Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Astralloy V Plates

Caricato da

JRodengineerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Astralloy V Plates

Caricato da

JRodengineerCopyright:

Formati disponibili

Astralloy-V

Abrasion and Impact Resistant, Air Hardened Wear Steel

Chemical Composition* % Weight

C

Mn

Ni

Cr

Mo

Si

.29

1.20

4.00

2.00

.50

.40

0.015

.010

Physical Properties Typical Values at 68F

BHN

Hardness

Tensile

Strength

Yield

Strength

Elongation in 2"

Charpy Test

Toughness Index

418 512

241 ksi

157 ksi

12%

22 ft. lbs. @ RT

Comparative Benefits

Astralloy-V Air Hardened

Quenched and Tempered Wear Steel

1. Hardness combined with toughness

1. Hardness with less toughness

2. Work hardenability up to 550 BHN

2. No work hardening ability

3. Lower coefficient of friction

3. Higher coefficient of friction

4. Excellent cold weather properties

4. Loss of properties at lower temperatures

5. Cold and hot formable and weldable,

without loss of properties

5. Loss of properties during heating and

welding

Note: The data contained in this document is accurate at time of printing, and intended for use as a general guide.

* Typical maximum values. Mill certifications are available upon request.

Astralloy-V is a unique deep air hardened

steel that is rich in chemical composition

and physical properties, through hardened

and unsurpassed in resistance to impact

and abrasion.

With continuous impact and abrasion,

Astralloy-V can reach a hardness in excess of

550 BHN without brittleness.

Astralloy Steel Products is a wholly-owned subsidiary of Nucor Corporation, the largest producer of steel in the United States.

Astralloy-V

Cutting

Forming and Rolling

Astralloy-V plate can be cut using traditional methods (oxy, plasma,

laser). Plates less than 1" do not need preheating, except in cold or

humid climates. Recommended preheating temperature is 250F

(120C). All plates larger than 1" should be preheated between

400F and 600F (205C and 315C) in order to avoid premature

hardening and cracking.

When preparing for forming or rolling Astralloy-V, we recommend

grinding all edges to round off sharp corners in order to prevent

cracking. The minimum ambient temperature should be at least

80F (25C) and when cold forming with a hydraulic press, the

required minimum internal radius is 24 times the plate thickness. It

is recommended that Astralloy-V be cross grained formed, however

it is not essential.

Preheated areas should be 2" to 3" on each side of the projected

cut. We recommend that is allowed sufficient time for preheating

so that the temperature can be evenly distributed throughout the

plate thickness.

When fabricating gears or sprockets, we recommend the material

be stress relieved between 500F and 600F (260C 315C). Please

contact our technical department for more information.

Shearing is not recommended, as damage to shears may result

from Astralloy-Vs higher physical properties.

Drilling

Astralloy-V can be drilled with a high speed alloy or hardened bit.

One of the greatest advantages of Astralloy-V, compared to other

wear steels, is that it can be hot formed and allowed to air cool

without losing its original properties. We recommend a minimum

temperature of 1600F (870C). Hot forming at a temperature

below 1450F (788C) will result in lower hardness, greater stress

levels and reduced abrasion resistance.

Welding

In order to weld Astralloy-V, a fresh and dry electrode that is low

in Hydrogen is recommended. The E7018 is excellent for normal

welding procedures, providing adequate strength with good

ductility.

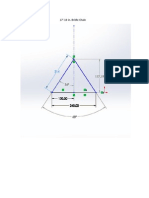

The drill bit must be sharpened so that it has an angle of 140 to

150, being careful to center the point of union between both

sides. The speed for cobalt drill bits should be 8 10 SFM and 4 6

SFM for high speed drills with a feed of 0.004" per revolution.

In colder climates, it is always recommended that the plate be

preheated to over 300F (149C) to remove moisture. The preheating

should be applied to areas that will be welded and must uniformly

penetrate the full thickness of the plate. In cold temperatures or

moving air, insulate the weld to prevent rapid cooling.

To prevent Astralloy-V from work hardening, it is essential to use

a positive power feed with abundant soluble lubricant to dissipate

heat and lubricate the cutting edges.

Standard Plate Sizes

Toll Free: 1-800-633-6635

96" x 240", 96" x 144", 96" x 120", 96" x 96", 48" x 240",

48" x 144", 48" x 120", 48" x 96"

www.astralloy.com

Potrebbero piacerti anche

- Algoma SteelDocumento18 pagineAlgoma Steelsahzaidi544Nessuna valutazione finora

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Documento4 pagineMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89Nessuna valutazione finora

- Dillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedDocumento4 pagineDillimax 690: High Strength Fine Grained Structural Steel Quenched and TemperedBui Chi TamNessuna valutazione finora

- JFE Everhard PDFDocumento12 pagineJFE Everhard PDFCris Yo CrisNessuna valutazione finora

- WEG 09 2017 Standard Stock Catalog Pump Motors Us100 Brochure English PDFDocumento46 pagineWEG 09 2017 Standard Stock Catalog Pump Motors Us100 Brochure English PDFmacaco28Nessuna valutazione finora

- Lista de Componentes ExC3000Documento1 paginaLista de Componentes ExC3000pressisoNessuna valutazione finora

- Effect of Laser Power and Substrate On The Hastelloy C276TM Coatings Features Deposited by Laser CladdingDocumento11 pagineEffect of Laser Power and Substrate On The Hastelloy C276TM Coatings Features Deposited by Laser CladdingAlex PizzattoNessuna valutazione finora

- SPR York 4 14 Line Boring Spec SheetDocumento2 pagineSPR York 4 14 Line Boring Spec SheetАлмаз КенжетаевNessuna valutazione finora

- Astm A 1011M PDFDocumento8 pagineAstm A 1011M PDFJuan CarlosNessuna valutazione finora

- Cold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDocumento3 pagineCold Formed Carbon Structural Steel Tubing Made From Metallic Precoated Sheet SteelDanZel DanNessuna valutazione finora

- SAE Grade SpecificationDocumento1 paginaSAE Grade SpecificationRamani Elampooranan K ENessuna valutazione finora

- 041 TS Hardox 550 in The Workshop UKDocumento5 pagine041 TS Hardox 550 in The Workshop UKNguyen Duc DungNessuna valutazione finora

- A 434 04Documento1 paginaA 434 04asepoNessuna valutazione finora

- Caixas Rolamentos UsaDocumento52 pagineCaixas Rolamentos Usakrlos_SW2009Nessuna valutazione finora

- CT SeriesDocumento6 pagineCT Seriessarvan shivaNessuna valutazione finora

- AUBO I5 USER MANUAL V4.3.1 USA PDFDocumento171 pagineAUBO I5 USER MANUAL V4.3.1 USA PDFMiro Mirach PremrlNessuna valutazione finora

- Non Standarad Dowel PinDocumento4 pagineNon Standarad Dowel Pinjaskaran singhNessuna valutazione finora

- Kaiser Aluminum Soft Alloy Tube PDFDocumento31 pagineKaiser Aluminum Soft Alloy Tube PDFgerrzen64Nessuna valutazione finora

- Colorkeyed SpecDocumento150 pagineColorkeyed Speccharlesc5746Nessuna valutazione finora

- Sapa Alloy 6005-6105Documento2 pagineSapa Alloy 6005-6105Bob LoblawNessuna valutazione finora

- Astm A269Documento5 pagineAstm A269Jose M-hNessuna valutazione finora

- Hot Rolled Steel SheetsDocumento14 pagineHot Rolled Steel SheetssuvraNessuna valutazione finora

- Domex 100 XF Data SheetDocumento2 pagineDomex 100 XF Data Sheetzubblwump5063Nessuna valutazione finora

- Pipe SpecificationDocumento14 paginePipe SpecificationAdam NumalNessuna valutazione finora

- Astm 434Documento3 pagineAstm 434Fabián MartínezNessuna valutazione finora

- Astm 194-2017 PDFDocumento13 pagineAstm 194-2017 PDFThiago CurvoNessuna valutazione finora

- Engineering Materials Data SheetDocumento6 pagineEngineering Materials Data Sheetrajarao1234Nessuna valutazione finora

- Sa-240 Asme Sec.2Documento1 paginaSa-240 Asme Sec.2arianaseriNessuna valutazione finora

- Comparison List Copper Bronze 2011 1Documento7 pagineComparison List Copper Bronze 2011 1NaldoVicenteNessuna valutazione finora

- MeasurIT Red Valve Expansion Joints J1 0802Documento3 pagineMeasurIT Red Valve Expansion Joints J1 0802cwiejkowskaNessuna valutazione finora

- Redflex BrochureDocumento24 pagineRedflex BrochuremecarrascogNessuna valutazione finora

- Astm C470.C470M 2009Documento4 pagineAstm C470.C470M 2009Carlos GuerraNessuna valutazione finora

- Anclajes Red HeadDocumento8 pagineAnclajes Red HeadLeonardo AvilaNessuna valutazione finora

- Astm A240 Uns S32205Documento3 pagineAstm A240 Uns S32205Mintone Sajayah BekabekaNessuna valutazione finora

- Kalpraxis Cement Plants PDFDocumento14 pagineKalpraxis Cement Plants PDFalbertbunguriNessuna valutazione finora

- Astm A325Documento2 pagineAstm A325ingsabrinaNessuna valutazione finora

- GB Teguflex A4 2015Documento8 pagineGB Teguflex A4 2015eliasx1Nessuna valutazione finora

- 13-8 PHteDocumento1 pagina13-8 PHtegeorgeNessuna valutazione finora

- Bs7531 Grade y MasterDocumento1 paginaBs7531 Grade y Masterheena jainNessuna valutazione finora

- Eaton Brass Products Master CatalogDocumento166 pagineEaton Brass Products Master CatalogMarvin Nta DgzNessuna valutazione finora

- 2007-Catálogo Burndy ConectoresDocumento724 pagine2007-Catálogo Burndy ConectoresAlexis ArayNessuna valutazione finora

- Wear Plate PDFDocumento19 pagineWear Plate PDFNorma SalazarNessuna valutazione finora

- 4140 High Tensile Steel PDFDocumento3 pagine4140 High Tensile Steel PDFFikri SiplhoNessuna valutazione finora

- ASTM A297 (HN) SpecificationDocumento5 pagineASTM A297 (HN) SpecificationGuglielmo CancelliNessuna valutazione finora

- Astm F3125 F3125M 18Documento6 pagineAstm F3125 F3125M 18Amine ait talebNessuna valutazione finora

- Spring SteelDocumento2 pagineSpring Steelvaishu1502Nessuna valutazione finora

- A 872 - 91 R02 Qtg3mi05mviwmgDocumento3 pagineA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdNessuna valutazione finora

- Bohler Guide For WeldingDocumento519 pagineBohler Guide For WeldingJoseph DsilvaNessuna valutazione finora

- Propiedades Grado 50 A572Documento2 paginePropiedades Grado 50 A572daniel moreno jassoNessuna valutazione finora

- Astm A192Documento11 pagineAstm A192Marcelo VicentiniNessuna valutazione finora

- Enovia VPLM VPM NavigatorDocumento11 pagineEnovia VPLM VPM NavigatorAsker Ali TPNessuna valutazione finora

- Materiales SM HVOFDocumento18 pagineMateriales SM HVOFAnonymous PJP78mSxNessuna valutazione finora

- Astm A192 Asme Sa192 PDFDocumento4 pagineAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Al6XN AlloyDocumento10 pagineAl6XN AlloyTommaso Di GiamberardinoNessuna valutazione finora

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Documento2 pagineHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261Nessuna valutazione finora

- Armox WeldingDocumento2 pagineArmox WeldingsudhavelNessuna valutazione finora

- 17-4 PHDocumento4 pagine17-4 PHfahimshah1301Nessuna valutazione finora

- Custom 465 Stainless SteelDocumento20 pagineCustom 465 Stainless SteelGrafton Montgomery100% (1)

- 15-5 PHDocumento2 pagine15-5 PHfedaquiNessuna valutazione finora

- Aisi H13Documento2 pagineAisi H13123vigenNessuna valutazione finora

- Decimeters To Centimeters Convertion ChartDocumento1 paginaDecimeters To Centimeters Convertion ChartJRodengineerNessuna valutazione finora

- Math Sequence Flow ChartDocumento1 paginaMath Sequence Flow ChartJRodengineerNessuna valutazione finora

- Ut Calibration Blocks DetailsDocumento44 pagineUt Calibration Blocks Detailsmdsajidalam100% (4)

- TI-83 and TI-84 ManualDocumento12 pagineTI-83 and TI-84 ManualJRodengineerNessuna valutazione finora

- Area of ParallelogramDocumento2 pagineArea of ParallelogramJRodengineerNessuna valutazione finora

- About Comunication SkillsDocumento8 pagineAbout Comunication SkillsJRodengineerNessuna valutazione finora

- TI-83 and TI-84 ManualDocumento12 pagineTI-83 and TI-84 ManualJRodengineerNessuna valutazione finora

- Love ScripturesDocumento1 paginaLove ScripturesJRodengineerNessuna valutazione finora

- How To Find Out The AREA of Unusual ShapesDocumento1 paginaHow To Find Out The AREA of Unusual ShapesJRodengineerNessuna valutazione finora

- Carbon Equivalency (CE) : C Carbon MN Manganese CR Chromium Mo Molybdenum V Vanadium Ni Nickel Cu Copper Si Silicon P Phosphorous Ti ? NB ? SDocumento1 paginaCarbon Equivalency (CE) : C Carbon MN Manganese CR Chromium Mo Molybdenum V Vanadium Ni Nickel Cu Copper Si Silicon P Phosphorous Ti ? NB ? SJRodengineerNessuna valutazione finora

- Magnaflux Zyglo Liquid Penetrant SystemsDocumento2 pagineMagnaflux Zyglo Liquid Penetrant SystemsJRodengineerNessuna valutazione finora

- Astralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelDocumento2 pagineAstralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelJRodengineerNessuna valutazione finora

- WELDING MATH - Heat Input - Tensile & Yield Strength - % Elongation - % Reduction - STUDYDocumento5 pagineWELDING MATH - Heat Input - Tensile & Yield Strength - % Elongation - % Reduction - STUDYJRodengineerNessuna valutazione finora

- Carbon (C)Documento14 pagineCarbon (C)JRodengineerNessuna valutazione finora

- A992 After Fire - Display ArticleDocumento4 pagineA992 After Fire - Display ArticleJRodengineerNessuna valutazione finora

- Hex Nut and Jam Nut DimensionsDocumento1 paginaHex Nut and Jam Nut DimensionsJRodengineerNessuna valutazione finora

- Alloying Variations of Austenetic SSDocumento1 paginaAlloying Variations of Austenetic SSJRodengineerNessuna valutazione finora

- ASTM Steel GradeDocumento1 paginaASTM Steel GradeRaymondLeungNessuna valutazione finora

- Binder Template (Brown and Green)Documento1 paginaBinder Template (Brown and Green)JRodengineerNessuna valutazione finora

- Sulfur (S)Documento18 pagineSulfur (S)JRodengineerNessuna valutazione finora

- Mil S 24371Documento1 paginaMil S 24371JRodengineerNessuna valutazione finora

- Astm A992 Beam: Submit QueryDocumento1 paginaAstm A992 Beam: Submit QueryJRodengineerNessuna valutazione finora

- ASTM A992 (Replacement For A572 Gr. 50) PDFDocumento4 pagineASTM A992 (Replacement For A572 Gr. 50) PDFPatrick DominguezNessuna valutazione finora

- Binder Template (Blue 1)Documento1 paginaBinder Template (Blue 1)JRodengineerNessuna valutazione finora

- Binder Template (Brown and Green)Documento1 paginaBinder Template (Brown and Green)JRodengineerNessuna valutazione finora

- AWS J1.1-2013 Resistance Weld. ControlsDocumento49 pagineAWS J1.1-2013 Resistance Weld. ControlsJRodengineerNessuna valutazione finora

- Binder Template (Side)Documento1 paginaBinder Template (Side)JRodengineerNessuna valutazione finora

- Binder Template (Side 2)Documento1 paginaBinder Template (Side 2)JRodengineerNessuna valutazione finora

- 17'-10 In. Bridle ChainDocumento2 pagine17'-10 In. Bridle ChainJRodengineerNessuna valutazione finora