Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Komatsu - Spec 1

Caricato da

giapy0000Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Komatsu - Spec 1

Caricato da

giapy0000Copyright:

Formati disponibili

Management No.

G027240

To :

Generator Plan Specification Sheet

(ESR-545-SCRN6 high pressure)

Equipped engine : SAA6D170E : Komatsu Diesel Co.,Ltd.

Remote Radiator method

2005 / 8 / 11

Approved by

Reviewed by

ENESERVE CORPORATION

Created by

Chapter 1 General Information

1-1 Summery

This Specification sheet is about the Diesel Engine Generator Equipment (hereinafter `this

generator) you are planning to purchase, and is to be designed, created, constructed, inspected,

and test operated based on this specification.

1-2 Components of equipments to be delivered

The following machines are to be delivered. As to the details of each machine is described in

Chapter 2 of this specification sheet.

1. Synchronous generators

2. Diesel engine

3phases, 545kW

585/574 kW

3300V

(1500/1800min -1)

3. Cubicle

4. Generator control panel

5. Generator distant supervisory board

6. Auxiliary machines (auxiliary fuel tank, auxiliary lubricant oil tank, large lubricant oil filter,

battery)

7. Special cooling water pump for inter-cooler

8. Remote radiator

1-3 Summery of structure

1. Generator flame is fuselage connected to engine flywheel housing, and rotor has one-axis

bearing, while the other axis is directly connected to engine flywheel through buffering

coupling plate.

2. Generator, diesel engines, auxiliary machines installed on the same station, are installed in

a steel plate noise filter, which shut out rain and wind, and has a protection covering for

sound insulation, and doors for maintenance.

3. Generator control panel has breaker necessary to drive generator, protection relays, control

machines such as PCs, gauges, synchronoscope, and those machines necessary for the

parallel running with the system, built-in.

4. Generator distant supervisory board shows abnormality of generators, alarm, or display of

driving status.

5. Lubricant oil circulation device has auxiliary tank (300L) beside the oil pan attached to

engine, defecates oil regardless of generators operation status (in operation or not), and

extends lubricant oils lifetime.

6. Engine is output controlled by Komatsu LE controller. Combined with AGC-TA, constant

control of received power or control of self-sustained operation become possible

7. Remote radiator is equipped to cool engines, intercooler, or fuel. Cooling fan controlled by

inverter is rotationally controlled depending on the temperature, and is also energy-saving

1-4 Applicable standard

This device has the applicable standard under the following existing standard, and is designed,

produced, and inspected under that

1. Japanese Industrial Standards (JIS)

JIS-C4004-1992 `rotary electric machine principle

2. Electrical standard investigation of the Institute of Electrical Engineers of Japan (IEEJ)

Standard

JEC-2130-2000 `synchronous machines

JEC-2100-1993 `rotary electric machines in general

JEC-C4003

`Variation of electric machines insulation

3. Japan Electrical Manufacturers' Association (JEMA) Standard

4. Electrical installation technology standard

5. Common specification sheet of electrical equipment work

1-5

Ambient Conditions

The followings are the conditions for the installation site of this generator.

1. Installation site

outdoor

2. Ambient temperature

5 - 40 degrees C

3. Altitude

300 m and below

4. Humidity level

40 80 % and below

5. dust or noxious fume

none

1-6 Noise Level

The noise level of average 4 points is under 68 dB(A), when tested 7m away from the side face

of Generator, 1m above the ground.

1-7 Rise of Temperature

The limit of temperature rise is under the following degree, measured by thermometer.

Stator winding

Bearing

110 degrees C (F-type)

55 degrees C

1-8 Dielectric Strength

After dielectric strength is measured and found no problem, test voltage is applied for one

minute continuously between the following live part and ground, to show it is OK. (2E+1000V)

Stator winding

test voltage: 14,200V (in case of high voltage 6600V)

1-9 Antivibration equipment

When operated in rated output, the amplitude(P-P) around the upper part of the space the

antivibration equipment is attached, is 0.25 mm and below.

1-10

Paint

The final painting color of this generator is our following standard color.

In case you request different colors we will discuss.

1. Exterior package

Muncell color

5Y7/1

2. Diesel engine

Muncell color

9,54B 1.87/0.44

3. Generator

Muncell color

5Y7/1

4. Generator supervisory board

Muncell color

5Y7/1

1-11

Size

Length overall

7.545 mm

Width overall

2.376 mm

Height overall

4.470 mm

1-12

Mass

Dry mass

12,000 kg

Running mass

13,000 kg

1-13

Supporting Data

We will submit the following documents and drawings.

Number of each documents and drawings are the minimum. In case you need more when

placing an order, please request.

Title

copies

Time of submit

Specification sheet of manufacturing

After formal contract

Completed chart

After product shipment

Note

Forms for government agencies

After formal reception of order

Certificate of analysis

After test drive and adjustment

Instruction manual

During test drive and adjustment

1-14

Major issues of legal procedures

*We will accept the following procedures and applications with your companys cooperation.

1. Submission, notification, consultation, and related procedures of the `Consideration request of

system linkage technology or `Demand application sheet to power companies

2. Submission of `Safety regulation alteration report or `Installation report of specific facilities to

government agencies.

3. Submission of `Installation report of hazardous material to fire department offices.

1-15

Test and inspection

After completed production, the gauges of this generator will go through the following tests and

inspections.

1. Gauges will be tested separately in our factories, with the result described in certificate of

factory test.

2. Diesel engines and generator are to be connected directly in the assembly factories, and go

through total test combined with control instruments. (Operation check of each protector and

relay, load test, speed governor test, and other necessary tests)

3. After field installation work is completed, the generator will pass in-company test.

*We will submit the certificate of this test as the certificate of test and inspection of this

generator.

1-16

How to operate as an independent generator

(Emergency generator is classified into a qualified item and has different specification)

When the generator is operated independently as an independent generator, under the

condition such as power outage, and electric power is supplied to special load, we will

discuss security verification, load capacity, and other related things separately.

The basic method of independent operation has 2 types, which are automatic independent

operation and manual independent operation.

Chapter 2 Specification of equipments

The specification of equipments to be delivered listed in Chapter 1, 1-2, of this specification sheet

are the following;

2-1

Equipment configuration

Equipments

On-board

Separated

equipments

equipments

Note

Synchronous generator

Diesel engines

Coolers (remote radiators)

Fuels

390L

Lubricants

600L

Accumulator battery

200AH2

Electrical box

bifacial

Battery charger box

Inverter board

10

Controllers

11

Generator distant supervisory board

12

Cycle filtration of lubricant oil

13

Fuel filter

14

Water-cooled fuel cooler

15

After cooler

16

Cooling water pump for Inter cooler

17

ROT filter

SAA6D170E

Radiator

inter

cooler built-in

300L

and

Element

filtration

accuracy is 3m

2-2

Specification of Configuration devices

1. Main data of synchronous generator

Name

Three-phase synchronous generator

Type

Drip-proof, horizontal shaft,

Number of phase

Three-phase

Method of connection

star-shaped

Pole number

Frequency

50/60 Hz

Power output

545 kW

Voltage

3300 V

Electric current

100.4 A

Power factor

95 % (behind)

Rotation frequency

1500/1800 min-1

Excitation system

Brushless system by AC [alternating-current] energization,

SCRstyle automatic voltage controller

Efficiency

96.6 / 96.6 %

Rating

continuous

Insulation class

F type

Cooling system

Self ventilation system

Mass

2,400 kg

2. Main data of Diesel engines

Name

Komatsu SAA6D170E

Type

4 cycles, water-cooled, straight standing style, direct-injection,

turbocharging

Number of cylinders

internal diameterprocess

Total process amount

23.15L

Compression ratio

14.3 : 1

Rated power output

574kW

1500min-1

585kW

1800min-1

6-170mm 170mm

Fuel in use

A heavy oil (JIS K2205 compliant), Sulfur content 0.8% and under

Dry weight

2470kg

Size of engines

Total length 2450 mm

Total width

1350 mm

Total height

1814.4 mm

Rotation direction

Counterclockwise from the flywheel side

Starting device

Starter 24 V 11 kW 1

Stop system

Fuel saving system, Stop by power-off

Air cleaner

Filter paper style

Protectors

Attached are the following 4 types of alarms

(1)Cooling water alarm

When the temperature of cooling water is 101

degrees C and above

(2)Hydraulic pressure alarm

When the Hydraulic pressure is 0.220.02Mpa and

below

(3)Over speed

50 Hz/1650min-1, 60Hz/1950min-1 and above

(4)Oil level

50L and below

3. Cooling equipment (Remote radiator style)

Cooling system

Engine jacket type

Water

pump

forced-circulation

system

(thermostat attached)

After-cooler type

Ebara FDP style, stainless, single suction, spiral

pump

3232FDFP6, 75A (Engine accessories)

Cooling fan

Mitsubishi pressure fan EJ-95GTB

Three-phase /

Water volume

Engine jacket type

Engine body

200V/1.5kW2

43L

After-cooler type

Remote radiator

55L

Piping

40L

Engine body

20L

Remote radiator

55L

Piping

25L

Total

238L

Water heater

AC230V

Antifreeze liquid

Komatsu genuine super coolant (AF-NAC)

1.5kW 1

30% and above

4. Fuel equipment

Fuel equipment

HPI unit injector system

Fuel pump

Gear pump

Injection nozzle

Porous nozzle

Governor

Computerized

Fuel filter

Filter paper style

Fuel tank

Capacity 390L

Level contact point

LO

2 circuits

HI

2 circuits

5. Lubricant equipment

Lubricant equipment

Lubricant system

Gear pump force feed system

Oil filter

Full flaw filter (cartridge type)

Oil cooler

Inner packed, water cooling system (plate type)

Engine oil

15W40, following the Komatsu recommendation

Oil capacity

196 L (oil pan =190 L,

Oil pan level contact point

LO

Auxiliary tank

600L

capacity

oil filter and others =6L)

1 circuit

Automatic supply valves directly connected to oil pan is

attached

Circulation tank

capacity

300L

CJC filter is attached

6. Accumulator battery equipment

Battery

Type

UP400-12

Voltage

12 V

Capacity

167 Ah (10 hour rate)

Quantity

Manufacturer

Shin-Kobe Electric Machinery Co., Ltd.

Accumulator battery

Type

BA-24H (for Shin-Kobe battery)

Input

AC 85V 132V

Floating battery voltage

26.8 V

Floating battery power current

0 4.3 A

Manufacturer

ENESERVE CORPORATION

7. Generator control panel

Eneserve

AGC-TA

Monitoring function of loaded condition, synchronous input function, output control function,

Quantity control of devices to generate, measurement function of generator, and other

functions are installed.

VF13-CMC

Mitsubishi Electric

Current transformer for gage

CD-40K (100/5A)

Mitsubishi Electric

Voltage transformer for gage

PD-50HF(6600/110V)

Mitsubishi Electric

Overcurrent relay

K2ZC-K2CA-N

Omron

Ground fault directed relay

K2ZC-K2GS-N

Omron

DC undervoltage relay

SDC-FH2

Omron

Sequence controller

FX2N-80MR-D

Mitsubishi Electric

Sequence controller

FX2N-2321F

Mitsubishi Electric

Sequence controller

FX2n-32CCL

Mitsubishi Electric

System observation device

CMS M400

Eneserve

AVR

NTA-5V-21T

Negishi MFG.

Synchronoscope

SY-25W

Eneserve

Voltage adjustment resistor

VR-1 (01k)

Eneserve

Vacuum

electromagnetic

breaker

8. System control panel

It is equipped with the function to control more than one generators.

VF13-PMC

Mitsubishi Electric

Current transformer for gage

CD-40K (/5A)

Mitsubishi Electric

Voltage transformer for gage

PD-50HF(6600/110V)

Mitsubishi Electric

Power transducer

LWTN-11AO-X

M-System

Power-factor meter

YP-8PF

Mitsubishi Electric

Voltmeter

YR-8UAV(6600/110V)

Mitsubishi Electric

Ammeter

YR-8UAA(200/5A)

Mitsubishi Electric

Power meter

YR-8NRI(02400kW)

Mitsubishi Electric

Battery charger

BA-24K

Eneserve

Sequence controller

FX2N-80MR-D

Mitsubishi Electric

Sequence controller

FX2N-16LNK

Mitsubishi Electric

Sequence controller

AJ65BTB1-16T

Mitsubishi Electric

Vacuum

electromagnetic

breaker

9. Electric box inside Generator

It has LE controller and engines to control engine, gauges to measure parts of generator,

and works as a relay terminal for the wiring of the separated generator control panel.

LE controller

6240-81-5200

Komatsu Diesel

Heat and Pressure transducer

RY240-4KY

Eneserve

Indicator

GC-24D

Eneserve

Pulse / Analog converter

APD/K

Eneserve

Inverter (for engine room fan)

VFNC1-2022P

Toshiba

Inverter

VFS11-2037P

Toshiba

CB400FK01-8*NN-NN/A

RKC Instrument

Fan controller

FC-1

Eneserve

Battery charger

BA-24H

Eneserve

(for remote radiator fan)

Temperature controller

(for engine room fan)

10

Potrebbero piacerti anche

- 1103 1104FeaturesBenefitsDocumento13 pagine1103 1104FeaturesBenefitsjulio cesarNessuna valutazione finora

- PI144H-311-TD-En Alternator Standard PI144H - 3 Ph-Winding 311Documento10 paginePI144H-311-TD-En Alternator Standard PI144H - 3 Ph-Winding 311mnezamiNessuna valutazione finora

- Instruction ManualDocumento30 pagineInstruction ManualsupriNessuna valutazione finora

- A041 J096Documento0 pagineA041 J096Michal HroudaNessuna valutazione finora

- Capella Wiring DiagramDocumento1 paginaCapella Wiring DiagramRandalNessuna valutazione finora

- Chapter One: History of A.M.IDocumento32 pagineChapter One: History of A.M.Im3areNessuna valutazione finora

- Cat Electronic Technician 2014A v1.0 Product Status ReportDocumento6 pagineCat Electronic Technician 2014A v1.0 Product Status Reportyao nestorNessuna valutazione finora

- Oktober TBNDocumento19 pagineOktober TBNwhisnu hyerlambangNessuna valutazione finora

- Kta50 g9Documento3 pagineKta50 g9xxxxxxxxxxxx100% (1)

- Battery ChargerDocumento16 pagineBattery Chargerdimasrimantikto100% (2)

- OHV PedigreeDocumento20 pagineOHV PedigreeMariorosales MendezNessuna valutazione finora

- Caterpillar XQ80 Towable Diesel Generator SetDocumento5 pagineCaterpillar XQ80 Towable Diesel Generator SetMacAllister MachineryNessuna valutazione finora

- 785B - (6hk5123-Up) PDFDocumento2 pagine785B - (6hk5123-Up) PDFRuan NortjeNessuna valutazione finora

- File 20191211 103211 C9.3 CG9 Emcp4.2 Uenr7508uenr7508 SisDocumento2 pagineFile 20191211 103211 C9.3 CG9 Emcp4.2 Uenr7508uenr7508 SisPhanNamNessuna valutazione finora

- Emcp 4: EMCP 4.2 Generator Set ControllerDocumento3 pagineEmcp 4: EMCP 4.2 Generator Set ControllerdinukaeeNessuna valutazione finora

- C1373Documento3 pagineC1373Harry Wart WartNessuna valutazione finora

- OQSxUserGuide Gen 2 V1.2Documento23 pagineOQSxUserGuide Gen 2 V1.2Ernie Gomez ColquichaguaNessuna valutazione finora

- 9003 Industrial DG-EngineSysDocumento2 pagine9003 Industrial DG-EngineSysAlejandro SanchezNessuna valutazione finora

- DCU 305 R3 and R3 LT Installation ManualDocumento44 pagineDCU 305 R3 and R3 LT Installation ManualmichaelfvNessuna valutazione finora

- QSK50-G4: EPA Tier 2 and TA Luft CompliantDocumento3 pagineQSK50-G4: EPA Tier 2 and TA Luft CompliantmualiminNessuna valutazione finora

- O & M Manual For The Fixed and Drawout Magum Transfer Switches - Instruction Booklet - IB01602011E - EATON® PDFDocumento44 pagineO & M Manual For The Fixed and Drawout Magum Transfer Switches - Instruction Booklet - IB01602011E - EATON® PDFpevareNessuna valutazione finora

- Gek - 64315E IsoDocumento6 pagineGek - 64315E IsoEsteban SáezNessuna valutazione finora

- 2.a. Electric Fire Pump ControllerDocumento12 pagine2.a. Electric Fire Pump ControllerNOMANNessuna valutazione finora

- Dse 509Documento2 pagineDse 509SOSNessuna valutazione finora

- Rehs2362 02Documento24 pagineRehs2362 02zekaNessuna valutazione finora

- TLG 12esx PDFDocumento9 pagineTLG 12esx PDFGeiler Benitez PiñaNessuna valutazione finora

- Generator Automatic Voltage Regulator Operation Manual: Tel: - Fax: - @Documento8 pagineGenerator Automatic Voltage Regulator Operation Manual: Tel: - Fax: - @Syed Mohammad Naveed100% (1)

- C32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpDocumento4 pagineC32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpJosé100% (1)

- DSE 7510 Data SheetDocumento4 pagineDSE 7510 Data SheetMd MoniruzzamanNessuna valutazione finora

- INSITE - 6.4 Overview Rev For HHIDocumento99 pagineINSITE - 6.4 Overview Rev For HHIsengottaiyanNessuna valutazione finora

- BGC-L Data Sheet 4921240306 UKDocumento5 pagineBGC-L Data Sheet 4921240306 UKRafael Charry Andrade100% (1)

- Cat Electronic Modular Control Panel (EMCP) 4.3 Upgrade KitDocumento2 pagineCat Electronic Modular Control Panel (EMCP) 4.3 Upgrade KitKaung KharNessuna valutazione finora

- 04 - 930E-4 IGBT 24V System (1) KomatsuDocumento41 pagine04 - 930E-4 IGBT 24V System (1) KomatsuGiovani Gon Ni100% (1)

- Kit NEXYS To APM303 - Install Procedure-EnglishDocumento7 pagineKit NEXYS To APM303 - Install Procedure-Englishzawmintun zpeNessuna valutazione finora

- CDVR 6Documento4 pagineCDVR 6wagner_guimarães_1100% (1)

- SDMO Ind Special Projects BOOKDocumento250 pagineSDMO Ind Special Projects BOOKMiguel PerezNessuna valutazione finora

- Manual Mnatencion 930E-2Documento158 pagineManual Mnatencion 930E-2Luis TorresNessuna valutazione finora

- MMC-4000 ManualDocumento94 pagineMMC-4000 ManualTalha Asad0% (1)

- Leroy Somer LSA 50.2 From Macfarlane Generators PDFDocumento12 pagineLeroy Somer LSA 50.2 From Macfarlane Generators PDFAnonymous 3RS6JNcNessuna valutazione finora

- CAT - G3516H Configuration Parameters - 3516HDocumento1 paginaCAT - G3516H Configuration Parameters - 3516Hwagner_guimarães_1Nessuna valutazione finora

- 3WT Accessories: SENTRON Automatic Transfer Controller ATC5300Documento1 pagina3WT Accessories: SENTRON Automatic Transfer Controller ATC5300ersanjeeb_456Nessuna valutazione finora

- Electrical SystemDocumento94 pagineElectrical SystemCollins ManseloNessuna valutazione finora

- Mt4400ac PDFDocumento4 pagineMt4400ac PDFabpr2008Nessuna valutazione finora

- 16V4000 - T1637K33 Rated Power 2700 BHP at 1900 R-MinDocumento9 pagine16V4000 - T1637K33 Rated Power 2700 BHP at 1900 R-MinJuan PujolNessuna valutazione finora

- Silo - Tips Manual Transaxle and Transfer Workshop Manual A26m R A26mx RDocumento116 pagineSilo - Tips Manual Transaxle and Transfer Workshop Manual A26m R A26mx RMay PosadasNessuna valutazione finora

- 'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDocumento5 pagine'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDavid PomaNessuna valutazione finora

- 3000/3200 Series: RatingsDocumento2 pagine3000/3200 Series: RatingsHyuri JúliaNessuna valutazione finora

- C1376Documento6 pagineC1376Harry Wart WartNessuna valutazione finora

- AML 210x297 Brochure Intl-Spec-Series 403Documento24 pagineAML 210x297 Brochure Intl-Spec-Series 403Daniel BarronNessuna valutazione finora

- Scada System For Power Module Diesel Generator Sets 32 X 2000 kVA D3516B 400VDocumento3 pagineScada System For Power Module Diesel Generator Sets 32 X 2000 kVA D3516B 400Vkvramanan_1100% (1)

- DSE5520 Operators ManualDocumento82 pagineDSE5520 Operators ManualAnonymous dyT6AgjSxSNessuna valutazione finora

- PL Ese560 - Vw-AsDocumento10 paginePL Ese560 - Vw-AsDaniel MuratallaNessuna valutazione finora

- Regulador Voltage CaterpilarDocumento3 pagineRegulador Voltage CaterpilarhossanaNessuna valutazione finora

- CTRLPSB023Documento4 pagineCTRLPSB023Fernando OjedaNessuna valutazione finora

- Fuel Rate Scaling (Fuel Correction Factor) - Diesel FuelDocumento1 paginaFuel Rate Scaling (Fuel Correction Factor) - Diesel Fuelvictor.ciprianiNessuna valutazione finora

- Da-6000ss (60H 110V)Documento15 pagineDa-6000ss (60H 110V)Geiler Benitez PiñaNessuna valutazione finora

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDocumento4 pagineDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryNessuna valutazione finora

- Section 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NoDocumento17 pagineSection 16620 - Natural Gas Engine Generator Set: Division 16 Electrical Project NovcharlesNessuna valutazione finora

- Generator CatalogeDocumento2 pagineGenerator CatalogeEngAhmedNessuna valutazione finora

- Dynamometer: Theory and Application to Engine TestingDa EverandDynamometer: Theory and Application to Engine TestingNessuna valutazione finora

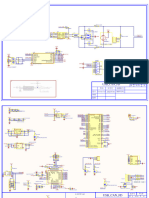

- CANFD_ProjectDocumento4 pagineCANFD_Projectgiapy0000Nessuna valutazione finora

- Speeduino Manual PDFDocumento58 pagineSpeeduino Manual PDFgiapy0000Nessuna valutazione finora

- Pinout Denso Hyundai Megatruck2010Documento1 paginaPinout Denso Hyundai Megatruck2010giapy0000Nessuna valutazione finora

- User'S Manual: PIC-P26J50 Proto Development BoardDocumento19 pagineUser'S Manual: PIC-P26J50 Proto Development Boardgiapy0000100% (1)

- Electric Diagram For SR-250 Upper1Documento1 paginaElectric Diagram For SR-250 Upper1giapy0000Nessuna valutazione finora

- 275kw Diesel Generator Datasheet J275u (English)Documento4 pagine275kw Diesel Generator Datasheet J275u (English)giapy0000Nessuna valutazione finora

- Gold Capacitors: Electric Double Layer CapacitorsDocumento28 pagineGold Capacitors: Electric Double Layer Capacitorsgiapy0000Nessuna valutazione finora

- Speeduino Manual PDFDocumento58 pagineSpeeduino Manual PDFgiapy0000Nessuna valutazione finora

- Release Sd2 EngDocumento12 pagineRelease Sd2 Enggiapy0000Nessuna valutazione finora

- R"i 1 - F'y" Uo: LB II IftDocumento2 pagineR"i 1 - F'y" Uo: LB II Iftgiapy0000Nessuna valutazione finora

- Odo PDFDocumento1 paginaOdo PDFgiapy0000Nessuna valutazione finora

- Atlas CopcoDocumento5 pagineAtlas Copcogiapy0000Nessuna valutazione finora

- VHP750 XHP750WCAT零件手册Documento66 pagineVHP750 XHP750WCAT零件手册giapy000050% (2)

- TQMT104x User's ManualDocumento30 pagineTQMT104x User's Manualgiapy0000Nessuna valutazione finora

- Odo PDFDocumento1 paginaOdo PDFgiapy0000Nessuna valutazione finora

- 0136-GG7 2004 Travel Supreme CAT 3126 072204 - 12720061017315717500 PDFDocumento96 pagine0136-GG7 2004 Travel Supreme CAT 3126 072204 - 12720061017315717500 PDFgiapy00000% (1)

- Features: or Modifications Due To Changes in Technical Specifications. Rev. A, Issue Date: 2006/11/6Documento34 pagineFeatures: or Modifications Due To Changes in Technical Specifications. Rev. A, Issue Date: 2006/11/6giapy0000Nessuna valutazione finora

- Safety Report Weekly 1st - Project TMCT 9-15 2023 (Week 2)Documento19 pagineSafety Report Weekly 1st - Project TMCT 9-15 2023 (Week 2)Ahmad FikriNessuna valutazione finora

- Building Construction 2. Masonry: Civil Engineering Materials and ConstructionDocumento55 pagineBuilding Construction 2. Masonry: Civil Engineering Materials and ConstructionGautam ChandraNessuna valutazione finora

- Solar Enclosure System Troubleshooting GuideDocumento1 paginaSolar Enclosure System Troubleshooting GuideTabishNessuna valutazione finora

- Ladder DiagramDocumento5 pagineLadder DiagramTimonan, Justin James H.Nessuna valutazione finora

- Floors - Notes, LecturesDocumento2 pagineFloors - Notes, LecturesMuhafeez Goolab100% (1)

- KL-500 10603Documento3 pagineKL-500 10603mohamed ShabaanNessuna valutazione finora

- Wiring Instructions For Series It Itb and Its ConnectorsDocumento52 pagineWiring Instructions For Series It Itb and Its ConnectorsРоман ДяченкоNessuna valutazione finora

- YSB23-0136 Bailee #4U ShowHouseDocumento2 pagineYSB23-0136 Bailee #4U ShowHouseLiesa StoneNessuna valutazione finora

- Material List Grounding Untuk PO Rev.1Documento2 pagineMaterial List Grounding Untuk PO Rev.1BANGGANessuna valutazione finora

- Thyristor: From Wikipedia, The Free EncyclopediaDocumento7 pagineThyristor: From Wikipedia, The Free EncyclopediaFadila LazimNessuna valutazione finora

- 01-CAP100 Single Line Diagram For Capacitor Bank of TLM PlantDocumento11 pagine01-CAP100 Single Line Diagram For Capacitor Bank of TLM PlantVidiya NovelinNessuna valutazione finora

- DTC DescriptorDocumento3 pagineDTC DescriptorEngine Tuning UPNessuna valutazione finora

- Capacitor Colour Code and MarkingsDocumento3 pagineCapacitor Colour Code and MarkingsbipinupNessuna valutazione finora

- Diagraru¡S: Vehicle Unit (VECU)Documento4 pagineDiagraru¡S: Vehicle Unit (VECU)WalterNessuna valutazione finora

- Freelander Electrical Circuit DiagramsDocumento74 pagineFreelander Electrical Circuit DiagramsElenaBaciu100% (2)

- Af1 Global Lce Fault CodesDocumento29 pagineAf1 Global Lce Fault Codeschristophetaglionehotmail.frNessuna valutazione finora

- 2AZ FE StartingDocumento16 pagine2AZ FE StartingLuks FernandezNessuna valutazione finora

- Murphy Autostart 700 PDFDocumento2 pagineMurphy Autostart 700 PDFBEN100% (1)

- Rectifier - Penyearah: MateriDocumento12 pagineRectifier - Penyearah: Materinabila isnainiNessuna valutazione finora

- Roofing Estimate TemplateDocumento8 pagineRoofing Estimate TemplateGénesis MartínezNessuna valutazione finora

- Sistema de Admision y Escape C-15Documento36 pagineSistema de Admision y Escape C-15Luis Cuellar100% (1)

- Non-Incendive - Nec: Quantum™ Rotary Control MonitorsDocumento8 pagineNon-Incendive - Nec: Quantum™ Rotary Control MonitorsLeo RojasNessuna valutazione finora

- NG SS 108-98009 0317-311646Documento6 pagineNG SS 108-98009 0317-311646chatty85Nessuna valutazione finora

- Valve Amps - Valve Amp Basics PDFDocumento8 pagineValve Amps - Valve Amp Basics PDFDirk SloosNessuna valutazione finora

- Omron Safety Relay G9SA Catalog & WiringDocumento15 pagineOmron Safety Relay G9SA Catalog & WiringDan SomervilleNessuna valutazione finora

- 3RV29011A Datasheet enDocumento5 pagine3RV29011A Datasheet enAnonymous OjDeGlsq5Nessuna valutazione finora

- VolvoDocumento29 pagineVolvoManuel SuarezNessuna valutazione finora

- Firearm Safety Certificate Study GuideDocumento51 pagineFirearm Safety Certificate Study GuideGreg Raven69% (13)

- Add A Wall LightDocumento4 pagineAdd A Wall Lightcelmic84Nessuna valutazione finora

- En Raico Therm Fs I 05 2021Documento15 pagineEn Raico Therm Fs I 05 2021EGUS cvbaNessuna valutazione finora