Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sa516 70

Caricato da

Thinh ViproTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sa516 70

Caricato da

Thinh ViproCopyright:

Formati disponibili

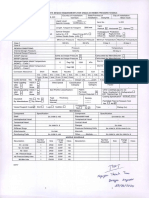

Pressure Vessel HTTEK J.S.

C

Finite Element Analysis ASME Code Calculations

Canadian Vessel Registration Vessel Modeling and Drafting

Material Database

##

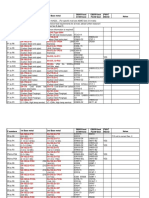

Material Properties:

464.0 Temp [F] - maximum design temperature

Material

Ambient

Strength

Design

Strength Max F

SA-36

Plate

16,600

16,600

SA-106 B

Seamless Pipe

17,100

17,100

SA-234 WPB

Fittings

17,100

17,100

SA-105

Forging

20,000

19,744

SA-516 70

Plate

20,000

20,000

SA-414 G

Sheet

21,400

21,400

SA-213 TP316L

Sms Tube

16,700

15,124

SA-240 316L

Plate

16,700

15,124

SA-312 TP316L

Sms. and Wld. Pipe

16,700

15,124

SA-403 316L

Sms and Weld Fittings

16,700

15,124

SA-479 316L

Bar

16,700

15,124

SA-213 TP316

Sms Tube

20,000

18,468

SA-240 316

Plate

20,000

18,468

SA-312 TP316

Sms. and Wld. Pipe

20,000

18,468

SA-403 316

Sms and Weld Fittings

20,000

18,468

SA-479 316

Bar

20,000

18,468

SA-213 TP304L

Sms Tube

16,700

15,096

SA-240 304L

Plate

16,700

15,096

SA-312 TP304L

Sms. and Wld. Pipe

16,700

15,096

SA-403 304L

Sms and Weld Fittings

16,700

15,096

SA-479 304L

Bar

16,700

15,096

SA-213 TP304

Sms Tube

20,000

13,224

SA-240 304

Plate

20,000

13,224

SA-312 TP304

Sms. and Wld. Pipe

20,000

17,788

SA-403 304

Sms and Weld Fittings

20,000

17,788

SA-479 304

Bar

20,000

17,788

SB-209 6061-T6 plate 0.051-0.249", wld

6,000

0

SB-209 6061-T651 plate 0.25-5", wld

6,000

0

SB-209 6061-T6 plate 0.051-0.249"

10,900

0

SB-209 6061-T651 plate 0.25-4.0"

10,900

0

SB-209 6061-T651 plate 4.0-5.0"

10,300

0

SB-211 A96061-T6 bar 0.125-0.249", wld

6,000

0

SB-234 A96061-T6 tubes 0.025-0.200", wld

6,000

0

SB-241 A96061-T6 sms. Pipe, wld

6,000

0

SB-247 A96061-T6 forging, wld

6,000

0

SB-308 A96061-T6 shapes, wld

6,000

0

Material properties are compliant with ASME Section II part D Table 1A

900

1,000

1,000

1,000

1,000

900

850

850

850

850

850

1,500

1,500

1,500

1,500

1,500

1,200

1,200

1,200

1,200

1,200

1,500

1,500

1,500

1,500

1,500

400

400

400

400

400

400

400

400

400

400

Carbon Steels

Stainless Steel 316L

Stainless Steel 316

Stainless Steel 304L

Stainless Steel 304

Aluminum

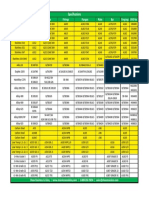

Fluid Properties:

85.3 P [psi] - pressure at top of vessel

10.50 H [ft] - fluid height

1.000 SG - specific gravity

Pdesign [psi] = P+0.433*SG*H ~~ design pressure including static head

Pdesign is to be used in the design of subsequent components (shell, head, nozzle, etc)

This sheet is for educational use only - use at your own risk.

85.3+0.433*1*10.5 = 89.9

HLHP

HTTEK

1.8288

I. DESIGN SHELL AND HEAD OF VESSEL VERTITAL

1.

2.

2.1.

Input data of distillation column:

591

Diameter of the tower

Di

Internal pressure

Pi

2.80 MPa

Design temperature

Material used

Permissible tensile stress

Corrosion allowable

Td

=

=

=

=

240 oC

SA-516 70

137.9 MPa

3.0 mm

1.00

Joint efficiency for shell

Required thickness of shell due to pressure

Internal pressure:

Circumferential Stress:

[see UG-27]

MAT

S

C.A

Ef

t_(m,int1) = (P_iR)/(SE_f-0.6P_i )+CA

0.591 m

9.1 mm

Where:

Internal pressure

Inside radius

Joint eff.

Permissible tensile stress

Corrosion allowable

Longitudinal Stress:

2.2.

Required thickness

Pi

R

Ef

S

CA

t_(m,int2) = (P_iR)/(2SE+0.4P_i )+CA

ts

Page 3

=

=

2.80 MPa

0.2955 m

=

=

=

1.00

137.9 MPa

3.0 mm

6.0 mm

10 mm

Potrebbero piacerti anche

- Tinh Dong Dat Va Gio Cho Tank-Full - Outer Tank123Documento51 pagineTinh Dong Dat Va Gio Cho Tank-Full - Outer Tank123Thinh Vipro100% (1)

- Example 10 Tank SteelDocumento74 pagineExample 10 Tank SteelThinh ViproNessuna valutazione finora

- Where:: No. Zi Yj (Z) T P (Z) P (Z) P (Z)Documento1 paginaWhere:: No. Zi Yj (Z) T P (Z) P (Z) P (Z)Thinh ViproNessuna valutazione finora

- Airline Cargo HandlingDocumento14 pagineAirline Cargo Handlingbhagwansingh22Nessuna valutazione finora

- CastingDocumento56 pagineCastingTushar Prakash ChaudhariNessuna valutazione finora

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocumento11 pagineDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcNessuna valutazione finora

- Farmlot Subdivision GuidelinesDocumento27 pagineFarmlot Subdivision GuidelinesArnoldAlarcon100% (18)

- Storage Volume of TanksDocumento90 pagineStorage Volume of TanksRamachandran VenkateshNessuna valutazione finora

- Line Calculation & Sizing (HYSYS) - PPT Professional Development Course-Bangladesh - 2015.10.05Documento18 pagineLine Calculation & Sizing (HYSYS) - PPT Professional Development Course-Bangladesh - 2015.10.05AriefNessuna valutazione finora

- Mechanical Design SpreadsheetDocumento1 paginaMechanical Design SpreadsheetHoney TiwariNessuna valutazione finora

- New Storage Tanks Design GuidelinesDocumento6 pagineNew Storage Tanks Design GuidelineschrisevabNessuna valutazione finora

- Cone Design ToolDocumento1 paginaCone Design ToolssierroNessuna valutazione finora

- A751-14a Standard Test Methods, Practices, and Terminology For Chemical Analysis of Steel ProductsDocumento5 pagineA751-14a Standard Test Methods, Practices, and Terminology For Chemical Analysis of Steel ProductsChutha0% (2)

- PSV Sizing (Steam)Documento2 paginePSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Copiar de Vessel - Weld - EfficiencyDocumento4 pagineCopiar de Vessel - Weld - EfficiencylavascudoNessuna valutazione finora

- Transportation LawDocumento17 pagineTransportation LawPrincess Cue AragonNessuna valutazione finora

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocumento4 pagineToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocumento2 pagineE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNessuna valutazione finora

- Pipe&Shell Design Tool 600KLDocumento1 paginaPipe&Shell Design Tool 600KLJoshua RiveraNessuna valutazione finora

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocumento44 pagineNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNessuna valutazione finora

- Trip TicketDocumento10 pagineTrip TicketJf Larong100% (1)

- Ch1 - Jigs & FixturesDocumento53 pagineCh1 - Jigs & Fixturesttetslm100% (2)

- Dim of Pipes Flanges and FittingsDocumento10 pagineDim of Pipes Flanges and FittingsGeorge Manuel100% (1)

- LNG Tank Cool Down Calculation 1. InputDocumento4 pagineLNG Tank Cool Down Calculation 1. InputThinh ViproNessuna valutazione finora

- 1 How To Activate The LinkDocumento6 pagine1 How To Activate The LinkThinh Vipro100% (1)

- Cold Chain VietnamDocumento3 pagineCold Chain VietnamLê Tất TiếnNessuna valutazione finora

- Half Pipe CalculationDocumento3 pagineHalf Pipe CalculationdhavaleshNessuna valutazione finora

- Heat Ex Changers EstimationDocumento46 pagineHeat Ex Changers Estimationshankarbt83Nessuna valutazione finora

- Construction Method by Jack UpDocumento23 pagineConstruction Method by Jack UpMikiRoniWijaya100% (1)

- Flowserve-Ball Valve Technical Manual For AKH3 IOMDocumento23 pagineFlowserve-Ball Valve Technical Manual For AKH3 IOMwholenumberNessuna valutazione finora

- Intercambiadores - Ejercicios MaterialDocumento62 pagineIntercambiadores - Ejercicios MaterialLuiz Gustavo YamamotoNessuna valutazione finora

- Baseplate Cirrcle 2018 - HUTATI LAPDocumento11 pagineBaseplate Cirrcle 2018 - HUTATI LAPThinh ViproNessuna valutazione finora

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocumento1 paginaHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNessuna valutazione finora

- Case Study Primark enDocumento4 pagineCase Study Primark enPavan KumarNessuna valutazione finora

- Intercambiadores - Tablas y GráficosDocumento62 pagineIntercambiadores - Tablas y GráficosLuiz Gustavo YamamotoNessuna valutazione finora

- Copiar de Nozzle - Design - ToolDocumento2 pagineCopiar de Nozzle - Design - ToollavascudoNessuna valutazione finora

- Calculation ReportDocumento229 pagineCalculation ReportDarioNessuna valutazione finora

- Nozzle DesignDocumento391 pagineNozzle Designantonio gutierrezNessuna valutazione finora

- NC Tech SpecsDocumento5 pagineNC Tech SpecsnavalarchmarineNessuna valutazione finora

- Hemispherical Head Design ToolDocumento1 paginaHemispherical Head Design ToolBanamali NaskarNessuna valutazione finora

- Cryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDocumento8 pagineCryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDv Maria PradhikaNessuna valutazione finora

- Dimensioning A Heat Exchanger Flange: About P3 EngineeringDocumento22 pagineDimensioning A Heat Exchanger Flange: About P3 EngineeringVilas AndhaleNessuna valutazione finora

- Answer For Task 9 TransportDocumento3 pagineAnswer For Task 9 TransportAung Kyaw Moe0% (1)

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocumento3 pagineSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigDocumento2 pagineAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigJhonny Rincones100% (1)

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolJaveed KhanNessuna valutazione finora

- Welding Electrodes SelectionDocumento19 pagineWelding Electrodes SelectionjerickNessuna valutazione finora

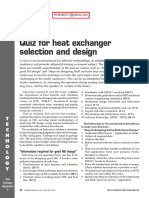

- Quiz For Heat Exchanger Selection and Design: T E C H N O L O G YDocumento10 pagineQuiz For Heat Exchanger Selection and Design: T E C H N O L O G Yrvkumar61Nessuna valutazione finora

- Standard SpecificationDocumento1 paginaStandard SpecificationĐạt TrầnNessuna valutazione finora

- Water Hammer EnvelopeDocumento3 pagineWater Hammer EnvelopeGJ CCNessuna valutazione finora

- Standard Design Details KapitolineDocumento359 pagineStandard Design Details KapitolineMohamed100% (2)

- Ejemplo Tubesheet Asme UHXDocumento14 pagineEjemplo Tubesheet Asme UHXPedro Montes MarinNessuna valutazione finora

- Electrical Generators Rev3.1Documento115 pagineElectrical Generators Rev3.1genergiaNessuna valutazione finora

- Combined Status of BoqmDocumento22 pagineCombined Status of Boqmhemant1284Nessuna valutazione finora

- A869-6-44-0005 PMS For RevampDocumento950 pagineA869-6-44-0005 PMS For RevampMastram HatheshNessuna valutazione finora

- Matl Specn.: Matl Temp - in Deg.fDocumento15 pagineMatl Specn.: Matl Temp - in Deg.fpandiangvNessuna valutazione finora

- Lecture 8fDocumento38 pagineLecture 8fhiteshNessuna valutazione finora

- Technical Data: 150x125 CNHA 5 18.5Documento5 pagineTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىNessuna valutazione finora

- Ngurv Ter - : de en Ow06/002.0Documento2 pagineNgurv Ter - : de en Ow06/002.0tranhonghakd5533Nessuna valutazione finora

- Data Sheet: Document NoDocumento3 pagineData Sheet: Document Nobagus handokoNessuna valutazione finora

- Cone CalculationDocumento3 pagineCone CalculationVicky NtrjnNessuna valutazione finora

- Calculo Brida Ejemplo PV - EliteDocumento8 pagineCalculo Brida Ejemplo PV - ElitePedro Montes MarinNessuna valutazione finora

- Shell Thickness Calculation ..: MAWP Design PressureDocumento6 pagineShell Thickness Calculation ..: MAWP Design PressureSatish ShindeNessuna valutazione finora

- Pressure & Temperature ClassificationDocumento1 paginaPressure & Temperature Classificationkeo85100% (1)

- Page No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressDocumento93 paginePage No:-Rev: - Doc., No: - Tag No: - 01. Cover Sheet Manufacture AddressSiva baalanNessuna valutazione finora

- Yanbu: Export Refinery ProjectDocumento7 pagineYanbu: Export Refinery ProjectJanakiraman MalligaNessuna valutazione finora

- Specs Chart PDFDocumento1 paginaSpecs Chart PDFsojeckNessuna valutazione finora

- Welding Neck Flanges 1Documento3 pagineWelding Neck Flanges 1bikkelbobNessuna valutazione finora

- ANSI-ASME B16.5 Blind Flange 300lb PDFDocumento1 paginaANSI-ASME B16.5 Blind Flange 300lb PDFVishal MistryNessuna valutazione finora

- 600.0 Temp Ambient Strength Design StrengthDocumento2 pagine600.0 Temp Ambient Strength Design StrengthBashu PoudelNessuna valutazione finora

- Asme9 Fea ReportDocumento10 pagineAsme9 Fea ReportCristian Camilo Zapata PardoNessuna valutazione finora

- Base de Datos de Materiales para RecipientesDocumento1 paginaBase de Datos de Materiales para RecipientespedroluischoqueNessuna valutazione finora

- 094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1Documento80 pagine094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1thongNessuna valutazione finora

- Pipe Specification Doniambo: Max MaxDocumento3 paginePipe Specification Doniambo: Max MaxHMMSPNessuna valutazione finora

- Mto - F.Documento36 pagineMto - F.lulalala8888Nessuna valutazione finora

- Consider Moving To This Location: Min. Distances For Safety Regulation of Oil StorageDocumento1 paginaConsider Moving To This Location: Min. Distances For Safety Regulation of Oil StorageThinh ViproNessuna valutazione finora

- Baseplate Cirrcle 2018 - HUTATI LAPDocumento6 pagineBaseplate Cirrcle 2018 - HUTATI LAPThinh ViproNessuna valutazione finora

- SAP2000 P-Delta - GuideDocumento5 pagineSAP2000 P-Delta - GuideThinh ViproNessuna valutazione finora

- Overview:: RemarksDocumento5 pagineOverview:: RemarksThinh ViproNessuna valutazione finora

- 1.1. PC - D350 - Class CDocumento1 pagina1.1. PC - D350 - Class CThinh ViproNessuna valutazione finora

- Ring Wall-Dam Vong Be Chua-HutatiDocumento10 pagineRing Wall-Dam Vong Be Chua-HutatiThinh ViproNessuna valutazione finora

- 09x.79.89.28.6 09x.89.28.6.79 09x.89.6.28.79 09x.28.6.89.79 09x.6.28.89.79 09x.28.6.1989 09x.6.28.1989 09x.1989.28.6Documento1 pagina09x.79.89.28.6 09x.89.28.6.79 09x.89.6.28.79 09x.28.6.89.79 09x.6.28.89.79 09x.28.6.1989 09x.6.28.1989 09x.1989.28.6Thinh ViproNessuna valutazione finora

- Operating Basis EarthquakeDocumento1 paginaOperating Basis EarthquakeThinh ViproNessuna valutazione finora

- Case Study - The Electric Car Dream - Sandeep Bhasin AIBS - Amity UniversityDocumento5 pagineCase Study - The Electric Car Dream - Sandeep Bhasin AIBS - Amity UniversitySandeep BhasinNessuna valutazione finora

- Observations On Supply-ChainDocumento3 pagineObservations On Supply-ChainBianca Andreea DrăganNessuna valutazione finora

- Corrosion Control by Modern Weld Overlay TechnologyDocumento3 pagineCorrosion Control by Modern Weld Overlay TechnologyAmanda Ariesta ApriliaNessuna valutazione finora

- Kugu Rad Att Plans 2007 EngDocumento61 pagineKugu Rad Att Plans 2007 EngElena TurcuNessuna valutazione finora

- Mangrol Fishery HarbourDocumento32 pagineMangrol Fishery HarbourVikram ThakurNessuna valutazione finora

- Alwasy Step Ahead in TechnologyDocumento4 pagineAlwasy Step Ahead in TechnologyjtpmlNessuna valutazione finora

- Previu KL DCP 2008Documento45 paginePreviu KL DCP 2008AlexNessuna valutazione finora

- AMUL's Distribution ChannelDocumento16 pagineAMUL's Distribution ChannelPrateek Jain100% (1)

- Report 69 Asset and Infrastructure Management For Airports: June 2012Documento23 pagineReport 69 Asset and Infrastructure Management For Airports: June 2012Basuki RahardjoNessuna valutazione finora

- All India Studyon Sectoral Demandof DieselDocumento104 pagineAll India Studyon Sectoral Demandof DieselAnonymous iMq2HDvVqNessuna valutazione finora

- NDDB - Odisha 25 02 2016Documento136 pagineNDDB - Odisha 25 02 2016rajNessuna valutazione finora

- Accepted Engineering Practice StandardsDocumento5 pagineAccepted Engineering Practice StandardsMuhammad Shakil JanNessuna valutazione finora

- Project ReportDocumento3 pagineProject Reportsatakshi29Nessuna valutazione finora

- Bridge Crane & Hoist InstallationDocumento7 pagineBridge Crane & Hoist Installationnike_y2kNessuna valutazione finora

- Aerolite RaftDocumento5 pagineAerolite RaftshombisNessuna valutazione finora

- Certificate of Achievement: Servsafe Food HandlerDocumento1 paginaCertificate of Achievement: Servsafe Food Handlerapi-479981874Nessuna valutazione finora

- Twi NNDocumento67 pagineTwi NNPrasathNessuna valutazione finora

- Products Description: Epad-10 Inch - ZT-180 Dual Core+512 Ram +4GB HDD+Android 7.2 OS - Support Flash 1QDocumento1 paginaProducts Description: Epad-10 Inch - ZT-180 Dual Core+512 Ram +4GB HDD+Android 7.2 OS - Support Flash 1QSuresh NakhuaNessuna valutazione finora