Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manta To Richmond SIMOPS Risk Matrix FINAL

Caricato da

Desmond ChangTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manta To Richmond SIMOPS Risk Matrix FINAL

Caricato da

Desmond ChangCopyright:

Formati disponibili

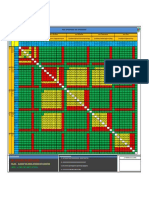

Manta to Richmond SIMOPS Matrix

Platform activities

= CONCURRENT OPERATIONS NOT ALLOWED

= CONCURRENT OPERATIONS ALLOWED WITH

CONTROLS & ONLY FOR SOME CONDITIONS

= CONCURRENT OPERATIONS ALLOWED WITH

Pr o d uct io n

f rom

p lat f o r m

w ells

Ho t w o r k in

w ellh ead o r

p r o d uct io n

ar ea

NORMAL CONTROLS

Gen er al

p lat f o r m

m an ual

m ain t en an ce /

Riggin g w o r k

Wo r k w it h o ut

iso lat io n f r o m

so ur ce o f

h yd r ao car b o n

r elease

An y o p en

p r o cess w o r k

(i.e. b r eakin g a

lin e)

An y w o r k t h at

co u ld r elease

t r ap p ed

p r essu r e

Other

Test o r

m ain t en an ce

Elect r ic

p lat f o r m saf et y w o r k

sh u t in syst em s

Scaf f o ld in g

Cr an e

o p er at io n s

Plat f o r m

p er so n n el in

w ellh ead an d

cellar d eck

Ho t w o r k

o n d r illin g

r ig

Sup p ly vessel Helico p t er

m o vem en t s o p er at io n s

Work Activities

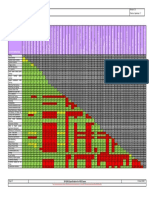

MANTA

R'MON

1. MOVING RIG INTO STAND OFF POSITION

2. RUNNING ANCHOR CABLES

3. WINCHING / MOVING INTO FINAL POSITION

4. WHEN THE RIG IS PRELOADING

5. WHEN THE RIG IS JACKING UP OR DOWN

6. WHEN THE DRILLING RIG IS CANTILEVERING

7. INSTALLING SAFETY INTERFACES / RIGGING UP

MANTA R'MON

8. SKIDDING THE DERRICK

9. CIRCULATING WELL

10. E-LINE PRE-WORK (cu t t in g Tu b in g )

11. REMOVING / INSTALLING XMAS TREE

12. REMOVING / INSTALLING BOP

13. PRESSURE TESTING BOP/RISER/DIVERTER/CASING/TUBING

14. PULLING / RUNNING COMPLETION TUBING

15.Pu m p in g cem en t t o ab an d o n co m p let io n p er f o r at io n

16. MILLING CASING WINDOW FOR SIDETRACK

17. DRILLING

18. WIRELINE LOGGING - CASED AND OPEN HOLE

19. RUNNING / CEMENTING CASING

20. RUNNING TUBING CONVEYED PERFORATORS - TCP

21. SLICKLINE / WIRELINE OPERATIONS

22. WORKING WITH COILED TUBING - CTU OPERATIONS

23. PUMPING ACID / NITROGEN - WELL STIMULATION

24. PRODUCING CLEAN UP TO FLARE BOOM

25. Co n t r o lled kick o p er at io n (< 500p si & n o su r f ace d r y g as)

26.Un co n t r o lled kick o p er at io n (> 500p si &/o r su r f ace d r y g as)

27. REMOVING SAFETY INTERFACES / RIGGING DOWN

28. PULLING SPUD CANS FREE

29. Mo vin g aw ay f r o m p lat f o r m t o st an d o f f p o sit io n

30. RETRIEVING ANCHOR CABLES

31. MOVING OUT OF RESTRICTED (500m ) ZONE

Notes:

Operational environmental data for rig approach/departure to be determined for each rig move - in general,

-

Maximum wind speed 20 knots moving into final position to MOPU.

Maximum wave combination 1.8m < 8 sec

Day light preferred for operations for final positioning of the rigs alongside the platforms & departing from same

Tug boats must meet marine operation manual.

each rig move to be individually assessed but in generally rig move is facilitated with help of tug boats to within

+/- 100m of the platform, then lowering the jack up legs until they touch down seabed. then slowly moving the rig to

the final approach position with the aid of the tugs whilst raising and lowering the tips of the spud cans in and out of

the seabed as required. Final positioning is done using anchor cables and winches.

All locations are approved by Manta prior to rig moves

December 2012 - (Rev. 1)

Potrebbero piacerti anche

- Simultaneous Operations (SIMOPS)Documento19 pagineSimultaneous Operations (SIMOPS)Desmond Chang71% (7)

- Simops Risk AssessmentDocumento3 pagineSimops Risk Assessmentzineddinmakram100% (1)

- SIMOPs Matrix - Combined - Rev-1Documento1 paginaSIMOPs Matrix - Combined - Rev-1DebadityachatterjeeNessuna valutazione finora

- 03a-Simultaneous Operations Operational ProcedureDocumento11 pagine03a-Simultaneous Operations Operational Proceduremichel louis friedman100% (1)

- SIMOPS Procedure - Pro-Saf-010-Ieoc Rev01-FinalDocumento13 pagineSIMOPS Procedure - Pro-Saf-010-Ieoc Rev01-Finalkhaled100% (2)

- Planning Communicating SIMOPSDocumento26 paginePlanning Communicating SIMOPSantonNessuna valutazione finora

- Simops MatrixDocumento17 pagineSimops MatrixthinkpadNessuna valutazione finora

- East Wind Simops MatrixDocumento2 pagineEast Wind Simops MatrixkhaledNessuna valutazione finora

- SIMOPS Check ListDocumento8 pagineSIMOPS Check ListWawan Setiawan100% (2)

- HSE Plan - FPSO Topside PDFDocumento48 pagineHSE Plan - FPSO Topside PDFdndudc100% (3)

- Ed Evacuation Escape RescueDocumento27 pagineEd Evacuation Escape Rescueliamo88880Nessuna valutazione finora

- Mopo SimopsDocumento1 paginaMopo SimopsMichael GanNessuna valutazione finora

- Simops Mopo MatrixDocumento6 pagineSimops Mopo MatrixPrathap SelvamNessuna valutazione finora

- 3S HSE MS Docs ContentDocumento85 pagine3S HSE MS Docs Contentrashid zamanNessuna valutazione finora

- HSE Practice SIMOPS ProcedureDocumento17 pagineHSE Practice SIMOPS ProcedureAjay Krishnan80% (5)

- PSSR Checksheet - Offshore Asset - DraftDocumento6 paginePSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- HSSE-S-002 - HSSE Awareness and CompetencyDocumento9 pagineHSSE-S-002 - HSSE Awareness and CompetencyAHMED AMIRANessuna valutazione finora

- Simultaneous OperationsDocumento22 pagineSimultaneous OperationsOgbadiboNessuna valutazione finora

- 95-0120 Cometence Assurance For HSE Critical ActivitiesDocumento48 pagine95-0120 Cometence Assurance For HSE Critical ActivitiesClive Nicli100% (2)

- SimopsDocumento24 pagineSimopsgilbertotiburcio100% (1)

- SimopsDocumento6 pagineSimopsravikrss100% (2)

- (III) PSSR Procedure (Rev00)Documento19 pagine(III) PSSR Procedure (Rev00)ahmedNessuna valutazione finora

- LMRA EnglishDocumento5 pagineLMRA EnglishemmanueljosephNessuna valutazione finora

- Simultaneous Operations (SIMOPS) TERM OF REFERANCE (TORDocumento25 pagineSimultaneous Operations (SIMOPS) TERM OF REFERANCE (TORkokykarkar80% (5)

- Confined Space Entry Procedure WorksheetDocumento5 pagineConfined Space Entry Procedure WorksheetToma AdrianaNessuna valutazione finora

- TN 015 Overrides 15Documento8 pagineTN 015 Overrides 15Luis SantosNessuna valutazione finora

- Understanding Oil and Gas HSE Management (37Documento34 pagineUnderstanding Oil and Gas HSE Management (37Madhur ChopraNessuna valutazione finora

- Environmental Risk RegisterDocumento3 pagineEnvironmental Risk RegisterSiyad SubairNessuna valutazione finora

- Petroleum Development Oman L.L.C.: H S & So Management Drilling and Well InterventionDocumento67 paginePetroleum Development Oman L.L.C.: H S & So Management Drilling and Well Interventionxu zhao0% (1)

- Aramco - Risk Assessment PDFDocumento14 pagineAramco - Risk Assessment PDFali bahmaniNessuna valutazione finora

- Offshore Risk Management - Security Assessment For Offshore Oil PDFDocumento26 pagineOffshore Risk Management - Security Assessment For Offshore Oil PDFlightangeldavidNessuna valutazione finora

- HSE Parts Count Guide PDFDocumento19 pagineHSE Parts Count Guide PDFBanjoNessuna valutazione finora

- I. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17Documento15 pagineI. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17KehindeNessuna valutazione finora

- Safety Moment - SIMOPS Gas VentingDocumento7 pagineSafety Moment - SIMOPS Gas VentingfareedfksNessuna valutazione finora

- New IOGP Assessment Contractor Questionnaireupdate - Mode2Documento6 pagineNew IOGP Assessment Contractor Questionnaireupdate - Mode2OKORO EVANNessuna valutazione finora

- Safety Hazards Associated With Oil and Gas Extraction ActivitiesDocumento13 pagineSafety Hazards Associated With Oil and Gas Extraction ActivitiesAnonymous y1pIqcNessuna valutazione finora

- 11 SIMOPs Procedure 11Documento14 pagine11 SIMOPs Procedure 11riyazali100% (5)

- Review Formalities HAZID ReportDocumento3 pagineReview Formalities HAZID ReportNaresh Nutakki50% (2)

- Ogp 456Documento36 pagineOgp 456Nitesh KirnakeNessuna valutazione finora

- HSE Bridging Document - OnGC & Quippo - CleanedDocumento27 pagineHSE Bridging Document - OnGC & Quippo - CleanedAnindra ByatshoshNessuna valutazione finora

- TSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina ElfDocumento18 pagineTSP PR-HSE-SAF-139 Rev 0 04/08/01 Simultaneous Operations: Total Fina Elfiwansalma100% (5)

- BP Golden Rules - Download From Step Change Web Site PDFDocumento16 pagineBP Golden Rules - Download From Step Change Web Site PDFDerouich2019Nessuna valutazione finora

- PSM 6 - Element 1 - Process Safety Culture (v3)Documento29 paginePSM 6 - Element 1 - Process Safety Culture (v3)Ahmed HamadNessuna valutazione finora

- Medevac Plan & ProcedureDocumento4 pagineMedevac Plan & ProcedureAmy Serrano100% (4)

- Incident Classification and ReportingDocumento56 pagineIncident Classification and ReportingMahmoud Ahmed Ali Abdelrazik100% (1)

- 6.63 Pipeline Hazid Envid ReportDocumento17 pagine6.63 Pipeline Hazid Envid ReportGaluh Pramudipto100% (7)

- Offshore QRA ChecklistDocumento2 pagineOffshore QRA ChecklistPillai Sreejith100% (5)

- Pre-Startup Safety Review (PSSR)Documento4 paginePre-Startup Safety Review (PSSR)EcoNessuna valutazione finora

- Shell Tank Overfill Model Bow TieDocumento17 pagineShell Tank Overfill Model Bow Tiehvananth100% (1)

- SIMOPS Simultaneous Operations For Onshore and Offshore FacilitiesDocumento4 pagineSIMOPS Simultaneous Operations For Onshore and Offshore FacilitiesGhasem BashiriNessuna valutazione finora

- Model Answers NeboshDocumento16 pagineModel Answers NeboshFahimAhmedNessuna valutazione finora

- HSE Bridging Document for L4G Subsea Well OperationsDocumento26 pagineHSE Bridging Document for L4G Subsea Well OperationsAbdur Rahman100% (1)

- Inhibit and OverridesDocumento97 pagineInhibit and OverridesbashiruxNessuna valutazione finora

- Permit To Work: Construction & Commissioning Procedures ManualDocumento16 paginePermit To Work: Construction & Commissioning Procedures ManualALADINHENessuna valutazione finora

- PDO Updates Approach to HSE AssuranceDocumento29 paginePDO Updates Approach to HSE AssuranceKhuda BukshNessuna valutazione finora

- HSE Exception Request Form Rev.1Documento1 paginaHSE Exception Request Form Rev.1Dhimaz YudiNessuna valutazione finora

- 737 CribDocumento33 pagine737 CribM0% (1)

- Cyonics 2201 Argon Laser ManualDocumento22 pagineCyonics 2201 Argon Laser ManualBruce KampermanNessuna valutazione finora

- P P P P: Wi - Rii$Hiip MiiiuiiDocumento31 pagineP P P P: Wi - Rii$Hiip MiiiuiiSimon StošickiNessuna valutazione finora

- Pioneer RG9 Owners PDFDocumento10 paginePioneer RG9 Owners PDFCornelius ConmodoroNessuna valutazione finora

- Stressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Documento4 pagineStressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Desmond ChangNessuna valutazione finora

- Stress LogDocumento6 pagineStress LogDesmond ChangNessuna valutazione finora

- Induction BendsDocumento16 pagineInduction BendsDesmond Chang100% (1)

- Markl SIFs & Asme ViiiDocumento3 pagineMarkl SIFs & Asme ViiiDesmond ChangNessuna valutazione finora

- Permit To Work Flow ChartDocumento2 paginePermit To Work Flow ChartDesmond ChangNessuna valutazione finora

- SIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDocumento2 pagineSIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDesmond ChangNessuna valutazione finora

- Process Control Fundamentals 2Documento73 pagineProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Simulation of Tees Reveals Stress IntensificationDocumento7 pagineSimulation of Tees Reveals Stress IntensificationDesmond ChangNessuna valutazione finora

- Cable CalculationsDocumento38 pagineCable CalculationsDesmond ChangNessuna valutazione finora

- Seismic Design and Response of NPP PipingDocumento97 pagineSeismic Design and Response of NPP Pipingkaruna346100% (1)

- Lopa Workbook Sept 2005Documento12 pagineLopa Workbook Sept 2005Desmond Chang100% (1)

- Ansys - DynamicsDocumento13 pagineAnsys - DynamicsNono_geotecNessuna valutazione finora

- Instrumentation TextbookDocumento166 pagineInstrumentation TextbookGerman ToledoNessuna valutazione finora

- PFD Calculation Program: #Value! #Value! #Value!Documento4 paginePFD Calculation Program: #Value! #Value! #Value!Desmond ChangNessuna valutazione finora

- Piping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDocumento52 paginePiping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDesmond Chang100% (1)

- Weld End Preparation at Unequal Wall ThicknessesDocumento4 pagineWeld End Preparation at Unequal Wall ThicknessesDesmond ChangNessuna valutazione finora

- Modal Analysis Training: Natural Frequencies, Mode Shapes, Extraction MethodsDocumento40 pagineModal Analysis Training: Natural Frequencies, Mode Shapes, Extraction MethodsDesmond Chang100% (1)

- Welding HabitatDocumento12 pagineWelding HabitatDesmond Chang100% (3)

- Corrosion and Materials Selection For Amine ServiceDocumento5 pagineCorrosion and Materials Selection For Amine Servicedj22500100% (1)

- PAS Understanding ISA 18.2 PDFDocumento9 paginePAS Understanding ISA 18.2 PDFtriminhdang_phar6701Nessuna valutazione finora

- ACI, ANSI, API standards for construction, safety, petroleum measurementDocumento32 pagineACI, ANSI, API standards for construction, safety, petroleum measurementDesmond Chang100% (1)

- Compression 1 2013Documento63 pagineCompression 1 2013pramodtry100% (1)

- Alarm MGT PlantpaxDocumento51 pagineAlarm MGT PlantpaxDina MaulidaNessuna valutazione finora

- Un 038Documento12 pagineUn 038Desmond ChangNessuna valutazione finora

- The Basics of Arc WeldingDocumento35 pagineThe Basics of Arc WeldingDesmond ChangNessuna valutazione finora

- Pin 0907Documento2 paginePin 0907amidi5555913Nessuna valutazione finora

- SWI Products SoftDocumento21 pagineSWI Products SoftDesmond ChangNessuna valutazione finora

- PDMS Update AvevaDocumento21 paginePDMS Update AvevaDesmond ChangNessuna valutazione finora

- OT Underground Mine Poster enDocumento1 paginaOT Underground Mine Poster enjellyonNessuna valutazione finora

- Pulp and Paper IndustriesDocumento37 paginePulp and Paper IndustriesBabylyn Austria100% (2)

- 2014 Award Recipients: 2014 Outstanding Student ChaptersDocumento5 pagine2014 Award Recipients: 2014 Outstanding Student ChaptersErma PrastyaNessuna valutazione finora

- Indian Bureau of Mines Minerals Developmemt and Regulation Division MCDR Inspection ReportDocumento13 pagineIndian Bureau of Mines Minerals Developmemt and Regulation Division MCDR Inspection ReportANILNessuna valutazione finora

- Prep Plant Location and ListDocumento16 paginePrep Plant Location and ListRishiraj SahooNessuna valutazione finora

- Marine Diesel OilDocumento2 pagineMarine Diesel OilAbner LlenosNessuna valutazione finora

- Filling Up India's Strategic Crude Oil ReservesDocumento1 paginaFilling Up India's Strategic Crude Oil ReservesShaishav MistryNessuna valutazione finora

- Petronas Group of Companies 2021Documento7 paginePetronas Group of Companies 2021Loges WarryNessuna valutazione finora

- MMN 01 2020 IUU ListDocumento6 pagineMMN 01 2020 IUU ListDeepakNessuna valutazione finora

- Raw Materials and Processes in Paper MakingDocumento8 pagineRaw Materials and Processes in Paper MakingAkbar Ramadhan SyambasNessuna valutazione finora

- The LNG Process: Step One: Liquefaction Step Three: TransportDocumento1 paginaThe LNG Process: Step One: Liquefaction Step Three: TransportHabibNessuna valutazione finora

- Type-Iii CNG Cascade B-PlanDocumento21 pagineType-Iii CNG Cascade B-PlansameerrmdbNessuna valutazione finora

- Glossary of Energy and Financial TermsDocumento2 pagineGlossary of Energy and Financial TermsBodegon PataerataNessuna valutazione finora

- Basics of Petroleum Engineering Group No 6Documento25 pagineBasics of Petroleum Engineering Group No 6Alhaj MassoudNessuna valutazione finora

- Concession Map 16.01.2019Documento1 paginaConcession Map 16.01.2019Mithilesh KumarNessuna valutazione finora

- European Marketscan: European Products ($/MT) ICE FuturesDocumento9 pagineEuropean Marketscan: European Products ($/MT) ICE FuturesWallace YankotyNessuna valutazione finora

- Floating Gas Solutions: Project DisciplineDocumento6 pagineFloating Gas Solutions: Project DisciplinesmashfacemcgeeNessuna valutazione finora

- BL Webinar IPB - Rencana EOR Menuju 1 Juta BOPDDocumento14 pagineBL Webinar IPB - Rencana EOR Menuju 1 Juta BOPDIwan100% (2)

- Milestone Mining Agreement 04.06.13Documento3 pagineMilestone Mining Agreement 04.06.13Craig S WrightNessuna valutazione finora

- Petron Corporation: Philippines' Largest Oil Refining CompanyDocumento3 paginePetron Corporation: Philippines' Largest Oil Refining CompanyERWIN CAYL CABANGALNessuna valutazione finora

- Oil & Gas Industry in IndonesiaDocumento17 pagineOil & Gas Industry in IndonesiaSuleiman BaruniNessuna valutazione finora

- About Company ProfileDocumento9 pagineAbout Company ProfilesritaranNessuna valutazione finora

- Sinopec Work Permit SystemDocumento22 pagineSinopec Work Permit SystemAmeerHamzaWarraichNessuna valutazione finora

- Paper MakingDocumento1 paginaPaper MakingBurak KucukkelesNessuna valutazione finora

- Extraction (L)Documento45 pagineExtraction (L)Praveen yadavNessuna valutazione finora

- Tree Felling: Best Practice Guidelines ForDocumento66 pagineTree Felling: Best Practice Guidelines ForAnteNessuna valutazione finora

- Sub Level CavingDocumento3 pagineSub Level CavingFirman CahyadiNessuna valutazione finora

- DGMS Circular 2014 PDFDocumento21 pagineDGMS Circular 2014 PDFSheshu Babu100% (1)

- T.O. (SH & CH) Division, HDC, Kopt: Traffic ChartDocumento2 pagineT.O. (SH & CH) Division, HDC, Kopt: Traffic Chartapi-20018544Nessuna valutazione finora

- Global Suppliers DirectoryDocumento6 pagineGlobal Suppliers DirectorySUPER INDUSTRIAL ONLINENessuna valutazione finora