Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Failure Analysis of Ball Valves Worcester

Caricato da

cvishwas1159Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Failure Analysis of Ball Valves Worcester

Caricato da

cvishwas1159Copyright:

Formati disponibili

TP-12D-1

Worcester Control Valves

Failure Analysis of Ball Valves

Failure Analysis Of New Valves

Features to Evaluate if the Valve has

Leakage or High Torque:

1. Look for misalignment of actuator, linkage, or handle. Need 0 to

90 rotation. Stem must be perpendicular to bodyno side loads.

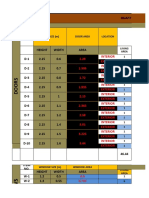

Carbon Steel Bolts

Bolt Dia.

SOLUTION: Check for centrality of the actuator, coupling, stem and

alignment of all brackets. Replace parts as necessary.

Use dial indicator to measure stem perpendicularity.

Stainless Steel and Alloy 20 Bolts

in/lb

ft/lb

Bolt Dia.

in/lb

ft/lb

!?4"

96 120

8 10

!?4"

72 94

68

%?16"

156 204

13 17

%?16"

120 144

10 12

#?8"

216 264

18 22

#?8"

192 216

16 18

\?16"

480 540

40 45

\?16"

336 384

28 32

!?2"

720 780

60 65

!?2"

504 522

42 46

2. Check body bolting torque; refer to IOM for correct torques. Torque

is for nonlubricated bolts.

SOLUTION: Using a calibrated torque wrench, check the torque of

bolts. Refer to attached chart or IOM.

3. Check flange bolting for proper insert compression. Body seal must

be compressed for seat sealing. Slip-on flanges and thick rubber

gaskets can affect performance of seal.

SOLUTION: Record location of piping supports, obtain photographs

and make a sketch. Retorque flange bolts, record style

and type of gasket and flange. Discuss data with

Flowserve personnel.

4. Normal torque when rotation 0 to 90 and back to 0. Measure

stem torque to open and close. Listen for scraping noises when

cycling; there must be no metal-to-metal galling. Compare data to

catalog ratings.

TABLE OF CONTENTS

Analysis of New Valves . . . . . . . . . . . . . . . . 1

Analysis of Valves in Service . . . . . . . . . . . . . .

Photos of Valve Failures . . . . . . . . . . . . . . . . 8

Glossary of Valve Terms . . . . . . . . . . . . . . . 10

SOLUTION: Measure torque according to ratings, listen for noises

and replace metal parts as needed. Check air pressure

at pneumatic actuator; make sure proper torque output

is available. Record air pressure at the actuator.

Flow Control Division

Worcester Control Valves

Failure Analysis of New Valves

5. Do a leak test on the valve. Pressure test from the other end of the

valve to evaluate second seat (not V-3 ball). If disassembling the

valve, mark the upstream and downstream seats and the twelve

oclock position on each seat.

SOLUTION: Record leakage data using flow meter or count

bubbles; determine if leakage is because of bad seats

or damaged ball. Return damaged seat to Flowserve for

evaluation; replace soft seats as necessary.

6. Examine surfaces of the seat and ball for nicks and scratches.

SOLUTION: Using a fingernail test, determine if scratches are

acceptable, or replace seats and metal parts if

necessary. Note, if scratches can be felt on ball, this

will cause leakage during normal use.

7. If the valve was cycled or tested at high pressure, there will be a

burnishing or contact band from the ball to seat and back of the

seat from the valve body.

SOLUTION: Determine if the contact is even. Full contact on seat

may mean over-pressuring of the valve. Check for

proper assembly of the valve.

Clean and repair parts as

necessary. Do not reuse body

seal gaskets. Assure that the S

gasket is properly installed.

This gasket is not reusable.

8. Evaluate the surface finishes on the seat

and the ball. Look for porosity, cracks and

imperfections. Contamination during

installation or improper handling can

cause leakage.

SOLUTION: Look at the orientation of the

seat and sealing wearpath. Any

deformation of soft parts will

require complete rebuilding of

the valve. If there is any

bending or metal deformation,

a new valve is required.

9. Check if valve seat was properly assembled. Look for gaps between

the seat and valve body from oversized or undersized seats.

SOLUTION: Some small seats can be put in backwards preventing

proper bolting of end caps and causing leakage.

10. Evaluate the metal surface finish: radial scratches, chatter,

smearing, tearing or improper machining.

SOLUTION: Inspect machined surfaces for drag lines that could

cause scratches to stem seals, and for improper

surface finish on the pipe ends which could cause

leaking behind the seats. Replace parts as necessary.

11. Look for evidence of porosity or void in the metal parts.

SOLUTION: Any porosity or voids that could cause seal or seat

leakage means metal parts have to be replaced.

Failure Analysis of Ball Valves

TP-12D-1

Flow Control Division

Worcester Control Valves

12. Stem nut and locking nut should be properly adjusted for zeroleak stem seal. Look for rough marks inside stem bore or

possible galling. Evaluate thrust washer and stem seal for

tearing or deformation.

Color Chart for Various Stem Component Materials

SOLUTION: Check that the stem seal nuts have been properly

adjusted by flattening out the Belleville washers and

back off 1/6 turn. Automated valves require a double

locknut, MP44 valves and V51 use heavy, single

locknut. Check that washers are not cracked or

missing.

Material

Color

Polyfill

Black

Peek

Tan

Graphite

Silver Gray

Carbon-Filled PTFE

Black

UHMWPE

Opaque White

Delrin

Brown

Filled TFE

Off-White

13. Missing parts or bent mounting kits can side load the stem or

reduce actuator torque.

SOLUTION: Check centrality and alignment of the actuator and

stem. Replace parts as necessary. Look for use of

proper coupling and slop between stem and coupling

and ball and stem for proper closing of the valve.

1A?f" 2" Size Top-Mount

Valves Shown

TP-12D-1

Failure Analysis of Ball Valves

Flow Control Division

Worcester Control Valves

Failure Analysis of Used Valves

NOTE: Assure all system pressure is zero and fluids are drained from

valve before loosening any bolts. If fluids are dangerous, perform

proper cleaning before valve is removed.

1. Review same causes as new valve.

SOLUTION: Record all process conditions and try to determine the

date and where the valve was bought.

2. Look for start-up problems such as weld splatter, dirt, scratches,

impingement of fluids and contamination forced into the seats or ball.

SOLUTION: Clean the valve, inspect all parts, polish ball, if

possible, rebuild and replace soft parts. No piping

compound should be in the valve.

7. Verify if hydrotesting of the valve was done in the closed position.

Pressure over 110% of maximum ratings will damage seat.

Determine if start-up testing was performed on valves. Find out if

the valve was hydrotested and then exposed to freezing

temperaturescavity pressure due to ice can bend metal parts.

SOLUTION: Verify temperature, possible system hydrotest and

misapplication of the valve. Use V3 vented ball, if

necessary, to prevent deformation of the seats.

Evaluate flatness of pipe ends with straight edge. No

deformation is allowed. Replace valve if necessary.

8. Thermal Effects: If valve is closed and full of liquid (1 temperature

rise equals 100 psi in trapped cavity) look for evidence of

deformation of seats, body seals, or pressure vessel.

3. Verify seats were made by Worcester Controls and properly installed.

SOLUTION: Return damaged seat and soft parts to Flowserve for

evaluation. Rebuild with authorized Worcester parts.

Use proper lubricants per IOMs.

SOLUTION: Check for thread damage or deformation of the body

bolts, seats or seals at pipe ends. Replace components

as needed.

4. Evaluate if the valve is new or has been reworked and remachined

by customer.

1A?f" 2" Top Mount Valves Shown

SOLUTION: Determine if there has been welding or painting which

would indicate rework of the valve. Look for counterfeit

valves with improper components. Determine if

alterations have damaged valve.

5. Evidence of metal corrosion or improper seat/seal selection for

application. Record pressure, temperature, media and relevant

information for analyzing failure. Record pressure at shutoff and

throttling pressure drop.

SOLUTION: Evaluate the extent of corrosion, re-evaluate material

selections, replace complete valve if necessary. Review

date of installation and discuss application with

Flowserve personnel.

6. Look for possible leak paths through stem seals, between

ball and seat, behind seat and possible wire drawing

of sealing surfaces. Document location of leakage.

SOLUTION: Determine where there is a leak path.

Replace soft parts. If there is wire

drawing or damage to the pipe ends or

ball, replace valve as needed.

Valve Shown in

Closed Position,

No Pressure

Failure Analysis of Ball Valves

TP-12D-1

Flow Control Division

Worcester Control Valves

9. Crushed ball downstream seat due to water hammer, overpressurization or piping stress can bend metal parts or deform

seats and/or balls.

Corrosion Allowance

Average Penetration Rate Per Year

Code

SOLUTION: Measure roundness of the ball, flatness of the pipe

ends, replace valve if damage has occurred.

10. Ball off-center, during assembly or improper stem adjustment can

force stem down into ball. Proper assembly of valve, to sales

drawing or IOM. Wrong stem-to-ball engagement can yield the

metal parts or ball wont cycle. Improper or missing stem seals

can affect stem engagement.

SOLUTION: Check the ball-stem engagement. Look for bent stems

and deformation of the ball or damage to the metal

parts. Assure correct assembly of parts.

Mils

Inches

<

0.002

50

<

20

0.020

508

20 50

0.020 0.050

508 1,270

>

50

0.050

1,270

Footnotes for Data Squares

1. Pitting

2. Stress Corrosion Cracking

3. Intergranular Attack

4. Crevice Attack

11. Cold flow of the seat due to excessive temperature pressure or

exceeding allowable throttling pressure drop.

SOLUTION: Check the proper closed position of the valve. Evaluate

the torque of the valve, the operator output torque and

replace valve if necessary, or use large actuators.

12. Popcorning, polymerization or deformation of the seat due to

media absorbed into the material and mechanically expanded.

SOLUTION: Return seats to Flowserve for evaluation. Clean valve,

replace seats and seals, and consult with factory, if

possible, to upgrade to alternate material such as FEP,

High-per Fill, etc.

End

Plug

Cavity Filler

Seats

S.S. Ring

(split)

Valve Body

(special profile)

TP-12D-1

Failure Analysis of Ball Valves

Body

Seal

S.S. Ring

(solid)

Flow Control Division

Worcester Control Valves

13. Look for rust or dirt and location of sealing band. Evaluate if the

relief slots are plugged and not functioning properly. May need

V-3 ball relief.

SOLUTION: Look for the sealing path of the body seal, seats and

stem seals. Replace soft parts if needed. If

deformation or damage to metal occurs, replace valve.

14. 360 ridge in the downstream seat could indicate

overpressurization or hydraulic water hammer.

SOLUTION: Check that the valve was properly assembled, the

rotation of the valve to its closed position and proper

actuator sizing.

18. Distortion of the seat due to thermal expansion. V-3 porting

maybe required. Upgrade to stronger seat.

SOLUTION: Refer to examples of seat failures in attached

document. Replace parts as needed. If metal parts are

damaged, replace valve.

15. Fold over where the seat has been extruded due to improper

support during cryogenic cool down or high temperature with

improper ball position. Exceeding allowable pressure drops.

NOTE: Ball must be fully open or fully closed while being cooled

to cryogenic temperatures.

SOLUTION: Check for ball stem alignment, replace the seats.

Check actuator mounting; review torque of the valve

using attached ratings.

16. Impingement or erosion damage to the seat.

SOLUTION: Replace seats. If damage occurs to metal parts,

replace valve.

High differential across

seat sucks seat out of cavity

17. Partial support. If valve is assembled with the valve not fully

closed, damage occurs to the seat. Look for twisted stem or

improper top works.

SOLUTION: Replace seats as needed. If metal damage has

occurred, replace valve. See photos of seat damage

on pages 8 and 9.

19. Wire drawing, backside or between the ball and seat. High-pressure

steam or throttling pressure drop. Do not throttle below 15 on

clean service. Consult factory for steam or slurry applications.

SOLUTION: Refer to throttling pressure drop, pressure temperature

ratings, and discuss application with factory.

20. Seats that are cracked or broken due to thermal shock or

misapplication.

SOLUTION: Record process conditions, upgrade to a stronger

seat, and replace valve if misapplied.

21. Body seals can be pinched between body and pipe end during

assembly or repair. Use lubrication to help body seal when bolted.

SOLUTION: Check the proper assembly of the body seals, but

most body seals are not reusable.

Ball Impingement

Upstream

Seat

Flattened

Area

1

2

3

4

Downstream

Seat

Ball will contact seat

during closure, causing

further damage

Pressure

Distance Along Pipe

Typical Velocities

Fluid

Condition

ft/s

m/s

Liquid

Normal

Maximum

5 10

40 50

1.5 3

12 15

Gas

Typical

250 400

(<Mach 0.3) 75 120

Steam or

Vapor

Low Pressure

Medium Pressure

70 100

100 170

(<Mach 0.1)

20 30

30 50

Superheated High

Pressure

115 330

(Mach 0.15) 35 100

Failure Analysis of Ball Valves

Flow through a partially open ball valve. Possible flow

conditions are:

pv at 1:

pv at 2:

pv at 3:

pv at 4:

Flashing downstream of ball

Cavitation in ball, flashing downstream of ball

Cavitation downstream of ball

No vapor formations

TP-12D-1

Flow Control Division

Worcester Control Valves

22. S-gaskets in backwards, or scraped at installation of center sec.

1A?s" 2" Top-Mount Valves

Shown

SOLUTION: Properly orient the S gaskets. On the welded pipe

ends, do not reuse on butt weld and socket weld

seals. The initial body seals are rubber. These should

be replaced with metal S gaskets.

23. Graphite seat seals cracked or sheared from use of improper

lubrication to assemble.

SOLUTION: Replace seats and body seals. Use proper lubrication.

Do not reuse seat seal or body seals.

24. Pipe stress can bend valve, causing seat or body seal failure. Look

for misalignment when valve is removed and record distance from

piping support.

SOLUTION: Get photo or measure piping support to determine if

pipe ends are being damaged or body bolts are being

deformed.

25. Do not use schedule 80 or 160 pipe without special pipe ends or

consulting factory.

26. Evaluate seat for arc-shaped deformation which indicates

improper ball closing.

NOTE: Full port valves 2" to 8" and reduced port valves 3" to 8"

now use a new seat design with cavity relieving seats (CPP).

Annular Groove

Feeder Groove

Cavity Pressure Relieving Seat

Contact Area

Contact Area

Contact Area

Contact Area

Cavity Pressure Condition

(zero differential)

Assembled Condition

(zero differential)

TP-12D-1

Failure Analysis of Ball Valves

Flow Control Division

Worcester Control Valves

A. Abrasive particles imbedded in the soft seats scratching both the

seat and ball. Results in high torque, leakage and damage to the

metal parts of the valves.

SOLUTION: Use harder seats and polyond the ball. Alternate is to

use a more abrasive-resistant seat such as rubber or

ultra-high molecular weight polyethylene. Improve

cleaning of system at start-up.

B. High temperature softening of the seat. Failure occurred on

upstream seat, foldover due to the pressure distribution across the

seat and partial support of an open ball.

SOLUTION: Use seat materials with higher temperature capabilities

such as the X, Alpha or Gamma. Review the service conditions and

the allowable throttling drop according to the catalog ratings.

C. This is a combination of erosion and corrosion due to excessive

throttling pressure drops. Solid particles in the flow may also cause

this erosion.

SOLUTION: Review the sizing of the valve to make sure you are

using larger ball openings and staying above 15%

open. Review the flow conditions for cavitation or

flashing and try to locate the valve where it is taking

less throttling pressure drop. If the media is

contaminated, try to use lower line velocities across

the valve to reduce the demonstrated wear.

D. This seat has been exposed to high temperatures and extremely

high cavity pressures. Usually this occurs when condensate or

liquids are trapped in the valve and then heated up, and overpressure then deforms the seat.

SOLUTION: Use the V3 cavity pressure relief and stronger seat

materials.

Failure Analysis of Ball Valves

TP-12D-1

Flow Control Division

Worcester Control Valves

E. An example of where the ball has not fully closed. The high-velocity

fluid flow across the valve wire draws the seat and distorts the

material. In closer examination you can see that the seat has

rotated in the valve cavity and foldover and damage has begun to

occur in more than one spot. Generally this could be attributed to:

improper actuator mounting, slop between the ball and stem,

wrong coupling or using the wrong parts. Another cause could be

twisting of the stem due to extremely high torque or improper

actuator/valve sizing.

TP-12D-1

F. This seat has been exposed to extremely high temperatures and

extruded due to cavity pressure or fluid flow.

SOLUTION: Install seats of high-pressure/temperature capability,

resize the valve to make sure it is within the

pressure/temperature curve and is not exceeding

catalog throttling drops.

Failure Analysis of Ball Valves

Flow Control Division

Worcester Control Valves

Glossary

Trouble Analysis for Valves

Cavitation:

The formation and collapse of bubbles when high velocity fluid flows

through a valve and the liquid goes below the vapor pressure.

S Gaskets:

316 Stainless Steel metal gaskets used for body seals. These are

covered with Teflon or graphite.

Cavity Pressure:

Cavity pressure can occur in the open or closed valve where liquid is

trapped around the OD of the ball or inside the valve cavity. This is

very critical in cryogenic valves, but can also occur with temperature

rise of liquids or steam condensate.

Surface Finish:

This is the machined surface of a part which gives you a static or

dynamic seal. Centrality, flatness, smoothness and type of finish are

very important to the cycle life and zero-leak capability of the valve.

Centrality:

This is the alignment of two concentric circles, such as the ball and

stem or the seats and body. If improperly aligned, there can be

uneven forces for sealing or rotation of the valve.

Contact Band:

When a valve is sealing there is an area of impression between the

seat and ball and the back side of the seat. This should be

approximately one third of the seat width. Full contact band is an

indication that the valve has been over-pressurized and the seat

damaged.

Cold Flow:

When the ball is pushed into the downstream seat, it may go beyond

the elastic limit of the Teflon. Excessive exposures at high pressure

can yield the seat and cause catastrophic failure.

Drag Lines:

This can occur in the area of the stem seal or in the back of the body

during the machining. A broken toll or machine burr can cause a

spiral cut, which affects sealing of the valve.

Throttling Pressure Drop:

The difference between the upstream and downstream pressure. As

the valve closes and the orifice between the ball and the seat gets

smaller, pressure drop increases. Ratings are established both for

throttling services and steam.

V3 Option:

In valves where the possibility of cavity pressure can occur, a small

hole is drilled on the upstream side of the ball to give venting of the

ball. In addition, there is a second hole below the stem of the valve to

relieve cavity pressure around the backside of an open valve. To get

bidirectional sealing, the one-piece seat is necessary, but cannot be

used on steam or cryogenic fluids.

Wire Drawing:

When a valve has been damaged due to scratching or excessive

throttling drops, the high-velocity fluid cuts through the soft seat,

causing a wear pattern which quickly destroys the seats.

Fingernail Test:

Rub the edge of your fingernail across a scratch. If the scratch can be

felt this is sufficient damage to affect sealing and wearing of the

seats. Metal parts should be buffed or replaced.

Flashing:

When fluid flow goes through an orifice, a pressure drop occurs. If

the fluids go below the vapor pressure, bubbles will form and cause

flashing.

Galling:

When dissimilar metals or metals of unequal hardness are rubbed

together, the softer metal starts to wear, and parts of the metal score

and tear, damaging the sealing surface.

Popcorning:

In the manufacturing of Teflon there are slight microscopic voids

within the material. Monomer or plastics in the liquid state will

migrate into these pores, and when they change into a solid, there is

mechanical deformation of the seat.

Porosity:

Small holes in the seats or metal parts where media can leak very

slowly, causing external leakage or contamination back into the

process.

10

Failure Analysis of Ball Valves

TP-12D-1

Flow Control Division

Worcester Control Valves

TP-12D-1

Failure Analysis of Ball Valves

11

Flow Control Division

Worcester Control Valves

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation.

TP-12D-1 6/03 Printed in USA

Potrebbero piacerti anche

- Pinch Valve SpecificationsDocumento7 paginePinch Valve SpecificationsPrakashNessuna valutazione finora

- Eurocorr2017Proceedings Paper88826Documento16 pagineEurocorr2017Proceedings Paper88826BhumitNessuna valutazione finora

- MEE Avoiding Bolt FailuresDocumento2 pagineMEE Avoiding Bolt Failuresridwan347Nessuna valutazione finora

- Bha RaluDocumento10 pagineBha RalujituNessuna valutazione finora

- Manual ScientificDocumento41 pagineManual Scientificwulalan wulanNessuna valutazione finora

- Corrosion in The Crude Distillation Unit Overhead Line: Contributors and SolutionsDocumento16 pagineCorrosion in The Crude Distillation Unit Overhead Line: Contributors and SolutionsMaría Alejandra Quintero PinillaNessuna valutazione finora

- Zero-Leakage Valve Solutions: Product & Capabilities OverviewDocumento20 pagineZero-Leakage Valve Solutions: Product & Capabilities OverviewAndry HermawanNessuna valutazione finora

- Hydrofluoric Acid Processing Valves: - PhillipsDocumento4 pagineHydrofluoric Acid Processing Valves: - Phillipsxaaabbb_550464353Nessuna valutazione finora

- On Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitDocumento17 pagineOn Oxygen-Induced Corrosion of An Oil Refinery Condensate Fraction at Ion UnitAzmi Mohammed NorNessuna valutazione finora

- Controlling Coupling Guard Leakage: Rotating Equipment/MaintenanceDocumento3 pagineControlling Coupling Guard Leakage: Rotating Equipment/MaintenanceinterveiwNessuna valutazione finora

- Corrosion Guide PDFDocumento23 pagineCorrosion Guide PDFredaNessuna valutazione finora

- Fso pm3 CaaDocumento2 pagineFso pm3 CaaskisascribdNessuna valutazione finora

- "State-Of-The-Art" Delayed Coking Structure For Frontier RefiningDocumento13 pagine"State-Of-The-Art" Delayed Coking Structure For Frontier Refiningandy175Nessuna valutazione finora

- Mobil Beacon 325 (Synthetic Ester)Documento2 pagineMobil Beacon 325 (Synthetic Ester)Anibal RiosNessuna valutazione finora

- AFT XStream Data SheetDocumento2 pagineAFT XStream Data SheetdelitesoftNessuna valutazione finora

- Presentation Q2 APE-1Documento24 paginePresentation Q2 APE-1mts1234Nessuna valutazione finora

- 2.familiarization of Centrifugal PumpDocumento2 pagine2.familiarization of Centrifugal PumpAayush AgrawalNessuna valutazione finora

- Improving Reliability of Commonly Used Hydraulic Valves 2017 PDFDocumento96 pagineImproving Reliability of Commonly Used Hydraulic Valves 2017 PDFDavid DelgadoNessuna valutazione finora

- Elastopipe A Flexible Piping System Trelleborg Offshore PDFDocumento2 pagineElastopipe A Flexible Piping System Trelleborg Offshore PDFprasad336100% (1)

- Acid Number Guide: Understanding AN TestsDocumento11 pagineAcid Number Guide: Understanding AN Testsrajeevup2004Nessuna valutazione finora

- Hastelloy Alloy B3 UNS N10675 Welding Rod Manufacturer in IndiaDocumento3 pagineHastelloy Alloy B3 UNS N10675 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNessuna valutazione finora

- SPC4 Bolt BrochureDocumento2 pagineSPC4 Bolt BrochureDoug HeinrichsNessuna valutazione finora

- Catalogue of ProductsDocumento96 pagineCatalogue of Productssf wNessuna valutazione finora

- CatalogueDocumento429 pagineCatalogueHarkamal SinghNessuna valutazione finora

- Piping Minimum Required Wall ThicknessDocumento8 paginePiping Minimum Required Wall ThicknessFadzil YahyaNessuna valutazione finora

- Evaluation of Corrosion in Different Parts of An Oil Refinery Using Corrosion CouponsDocumento83 pagineEvaluation of Corrosion in Different Parts of An Oil Refinery Using Corrosion CouponsEduardo VillacrésNessuna valutazione finora

- Receive Hardcopy Magazine PublicationDocumento3 pagineReceive Hardcopy Magazine PublicationInspection EngineerNessuna valutazione finora

- Procedures For Assessing The FitnessDocumento12 pagineProcedures For Assessing The FitnessRaja HoneNessuna valutazione finora

- MSDS - Xylar - 2 - 2022Documento14 pagineMSDS - Xylar - 2 - 2022SYED MAZHAR100% (2)

- Corrosion Handbook - Morris Place March 2008Documento96 pagineCorrosion Handbook - Morris Place March 2008Bilal KhashanNessuna valutazione finora

- Trane SemiHermetic CompressorsDocumento169 pagineTrane SemiHermetic CompressorsGerson RomeroNessuna valutazione finora

- Shovel Lubrication PDFDocumento2 pagineShovel Lubrication PDFSounak SasmalNessuna valutazione finora

- Polyaspartic Webinar Protective and MarineDocumento47 paginePolyaspartic Webinar Protective and MarinequimizaNessuna valutazione finora

- Reformer Tube IntegrityDocumento4 pagineReformer Tube IntegrityBaher ElsheikhNessuna valutazione finora

- Data SAF2205 04Documento8 pagineData SAF2205 04il_yoo_1Nessuna valutazione finora

- Optimization of AUT - PA Inspection Techniques For Detection of (HIC & SOHIC) Using Ominiscan MX in Fixed Plant EquipmentsDocumento11 pagineOptimization of AUT - PA Inspection Techniques For Detection of (HIC & SOHIC) Using Ominiscan MX in Fixed Plant EquipmentsRoderick Barrantes AlpuertoNessuna valutazione finora

- Research and Created By: V. Menchavez JWPS Journeyman Welding & Piping ServicesDocumento10 pagineResearch and Created By: V. Menchavez JWPS Journeyman Welding & Piping ServicesKentDemeterioNessuna valutazione finora

- BI0323 Sonar Flow Meter Versus Mag Flow MeterDocumento4 pagineBI0323 Sonar Flow Meter Versus Mag Flow MeterSusan McCulloughNessuna valutazione finora

- Coker Furnace On-Line Spalling: Safe, Clean, Profitable MethodDocumento11 pagineCoker Furnace On-Line Spalling: Safe, Clean, Profitable MethodpoloNessuna valutazione finora

- Inorganic ScaleDocumento1 paginaInorganic ScalealiNessuna valutazione finora

- A Review of Sustained Casing Pressure Occurring On The OcsDocumento62 pagineA Review of Sustained Casing Pressure Occurring On The OcsAscending AgondonterNessuna valutazione finora

- Erosion in Choke Valves - Wear 1995 PDFDocumento12 pagineErosion in Choke Valves - Wear 1995 PDFAPINessuna valutazione finora

- Assessing defects in pressure vessel nozzlesDocumento27 pagineAssessing defects in pressure vessel nozzlesvenkatrangan2003Nessuna valutazione finora

- Blind ListingDocumento2 pagineBlind ListingMadhan KannanNessuna valutazione finora

- Intro To DMAICDocumento40 pagineIntro To DMAICsamfisher8989Nessuna valutazione finora

- Sealweld 5050 Ball Valve SealantDocumento2 pagineSealweld 5050 Ball Valve SealantMabelinha DNessuna valutazione finora

- 01 Saip 38Documento14 pagine01 Saip 38Arjun RawatNessuna valutazione finora

- Asset Data Management for Energy Sector Hose SafetyDocumento2 pagineAsset Data Management for Energy Sector Hose Safetyjson_gabionNessuna valutazione finora

- Equipment Criticality Analysis - Is It A Waste of Time? - Assetivity PDFDocumento11 pagineEquipment Criticality Analysis - Is It A Waste of Time? - Assetivity PDFPedro JoséNessuna valutazione finora

- General Practice in Failure Analysis PDFDocumento12 pagineGeneral Practice in Failure Analysis PDFAhmed AymanNessuna valutazione finora

- Sabp W 002Documento7 pagineSabp W 002zoopladoNessuna valutazione finora

- Installation - Operation - Maintenance: S70-101 IOM/JAN 2000Documento66 pagineInstallation - Operation - Maintenance: S70-101 IOM/JAN 2000arielfernandomaxNessuna valutazione finora

- Corrosion Loop - Wikipedia PDFDocumento10 pagineCorrosion Loop - Wikipedia PDFEndhy Wisnu NovindraNessuna valutazione finora

- TÜV Industrie Service GmbH Waterside Scaling, Deposition and Corrosion in Steam GeneratorsDocumento19 pagineTÜV Industrie Service GmbH Waterside Scaling, Deposition and Corrosion in Steam Generatorsking1qNessuna valutazione finora

- John CraneDocumento83 pagineJohn CraneVj KrshkumrNessuna valutazione finora

- Bhel Ref No: PW / TSX /hindalco/ Hindalco Mahan, 6X150 MW: ObjectiveDocumento2 pagineBhel Ref No: PW / TSX /hindalco/ Hindalco Mahan, 6X150 MW: ObjectiveVenkat RamanNessuna valutazione finora

- Plant Maintenance A Complete Guide - 2020 EditionDa EverandPlant Maintenance A Complete Guide - 2020 EditionNessuna valutazione finora

- Material Handling Equipment World Summary: Market Values & Financials by CountryDa EverandMaterial Handling Equipment World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Corrosion Failures: Theory, Case Studies, and SolutionsDa EverandCorrosion Failures: Theory, Case Studies, and SolutionsNessuna valutazione finora

- Asset Integrity Management A Complete Guide - 2020 EditionDa EverandAsset Integrity Management A Complete Guide - 2020 EditionNessuna valutazione finora

- Fea Worm Gear With Reverse Taper PaperDocumento6 pagineFea Worm Gear With Reverse Taper Papercvishwas1159Nessuna valutazione finora

- FEA Worm Gear StrengthDocumento5 pagineFEA Worm Gear Strengthcvishwas1159Nessuna valutazione finora

- Gear Technology April 2003Documento52 pagineGear Technology April 2003cvishwas1159Nessuna valutazione finora

- Eriks Gasket PresentationDocumento125 pagineEriks Gasket Presentationcvishwas1159Nessuna valutazione finora

- Rubber Design Vibration and Noise ControlDocumento14 pagineRubber Design Vibration and Noise Controlcvishwas1159Nessuna valutazione finora

- Piping Code Paradoxes B31 3 Appen PDocumento16 paginePiping Code Paradoxes B31 3 Appen Psammar_10Nessuna valutazione finora

- Valves and Sealing Directory - Valve StandardsDocumento11 pagineValves and Sealing Directory - Valve Standardscvishwas1159Nessuna valutazione finora

- Preferred Metric SizesDocumento1 paginaPreferred Metric Sizescvishwas1159Nessuna valutazione finora

- Bolt Load CalculationsDocumento3 pagineBolt Load Calculationscvishwas1159Nessuna valutazione finora

- Plete Busak ShamanDocumento155 paginePlete Busak Shamancvishwas1159Nessuna valutazione finora

- Control Valve Noise PDFDocumento8 pagineControl Valve Noise PDFjeyaselvanmNessuna valutazione finora

- James Walker o Ring GuideDocumento32 pagineJames Walker o Ring Guidecvishwas1159Nessuna valutazione finora

- Rotabolt Tension Control James WalkerDocumento12 pagineRotabolt Tension Control James Walkercvishwas1159Nessuna valutazione finora

- AST Control Ball ValveDocumento6 pagineAST Control Ball Valvecvishwas1159Nessuna valutazione finora

- Construction Layout - PresentationDocumento15 pagineConstruction Layout - Presentationzsolt_almasi9764Nessuna valutazione finora

- Start Up Blue BookDocumento40 pagineStart Up Blue BookVaishnav ParivarNessuna valutazione finora

- CP220i Manual Standard Part Numbers Complete - MasterDocumento67 pagineCP220i Manual Standard Part Numbers Complete - Masterjacklyn ade putra100% (1)

- Item - List - View (2) 52Documento631 pagineItem - List - View (2) 52dbbony 00990% (1)

- 3.HYDRANT For TejgaonDocumento6 pagine3.HYDRANT For Tejgaonmujahid_islam85Nessuna valutazione finora

- Wood Shear Wall Design Examples For WindDocumento4 pagineWood Shear Wall Design Examples For WindAbdurrahman ÇINARNessuna valutazione finora

- Hollow Core Diaphragm DesignDocumento49 pagineHollow Core Diaphragm DesignMarcus LindonNessuna valutazione finora

- TOR - New Leyte Airport - Year 2015Documento21 pagineTOR - New Leyte Airport - Year 2015Edna Cruz-BayanNessuna valutazione finora

- PUF Panel Vs LGS StructureDocumento1 paginaPUF Panel Vs LGS StructureKantishNessuna valutazione finora

- Duct Construction Standardssflb-Editing PDFDocumento20 pagineDuct Construction Standardssflb-Editing PDFClaudia Alvarenga de PaulaNessuna valutazione finora

- Oil Tanker Design EquipmentDocumento59 pagineOil Tanker Design EquipmentBorislav Petrov100% (3)

- Pow 17J00056Documento3 paginePow 17J00056GigiNessuna valutazione finora

- 106602711Documento34 pagine106602711Mauro BalbiNessuna valutazione finora

- Calculation and Selection ResultDocumento18 pagineCalculation and Selection ResultNery TorresNessuna valutazione finora

- E33 Epoxy Grout Technical Data SheetDocumento2 pagineE33 Epoxy Grout Technical Data SheetUa AnyanhunNessuna valutazione finora

- Water and Sewerage AuthorityDocumento43 pagineWater and Sewerage AuthorityCarl Crow100% (1)

- Electrical ClearancesDocumento10 pagineElectrical ClearancesJulios Charl Panuncialman TagupaNessuna valutazione finora

- CVS-English Brief-2018925024Documento6 pagineCVS-English Brief-2018925024mohamed ahmedNessuna valutazione finora

- Quantity of cement, sand and doors for new homeDocumento14 pagineQuantity of cement, sand and doors for new homeRoland CepedaNessuna valutazione finora

- MGS Underground Construction (22.06.2023) Further ReviewDocumento4 pagineMGS Underground Construction (22.06.2023) Further Reviewyin hoe ongNessuna valutazione finora

- HW 200Documento40 pagineHW 200Nguyễn Trọng HùngNessuna valutazione finora

- Schedule Change ManagementDocumento10 pagineSchedule Change ManagementFreydell A BarretoNessuna valutazione finora

- Download Aci 309r 05 Concrete Specification PDFDocumento3 pagineDownload Aci 309r 05 Concrete Specification PDFShokhieb Showbad CarriebNessuna valutazione finora

- Eccentrically Loaded ColumnsDocumento2 pagineEccentrically Loaded ColumnsKing RickNessuna valutazione finora

- Understanding Property Lines and Building LayoutsDocumento1 paginaUnderstanding Property Lines and Building LayoutsGravity SuperNessuna valutazione finora

- Quality Assurance and QC for Sewer and Water Main RehabilitationDocumento68 pagineQuality Assurance and QC for Sewer and Water Main RehabilitationVasaNessuna valutazione finora

- Architectural Design 5 - Minor Plate 1Documento14 pagineArchitectural Design 5 - Minor Plate 1Zhaimer Joy BuenaventuraNessuna valutazione finora

- Wind FarmDocumento122 pagineWind Farmriz2010Nessuna valutazione finora

- Construction Contracts GuideDocumento5 pagineConstruction Contracts Guidejunlab0807100% (1)

- Acquisition of PP&E Acquisition of PP&EDocumento20 pagineAcquisition of PP&E Acquisition of PP&EbereniceNessuna valutazione finora