Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

8D

Caricato da

JeanUndangCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

8D

Caricato da

JeanUndangCopyright:

Formati disponibili

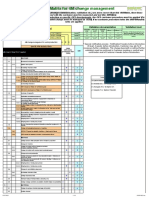

THE WOODBRIDGE GROUP - 8D Response Report

WHO IS EFFECTED BY THE PROBLEM?

Company:

Address:

Location:

Part No./Code

Product Name:

INTERNAL

or

EXTERNAL

D1 TEAM MEMBER NAMES/TITLES:

Champion:

Team Leader:

Team Members:

Date Open:

8D No.:

Customer

Initial Response:

Complaint No.:

Target Close Date:

Revision Date(s):

8D Initiator:

8D Initiator's Spvr:

Actual Close Date:

D2 PROBLEM STATEMENT/DESCRIPTION (quantify) (one defect per 8D)

D3 CHOOSE AND VERIFY INTERIM CONTAINMENT ACTION(S) (ICA):

%

Effective:

Target

Date:

Actual

Date:

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE ICA?

D4 DEFINE AND VERIFY ROOT CAUSE(S):

% Contribution:

HOW DID YOU VERIFY THE ROOT CAUSE(S)?

D5 CHOOSE AND VERIFY PERMANENT CORRECTIVE ACTION(S) (PCA):

% Effective:

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE PCA?:

D6 IMPLEMENT AND VALIDATE PERMANENT CORRECTIVE ACTION(S) (PCA):

Target

Date:

Actual

Date:

Target

Date:

Actual

Date:

HOW WILL YOU VALIDATE THE PCA?

D7 SYSTEM PREVENTION ACTIONS TO PREVENT RECURRENCE:

Mistake Proofing: How are you going to ensure it can't happen again?

HAS CORRECTIVE ACTION/IMPLEMENTATION BEEN REVIEWED AGAINST DOCUMENTS?:

FMEA

Proc./Work Instr.

Flowchart

Control Plan

Check boxes that apply:

D8 TEAM AND INDIVIDUAL RECOGNITION: Recognize the collective efforts of the team.

Add to Internal Audit

Original: To the dept. Sprv/Mgr. Copy: All initial 8D's and revisions must be sent to appropriate personnel at the location.

If this is a WFC customer related 8D, copy to the Corporate Quality Management Department in Mississauga, Ontario

WGCPF-001 page 1 of 9

Rev. 5

18-Nov-03

THE WOODBRIDGE GROUP - 8D Response Report

Instructions

WHO IS EFFECTED BY THE PROBLEM?

Company:

Address:

Location:

Part No./Code

Product Name:

INTERNAL

or

EXTERNAL

D1 TEAM MEMBER NAMES/TITLES:

Champion:

Team Leader:

Team Members:

Date Open:

8D No.:

Customer

Initial Response:

Complaint No.:

Target Close Date:

Revision Date(s):

8D Initiator:

8D Initiator's Spvr:

Actual Close Date:

D2 PROBLEM STATEMENT/DESCRIPTION (quantify) (one defect per 8D)

What are the symptoms that the customer is seeing? Specify the internal/external customer

problems by identifying in quantifiable terms who, what, when, where, why, how, how many (5W2H)

of the problem.

LINK TO PROBLEM SOLVING WORKSHEET - PROBLEM DESCRIPTION

D3 CHOOSE AND VERIFY INTERIM CONTAINMENT ACTION(S) (ICA):

Define and implement containment actions to isolate the problem from any internal/external customer until permanent

corrective action is available. Verify the effectiveness of the action. The ICA is a type of 'Band-Aid' used to protect the

customer until the root cause is determined and the permanent correction can be implemented.

LINK TO DECISION MAKING WORKSHEET & RISK ANALYSIS

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE ICA?

%

Effective:

Target

Date:

Actual

Date:

How

effective is

your ICA so

the customer

does not see

the

problem?

How can you make the problem come and go - prove it - test results - document it.

D4 DEFINE AND VERIFY ROOT CAUSE(S):

% Contribution:

Identify all potential causes (due to a change) which could explain why the problem occurred. Isolate and verify the Root Cause by testing

each potential cause against the problem description and test data (does it explain the IS,IS/NOT'S in D2?). Identify alternative corrective

actions to eliminate root cause.

LINK TO PROBLEM SOLVING WORKSHEET - ROOT CAUSE WITH THEORY TESTING

HOW DID YOU VERIFY THE ROOT CAUSE(S)?

What % of the

problem is caused by

the root cause(s)

(must have 100%

total)

How can you make the problem come and go - prove it - test results - document it.

D5 CHOOSE AND VERIFY PERMANENT CORRECTIVE ACTION(S) (PCA):

% Effective:

Through pre-production test programs, quantitatively confirm that the selected corrective actions will resolve the problems for the

customer and will not cause undesirable side effects. Define contingency action, if necessary based on the risk assessments. This step

describes WHAT you will do.

LINK TO DECISION MAKING WORKSHEET & RISK ANALYSIS

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE PCA?:

How can you make the problem come and go - prove it - test results - document it.

D6 IMPLEMENT AND VALIDATE PERMANENT CORRECTIVE ACTION(S) (PCA):

How effective is your

PCA so the problem is

cured not masked?

(must have 100%

total)

Target

Date:

Actual

Date:

Target

Date:

Actual

Date:

Define and implement the best permanent corrective actions. Include the removal of the ICA. Choose on-going controls to ensure the

root cause is eliminated. Once in production, monitor and evaluate the long-term effects and implement contingency actions, if

necessary. This step describes HOW you will do it.

LINK TO PLANING AND PROBLEM PREVENTION WORKSHEET

HOW WILL YOU VALIDATE THE PCA?

Use validation tools for long term results: Trend - Pareto - Paynter, etc.

D7 SYSTEM PREVENTION ACTIONS TO PREVENT RECURRENCE:

Mistake Proofing: How are you going to ensure it can't happen again?

Modify the management systems, operating systems, practices and procedures to prevent recurrence of this and all similar problems.

(What is the "Escape Root Cause"? What in your system allowed this problem or any problem from leaving your plant and not getting

detected?). Choose on-going controls, including mistake proofing methodology, such as the use of process or design features to prevent

manufacture of nonconforming product/service. Review control plans, FMEA's, flowcharts, etc. for revisions.

Note: Develop Action Plan (can use worksheets to help brainstorm)

HAS CORRECTIVE ACTION/IMPLEMENTATION BEEN REVIEWED AGAINST DOCUMENTS?:

FMEA

Proc./Work Instr.

Flowchart

Control Plan

Check boxes that apply:

D8 TEAM AND INDIVIDUAL RECOGNITION: Recognize the collective efforts of the team.

Add to Internal Audit

Original: To the dept. Sprv/Mgr. Copy: All initial 8D's and revisions must be sent to appropriate personnel at the location.

If this is a WFC customer related 8D, copy to the Corporate Quality Management Department in Mississauga, Ontario

WGCPF-001 page 2 of 9

Rev. 5

18-Nov-03

THE WOODBRIDGE GROUP - 8D Response Report

WHO IS EFFECTED BY THE PROBLEM?

Example Customer

Company:

1234 Somewhere St.

Address:

Mytowne, MI

Location:

26003

Part No./Code

Front Seat Back Cushion

Product Name:

INTERNAL

or

EXTERNAL

D1 TEAM MEMBER NAMES/TITLES:

Champion:

Al Bossman

Team Leader:

Joe Smith

Team Members:

Les Shippet, Stan Tistics, Ima

Goodguy

5/25/2003

BR-03-001

Date Open:

8D No.:

5/26/2003

Initial Response:

6/10/2003

Target Close Date:

5/30/03, 6/5/03

Revision Date(s):

Joe Smith

8D Initiator:

Al Bossman

Supervisor:

6/9/2003

Actual Close Date:

D2 PROBLEM STATEMENT/DESCRIPTION (quantify) (one defect per 8D)

Front Seat Back Cushions 26003 have voids.

June returns from Example Customer exceeded 450 TPPM.

Of the 31 pieces returned, 26 pieces were rejected for voids (84% of returns).

TPPM calculation = 31 rejections/35,000 pieces shipped x 1,000,000 = 886 TPPM

D3 CHOOSE AND VERIFY INTERIM CONTAINMENT ACTION(S) (ICA):

Review all material in-house and at Example Customer. Post "Alert" in plant and communicate

defect to all management personnel. 100% inspection area set up in cell 1 for each shift.

Management audit in warehouse and hand initial each label.

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE ICA?

%

Effective:

100%

Target

Date:

Actual

Date:

26-May-03 26-May-03

Paynter Chart

Attribute p-chart (0 found) by management audit.

D4 DEFINE AND VERIFY ROOT CAUSE(S):

% Contribution:

1. Foam splashing on seal. 2. Malfunctioning auto vent: Cleaned after demold, proper air pressure and cycling

is occurring but still malfunctioning by clogging.

1. 70%

2. 30%

HOW DID YOU VERIFY THE ROOT CAUSE(S)?

Can make voids come and go by altering pour pattern without splash and with splash. New auto vents produce

no clogs thus no voids.

D5 CHOOSE AND VERIFY PERMANENT CORRECTIVE ACTION(S) (PCA):

% Effective:

1. Change robot pour pattern 2. Change auto vent.

HOW DID YOU VERIFY THE EFFECTIVENESS OF THE PCA?:

100%

Monitored 30 pours for splash and checked auto vent after 30th pour for no clogs.

Target

Date:

D6 IMPLEMENT AND VALIDATE PERMANENT CORRECTIVE ACTION(S) (PCA):

Actual

Date:

1. Moved pour head 10 mm from the parting line (was 35 mm) and start in front and end in back. 2. Replaced

auto vent with new one.

HOW WILL YOU VALIDATE THE PCA?

Paynter chart 100% on-line inspection first 3 shipments.

Attribute study from management dock audits on first 3 shipments to Example Customer (np-chart 10 pieces

every hour at end of line).

D7 SYSTEM PREVENTION ACTIONS TO PREVENT RECURRENCE:

Mistake Proofing: How are you going to ensure it can't happen again?

30-May-03 29-May-03

Target

Date:

Add pour pattern to FMEA. Statistically monitor cycles/pours to determine when auto vents should be changed

(prior to clog). Add auto vent check to PM program and revised work instruction BRPMW-018

HAS CORRECTIVE ACTION/IMPLEMENTATION BEEN REVIEWED AGAINST DOCUMENTS?:

FMEA

Flowchart

Proc./Work Instr.

Control Plan

Check boxes that apply:

D8 TEAM AND INDIVIDUAL RECOGNITION: Recognize the collective efforts of the team.

05-Jun-03 05-Jun-03

Add to Internal Audit

Original: To the dept. Sprv/Mgr. Copy: All initial 8D's and revisions must be sent to appropriate personnel at the location.

If this is a WFC customer related 8D, copy to the Corporate Quality Management Department in Mississauga, Ontario

WGCPF-001 page 3 of 9

Rev. 5

Actual

Date:

18-Nov-03

PROBLEM DESCRIPTION (D2)

0

1. Operational

Definition

(Type in D2 here)

What's wrong with

what? Why?

2. Description

of Problem

WHAT

IS

IS NOT

GET INFO ON

Object

Defect

WHERE

Seen on object

Seen

geographically

WHEN

First seen

When else seen

When seen in

process (life cycle)

HOW BIG

How many objects

have the defect?

How many defects

per object?

What is the trend?

Updated By:

WGCPF-001 page 4 of 9

Update Date:

Rev. 5

Update #:

18-Nov-03

PROBLEM SOLVING WORKSHEET (D4)

1. Operational Definition

(Type in D2 here)

What's wrong with what? Why?

2. Description

of Problem

WHAT

IS

IS NOT

(Type in D2 here)

3. Deductions About Facts and Other Information

3a. Differences

3b. Changes

4. Possible Causes

List Change-How Theories

Date

A

Object

0

Defect

0

WHERE

Seen on object

0

Seen

geographically

D

0

WHEN

First seen

When else seen

When seen in

process (life cycle)

F

0

HOW BIG

How many objects

have the defect?

How many defects

per object?

5. Test causes for probability (+, -, ?) Page 2

Does it explain Is/Is Not fact?

6. Steps to verify Root Cause?

(make the problem come and go)

What is the trend?

Updated By:

WGCPF-001 page 5 of 9

Update Date:

Rev. 5

Update #:

18-Nov-03

TESTING POSSIBLE CAUSES (D4 Continued)

"IS's"

Ch

an

g

Th e-Ho

eo

w

rie

s

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Comments/

Follow-Up

Items

Updated By:

WGCPF-001 page 6 of 9

Update Date:

Rev. 5

18-Nov-03

Update #:

DECISION MAKING WORKSHEET (D3 & D5)

(1) END RESULT:

(4) CHOICES AVAILABLE - (INNOVATE)

(2) CRITERIA:

GIVENS: (mandatory, measurable, realistic)

(5) INFO

(3) How

Relative MERIT (total score)

WGCPF-001 page 7 of 9

Y/N (5) INFO

Y/N (5) INFO

Y/N (5) INFO

(5) How

INFO

Important

WANTS: flexible limits, subjective, realistic

(1-10)

0

0

Updated By:

(5) How

INFO

Good

(0-10)

Score

(5) How

INFO

Good

(0-10)

Score

Good

(0-10)

Score

0

Update Date:

Rev. 5

(5) How

INFO

Good

(0-10)

Score

Y/N

18-Nov-03

0

Update Rev #:

DECISION MAKING WORKSHEET - RISK ANALYSIS (D3 & D5)

(6) RISK ANALYSIS: State your risks in "IFTHEN" terms.

1st Choice

Investigate one choice at a time

1. RISK

What characteristics of

this choice may fail to

satisfy the GIVENS?

2. RISK

What features or

characteristics of this

choice compromise or

threaten an important

WANT?

"If we do this, what might happen, contrary to our interest?"

2nd Choice

3rd Choice

3. UNIVERSAL

Use the checklist to stimulate ideas.

Basic Sources of Trouble:

People

Organization

External Influences

Facilities

Equipment

Ideas

Policies

Processes

Materials

Money - Economics

Capacity

Quality

Timing

Personal Influence

"SERIOUSNESS" No. 10 means rejection if "PROBABILITY" is certain (10 x 10).

Updated By:

WGCPF-001 page 8 of 9

Rev. 5

P = Probability (1-10)

S = Severity (1-10)

Update Date:

18-Nov-03

7. Make the Final Balanced Choice

Update Rev #:

PLANNING AND PROBLEM PREVENTION WORKSHEET (D6)

1. OBJECTIVE OF THE PLAN (Goal with timing):

2. KEY STEPS

3. POTENTIAL PROBLEMS

4. PRIORITY

P

S

Revised By:

WGCPF-001 page 9 of 9

Revision Date:

Rev. 5

5. POSSIBLE CAUSES

6. PREVENTION ACTIONS

Revision #:

18-Nov-03

7. PROTECTION ACTIONS

8. CUES (DATE OR EVENT)

9. WHO

Potrebbero piacerti anche

- 8 D Report FormatDocumento9 pagine8 D Report FormatAlok MehtaNessuna valutazione finora

- Chapter 2: Science, Technology, and Society in Human Condition Lesson 1: Human FlourishingDocumento5 pagineChapter 2: Science, Technology, and Society in Human Condition Lesson 1: Human FlourishingJcNessuna valutazione finora

- Develop Your Kuji In Ability in Body and MindDocumento7 pagineDevelop Your Kuji In Ability in Body and MindLenjivac100% (3)

- Group 7 Scope StatementDocumento17 pagineGroup 7 Scope Statementapi-335995226100% (4)

- Assignment 1 - Tiered LessonDocumento15 pagineAssignment 1 - Tiered Lessonapi-320736246Nessuna valutazione finora

- Development Procedure 16-08-2021Documento6 pagineDevelopment Procedure 16-08-2021CompdevpNessuna valutazione finora

- Pfmea ExampleDocumento5 paginePfmea Exampleesivaks2000Nessuna valutazione finora

- Engineering Change Request FormDocumento1 paginaEngineering Change Request FormSudhaNessuna valutazione finora

- PPAP Package for Inner Pipe PartDocumento31 paginePPAP Package for Inner Pipe PartPk NimiwalNessuna valutazione finora

- LSAI SQA Manual FileDocumento39 pagineLSAI SQA Manual FileSivakumar LNessuna valutazione finora

- MTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Documento9 pagineMTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Sahil WadhwaNessuna valutazione finora

- Failure Modes and Effects Analysis (Design FMEA) : Show MSR-Columns MSR-columns Hidden or DeletedDocumento2 pagineFailure Modes and Effects Analysis (Design FMEA) : Show MSR-Columns MSR-columns Hidden or Deleted576410% (1)

- WI-R&D-33 - Field Validation of ClutchDocumento3 pagineWI-R&D-33 - Field Validation of ClutchDisha ShahNessuna valutazione finora

- Product Audit PlanDocumento2 pagineProduct Audit PlanMUNENDRA SHAKYANessuna valutazione finora

- APQP and PPAP ExplainedDocumento3 pagineAPQP and PPAP ExplainedignaunaqNessuna valutazione finora

- Histogram TemplateDocumento2 pagineHistogram Templateesivaks2000Nessuna valutazione finora

- Clutch Auto PDFDocumento52 pagineClutch Auto PDFHarshvardhan KothariNessuna valutazione finora

- Floor Plan ProductionDocumento3 pagineFloor Plan Productionshani0300Nessuna valutazione finora

- Product Identification TagDocumento3 pagineProduct Identification TagshalinmishraNessuna valutazione finora

- Part Submission Warrant: Aimler HryslerDocumento1 paginaPart Submission Warrant: Aimler HryslerAlan GrajedaNessuna valutazione finora

- 20 11 2019Documento1 pagina20 11 2019Oviya VenkateshNessuna valutazione finora

- JD FormatDocumento4 pagineJD FormatAshutosh SinghNessuna valutazione finora

- Responsibility and Authority - QMSDocumento47 pagineResponsibility and Authority - QMSDisha Shah50% (2)

- TEAM fEASIBILITYDocumento2 pagineTEAM fEASIBILITYPk NimiwalNessuna valutazione finora

- GM FMEA DoneDocumento12 pagineGM FMEA DoneSuraj RawatNessuna valutazione finora

- Extract PQA data and view project status in ExcelDocumento18 pagineExtract PQA data and view project status in ExcelRiadh JellaliNessuna valutazione finora

- Advance Product Quality Planning Status ReportDocumento30 pagineAdvance Product Quality Planning Status ReporttapanNessuna valutazione finora

- PPAP 101 - What You Need To KnowDocumento9 paginePPAP 101 - What You Need To KnowQGFNessuna valutazione finora

- Packaging Details: Vendor Name & AddressDocumento4 paginePackaging Details: Vendor Name & AddressPk NimiwalNessuna valutazione finora

- Master Form VDADocumento4 pagineMaster Form VDAapi-3856433Nessuna valutazione finora

- R-13 Tool Box Training SheetDocumento1 paginaR-13 Tool Box Training SheetRavikant PandeyNessuna valutazione finora

- Bin CleaningDocumento2 pagineBin CleaningRS MANIKANDANNessuna valutazione finora

- Deckblatt - : First Sample Test Report VDADocumento9 pagineDeckblatt - : First Sample Test Report VDAJuliaNessuna valutazione finora

- CUSTOMER EVENTS BY MODEL AND MONTHDocumento29 pagineCUSTOMER EVENTS BY MODEL AND MONTHBiswaranjan SahooNessuna valutazione finora

- MD 010 Design Validation Sop 1 0 110905125013 Phpapp02Documento1 paginaMD 010 Design Validation Sop 1 0 110905125013 Phpapp02Omer ZiaNessuna valutazione finora

- VDA FMEA Process AnalysisDocumento54 pagineVDA FMEA Process Analysishmp90Nessuna valutazione finora

- 4M Change ManagementDocumento2 pagine4M Change ManagementDamodaran RajanayagamNessuna valutazione finora

- Procedure - Special CharacteristicsDocumento13 pagineProcedure - Special Characteristicsalexandru.ghiniaNessuna valutazione finora

- PSW Signature TemplateDocumento1 paginaPSW Signature TemplateKM MuiNessuna valutazione finora

- Reference PDCA-FTA New 2021Documento6 pagineReference PDCA-FTA New 2021ubllcNessuna valutazione finora

- APQP FormDocumento103 pagineAPQP FormJERFSON AUGUSTONessuna valutazione finora

- Form30TM Advanced Product Quality Planning-APQPDocumento1 paginaForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiNessuna valutazione finora

- SRG Global PPAP ChecklistDocumento61 pagineSRG Global PPAP Checklistanamika tripathiNessuna valutazione finora

- F Qa 48 Ppap Readiness Sheet For 0.7lDocumento4 pagineF Qa 48 Ppap Readiness Sheet For 0.7lVikas RaiNessuna valutazione finora

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Documento10 pagineNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreNessuna valutazione finora

- Defect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byDocumento6 pagineDefect Rate Monitoring: Part Name: Checked By: Part Number: Customer Month Approved byParthiban DNessuna valutazione finora

- Gage R&R Data Sheet AnalysisDocumento1 paginaGage R&R Data Sheet AnalysisCu Built Engineers Pvt. Ltd.Nessuna valutazione finora

- Setco Automotive LTD.: NP ChartDocumento4 pagineSetco Automotive LTD.: NP ChartDisha ShahNessuna valutazione finora

- Exemple PPAPDocumento62 pagineExemple PPAPmoezNessuna valutazione finora

- KS Munjal Industries responds to customer complaint about dull zinc platingDocumento1 paginaKS Munjal Industries responds to customer complaint about dull zinc platingKaramjit SinghNessuna valutazione finora

- 8DDocumento8 pagine8DRomie CubalNessuna valutazione finora

- PSWDocumento1 paginaPSWIonut EduardNessuna valutazione finora

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocumento10 pagineWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNessuna valutazione finora

- Packing Approval SheetDocumento2 paginePacking Approval SheetSumeet RatheeNessuna valutazione finora

- Suppliers Quality Assurance Manual (PDFDrive)Documento135 pagineSuppliers Quality Assurance Manual (PDFDrive)umtNessuna valutazione finora

- GM Machining CP REV 03Documento17 pagineGM Machining CP REV 03Suraj RawatNessuna valutazione finora

- Histogram X-Bar Chart: Company NameDocumento1 paginaHistogram X-Bar Chart: Company NameSachin RamdurgNessuna valutazione finora

- Aiag Vda FmeaDocumento244 pagineAiag Vda Fmeav56btmnrc4Nessuna valutazione finora

- PPAP/APQP Requirements Checklist FormDocumento17 paginePPAP/APQP Requirements Checklist FormalexrferreiraNessuna valutazione finora

- Procedure For Set Up Approval, in Process & Final InspectionDocumento7 pagineProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNessuna valutazione finora

- APQPStatus Reporting GuidelinesDocumento19 pagineAPQPStatus Reporting GuidelinesskluxNessuna valutazione finora

- DFX Design For X A Complete Guide - 2020 EditionDa EverandDFX Design For X A Complete Guide - 2020 EditionNessuna valutazione finora

- Automotive Quality Management Systems A Complete Guide - 2020 EditionDa EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionNessuna valutazione finora

- 8D Report Solves Seat Cushion VoidsDocumento9 pagine8D Report Solves Seat Cushion VoidsPedro Pi100% (3)

- Receiving Welcoming and Greeting of GuestDocumento18 pagineReceiving Welcoming and Greeting of GuestMarwa KorkabNessuna valutazione finora

- Chapter 4 Matrices Form 5Documento22 pagineChapter 4 Matrices Form 5CHONG GEOK CHUAN100% (2)

- Learn Six Sigma Process and Methodology BasicsDocumento4 pagineLearn Six Sigma Process and Methodology BasicsGeorge MarkasNessuna valutazione finora

- DELA PENA - Transcultural Nursing Title ProposalDocumento20 pagineDELA PENA - Transcultural Nursing Title Proposalrnrmmanphd0% (1)

- Lesson Rubric Team Group (Lesson Plan 1)Documento2 pagineLesson Rubric Team Group (Lesson Plan 1)Yodalis VazquezNessuna valutazione finora

- Shailesh Sharma HoroscopeDocumento46 pagineShailesh Sharma Horoscopeapi-3818255Nessuna valutazione finora

- Neptune Sign House AspectDocumento80 pagineNeptune Sign House Aspectmesagirl94% (53)

- Co2 d30 Laser MarkerDocumento8 pagineCo2 d30 Laser MarkerIksan MustofaNessuna valutazione finora

- Outgoing Call Block BroadcastReceiver ExampleDocumento3 pagineOutgoing Call Block BroadcastReceiver ExampleZainUlAbidinNessuna valutazione finora

- C code snippets with answersDocumento14 pagineC code snippets with answersqwerty6327Nessuna valutazione finora

- Key Note Units 3-4Documento4 pagineKey Note Units 3-4Javier BahenaNessuna valutazione finora

- Dasha TransitDocumento43 pagineDasha Transitvishwanath100% (2)

- Mind MapDocumento1 paginaMind Mapjebzkiah productionNessuna valutazione finora

- Worksheet 9-2 - Math 7Documento2 pagineWorksheet 9-2 - Math 7bfbrfvlfrerNessuna valutazione finora

- Remapping The Small Things PDFDocumento101 pagineRemapping The Small Things PDFAme RaNessuna valutazione finora

- A Method For Identifying Human Factors Concerns During The HAZOP Process - Dennis AttwoodDocumento5 pagineA Method For Identifying Human Factors Concerns During The HAZOP Process - Dennis AttwoodAlvaro Andres Blanco GomezNessuna valutazione finora

- Mri 7 TeslaDocumento12 pagineMri 7 TeslaJEAN FELLIPE BARROSNessuna valutazione finora

- Livros Vet LinksDocumento12 pagineLivros Vet LinksÉrica RebeloNessuna valutazione finora

- Imports System - data.SqlClient Imports System - Data Imports System PartialDocumento2 pagineImports System - data.SqlClient Imports System - Data Imports System PartialStuart_Lonnon_1068Nessuna valutazione finora

- TheMindReader TeaserA WhatDocumento7 pagineTheMindReader TeaserA WhatnakulshenoyNessuna valutazione finora

- Failure Reporting, Analysis, and Corrective Action SystemDocumento46 pagineFailure Reporting, Analysis, and Corrective Action Systemjwpaprk1Nessuna valutazione finora

- Lenovo IdeaPad U350 UserGuide V1.0Documento138 pagineLenovo IdeaPad U350 UserGuide V1.0Marc BengtssonNessuna valutazione finora

- Proportions PosterDocumento1 paginaProportions Posterapi-214764900Nessuna valutazione finora

- Windows Server 2016 Editions ComparisonDocumento4 pagineWindows Server 2016 Editions ComparisonmasterredhardNessuna valutazione finora

- Time Series Data Analysis For Forecasting - A Literature ReviewDocumento5 pagineTime Series Data Analysis For Forecasting - A Literature ReviewIJMERNessuna valutazione finora

- Manual For The MCPL Programming LanguageDocumento74 pagineManual For The MCPL Programming Languagechri1753Nessuna valutazione finora