Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

09 Mbenisa PDF

Caricato da

Nhan LeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

09 Mbenisa PDF

Caricato da

Nhan LeCopyright:

Formati disponibili

Muamar Benisa

Researcher

Al-Merghab University

Faculty of Engineering

Al-Khoms

Libya

Bojan R. Babi

Professor

University of Belgrade

Faculty of Mechanical Engineering

Aleksandar Grbovi

Assistant Professor

University of Belgrade

Faculty of Mechanical Engineering

Zoran Stefanovi

Professor

University of Belgrade

Faculty of Mechanical Engineering

Numerical Simulation as a Tool for

Optimizing Tool Geometry for Rubber

Pad Forming Process

To produce a new component there are a trial and error stage to obtain a

part without defects, which strongly depends on operators experience. At

this stage, the experience of designer and manufacturers should give an

important aid to reduce trials to realize the minimization of response time

and cost with maximization of the product equality. Rubber pad forming

highly improves the formability of the blank because the contact surfaces

between the rigid die and the rubber pad is flexible. This method enables to

produce sheet metal components with complex contour by relatively low

cost because only one rigid die is required. However, in aerospace field,

parts are produced in small sheet metal bending and small number of

components. It means that it is not worthy for large investments in tools

and process design. For these reasons, it is necessary to use FE simulation

of manufacturing process during the conceptual design.

Keywords: Rubber pad forming, Sheet metal forming, FE simulation,

Optimization.

1. INTRODUCTION

There are other alternatives to form complex shape

besides conventional forming processes such as deep

drawing, bending, stretching, stamping and blanking.

Among sheet forming rubber pad forming, also known

as flexible die forming, uses a rubber diaphragm as one

half of tool. This method requires only one solid tool

half, which is usually, punch. The rubber pad is used to

distribute equal pressure on all work piece surface as it

is pressed around the form block. Rubber pad forming is

designed for the use of fabricating parts with relatively

complex shape. The form block height is usually less

than 100 mm, when production rates are relatively high

with cycle times averaging 1 min or less [1].

In the aircraft industry most of the sheet parts, such

as ribs, frames, doors and windows are fabricated using

the rubber-pad forming processes. The main advantages

of this forming process compared to conventional one

are that: e.g. the forming equipment is simple and the

quality of its products is high and using it instead of the

conventional one. Because just one rigid die needs to be

accurately manufactured, the time and cost can be

greatly reduced, and the rubber pad and rigid die do not

need to be assembled precisely. Also no die clearance or

alignment checks are needed. Furthermore the same

flexible pad can be used to form several different work

piece shapes, because the rubber-pad has the ability to

return to its original shape. The thinning of the work

metal, which occurs in conventional deep drawing, is

considerably reduced. One more advantage, lubrication

is usually not needed with this process and good surface

finish can be achieved. The set-up time can be

Received: May 2013, Accepted: Dcember 2013

Correspondence to: Prof. Dr. Bojan Babi

Faculty of Mechanical Engineering,

Kraljice Marije 16, 11120 Belgrade 35, Serbia

E-mail: bbabic@mas.bg.ac.rs

doi:10.5937/fmet1401067B

Faculty of Mechanical Engineering, Belgrade. All rights reserved

considerably reduced in this kind of process, because

there are no die clearance or alignment checks that need

to be made. The rubber-pad forming processes have

certain disadvantages. However the rubber pad has a

limited life time that strongly depends on the severity of

the forming in combined with the pressure level. The

lack of sufficient forming pressure results in parts with

less sharpness or with wrinkle, which leads to

reworking the part to correct the shape and dimensions

with low production rate. Therefore it is suitable mostly

for small series (typical of aircraft industry) [1,2,7].

Fortunately there are a number of research

development articles written on the use of rubber pad

forming. For instance Antonio [2] investigated the

capability to produce shallow formed parts with a

reduced metal thinning. E. Akdemir [4] presented the

significant numerical simulation associated with flexible

forming process by 3D finite element simulation. Their

investigation showed the influence of the rubber pad

hardness and the stress distribution in the forming of

different blank material types. They also investigated

contact friction, die design crucial parameters that

required adjustment before actual operation. Ramezani

[6] presented an experimental study for the rubber-pad

forming process to stamp aluminium blank and

investigated the effect of the rubber type and stamping

velocity on the process. Finite element simulation was

used to analyse the process and compared with

experimental measurements to validate the finite

element model. Sala [7] optimized the Guerin rubber

pad forming process of an aluminium alloy fuselage

frame, which belonging to the AerMacchi MB-339

trainer and used the own finite element code. Several

effects depending on stamping velocity, geometry, heat

treatment of the sheet metal and rubber-pad parameters

have been investigated. S. Thiruvarudchelvan [8]

presented several techniques that have been introduced

and developed the role of urethane in the design of

FME Transactions (2014) 42, 67-73

67

metal forming tool such as sheet metal ashtray, plates, a

tube bulging technique, a novel blank holding technique

for deep drawing of cups of different shapes and

redrawing of cups. Battikha [9] presented the capability

of the rubber pad forming process and optimized the

process parameters to find out a product without defect.

Yaniong Liu and Lin Hua [10] reported that the finite

element simulation and experiment methods were

investigated the concave and convex rubber-pad

forming process. The forming load, thickness variation

of formed plate and variations in the channel width to

rib width ratio were also performed. Fabrizio and

Loreddana [11] presented the flexible forming of thin

sheet from aluminium alloy using different flexible die

geometries and materials. They have investigated the

forming force during the forming process for different

dies and evaluated together with the part spring back.

These investigations showed the sufficient agreement

between numerical and experimental data. Ramezani et

al. [12] presented a theoretical model for static and

kinematic friction in rubber pad forming process. They

applied these models to finite element simulation of an

axisymmetric rubber pad forming operation.

Experiments of rubber pad forming were carried out

using flexible punch.

The result of finite element simulation using the new

models

illustrated

better

agreement

between

experiments and numerical simulation. Lee et al. [13]

presented deformation characteristics of an extruded

rectangular aluminium tube in rubber pad bending and

process parameters such as material property of rubber

and roller diameters. The finite element analyses were

performed. Based on the FE analyses and parametric, a

critical value of sectional deformation and minimum

formable radius of curvature while maintaining suitable

section bending rigidly were determined. Linfapeng

[14] presented the micro/meso sheet soft punch

stamping process to fabricate the micro channel via

numerical simulation and experiments. They have

analysed the significant parameters with this process,

such as hardness of soft punch and lubrication

condition, and the numerical results have validated by

experimentally. Yanxiong Liu and Lin Hua [15] have

investigated the finite element to analysis the rubber pad

forming process and the main parameters of this process

such as rubber hardness and geometric dimension of the

rigid die of metallic bipolar plate and verification these

results with experiments.

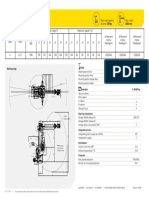

Figure 1. Schematic of rubber pad forming

68 VOL. 42, No 1, 2014

These finite element models of rubber pad forming

process are studied to investigate the effect of tool

geometry for supporting ribs of an aircraft tail, to

optimize the tool geometry and to find out the right

design of tool for a defect free product. Non-linear FE

analysis (using the ANSYS Workbench) was conducted

in order to analyse stress distribution, strain distribution,

forming load and deformation mechanics during the

rubber pad forming process. This analysis was carried

out on a commercially available finite element package

with appropriate nonlinear material and friction model.

2. FINITE ELEMENT MODELING

The deformation characteristic of support rib with

lightening hole using the rubber pad forming process is

conducted, Figure 1. During the process the blank is

placed between the die and rubber pad, which is later

held in a container to enclosing the flexible punch, and

the die is held on the hydraulic testing machine. At this

stage, the rubber bad (flexible punch) moves down to

form the blank. As a flexible punch moves down, the

rubber deforms elastically and offers a counter pressure,

making the rubber pad and blank flows into cavity of

the die. This process can be divided into three steps:

first step is self-deformation of rubber, second step is

blank draws to the surface of die and produces outer

bending, and the third is rubber pad pushing the blank in

to the die cavity. The Polyurethane rubber with Shore A

hardness of 70 (HD70) was used as a rubber pad to

stamping the aluminum blank which has thickness of

0.6 mm.

Figure 2. (a) Geometrical model of the rib with lightening

hole, (b) Geometry parameters varied in FE simulations of

rubber pad forming

In order to reduce the processing time and to

improve the precision of calculations which lead to the

right design of tool dimensions, 2D axisymmetric FE

models were created for different die dimensions

(parameters) Figure 2 (a) illustrates the geometrical

model of the rib with lightening hole and Geometry

parameters varied in FE simulations of rubber pad

forming (Figure 2 (b)) . The models in FE analysis

included only three parts: a rigid die, a blank and a

rubber pad (flexible punch). To simplify the model, the

container of the rubber pad was not considered and

constrains were applied on the rubber pad instead of

container as shown in Figure 3.

FME Transactions

Figure 3. Constraints as applied in symmetry FE model of

rib with lighten hole

Figure 4 Rigid punch, sheet metal and rubber pad models

However, in these models die was modeled as a

rigid body, so the mesh for this element was not

generated (Figure 4). Multilinear isotropic hardening

properties of 2024-T3 aluminum alloy were assigned to

the blank in order to successfully simulate large plastic

strain of the blank. These properties were determined

from stress-strain curve obtained in the tensile test

(Figure 5). For this material the elastic module (E) is

71GPa and Poisson ratio () is 0.334.

Figure 5. Experimental tensile stress- strain curve for

aluminum blank sheet

FME Transactions

Von Mises yield criterion coupled with isotropic

work hardening assumption was also applied. The

behavior of the nonlinear hyper-elastic and

incompressible rubber-like material was again described

by Mooney-Rivlin model. HD70 was used as a material

of a rubber pad, with the values of C10 and C01 equal

to 0.736 MPa and 0.184 MPa respectively.

The frictional behavior between the rubber pad and

the blank, as well as the die and the blank, were

assumed to follow Coulombs model. The friction

coefficient at the former and later contact pair were

considered to be 0.2 and 0.1 respectively.

CONTA171 andTARGE169 have been created at

interface contacts. CONTA171 is used to represent

contact and sliding between 2-D "target" surfaces

TARGE169 and a deformable surface, defined by this

element. The element is applicable to 2-D structural and

coupled field contact analyses. TARGE169 is used to

represent various 2-D "target" surfaces for the

associated contact elements CONTA171.The target has

been presented on the upper surfaces of blank (interface

between blank and rubber) and die. On the other hand,

the contact has been presented on lower surfaces of

blank and rubber.

As it is already mentioned, the container was not

modeled in order to fix the rubber pad correctly .The

frictionless support was applied on the side surfaces of

the rubber. In order to simulate the forming load on the

blank the displacement was applied on top surface of

the rubber. Remote displacement with zero in all

direction was applied on the lower surface of the die,

Figure3. However, in this study deformable materials

have been modeled with plane 183. Plane 183 has

quadratic displacement, plasticity, hyperelasticity,

creep, stress stiffening, large deflection and large strain

capability. Plane 183 has mixed formulation capability

and can be used to calculate deformation of nearly

incompressible, Elastoplastic material and fully

incompressible hyperelastic material. It should be

mentioned that the number of nods and elements are

200, 4450 and 200 nodes, where the elements are 102,

4220 and 172 which employed for blank, rubber pad

and die respectively

3. RESULTS AND DISCUSION

As mentioned above, the forming force was presented

as displacement applied on the upper edge of the

rubber-pad (Figure 3). Figure 6 illustrates the step-bystep forming process using the rubber-pad. It is clear

that the process can be divided into three stages (or

steps). The first stage is the flexible die (rubber-pad)

selfdeformation; the second starts with the blank

deformation (under the pressure of a rubber-pad when it

reaches the bottom of a rigid die); and, finally, during

third stage the blank fills the die cavities until they are

completely filled.

Figure 7 shows the maximum value of the forming

force of the rib with lightening hole, and it was 6735 N.

It can be seen that the magnitude of forming force

increases as the forming steps increase, that is, as more

bending regions have to be obtained (Figure 6 and

Figure 7).

VOL. 42, No 1, 2014 69

Figure 6. The three stages of supporting rib forming using

rubber pad forming process

Figure 7. Forming forces for FE model of rib with lighten

hole

As seen in Figure 7, the FE simulation of the

forming process for rib with the lightening hole goes

through three stages/steps (corresponding to the forming

process), During the first step self-forming of the

rubber rubber deforms elastically and offers a counter

pressure, so the forming load is very small (Figure 6 (a)

and Figure 7). Time needed for this step is short (35%

of total simulation time). After 35% of simulation time,

the second step starts and forming load increases

slightly to produce outer bending. During the last step,

after approximately 65% of simulation time, the blank

70 VOL. 42, No 1, 2014

starts to fill the cavity of the rigid die and forming force

increases sharply (Figure 6 (c) and Figure 7).

During the forming process, thinning and thickening

phenomena can occur. However, if the maximum

thickness reduction reaches a critical value, the part will

be cracked. This phenomenon should be avoided in real

production. According to Sala [7], Takuda [5], and

Benisa et. all [16], the acceptable value of plastic strain

for 2024-T3 aluminum is 0.186 mm/mm and this value

was used as a boundary in FE simulations. This means

when the value of plastic strain in simulation reached

0.186 mm/mm the model was considered unacceptable.

Generally, some parameters have higher influence on

the value of plastic strain during the rubber pad forming

process (tool geometry, hardness of the rubber, used

lubricants), and here tool geometry parameters (RI, RII,

RIII and H shown in Figure 2(b)) have been studied.

In order to study the effect of the values of these

parameters on the rubber pad forming process, RI, RII,

RIII and H have been varied. Firstly, the values of RI,

RII and RIII were fixed (2mm in the first case and 3mm

in the second), while the fourth parameter H has been

varied. The same procedure was repeated with other

combinations of parameters (3 values were fixed, the

fourth was changeable) in order to analyze the effect of

each of them on strain concentration and to find

combination which will minimize plastic strain. On the

basis of obtained results, more FE models of tools (with

different values of geometry parameters) have been

developed and analyzed. These simulations showed that

the values of stress and strain strongly depend on the

tool rib geometry (RI, RII, RIII and H).

Different FE models based on different tool

dimensions for both cases (fixed values 2mm & 3mm)

were used in simulations. The geometry parameters that

were not fixed were varied from 1 mm to 5 mm. Figure

8 illustrates the relationships between the plastic strain

and the geometry parameters for each model in case one

and case two.

As it can be seen in Figure 8, plastic strain strongly

depends on the geometry parameters RI, RII, RIII and H

and these dependencies may be expressed in

mathematical terms. It is also clear that increasing the

values of RI, RII and RIII or decreasing the value of H

(while other parameters are fixed), the plastic strain

decreases. At the same time, the capability of forming

the blank increases, too. However, when RII 2, RI 2

and H < RII, for example, the plastic strain is less than

0.186 mm/mm.

On the other hand, when RI equals 1 mm and 1.5

mm, respectively, the plastic strain is greater than

acceptable plastic strain 0.186 mm/mm (in both cases,

one and two). Magnitudes of the plastic strain in case

one is 0.219 mm/mm (when RI=1 mm, Figure 9) and

0.211 mm/mm (when RI= 1.5 mm, Figure 10), while

magnitudes of the plastic strain in case two is 0.218

mm/mm (when RI=1 mm, Figure 9) and 0.167 mm/mm

(when RI= 1.5 mm, Figure 10). Figure 9 and Figure 10

show that stress concentration appears in RI region in

both cases. However, if H is greater than RII (H=4.5mm,

Figure 11), the maximum plastic strain is 0.438 mm/mm

in the first case and 0.244 mm/mm in the second case

(which is greater than 0.186 mm/mm) and stress

concentration takes place at RII region. But, when H is

FME Transactions

less than RII the value of plastic strain is always less

than 0.186 mm/mm (Figure 14). The plastic stain is less

than 0.186 mm/mm when RI >2 mm, and the similar can

be said about radius RII, which must be greater than

2mm (as shown in Figures 12 and 13).

Figure 11. H=4.5 mm a) first case (RI, RII and RIII equal 2

mm) b) second case (RI, RII and RIII equal 3 mm)

Figure12. RI=2.5 mm a) first case (RII, RIII and H equal 2 mm)

b) second case (RII, RIII and H equal 3 mm)

Figure 8. Influence of geometry parameters on plastic

strain during rubber pad forming process: a) case one, b)

case two

Figure 13 RII=3 mm a) first case (RI, RIII, and H equal 2 mm)

b) second case (RI, RIII, and H equal 3 mm)

Figure 9. RI=1 mm a) first case (RII, RIII, and H equal 2 mm)

b) second case (RII, RIII, and H equal 3 mm)

Figure 14. H=1.5 mm a) first case (RI, RII, and RIII equal 2

mm) b) second case (RI, RII, and RIII equal 3 mm)

Figure 10. RI=1.5 mm a) first case (RII, RIII, and H equal

2mm) b) second case (RII, RIII, and H equal 3mm)

FME Transactions

Simulations showed that the values of RIII in all

models and both cases should be greater than or equal to

RII in order to make an easy forming and to avoid

uncompleted cavity tool forming (Figure 15). In Figure

15 it is obvious that when RIII=1.5 mm, and RII is 2

VOL. 42, No 1, 2014 71

mm (first case) and 3 mm (second case), cavity of the

tool is not completely filled (there is a gap between

sheet and tool surface). When RIII=3.5 mm and

RIII=4.5 mm (which is greater than value of RII in both

cases) the cavity is completely filled and the value of

plastic strain is within acceptable range (Figure 15).

mm, 4 mm and 5 mm respectively, and H is less than or

equal to RII (4 mm in Figure 16 (j) and 3 mm in Figure

16 (k)), the plastic strain is less than 0.186 mm/mm

(0.175 mm/mm in Figure 16 (j) and 0.134 mm/mm in

Figure 16 (k)). In case when H=3 mm and is equal to

RIII (which is less than RII=4mm, Figure 16 (h)), while

RI equal to 2 mm, the tool cavity is completely filled

with sheet metal, and the value of plastic strain is low

(0.129 mm/mm).

Figure 15. The influence of RIII on the filling the cavity of the

tool rib a) case one (RI, RII and RIII equal 2mm) b) case two

(RI, RII and RIII equal 3mm)

Furthermore, even if we select parameters (RI, RII,

RIII and H) randomly, we come to the same conclusions

as previously described. For example, in Figure 16 (a)

the plastic strain value is 0.212 mm/mm and it is higher

than acceptable plastic strain (0.186 mm/mm). This high

value of plastic strain is because H=4 mm which is

greater than RII (3mm), furthermore the value of RI is

equal to 1.5 mm and less than 2 mm. However, the tool

cavity is completely filled with sheet when RII=RIII= 3

mm. When the value of RI is equal to 1 mm and the

other parameters (RII, RIII and H) are equal to 3 mm,

the plastic strain value is 0.218 mm/mm and it is

concentrated at RI region, but the tool cavity is

completely filled because RIII is equal to RII=3mm

(Figure 16(b)). The plastic strain is equal to 0.129

mm/mm when the value of RI is equal to 2 mm and the

value of H is equal to 3mm, which is less than RII

(4mm). But, the tool cavity is not filled because RIII is

equal to 2 mm and less than RII (Figure 16 (c)).

When RI=1.5 mm, RII=2 mm and RIII=H= 3mm,

the plastic strain value is 0.217 mm/mm and the tool

cavity is completely filled (RI is less than 2mm and H

and RIII greater than RII, Figure 16(d)). The tool cavity

is completely filled with low plastic strain value (0.142

mm/mm) in case when RI is equal to 2 mm and

RII=RIII=H=3 mm (Figure 16 (e)).

The same tool cavity situation happens as in

previous when RI=2 mm, RII=RII=3 mm and H is equal

to 2 mm (which less than RII) and the plastic strain is

0.118 mm/mm (Figure 16(f)). On the other hand, when

H is equal to 3mm and RI=RII=RIII=2 mm (that is

H>RII and RIII<RII), the value of plastic strain is 0.198

mm/mm and is higher than 0.186 mm/mm and the tool

cavity is not completely filled (Figure16 (g)). The figure

16 (h) shows the sheet complely filling the tool cavity

with low value of plastic strain (0.129 mm/mm). As it

can be seen this happens when RIII=3 mm and RII

=4mm, while H=3 mm is less than RII and RI is equal

to 2mm.

Figures 16 (j) and 16 (k) show that when the first

three geometry parameters (RI, RII, RIII) are equal to 2

72 VOL. 42, No 1, 2014

Figure 16 More randomly selected geometry parameters

4. CONCLUSION

In this study two different cases were analyzed using FE

simulations and several different FE models of ribs

tools have been developed for the purpose of

investigating the geometry of tool used in the rubber

pad forming process. These models were analyzed in

details numerically and the most important conclusions

of this study could be:

The values of RI and RII should be grater than or

equal to 2 mm in order to avoid stress concentration

in their regions. However, the plastic strain will not

reach unacceptable plastic stain.

To avoid thinning phenomenon and to make an

easy forming with complete rib tool cavity filling,

the value of H should be less than RII and the value

of RIII should be greater than or equal to RII.

To get plastic strain in the blank less than 0.186

mm/mm and completely fill the cavity of the tool, the

values of RII & RIII should be increased with decreasing

the value of H. On the other hand, it is known that

increase of the bending radius may cause increase in the

spring back phenomenon, which is not preferable.

Therefore, to get an acceptable tool design we have to

make a kind of compromise of the values of these

parameters. This is why the connection between the

values of RI and RII and spring back phenomenon will

be analyzed in next work using FE method. As we saw

in presented results of simulations, the influence of RIII

and H on filling tool cavity is significant, but RIII and H

are not influencing the spring back, while the influence

of RI and RII on both phenomena is very important.

FME Transactions

REFERENCES

[1] ASM Handbook Vol. 14B Metal Working: Sheet

Forming, 2006.

[2] Thiruvarudchelvan, S.: Elastomers in Metal

Forming, Journal of Material Processing, Vol. 39,

pp. 55-82, 1993.

[3] Del Prete, A., Panadia, G., and Manisi, B.:

Computer Aided Modelling Of Rubber Forming

Process, Key Engineering Material Vol. 473, pp.

637-644, 2011

[4] Dirikolu, H.M. and Akdemir, E.: Computer Aided

Modelling of Flexible Forming Process, Material

Processing Technology Vol. 148 pp. 376-381,

2004.

[5] Takuda, H. and Hatta, N.: Numerical Analysis of

the Formability of Aluminum 2024 Alloy Sheet and

Its Laminates with Steel Sheets, Metallurgical and

material transaction A, Vol. 29A, pp. 2829-2834,

1998.

[6] Ramezani, M., Ripin, Z.M. and Ahmad, R.: Sheet

metal forming with the aid flexible punch,

numerical approach and experimental validation,

CIRP Journal of Manufacturing Science and

Technology, Vol. 3. No. 3, pp. 196203, 2010.

[7] Sala, G.: A Numerical and Experimental Approach

to Optimize Sheet Stamping Technologies: Part II

Aluminium Alloys Rubber-Forming, Materials and

Design, Vol. 22 pp.299315, 2001.

[8] Thiruvarudchelvan, S.: The Potential Role Of

Flexible Tools in Metal Forming. Material

Processing Technology Vol. 122 pp. 293-300,

2002.

[9] David J.B. and Battikha, E.: Optimization of

Aluminium Sheet Forming Using a Flexible Die,

Material Processing Technology Vol. 55, pp. 218223, 1995.

[10] Liu, Y., Hua L., Lan. J. and Wei X.: Studies of the

Deformation Styles of the Rubber-Pad Forming

Process Used For Manufacturing Metallic Bipolar

Plates, Journal of Power Sources Vol. 195, pp.

8177-8184, 2010.

[11] Quadrini, F., Santo L. and Squeo, E.A.: Flexible

Forming of Thin Aluminum Alloy Sheets,

International Journal of Modern Manufacturing

Technologies, Vol. II, No. 1, pp. 79-84, 2010.

[12] Ramezani, M., Ripin, Z.M. and Ahmad, R.:

Computer Aided Modelling of Friction in Rubber

Pad Forming Process, Journal of Material

Processing Technology Vol. 209, pp. 4925-4934,

2009.

FME Transactions

[13] Lee, J.W., Kwon, H.C., Rhee. M.H. and Im, Y.T.:

Determination of Forming Limit of a Structural

Aluminum Tube in Rubber Pad Bending, Material

Processing Technology, Vol. 140, pp. 487-493,

2003.

[14] Peng, L., Hu, P., Lai, X., Mei, D. and Ni, J.:

Investigation of Micro/Meso Sheet Soft Stamping

Process-Simulation and Experiments, Material And

Design, Vol. 30, pp. 783-790, 2003.

[15] Liu, Y. and Hua, L.: Fabrication of Metallic Bipolar

Plate for Proton Exchange Membrane Fuel Cells By

Rubber Pad Forming, Journal of Power Source Vol.

195, pp. 3529-3535, 2010.

[16] Benisa, M., Babic, B., Grbovic, A. and Stefanovic,

Z.: Computer-Aided Modeling of the Rubber-Pad

Forming Process, Materials and Technology Vol.

46, No. 5, pp. 503510, 2012.

Muamar Benisa, ,

,

,

.

.

.

.

.

[1].

VOL. 42, No 1, 2014 73

Potrebbero piacerti anche

- Numerical Simulation As A Tool For Optimizing ToolDocumento8 pagineNumerical Simulation As A Tool For Optimizing ToolRui MatiasNessuna valutazione finora

- AIMTDR Paper1Documento5 pagineAIMTDR Paper1pprudvi108Nessuna valutazione finora

- Proc Ese 1233Documento4 pagineProc Ese 1233Carlos ArenasNessuna valutazione finora

- Analysis of Thickness Distribution in Cup Produced by Rubber Pad FormingDocumento9 pagineAnalysis of Thickness Distribution in Cup Produced by Rubber Pad FormingjeovanNessuna valutazione finora

- 2009.1 Optimization of Die Design For Forging of A Turbo-Charger Impeller and A Ring Gear Using Process SimulationDocumento17 pagine2009.1 Optimization of Die Design For Forging of A Turbo-Charger Impeller and A Ring Gear Using Process SimulationAbuabdullahZakiNessuna valutazione finora

- Final Rapid PrototypingDocumento9 pagineFinal Rapid PrototypingSunny BediNessuna valutazione finora

- Rubber Pad FormingDocumento15 pagineRubber Pad FormingAdula Rajasekhar67% (3)

- Incremental Sheet Metal Forming On CNC Milling Machine-ToolDocumento4 pagineIncremental Sheet Metal Forming On CNC Milling Machine-ToolDionysius WahyoeNessuna valutazione finora

- Experimental Studies On Formability in Single Point Incremental FormingDocumento27 pagineExperimental Studies On Formability in Single Point Incremental Formingvenkatesh mohanNessuna valutazione finora

- Process Design For Closed-Die Forging of Bevel Gear by Finite Element AnalysesDocumento7 pagineProcess Design For Closed-Die Forging of Bevel Gear by Finite Element AnalysesskullatNessuna valutazione finora

- Local Contact Conditions in Sheet Metal Forming and Their Simulation in Laboratory Test MethodsDocumento7 pagineLocal Contact Conditions in Sheet Metal Forming and Their Simulation in Laboratory Test Methodsazhar aliNessuna valutazione finora

- Experimental Study Aiming To Enhance The Surface Finish of Fused Deposition Modeled PartsDocumento4 pagineExperimental Study Aiming To Enhance The Surface Finish of Fused Deposition Modeled Partsnewkid2202Nessuna valutazione finora

- 2560 PDFDocumento21 pagine2560 PDFsachinNessuna valutazione finora

- Numerical Simulation of Sheet Stamping Process Using Flexible PunchDocumento13 pagineNumerical Simulation of Sheet Stamping Process Using Flexible PunchRui MatiasNessuna valutazione finora

- Review On Various Kinds of Die Less Forming Methods: Sayed Mojtaba Tabibian, Maryam Khanian NajafabadiDocumento5 pagineReview On Various Kinds of Die Less Forming Methods: Sayed Mojtaba Tabibian, Maryam Khanian NajafabadiCarlos ArenasNessuna valutazione finora

- Of Drilling of (GF/PC) Glass Fiber Reinforced Influence of Process Parameters On DelaminationDocumento4 pagineOf Drilling of (GF/PC) Glass Fiber Reinforced Influence of Process Parameters On DelaminationSundaraPandiyanNessuna valutazione finora

- RTV Molds Using RPDocumento4 pagineRTV Molds Using RPhappydude7632Nessuna valutazione finora

- Effect of Rubber Forming Process Parameters On Micro Patterning of Thin Metallic PlatesDocumento6 pagineEffect of Rubber Forming Process Parameters On Micro Patterning of Thin Metallic PlatesRui MatiasNessuna valutazione finora

- Impact of Vapor Polishing On Surface Roughness and Mechanical Properties For 3D Printed ABSDocumento10 pagineImpact of Vapor Polishing On Surface Roughness and Mechanical Properties For 3D Printed ABSIrina BesliuNessuna valutazione finora

- A Numerical and Experimental Approach To Optimise Sheet Stamping Technologies: Aluminium Alloys Rubber-FormingDocumento17 pagineA Numerical and Experimental Approach To Optimise Sheet Stamping Technologies: Aluminium Alloys Rubber-FormingRui MatiasNessuna valutazione finora

- Draft For SeminarDocumento5 pagineDraft For SeminarAamir ShabbirNessuna valutazione finora

- An Experimental Study of Influence of Drill Geometry On Drilling of Carbon Fibre Reinforced Plastic CompositesDocumento9 pagineAn Experimental Study of Influence of Drill Geometry On Drilling of Carbon Fibre Reinforced Plastic CompositesIJERDNessuna valutazione finora

- Lightweight BIW Clinching TechnologyDocumento20 pagineLightweight BIW Clinching TechnologyMaratNessuna valutazione finora

- Investigating Aluminum Sheet Wrinkling During The Deep Drawing ProcessDocumento12 pagineInvestigating Aluminum Sheet Wrinkling During The Deep Drawing ProcessElaine JohnsonNessuna valutazione finora

- Deep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnDocumento4 pagineDeep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnbrahimNessuna valutazione finora

- Friction Coefficient in Rubber Forming Process of Ti-15-3 AlloyDocumento8 pagineFriction Coefficient in Rubber Forming Process of Ti-15-3 AlloyAdemar CardosoNessuna valutazione finora

- Design For 3D Tire MoldDocumento12 pagineDesign For 3D Tire MoldChokchai BoonchuayNessuna valutazione finora

- Investigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingDocumento5 pagineInvestigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingR Moses KrupavaramNessuna valutazione finora

- Optimization For Extrusion Process of Aluminum Controller HousingDocumento6 pagineOptimization For Extrusion Process of Aluminum Controller Housingdimaskentuk13Nessuna valutazione finora

- Unit 4 New MPDocumento31 pagineUnit 4 New MPPriya DharshniNessuna valutazione finora

- Spin Casting Characterization Design For Runner DesignDocumento9 pagineSpin Casting Characterization Design For Runner DesignuzairmetallurgistNessuna valutazione finora

- Grid Marking and Measurement PDFDocumento10 pagineGrid Marking and Measurement PDFAngelito Gonzalez HernandezNessuna valutazione finora

- Review of Rubber Based Sheet Hydro-Forming ProcessesDocumento5 pagineReview of Rubber Based Sheet Hydro-Forming ProcesseslachhelNessuna valutazione finora

- Design and Fabrication of Silicon RubberDocumento6 pagineDesign and Fabrication of Silicon RubberHuy Nguyễn Võ XuânNessuna valutazione finora

- Ijramt 2 4 52Documento8 pagineIjramt 2 4 52arjun.recordsNessuna valutazione finora

- Aluminium Alloy GDC & ProblemsDocumento11 pagineAluminium Alloy GDC & ProblemsN.B.PNessuna valutazione finora

- An Experimental Investigation On Abrasive Jet Machining by Erosion Abrasive GrainDocumento3 pagineAn Experimental Investigation On Abrasive Jet Machining by Erosion Abrasive GrainPkNessuna valutazione finora

- Optimization of Sheet Metal Forming Processes by The Use of Numerical SimulationsDocumento6 pagineOptimization of Sheet Metal Forming Processes by The Use of Numerical SimulationsRaghu VenkatNessuna valutazione finora

- Executive SummaryDocumento12 pagineExecutive SummaryEdina Uzunović HodžićNessuna valutazione finora

- Investigation of The Influence of Coating and The Tapered Entry in The Internal Forming Tapping ProcessDocumento13 pagineInvestigation of The Influence of Coating and The Tapered Entry in The Internal Forming Tapping ProcessLincoln BrandãoNessuna valutazione finora

- An Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFDocumento7 pagineAn Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFnewkid2202Nessuna valutazione finora

- Rolling & Extrusion Case StudyDocumento20 pagineRolling & Extrusion Case StudyMahmoud KassabNessuna valutazione finora

- A Study On The Ultra Precision Progressive Die Making For Sheet Metal Forming by Computer SimulationDocumento4 pagineA Study On The Ultra Precision Progressive Die Making For Sheet Metal Forming by Computer SimulationGerardo ArroyoNessuna valutazione finora

- Sheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesDocumento23 pagineSheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesManolo GipielaNessuna valutazione finora

- Fabrication of Metallic Bipolar Plate For Proton Exchange Membrane Fuel Cells by Rubber Pad FormingDocumento7 pagineFabrication of Metallic Bipolar Plate For Proton Exchange Membrane Fuel Cells by Rubber Pad FormingRui MatiasNessuna valutazione finora

- Riview On Cold Drawing Process PDFDocumento7 pagineRiview On Cold Drawing Process PDFAmandeep Singh GujralNessuna valutazione finora

- Design and Analysis of IS513CR2 Using FEADocumento34 pagineDesign and Analysis of IS513CR2 Using FEAakhilesh vaibhavNessuna valutazione finora

- IJRET - Influence of Feeding System in Injection Moulding For Lower Washer of A BearingDocumento4 pagineIJRET - Influence of Feeding System in Injection Moulding For Lower Washer of A BearingInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- v61 124 PDFDocumento5 paginev61 124 PDFAnya CooperNessuna valutazione finora

- An Investigation of Optimum Cutting Conditions in Face Milling Aluminum 7075-t6 Using Design of ExperimentDocumento11 pagineAn Investigation of Optimum Cutting Conditions in Face Milling Aluminum 7075-t6 Using Design of ExperimentMukund PatelNessuna valutazione finora

- 05-46 Blocking Die Impression Shape Design For WebDocumento4 pagine05-46 Blocking Die Impression Shape Design For WebLungani SibindiNessuna valutazione finora

- Determination of The Maximum Forming Angle of Some Carbon Steel Metal SheetsDocumento4 pagineDetermination of The Maximum Forming Angle of Some Carbon Steel Metal Sheetsዘረአዳም ዘመንቆረርNessuna valutazione finora

- Ijmer 45061827Documento10 pagineIjmer 45061827rathish14uNessuna valutazione finora

- 2001 The Bending of An Aluminum Structural Frame With A Rubber PadDocumento6 pagine2001 The Bending of An Aluminum Structural Frame With A Rubber PadL ZhangNessuna valutazione finora

- 4-284 MatejicDocumento8 pagine4-284 MatejicTechky ManiacsNessuna valutazione finora

- Masiagutova Et Al. (2021) - Side Surface Topography Generation During Laser Powder Bed Fusion of AlSi10MgDocumento24 pagineMasiagutova Et Al. (2021) - Side Surface Topography Generation During Laser Powder Bed Fusion of AlSi10Mgfrankypanky123Nessuna valutazione finora

- Motor StatorDocumento6 pagineMotor StatorNhan LeNessuna valutazione finora

- 17 TiszaM.2013 RecentDevelopmentTrendsDocumento16 pagine17 TiszaM.2013 RecentDevelopmentTrendsNhan LeNessuna valutazione finora

- Analysis of Springback in Flanging ProcessDocumento8 pagineAnalysis of Springback in Flanging ProcessNhan LeNessuna valutazione finora

- Autoform Analysis in Sheet Metal FormingDocumento15 pagineAutoform Analysis in Sheet Metal FormingNhan LeNessuna valutazione finora

- Material Properties That Affect Sheet Metal FormabilityDocumento24 pagineMaterial Properties That Affect Sheet Metal FormabilityNhan LeNessuna valutazione finora

- N and K ValuesDocumento1 paginaN and K ValuesNhan LeNessuna valutazione finora

- EN-Catia v5r13 Designer Guide Chapter9-Working With Wireframe and Surface Design Workbench PDFDocumento40 pagineEN-Catia v5r13 Designer Guide Chapter9-Working With Wireframe and Surface Design Workbench PDFNhan LeNessuna valutazione finora

- FASTBLANK For ProE Instructions PDFDocumento11 pagineFASTBLANK For ProE Instructions PDFNhan LeNessuna valutazione finora

- Material Poisson's RatioDocumento3 pagineMaterial Poisson's RatioNhan LeNessuna valutazione finora

- Types of StrainDocumento33 pagineTypes of StrainmurasanNessuna valutazione finora

- LENHmoi NhanDocumento16 pagineLENHmoi NhanNhan LeNessuna valutazione finora

- GOS WP HardTurning F PDFDocumento26 pagineGOS WP HardTurning F PDFNhan LeNessuna valutazione finora

- Cmti 1228918957257618 1Documento32 pagineCmti 1228918957257618 1Nhan LeNessuna valutazione finora

- Computer-Integrated ManufacturingDocumento5 pagineComputer-Integrated ManufacturingNhan LeNessuna valutazione finora

- Steam Ejector HysysDocumento4 pagineSteam Ejector Hysysfluto100% (1)

- 2007 - Study On Optical Polishing of Optical Glass by Means of Ultrasonic Magnetorheological Compound FinishingDocumento5 pagine2007 - Study On Optical Polishing of Optical Glass by Means of Ultrasonic Magnetorheological Compound FinishingMayank Rajesh Kumar ShrivastavaNessuna valutazione finora

- LS-DYNA Aerospace MGD v12-1 PDFDocumento151 pagineLS-DYNA Aerospace MGD v12-1 PDFBrian ForsmanNessuna valutazione finora

- Physics of RunningDocumento8 paginePhysics of Runningcamil salameNessuna valutazione finora

- Complete Textile Mechanics LabDocumento47 pagineComplete Textile Mechanics LabEngr Mujahid MehdiNessuna valutazione finora

- The Scaled Boundary Finite Element Method - Lecture A: Smteam@gmx - CH - WWW - Erdbebenschutz.chDocumento23 pagineThe Scaled Boundary Finite Element Method - Lecture A: Smteam@gmx - CH - WWW - Erdbebenschutz.chZenPhiNessuna valutazione finora

- Cle6016 Pre-Stressed-Concrete-Structures TH 1.1 47 Cle6016 4Documento2 pagineCle6016 Pre-Stressed-Concrete-Structures TH 1.1 47 Cle6016 4Manu Jacob Steaphen 19MST0050Nessuna valutazione finora

- Design of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Documento1 paginaDesign of Machinery Robert L. Norton: 3Rd Ed. by © Mcgraw-Hill 2004Fernando Pauli PradoNessuna valutazione finora

- Energy Science and Engineering (KOE 033)Documento46 pagineEnergy Science and Engineering (KOE 033)ShivendraSaurabhNessuna valutazione finora

- MODULE 6-Electric Current and Ohm's LawDocumento90 pagineMODULE 6-Electric Current and Ohm's Lawpat jabNessuna valutazione finora

- Sag & TensionDocumento51 pagineSag & TensionMohammed K Hawa0% (1)

- 1 s2.0 S0301562917302077 MainDocumento9 pagine1 s2.0 S0301562917302077 MainFabian Torres RoblesNessuna valutazione finora

- Shear CenterDocumento24 pagineShear Centerhbuyhbuy100% (1)

- Fluid Flow Operations Lecture 1: Introduction: Dr. Srinivas Krishnaswamy Assistant Professor Chemical EngineeringDocumento22 pagineFluid Flow Operations Lecture 1: Introduction: Dr. Srinivas Krishnaswamy Assistant Professor Chemical EngineeringPRAJWAL RASTOGINessuna valutazione finora

- AGARDAG328Documento200 pagineAGARDAG328ENessuna valutazione finora

- Aryan+Patel+ +Impulse+and+Momentum - Pdf.kamiDocumento2 pagineAryan+Patel+ +Impulse+and+Momentum - Pdf.kamiAryan PatelNessuna valutazione finora

- Waves EBDocumento94 pagineWaves EBsetosam37Nessuna valutazione finora

- Aakash Physics Study Package 5 SolutionsDocumento134 pagineAakash Physics Study Package 5 SolutionsfociweNessuna valutazione finora

- Centripetal Force Multiple Choice QuestionsDocumento3 pagineCentripetal Force Multiple Choice QuestionsMalaika ChaudharyNessuna valutazione finora

- Cyclic Plasticity Behaviors of Steam Turbine Rotor Subjected To Cyclic Thermal and Mechanical LoadsDocumento30 pagineCyclic Plasticity Behaviors of Steam Turbine Rotor Subjected To Cyclic Thermal and Mechanical Loadsomar900314Nessuna valutazione finora

- 07A - Chapter 7 - Sec 7.1-7.3, App F - BlackDocumento14 pagine07A - Chapter 7 - Sec 7.1-7.3, App F - BlackStevina LangrimariNessuna valutazione finora

- Beam Element: Beams and Shafts Module-3Documento14 pagineBeam Element: Beams and Shafts Module-3Manda Ramesh BabuNessuna valutazione finora

- M-900 Robot Working Range: 330 KG 3203 MMDocumento1 paginaM-900 Robot Working Range: 330 KG 3203 MMjosjcrsNessuna valutazione finora

- Engineering Science N4 Summary NotesDocumento1 paginaEngineering Science N4 Summary Notesrcpretorius22% (9)

- Semi 4 Ex Sol 2Documento3 pagineSemi 4 Ex Sol 2Devendra ChauhanNessuna valutazione finora

- Screenshot 2023-04-26 at 6.58.53 AMDocumento1 paginaScreenshot 2023-04-26 at 6.58.53 AM25hshalabiNessuna valutazione finora

- DR Rajbal SinghDocumento18 pagineDR Rajbal Singhsayed sahilNessuna valutazione finora

- Sph1101 2016july SuppDocumento5 pagineSph1101 2016july SuppAndrew May NcubeNessuna valutazione finora

- Previous Year Questions - EM WAVESDocumento11 paginePrevious Year Questions - EM WAVESYuvrajNessuna valutazione finora