the installation of the Anode/electrode, check Installed as per the standard

installation details, Anode/Electrode main cable to anode JB and anode/electrode cable

splicing /jointing with approved splice/joint kit and protected well

Check the number of anodes, anode loop resistance and record as per the respective

ITP form

Check the anode ribbon to conductor bar installation and connection as per standard

installation drawing with proper spot welding

Check the test posts were installed as per the IFC layout drawings and it is matching

the typical installation detail drawings. Check for the alignment, verticality, terminal box

and terminal damages and missing bolts, nuts and washers and ready for cabling and

termination

After the completion of the termination, check the termination standards, marking and

tightness.

Carry out the soil potential reference cell test with portable copper/copper sulphate

electrode and the record the results as per the respective ITP forms.

Check the insulating flanges installed as per the piping layout drawing complete the

insulating flange test with insulating flange tester or Megger tester

Carry out the final Inspection, area and internal cleanliness, Document review and

ready for energize

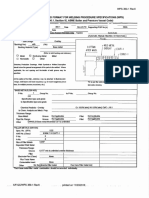

The following are the Inspection and test forms to be followed during the Inspection of

the Cathodic Protection system Inspection

1. QCP-701-CS-20 Cathodic Protection system Transformer-Rectifier

2. QCP-701-CS-21 Cathodic Protection System

3. QCP-701-TS-20 Cathodic Protection system Transformer-Rectifier

4. QCP-701-TS-21 Cathodic Protection System

7. DOCUMENT

ITP forms-

4 Pages

This document is the property of COMPANY it must not be stored, reproduced or disclosed to others without written authorization from the Company.

Potrebbero piacerti anche

- Cathodic ProtectionDocumento7 pagineCathodic ProtectionWaheeb SaidNessuna valutazione finora

- Cathode Protection ITPDocumento19 pagineCathode Protection ITPBilibili weekly TOP 10 videosNessuna valutazione finora

- ITP Inspection and Test Plan 6MODocumento2 pagineITP Inspection and Test Plan 6MOAS DevNessuna valutazione finora

- NDT Inpection ManuelDocumento120 pagineNDT Inpection Manuelhideko007Nessuna valutazione finora

- Project Quality Plan: Document No: BK91-1312-INF-829-QAC-PLN-0001Documento53 pagineProject Quality Plan: Document No: BK91-1312-INF-829-QAC-PLN-0001Berry UmpolaNessuna valutazione finora

- Method Statement Cathodic ProtectionDocumento10 pagineMethod Statement Cathodic Protectionkamil67% (3)

- Cathodic Protection SystemDocumento11 pagineCathodic Protection SystemphuongNessuna valutazione finora

- Cathodic Protection en - WikipediaDocumento8 pagineCathodic Protection en - WikipediaPRABHU SHANKAR MNessuna valutazione finora

- SP 1129Documento25 pagineSP 1129Selva NizanthNessuna valutazione finora

- Auditing of Cathodic Protection Systems and Anticorrosion Coating Conservation Status in Oil and Gas Pipelines (CIPS - DCVG Surveys)Documento14 pagineAuditing of Cathodic Protection Systems and Anticorrosion Coating Conservation Status in Oil and Gas Pipelines (CIPS - DCVG Surveys)Laith SalmanNessuna valutazione finora

- ES-L-60 REV2.1 Spec For Inspection of Subsea PipelinesDocumento50 pagineES-L-60 REV2.1 Spec For Inspection of Subsea PipelinesVivek Patil100% (2)

- Platform Inspection-General Report Template R001Documento44 paginePlatform Inspection-General Report Template R001St3fandragos4306100% (2)

- QAQC ManualDocumento33 pagineQAQC ManualNagender Shreeram100% (1)

- Itp PipingDocumento15 pagineItp PipingEkhy Transmisi100% (1)

- KP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Documento7 pagineKP-00+++-CQ712-G0011 - Rev.A - ITP For For Cathodic Protection (CP)Utku Can Kılıç100% (2)

- Cathodic Protection Works Forms Which Will Be Attached To The ITPDocumento7 pagineCathodic Protection Works Forms Which Will Be Attached To The ITPUtku Can Kılıç100% (1)

- DC Voltage Gradient Surveys: Frequently Asked QuestionsDocumento26 pagineDC Voltage Gradient Surveys: Frequently Asked QuestionsVCNessuna valutazione finora

- DCVG MethodDocumento12 pagineDCVG MethodAmanSharmaNessuna valutazione finora

- Inspection and Test Plan For Structure Steel Erection WorksDocumento11 pagineInspection and Test Plan For Structure Steel Erection WorksVijaya BaraniNessuna valutazione finora

- Method Statement For Cathodic Protection SystemDocumento30 pagineMethod Statement For Cathodic Protection SystemLaith Hamid86% (7)

- Request For Inspection (Rfi) : Project TitleDocumento2 pagineRequest For Inspection (Rfi) : Project TitleJing Wei Fong100% (1)

- Attachment I Itp Cathodic PDocumento3 pagineAttachment I Itp Cathodic Pmhamoet100% (2)

- QP-018, Quality Manual Procedure For Coupon and Probes MonitoringDocumento12 pagineQP-018, Quality Manual Procedure For Coupon and Probes MonitoringIksan Adityo MulyoNessuna valutazione finora

- Qa-Qc Quality PDFDocumento60 pagineQa-Qc Quality PDFNaveed Ahmed Get-InfoNessuna valutazione finora

- 4.-QA-QC-Plan-job Desc Field PDFDocumento12 pagine4.-QA-QC-Plan-job Desc Field PDFAli HajirassoulihaNessuna valutazione finora

- 9686-6150-ITP-000-0004 - B1 Inspection Test Plan For Cathodic ProtectionDocumento17 pagine9686-6150-ITP-000-0004 - B1 Inspection Test Plan For Cathodic Protectionvenkatesh100% (1)

- Report On Bonded Flexible Pipes2009Documento56 pagineReport On Bonded Flexible Pipes2009mostafa_1000100% (1)

- Procedure For Holiday Testing PDFDocumento2 pagineProcedure For Holiday Testing PDFSaptarshi MandalNessuna valutazione finora

- ECDA Indirect InspectionsDocumento24 pagineECDA Indirect InspectionskhanhtruongNessuna valutazione finora

- Flushing ProcedureDocumento1 paginaFlushing Proceduremahi1437Nessuna valutazione finora

- ITP's and ITR's A Necessary - Monster - PDFDocumento5 pagineITP's and ITR's A Necessary - Monster - PDFshastri85Nessuna valutazione finora

- SP-1171 Specification For Quality Assurance Requirements For Product and Service - Rev2Documento26 pagineSP-1171 Specification For Quality Assurance Requirements For Product and Service - Rev2shashi_nsp100% (2)

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocumento1 paginaStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNessuna valutazione finora

- x5 Cathodic Protection Construction ProgramDocumento10 paginex5 Cathodic Protection Construction ProgramNoor A Qasim100% (1)

- Cathodic Protection System For Offshore StructureDocumento13 pagineCathodic Protection System For Offshore StructureheikelNessuna valutazione finora

- SETTLEMENT Test ProcedureDocumento9 pagineSETTLEMENT Test Procedurehrdsby100% (2)

- Testing CertificationDocumento2 pagineTesting Certificationmanox007Nessuna valutazione finora

- Blasting & Coating Procedure For Fabricated Steel StructureDocumento8 pagineBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Site QAQC PlanDocumento9 pagineSite QAQC PlanP SHANKAR BABU100% (1)

- 04CP Survey Methods For Offshore PipelinesDocumento11 pagine04CP Survey Methods For Offshore PipelinesDeepoffshore Dalgıç100% (1)

- QA QC ProceduresDocumento16 pagineQA QC ProceduresAmir Shaik100% (2)

- 00.1.corrosion Control Jetty PileDocumento48 pagine00.1.corrosion Control Jetty PileSyafrudin MegnumzNessuna valutazione finora

- Cathodic Protection Drawings SP-1136Documento4 pagineCathodic Protection Drawings SP-1136anuprajoshNessuna valutazione finora

- Vessel Cleaning ProcedureDocumento6 pagineVessel Cleaning ProcedureZool HilmiNessuna valutazione finora

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDocumento17 pagineInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- Itp PaintingDocumento14 pagineItp PaintingNamta George100% (4)

- (Package-2-Mech Works) : Clean Fuels ProjectDocumento14 pagine(Package-2-Mech Works) : Clean Fuels ProjectsarangpuneNessuna valutazione finora

- Method Statement For Installation of Gate Valves & Check Valves (Ps-17, Ps40 &Psw1)Documento18 pagineMethod Statement For Installation of Gate Valves & Check Valves (Ps-17, Ps40 &Psw1)shujad77100% (1)

- MUKSYN-Procedure For Radiographic TestingDocumento24 pagineMUKSYN-Procedure For Radiographic Testingcloud23100% (1)

- Subsea Riser Pipeline Visual Inspection ProcedureDocumento13 pagineSubsea Riser Pipeline Visual Inspection ProcedureMy Osoef100% (1)

- Cable Tray & Ladder ITPDocumento1 paginaCable Tray & Ladder ITPSyed Kareem Iqbal100% (1)

- Cathodic Protection System Inspection and Test PlanDocumento10 pagineCathodic Protection System Inspection and Test PlanNoor A QasimNessuna valutazione finora

- Cathodic Protection PDFDocumento24 pagineCathodic Protection PDFJorge Luis Clavijo Iturri50% (2)

- Load Test ProcedureDocumento70 pagineLoad Test ProcedureMohammed Rizwan Ahmed75% (4)

- Method Statement GIS HV TestDocumento28 pagineMethod Statement GIS HV Testnayagammailbox75% (4)

- 3.0 Inspection & Test PlanDocumento10 pagine3.0 Inspection & Test PlanAbdul Hakam Mohamed Yusof80% (5)

- Installation of Fire Detection SystemDocumento8 pagineInstallation of Fire Detection SystemUtku Can KılıçNessuna valutazione finora

- DRP001 Ouf Pro Q 000 515 O1Documento15 pagineDRP001 Ouf Pro Q 000 515 O1Daniel MartinezNessuna valutazione finora

- p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemDocumento5 paginep103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemAnandu AshokanNessuna valutazione finora

- ELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermDocumento15 pagineELS013 - Rev10 - Gen Spec For Fabrication of Composite ThermAhmed GomaaNessuna valutazione finora

- DVS 2203 - 01 Testing of Welded Joints of Thermoplastic Sheets and PipesDocumento2 pagineDVS 2203 - 01 Testing of Welded Joints of Thermoplastic Sheets and PipesAhmed GomaaNessuna valutazione finora

- DVS 2203 - 05 Testing of Welded Joints of Thermoplastics Plates and Tubes Technological Bend TestDocumento3 pagineDVS 2203 - 05 Testing of Welded Joints of Thermoplastics Plates and Tubes Technological Bend TestAhmed GomaaNessuna valutazione finora

- Erection Welding and Lamination of Plastic Pipelines UN 9253-07Documento8 pagineErection Welding and Lamination of Plastic Pipelines UN 9253-07Ahmed GomaaNessuna valutazione finora

- WPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelDocumento1 paginaWPS-02 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless SteelAhmed Gomaa100% (1)

- 04-Project Integration Management-2019!06!13 13-20-09Documento113 pagine04-Project Integration Management-2019!06!13 13-20-09Ahmed GomaaNessuna valutazione finora

- 125 Useful English PhrasesDocumento11 pagine125 Useful English PhrasesMohan PereraNessuna valutazione finora

- WPS 360-1 Rev0 PDFDocumento14 pagineWPS 360-1 Rev0 PDFAhmed GomaaNessuna valutazione finora

- JSA - Mechanical-Excavation PDFDocumento1 paginaJSA - Mechanical-Excavation PDFAhmed GomaaNessuna valutazione finora

- How To Use MPI Yokes PDFDocumento12 pagineHow To Use MPI Yokes PDFAhmed Gomaa100% (1)

- Quantitative Metallography of Two-Phase Titanium AlloysDocumento6 pagineQuantitative Metallography of Two-Phase Titanium AlloysAhmed GomaaNessuna valutazione finora

- Hirarc - Hazard Identification, Risk Assessment & Risk Control PDFDocumento21 pagineHirarc - Hazard Identification, Risk Assessment & Risk Control PDFAhmed GomaaNessuna valutazione finora

- Numero 35 Art 25 PDFDocumento10 pagineNumero 35 Art 25 PDFAhmed GomaaNessuna valutazione finora

- Processing of Titanium & Aluminium AlloysDocumento61 pagineProcessing of Titanium & Aluminium AlloysAhmed GomaaNessuna valutazione finora

- Modeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysDocumento26 pagineModeling Mechanical Properties of Welds in Plates of Commercial Titanium AlloysAhmed GomaaNessuna valutazione finora

- Ruthenium Enhanced: TitaniumDocumento8 pagineRuthenium Enhanced: TitaniumAhmed GomaaNessuna valutazione finora

- WJ 2007 12 PDFDocumento124 pagineWJ 2007 12 PDFAhmed GomaaNessuna valutazione finora

- Fulltext PDFDocumento151 pagineFulltext PDFAhmed GomaaNessuna valutazione finora

- Welding of An Advanced High Strength Titanium AlloyDocumento8 pagineWelding of An Advanced High Strength Titanium AlloyAhmed GomaaNessuna valutazione finora

- Irndt Central Certification Program For NDT PersonnelDocumento31 pagineIrndt Central Certification Program For NDT PersonnelAhmed GomaaNessuna valutazione finora

- Characterization of Refractory Titanium Alloys Welded by TIG and Laser ProcessesDocumento5 pagineCharacterization of Refractory Titanium Alloys Welded by TIG and Laser ProcessesAhmed GomaaNessuna valutazione finora

- Fawad Hussain, Feedback On Industrial Visit To Sahiwal Coal Power PlantDocumento2 pagineFawad Hussain, Feedback On Industrial Visit To Sahiwal Coal Power PlantSyed Fawad MarwatNessuna valutazione finora

- Leave of Absence Form (Rev. 02 072017)Documento1 paginaLeave of Absence Form (Rev. 02 072017)KIMBERLY BALISACANNessuna valutazione finora

- Trane Air Cooled Scroll Chillers Installation Operation MaintenanceDocumento276 pagineTrane Air Cooled Scroll Chillers Installation Operation MaintenanceBay Mưa100% (1)

- RDG UNIT 2 Skimming Class A 2021Documento17 pagineRDG UNIT 2 Skimming Class A 2021Yuly Rumondang Wulan SiallaganNessuna valutazione finora

- BlahDocumento8 pagineBlahkwood84100% (1)

- 1 PolarographyDocumento20 pagine1 PolarographyRiya Das100% (1)

- Foundation Engineering. 02 Soil CompressibilityDocumento63 pagineFoundation Engineering. 02 Soil Compressibilitysammy lopezNessuna valutazione finora

- Theories of Learning and Learning MetaphorsDocumento4 pagineTheories of Learning and Learning MetaphorsTrisha Mei Nagal50% (2)

- W01 M58 6984Documento30 pagineW01 M58 6984MROstop.comNessuna valutazione finora

- Guimbungan, Core Competency Module 1 - Part 3 PDFDocumento11 pagineGuimbungan, Core Competency Module 1 - Part 3 PDFSharlyne K. GuimbunganNessuna valutazione finora

- MINUZA Laptop Scheme Programs ThyDocumento9 pagineMINUZA Laptop Scheme Programs Thyanualithe kamalizaNessuna valutazione finora

- 351 UN 1824 Sodium Hydroxide SolutionDocumento8 pagine351 UN 1824 Sodium Hydroxide SolutionCharls DeimoyNessuna valutazione finora

- Eko Serbia A.D. Beograd Rules For The Purchase of Fuel Through AccountsDocumento2 pagineEko Serbia A.D. Beograd Rules For The Purchase of Fuel Through AccountsMarko Perovic PerkeNessuna valutazione finora

- Planificare Săptămânală - Clasa A II-a (Fairyland 2)Documento6 paginePlanificare Săptămânală - Clasa A II-a (Fairyland 2)Oxy Oxy100% (1)

- Pescatarian Mediterranean Diet Cookbook 2 - Adele TylerDocumento98 paginePescatarian Mediterranean Diet Cookbook 2 - Adele Tylerrabino_rojoNessuna valutazione finora

- DTC P1602 Deterioration of Battery: DescriptionDocumento5 pagineDTC P1602 Deterioration of Battery: DescriptionEdy SudarsonoNessuna valutazione finora

- Study of Behavior of Bacterial ConcreteDocumento20 pagineStudy of Behavior of Bacterial ConcreteGodwin KopelliNessuna valutazione finora

- Pure Vegeterian: Kousika (CaterersDocumento2 paginePure Vegeterian: Kousika (CaterersShylender NagaNessuna valutazione finora

- Presentation On "Insurance Sector": Submitted By: Faraz Shaikh Roll No: 9 Mba MarketingDocumento16 paginePresentation On "Insurance Sector": Submitted By: Faraz Shaikh Roll No: 9 Mba MarketingFakhruddin DholkawalaNessuna valutazione finora

- Baxshin LABORATORY: Diagnostic Test and AnalysisDocumento1 paginaBaxshin LABORATORY: Diagnostic Test and AnalysisJabary HassanNessuna valutazione finora

- Teleperformance Global Services Private Limited: Full and Final Settlement - December 2023Documento3 pagineTeleperformance Global Services Private Limited: Full and Final Settlement - December 2023vishal.upadhyay9279Nessuna valutazione finora

- EBANX Beyond Borders 2020Documento71 pagineEBANX Beyond Borders 2020Fernanda MelloNessuna valutazione finora

- NASA ISS Expedition 2 Press KitDocumento27 pagineNASA ISS Expedition 2 Press KitOrion2015Nessuna valutazione finora

- CHAPTER 8 f4 KSSMDocumento19 pagineCHAPTER 8 f4 KSSMEtty Saad0% (1)

- Celltac MEK 6500Documento3 pagineCelltac MEK 6500RiduanNessuna valutazione finora

- Idioms and PharsesDocumento0 pagineIdioms and PharsesPratik Ramesh Pappali100% (1)

- EESC 111 Worksheets Module 5Documento5 pagineEESC 111 Worksheets Module 5Keira O'HowNessuna valutazione finora

- Case Study LenovoDocumento10 pagineCase Study LenovoGOHAR GHAFFARNessuna valutazione finora

- Lesson 4: Health and Fitness AdvertisingDocumento4 pagineLesson 4: Health and Fitness AdvertisingCatherineNessuna valutazione finora

- Preparing Polymers For The Jar TestDocumento5 paginePreparing Polymers For The Jar Testarvin4dNessuna valutazione finora