Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A CFD Analysis of The Operating Conditions of A Multitube PD Membrane Prification H2

Caricato da

claralisieTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A CFD Analysis of The Operating Conditions of A Multitube PD Membrane Prification H2

Caricato da

claralisieCopyright:

Formati disponibili

A CFD Analysis of the Operating Conditions of a

Multitube Pd Membrane for H2 Purification

B. Castro-Dominguez, R. Ma, A.G Dixon, and Y. H. Ma

Chemical Engineering Department, Worcester Polytechnic Institute, Worcester, MA, USA

Introduction

The production of hydrogen is a major process for the chemical industry as well as for the

energy sector. Using palladium membranes is an economic and efficient method to purify

H2. They remove H2 by catalyzing the dissociation of the molecule at the surface and

diffusing it through the lattice of the metal. The physics and geometry involved make the

behavior of multitube membrane modules difficult to predict and simulate, but necessary

for the implementation of this technology. This work uses COMSOL Multiphysics 4.4 to

study the operating conditions of a seven membrane module. The influence of different

Reynolds numbers on both, recovery and membrane utilization, is discussed. An optimum

point to maximize the efficiency of the module is presented.

Computational Methods

To simulate the fluid flow and mass transport,

the following equations were used:

Equation of motion:

u u = [pl + u + u

u l)

Species continuity equation:

j =

m

D w

m M

w D

M

Hydrogen Mole Fraction

Hydrogen Mole Fraction

a)

a)

b)

b)

c)

c)

p

p

2

2

Where P2 , p

, p2 are the H2

2

permeance, H2 partial pressure in the

shell and tube side, respectively.

j + u w = R

Different Re numbers displayed different H2 mole fraction profiles within the

membrane module. At low Re numbers, the H2 recovery is maximized, but the

membrane usage capacity is not exploited (Fig 4a). As the Re number increases, the

membranes were used further down axially, but recovery decreased (Fig 4b).

Fig 5. shows a H2 depleted boundary layer or concentration polarization. At high Re

numbers, the boundary layer becomes thinner, but the H2 recovery of the process

reduces.

Sieverts law was used as the boundary

to simulate the H2 flux across the

membranes:

n N = P2

u = 0

H2 Mole Fraction Profile

Simulation setup

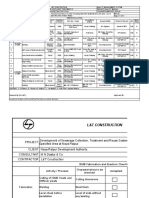

The multitube membrane module consists of seven Pd membranes (Fig.1). Hydrogen

enriched syngas is fed at the shell side while the permeated H2 gas is collected from

inside of the membrane tubes.

The simulation used Reacting Flow as

the physics. Table 1. shows the

parameters used in this simulation.

Fine mesh was used for the simulation

as shown in Fig 2. with 3,181,368

degrees of freedom.

Fig 1. Representative sketch of the actual

multitube membrane module

Table 1: Operational setting of the module

Shell Pressure / atm

Tube Pressure / atm

H2 Permeance / mol m-2s-1Pa-0.5

Reynolds number

Initial gas composition / mole %

H2

N2

CO

CO2

CH4

12.6

1

7.7 104

1-300

Fig 4. Axial view of the H2 mole fraction

distribution at different Re numbers: a) Low

Re number, b) Medium Re, c) High Re

Fig 5. Cross-sectional view of the H2 mole

fraction distribution at different Re

numbers: a) Low Re number, b) Medium

Re, c) High Re

Recovery ( R 2 (%) ) and

membrane usage ( % )

were computed as:

43

50

5

1.5

0.5

R 2 (%) =

Fig 2. Cross-sectional view of the mesh

used in the simulation

(%) =

Results

Velocity Profile (m/s)

F

2

2

F

2

100

100

Fig 6. Recovery of H2 and membrane utilization

as a function of Re numbers

The optimum point for operating the module is represented at the

intersection where the recovery and membrane utilization overlap (Fig 6.).

Velocity Profile

The velocity of the gas

decreases after the

expansion between the

inlet and the membrane

module. Velocity

increases and mixing

occurs when the gases

encounter the

membranes.

Conclusions

1. Low Re numbers displayed high recoveries, but the membranes were utilized

ineffectively.

2. High Re numbers use the membranes more evenly and reduced concentration

polarization, but H2 recovery decreased.

3. A tradeoff between usage of the membrane and H2 recovery was successfully

depicted. An optimized Re number was presented balancing both properties.

Acknowledgements

Fig 3. Velocity profile of syngas inside the

membrane module at moderate Re numbers

The authors are grateful for the financial support provided by the U.S. Department of

Energy through the project Engineering Design and Advanced H2 CO2 Pd and

Pd/Alloy Composite Membrane Separations and Process Intensifications (No. DEFE0004895).

Excerpt from the Proceedings of the 2014 COMSOL Conference in Boston

Potrebbero piacerti anche

- Nanostructured Polymer Membranes, Volume 1: Processing and CharacterizationDa EverandNanostructured Polymer Membranes, Volume 1: Processing and CharacterizationNessuna valutazione finora

- The Fluidized-Bed Membrane Reactor For Steam Methane Reforming: Model Verification and Parametric StudyDocumento14 pagineThe Fluidized-Bed Membrane Reactor For Steam Methane Reforming: Model Verification and Parametric StudyWahab ChodharyNessuna valutazione finora

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDa EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- Sequential Simulation of Dense Oxygen Permeation Membrane Reactor For Hydrogen Production From Oxidative Steam Reforming of Ethanol With ASPEN PLUS 20Documento8 pagineSequential Simulation of Dense Oxygen Permeation Membrane Reactor For Hydrogen Production From Oxidative Steam Reforming of Ethanol With ASPEN PLUS 20serchNessuna valutazione finora

- Detailed Mathematical Modelling of Membrane ModulesDocumento8 pagineDetailed Mathematical Modelling of Membrane Modulesrocksoad23Nessuna valutazione finora

- The Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationDa EverandThe Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationShulamith SchlickNessuna valutazione finora

- CFD Modelling of Mixing Effects On The Course of Parallel Chemical Reactions Carried Out in A Stirred TankDocumento7 pagineCFD Modelling of Mixing Effects On The Course of Parallel Chemical Reactions Carried Out in A Stirred TankharriolaNessuna valutazione finora

- Research Article Numerical Analysis of A Gas Separation of CH /CO Using Hollow Fiber Membrane ModuleDocumento10 pagineResearch Article Numerical Analysis of A Gas Separation of CH /CO Using Hollow Fiber Membrane ModuleM Salman QadirNessuna valutazione finora

- 13 - 01 - IJHE (Membrane)Documento12 pagine13 - 01 - IJHE (Membrane)landaNessuna valutazione finora

- Majidyfar 2011 943-954Documento12 pagineMajidyfar 2011 943-954ezekielNessuna valutazione finora

- Rxn10 - FEMLAB-Fixed Bed ReactorDocumento15 pagineRxn10 - FEMLAB-Fixed Bed ReactorvijendranbNessuna valutazione finora

- Non Newtonian Behavior Effect On Gas-Liquid Mass Transfer Using Anchor Impeller For CSTR BioreactorDocumento5 pagineNon Newtonian Behavior Effect On Gas-Liquid Mass Transfer Using Anchor Impeller For CSTR BioreactorJang Pyong HwaNessuna valutazione finora

- An Improved Reconstruction Method For Compressible Ows With Low Mach Number FeaturesDocumento22 pagineAn Improved Reconstruction Method For Compressible Ows With Low Mach Number FeaturesgoldenthangamNessuna valutazione finora

- Modeling and Parametric Study For CO2/CH4Documento6 pagineModeling and Parametric Study For CO2/CH4CardeJAFNessuna valutazione finora

- InTech-Two Dimensional Pem Fuel Cells Modeling Using Comsol Multiphysics PDFDocumento13 pagineInTech-Two Dimensional Pem Fuel Cells Modeling Using Comsol Multiphysics PDFMostafa AnnakaNessuna valutazione finora

- Sequential Simulation of A Fluidized Bed-Aspen PlusDocumento6 pagineSequential Simulation of A Fluidized Bed-Aspen PlusAzharuddin Ehtesham FarooquiNessuna valutazione finora

- HDS Reactor ModelDocumento4 pagineHDS Reactor Modelpcyadav8Nessuna valutazione finora

- Hydrogen Storage Media Through Nanostructured Polymeric MaterialsDocumento4 pagineHydrogen Storage Media Through Nanostructured Polymeric MaterialsSaumya SinhaNessuna valutazione finora

- Membranes: Hydrogen Production Via Steam Reforming: A Critical Analysis of MR and RMM TechnologiesDocumento20 pagineMembranes: Hydrogen Production Via Steam Reforming: A Critical Analysis of MR and RMM TechnologieschemNessuna valutazione finora

- COMSOL Modelling and Simulation of PEM Fuel Cell's FlowDocumento7 pagineCOMSOL Modelling and Simulation of PEM Fuel Cell's FlowMd Saiful Islam RajonNessuna valutazione finora

- DPF RegenerationDocumento13 pagineDPF RegenerationMaureen MossNessuna valutazione finora

- CFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageDocumento7 pagineCFD Analysis of Two-Bucket Savonius Rotor Using Fluent PackageAlireza Ab100% (1)

- COMSOL Modelling and Simulation of PEM Fuel Cell's Flow ChannelsDocumento7 pagineCOMSOL Modelling and Simulation of PEM Fuel Cell's Flow ChannelsBeichaNessuna valutazione finora

- Membrane ReactorDocumento9 pagineMembrane ReactorAzharuddin Ehtesham FarooquiNessuna valutazione finora

- Rahim I 2008Documento5 pagineRahim I 2008samandondonNessuna valutazione finora

- CFD Simulation of Regression Rate in Hybrid RocketsDocumento9 pagineCFD Simulation of Regression Rate in Hybrid Rocketsalberto_bettellaNessuna valutazione finora

- Communications: Theoretical Model For Nanoporous Carbon SupercapacitorsDocumento5 pagineCommunications: Theoretical Model For Nanoporous Carbon SupercapacitorsTauno ToomingNessuna valutazione finora

- Methanol SimulationDocumento9 pagineMethanol SimulationMaria Jose TorresNessuna valutazione finora

- 338-Article Text-1751-2-10-20080123Documento16 pagine338-Article Text-1751-2-10-20080123FurqanNessuna valutazione finora

- Cha-10Documento6 pagineCha-10kivumbi AchileoNessuna valutazione finora

- An Assessment of Drag Models in Eulerian-Eulerian CFD Simulation of Gas-Solid Flow Hydrodynamics in Circulating Fluidized Bed RiserDocumento19 pagineAn Assessment of Drag Models in Eulerian-Eulerian CFD Simulation of Gas-Solid Flow Hydrodynamics in Circulating Fluidized Bed RiserSAI Khalid HichamNessuna valutazione finora

- Effects of Porosity Change of Gas Diffuser On Performance of Proton Exchange Membrane Fuel CellDocumento9 pagineEffects of Porosity Change of Gas Diffuser On Performance of Proton Exchange Membrane Fuel CellMalika AchouriNessuna valutazione finora

- Models - Cfd.pem ElectrolyzerDocumento46 pagineModels - Cfd.pem ElectrolyzerLại Thế KhánhNessuna valutazione finora

- A Parametric Study of Layered Bed PSA For Hydrogen PurificationDocumento16 pagineA Parametric Study of Layered Bed PSA For Hydrogen PurificationMateo PosadaNessuna valutazione finora

- Membrane Separation (MS)Documento16 pagineMembrane Separation (MS)Walter CarguaNessuna valutazione finora

- CFD Simulation of An Expanded Granular Sludge Bed (EGSB) Reactor For Biohydrogen ProductionDocumento10 pagineCFD Simulation of An Expanded Granular Sludge Bed (EGSB) Reactor For Biohydrogen ProductionGurusangmeshHiremathNessuna valutazione finora

- 2019 2 Zone Dry Reforming FB and MR CejDocumento10 pagine2019 2 Zone Dry Reforming FB and MR Cejmehrdad mahmoudiNessuna valutazione finora

- Nergy and Nvironment: Optimal Design of PEM Fuel Cells To Generate Maximum Power: A CFD StudyDocumento10 pagineNergy and Nvironment: Optimal Design of PEM Fuel Cells To Generate Maximum Power: A CFD StudyVenkateswarlu VelisalaNessuna valutazione finora

- 48 - Reservoir SimulationDocumento20 pagine48 - Reservoir Simulationrizal tri susilo100% (2)

- Nodal Methods For Three-Dimensional Simulators: (Received JulyDocumento23 pagineNodal Methods For Three-Dimensional Simulators: (Received JulyTopan SetiadipuraNessuna valutazione finora

- Processes: A Computational Fluid Dynamics Approach For The Modeling of Gas Separation in Membrane ModulesDocumento13 pagineProcesses: A Computational Fluid Dynamics Approach For The Modeling of Gas Separation in Membrane ModulesAiman LatifNessuna valutazione finora

- 2006 Sayson NLBDocumento3 pagine2006 Sayson NLBMajid MousaviNessuna valutazione finora

- RV3 Modelling AproachesDocumento23 pagineRV3 Modelling AproachesdavpaffNessuna valutazione finora

- Hyper Branched PolymersDocumento20 pagineHyper Branched PolymerspikkleNessuna valutazione finora

- Modeling and Simulation of Airlift BioreactorsDocumento9 pagineModeling and Simulation of Airlift BioreactorsAnjanaNessuna valutazione finora

- 2CV.2.30 Paper 27th 2019Documento12 pagine2CV.2.30 Paper 27th 2019George PerakisNessuna valutazione finora

- CFD Simulation of CO2 Sorption in A Circulating Fluidized Bed Using The Deactivation Kinetic ModelDocumento8 pagineCFD Simulation of CO2 Sorption in A Circulating Fluidized Bed Using The Deactivation Kinetic Modelziglat2004Nessuna valutazione finora

- Macromol. Symp. 102, 9-17 (1996)Documento9 pagineMacromol. Symp. 102, 9-17 (1996)elderwanNessuna valutazione finora

- Combustion Fluent OpenFoam PDFDocumento6 pagineCombustion Fluent OpenFoam PDF8n80bi880Nessuna valutazione finora

- Performance of Hollow Fiber Membrane Gas-Liquid Contactors To Absorb Co UsingDocumento13 paginePerformance of Hollow Fiber Membrane Gas-Liquid Contactors To Absorb Co UsingPitri YantiNessuna valutazione finora

- Che 382: Unit Operations LaboratoryDocumento6 pagineChe 382: Unit Operations LaboratoryFazlinda ZiadiNessuna valutazione finora

- Multiphase FlowDocumento8 pagineMultiphase FlowDr Mohammed AzharNessuna valutazione finora

- Cryo Ads SysDocumento13 pagineCryo Ads Syskumarvs3Nessuna valutazione finora

- CO2 Removal From Synthetic Natural Gas For City Gas Use PDFDocumento6 pagineCO2 Removal From Synthetic Natural Gas For City Gas Use PDFHassan HassanpourNessuna valutazione finora

- Modeling and Simulation of Membrane Separation Process Using Computational Fluid DynamicsDocumento26 pagineModeling and Simulation of Membrane Separation Process Using Computational Fluid DynamicsBrenda DavisNessuna valutazione finora

- 2017 AdvancesDocumento8 pagine2017 AdvancesAkshai Ashok KumarNessuna valutazione finora

- Mathematical Modeling of CO /CH Separation by Hollow Fiber Membrane Module Using Finite Difference MethodDocumento11 pagineMathematical Modeling of CO /CH Separation by Hollow Fiber Membrane Module Using Finite Difference Methodarun aryaNessuna valutazione finora

- Effects of High Hydrogen Dilution Ratio On Optical Properties of Hydrogenated Nanocrystalline Silicon Thin FilmsDocumento6 pagineEffects of High Hydrogen Dilution Ratio On Optical Properties of Hydrogenated Nanocrystalline Silicon Thin FilmsMark LieNessuna valutazione finora

- 10.1023/a 1019100925300Documento7 pagine10.1023/a 1019100925300Vishakha GaurNessuna valutazione finora

- How To Do Structural and Thermal Analysis of Disc Brake Rotor Using Ansys Software - GrabCAD TutorialsDocumento1 paginaHow To Do Structural and Thermal Analysis of Disc Brake Rotor Using Ansys Software - GrabCAD TutorialsclaralisieNessuna valutazione finora

- Reducing The CO2 Emissions in Croatian Cement IndustryDocumento8 pagineReducing The CO2 Emissions in Croatian Cement IndustryclaralisieNessuna valutazione finora

- Mixing of Secondary Gas Injection in A Bubbling Fluidized BedDocumento15 pagineMixing of Secondary Gas Injection in A Bubbling Fluidized BedclaralisieNessuna valutazione finora

- Numerical Simulation of Gas and Solid Flow Behavior in The Pre-Calciner With Large Eddy Simulation ApproachDocumento7 pagineNumerical Simulation of Gas and Solid Flow Behavior in The Pre-Calciner With Large Eddy Simulation ApproachclaralisieNessuna valutazione finora

- Experimental Flow Field Characteristics of OFA For Large-Angle Counter Flow of Fuel-Rich Jet Combustion TechnologyDocumento9 pagineExperimental Flow Field Characteristics of OFA For Large-Angle Counter Flow of Fuel-Rich Jet Combustion TechnologyclaralisieNessuna valutazione finora

- Devolatilization Characteristics of Large Particles of Tyre Rubber Under Combustion Conditions PDFDocumento11 pagineDevolatilization Characteristics of Large Particles of Tyre Rubber Under Combustion Conditions PDFclaralisieNessuna valutazione finora

- Finite Element Modeling For Inspection of CANDU® Steam GeneratorsDocumento4 pagineFinite Element Modeling For Inspection of CANDU® Steam GeneratorsclaralisieNessuna valutazione finora

- Tracer Experiment in Plug Flow ReactorDocumento6 pagineTracer Experiment in Plug Flow ReactorAfrillia FahrinaNessuna valutazione finora

- Review of Aeroelasticity For Wind Turbine Current Status, Research Focus and Future PerspectivesDocumento16 pagineReview of Aeroelasticity For Wind Turbine Current Status, Research Focus and Future PerspectivesclaralisieNessuna valutazione finora

- A. Lecoanet, D. G. Ivey, H. Henein Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, CanadaDocumento1 paginaA. Lecoanet, D. G. Ivey, H. Henein Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, CanadaclaralisieNessuna valutazione finora

- D. Maciel, N. Bouchonneau 1. Universidade Federal de Pernambuco, Recife, Pernambuco, BrasilDocumento1 paginaD. Maciel, N. Bouchonneau 1. Universidade Federal de Pernambuco, Recife, Pernambuco, BrasilclaralisieNessuna valutazione finora

- Adaptive Pitch Control of Wind Turbine For Load Mitigation U 2017 RenewableDocumento12 pagineAdaptive Pitch Control of Wind Turbine For Load Mitigation U 2017 RenewableclaralisieNessuna valutazione finora

- L Uiz R. de Souza JR., L Eonardo Lorenz 1. Universidade Federal Do Paraná, Curitiba, Paraná, BrazilDocumento1 paginaL Uiz R. de Souza JR., L Eonardo Lorenz 1. Universidade Federal Do Paraná, Curitiba, Paraná, BrazilclaralisieNessuna valutazione finora

- H SO Catalysis: Perspective & Opportunities For Reducing SO EmissionsDocumento16 pagineH SO Catalysis: Perspective & Opportunities For Reducing SO EmissionsclaralisieNessuna valutazione finora

- CFD Analysis of Flow Fields For Shrouded Wind Turbine 2017 Alexandria EnginDocumento9 pagineCFD Analysis of Flow Fields For Shrouded Wind Turbine 2017 Alexandria EnginclaralisieNessuna valutazione finora

- Study of A Full Scale Oxy-Fuel Cement Rotary Kiln PDFDocumento10 pagineStudy of A Full Scale Oxy-Fuel Cement Rotary Kiln PDFclaralisieNessuna valutazione finora

- A Computational Fluid Dynamics Study of Fluid Catalytic Cracking CyclonesDocumento7 pagineA Computational Fluid Dynamics Study of Fluid Catalytic Cracking CyclonesclaralisieNessuna valutazione finora

- Accelerated Internationalization and Resource Leverage STR 2015 Journal of WDocumento11 pagineAccelerated Internationalization and Resource Leverage STR 2015 Journal of WclaralisieNessuna valutazione finora

- Active Structural Control of A Floating Wind Turbine 2017 Journal of SoundDocumento26 pagineActive Structural Control of A Floating Wind Turbine 2017 Journal of SoundclaralisieNessuna valutazione finora

- A Cost and Performance Comparison of LRTM and VI For The Manu 2011 RenewableDocumento6 pagineA Cost and Performance Comparison of LRTM and VI For The Manu 2011 RenewableclaralisieNessuna valutazione finora

- Aero Acoustics Noise Evaluation of H Rotor Darrieus Wind Turbines 2014 EnergDocumento9 pagineAero Acoustics Noise Evaluation of H Rotor Darrieus Wind Turbines 2014 EnergclaralisieNessuna valutazione finora

- Advanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enDocumento14 pagineAdvanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enclaralisieNessuna valutazione finora

- A Direct Approach of Design Optimization For Small Horizontal 2015 ProcediaDocumento5 pagineA Direct Approach of Design Optimization For Small Horizontal 2015 ProcediaclaralisieNessuna valutazione finora

- NACA Airfoil Optimization: Created in COMSOL Multiphysics 5.3aDocumento5 pagineNACA Airfoil Optimization: Created in COMSOL Multiphysics 5.3aclaralisieNessuna valutazione finora

- Adaptive Robust Control of A Class of Non Affine Variable Spee 2016 ISA TranDocumento9 pagineAdaptive Robust Control of A Class of Non Affine Variable Spee 2016 ISA TranclaralisieNessuna valutazione finora

- Adaptive Neuro Fuzzy Estimation of Diffuser Effects On Wind Turbin 2015 EnerDocumento10 pagineAdaptive Neuro Fuzzy Estimation of Diffuser Effects On Wind Turbin 2015 EnerclaralisieNessuna valutazione finora

- Adaptive Neuro Fuzzy Generalization of Wind Tur - 2014 - Renewable and Sustainab PDFDocumento7 pagineAdaptive Neuro Fuzzy Generalization of Wind Tur - 2014 - Renewable and Sustainab PDFclaralisieNessuna valutazione finora

- 3D URANS Analysis of A Vertical Axis W 2015 Journal of Wind Engineering andDocumento8 pagine3D URANS Analysis of A Vertical Axis W 2015 Journal of Wind Engineering andclaralisieNessuna valutazione finora

- A Boundary Integral Equation Over The Thin Ro 2016 Engineering Analysis WithDocumento7 pagineA Boundary Integral Equation Over The Thin Ro 2016 Engineering Analysis WithclaralisieNessuna valutazione finora

- Advanced Brake State Model and Aerodynamic Post Stall Model - 2013 - Renewable PDFDocumento6 pagineAdvanced Brake State Model and Aerodynamic Post Stall Model - 2013 - Renewable PDFclaralisieNessuna valutazione finora

- Benefits and Limitations of BEPDocumento2 pagineBenefits and Limitations of BEPAnishaAppuNessuna valutazione finora

- Art of War Day TradingDocumento17 pagineArt of War Day TradingChrispen MoyoNessuna valutazione finora

- EngHub How To Break HabitsDocumento13 pagineEngHub How To Break HabitsViktoria NovikovaNessuna valutazione finora

- Sap New GL: Document Splitting - Configuration: ChooseDocumento3 pagineSap New GL: Document Splitting - Configuration: ChooseChandra Sekhar PNessuna valutazione finora

- Electrical Engineering Lab Vica AnDocumento6 pagineElectrical Engineering Lab Vica Anabdulnaveed50% (2)

- The Reason: B. FlowsDocumento4 pagineThe Reason: B. FlowsAryanti UrsullahNessuna valutazione finora

- Albert Roussel, Paul LandormyDocumento18 pagineAlbert Roussel, Paul Landormymmarriuss7Nessuna valutazione finora

- L5V 00004Documento2 pagineL5V 00004Jhon LinkNessuna valutazione finora

- 32 Hyderabad HITEC City BisleriDocumento23 pagine32 Hyderabad HITEC City BisleriSridhar ViswanathanNessuna valutazione finora

- Presenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoDocumento23 paginePresenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoHorace EstrellaNessuna valutazione finora

- Xtype Power Train DTC SummariesDocumento53 pagineXtype Power Train DTC Summariescardude45750Nessuna valutazione finora

- Vieworks DR Panel BrochureDocumento8 pagineVieworks DR Panel Brochuretito goodNessuna valutazione finora

- Refutation EssayDocumento6 pagineRefutation Essayapi-314826327Nessuna valutazione finora

- Essentials: Week by WeekDocumento18 pagineEssentials: Week by WeekHirenkumar ShahNessuna valutazione finora

- Marketing Micro and Macro EnvironmentDocumento8 pagineMarketing Micro and Macro EnvironmentSumit Acharya100% (1)

- Unbound DNS Server Tutorial at CalomelDocumento25 pagineUnbound DNS Server Tutorial at CalomelPradyumna Singh RathoreNessuna valutazione finora

- Lenovo NotebooksDocumento6 pagineLenovo NotebooksKamlendran BaradidathanNessuna valutazione finora

- Manual de Operacion y MantenimientoDocumento236 pagineManual de Operacion y MantenimientoalexNessuna valutazione finora

- Final Test Level 7 New Format 2019Documento3 pagineFinal Test Level 7 New Format 2019fabian serranoNessuna valutazione finora

- Advocacy Firm Business Plan by SlidesgoDocumento40 pagineAdvocacy Firm Business Plan by SlidesgoirinaNessuna valutazione finora

- Ismb ItpDocumento3 pagineIsmb ItpKumar AbhishekNessuna valutazione finora

- DCN Dte-Dce and ModemsDocumento5 pagineDCN Dte-Dce and ModemsSathish BabuNessuna valutazione finora

- Spring 2010 - CS604 - 1 - SolutionDocumento2 pagineSpring 2010 - CS604 - 1 - SolutionPower GirlsNessuna valutazione finora

- Java Complete Collection FrameworkDocumento28 pagineJava Complete Collection FrameworkkhushivanshNessuna valutazione finora

- Daily Lesson Log Quarter 1 Week 1Documento5 pagineDaily Lesson Log Quarter 1 Week 1John Patrick Famadulan100% (1)

- The Rock Reliefs of Ancient IranAuthor (Documento34 pagineThe Rock Reliefs of Ancient IranAuthor (mark_schwartz_41Nessuna valutazione finora

- Strategic Marketing: The University of Lahore (Islamabad Campus)Documento3 pagineStrategic Marketing: The University of Lahore (Islamabad Campus)Sumaira IrshadNessuna valutazione finora

- Caradol sc48 08Documento2 pagineCaradol sc48 08GİZEM DEMİRNessuna valutazione finora

- PreviewpdfDocumento29 paginePreviewpdfSoemarlan ErlanNessuna valutazione finora

- Rishika Reddy Art Integrated ActivityDocumento11 pagineRishika Reddy Art Integrated ActivityRishika ReddyNessuna valutazione finora

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDa EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseValutazione: 3.5 su 5 stelle3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 5 su 5 stelle5/5 (5)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDa EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNessuna valutazione finora

- The Other End of the Leash: Why We Do What We Do Around DogsDa EverandThe Other End of the Leash: Why We Do What We Do Around DogsValutazione: 5 su 5 stelle5/5 (65)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 3.5 su 5 stelle3.5/5 (34)

- Fire Season: Field Notes from a Wilderness LookoutDa EverandFire Season: Field Notes from a Wilderness LookoutValutazione: 4 su 5 stelle4/5 (142)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraDa EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraValutazione: 3 su 5 stelle3/5 (10)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionDa EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionValutazione: 4 su 5 stelle4/5 (811)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDa EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsValutazione: 4 su 5 stelle4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDa EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldValutazione: 4.5 su 5 stelle4.5/5 (18)

- Spoiled Rotten America: Outrages of Everyday LifeDa EverandSpoiled Rotten America: Outrages of Everyday LifeValutazione: 3 su 5 stelle3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDa EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildValutazione: 4.5 su 5 stelle4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeDa EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeValutazione: 4.5 su 5 stelle4.5/5 (699)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsDa EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsValutazione: 3.5 su 5 stelle3.5/5 (13)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDa EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldValutazione: 4 su 5 stelle4/5 (593)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDa EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorValutazione: 4.5 su 5 stelle4.5/5 (137)

- Come Back, Como: Winning the Heart of a Reluctant DogDa EverandCome Back, Como: Winning the Heart of a Reluctant DogValutazione: 3.5 su 5 stelle3.5/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeDa EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeValutazione: 4.5 su 5 stelle4.5/5 (6)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderDa EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderValutazione: 4 su 5 stelle4/5 (283)