Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Product Data Sheet: Conservation Vent

Caricato da

napster386Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Product Data Sheet: Conservation Vent

Caricato da

napster386Copyright:

Formati disponibili

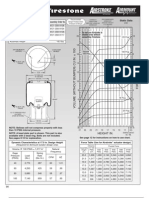

94020

Conservation Vent

PRODUCT DATA SHEET

Conservation Vent with

Cryogenic Hood Option

94020 with Optional

Limit Switches for

Vacuum & Pressure

(Pressure/Vacuum)

Open Vent

Conservation Vent

6, 8, 10 & 12

Conservation Vent with

Flame Snuffer Option

Suitable materials available for

corrosive and extreme temperature

service

Pallet reaction lip for smooth lift

and reseating

Vertical lift pallets assure reliable

operation and maximum flow

Floating diaphragm results in a positive

seal and minimal blow-down

Capacity certified to API Standards

The Shand & Jurs Model 94020 Conservation Vent (Pressure/Vacuum)

The Shand & Jurs Model 94020 Conservation Vent

is designed utilizing over 80 years of experience in

producing high quality and dependable conservation

fittings. Continued design improvements provide these

vents with high efficiency, maximum flow capacity and

minimum leakage. The easily serviceable configuration

and lightweight construction reduces maintenance and

installation costs.

Standard materials of construction are low copper

aluminum, cast iron, ductile iron, cast steel and 316

stainless steel for body materials. Aluminum, stainless

steel and steel body vents come standard with integral

seats and have optional replaceable seats. Cast iron

and ductile iron bodies come with replaceable seats as

standard design. Replaceable seats are made of corrosion

resistant molded thermosetting phenolic, teflon, aluminum,

316 stainless steel or stainless steel teflon coated and are

easily replaced.

TANK PRESSURE

WELL BELOW SETTING

Diaphragms are air cushion seated and are constructed of

FEP Teflon for reliability and extended service life. Teflon

diaphragms contribute to high resistance to adhesion of ice

and gum formations, thus assuring protection against pallet

sticking to the seating surface. The body is self-draining

and drip rings keep condensates from the seating surfaces.

The carefully engineered body, seat, and pallet assembly

results in a superior combination of tight sealing and high

capacity at low over-pressure with minimal blowdown.

Conservation Vents are available in a full range of sizes

and configurations, such as closed vent hoods (pipe-away),

cryogenic hoods and flame snuffers. Standard pressure and

vacuum settings are 1/2 oz./sq. in. The S&J Model 94020

Conservation Vent is available with optional pressure and

vacuum limit switches and visual indicators.

APPROACHING

SET POINT

SET POINT EXCEEDED

Shand & Jurs Expanda-Seal option is available on all pressure pallet assemblies. This feature, shown in red,

significantly reduces leakage. The ballooning effect of the teflon diaphragm effectively seals the valve. The ExpandaSeal feature ensures less than .5 SCFH of leakage at 95% of the set point.

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

20

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

PDS94020-2D

94020

Conservation Vent

PRODUCT DATA SHEET

(Pressure/Vacuum)

SPECIFICATIONS:

Sizes: . ...................................... 2, 3, 4, 6, 8, 10 & 12

Standard Settings*:

Pressure & Vacuum: . ............... 1/2 oz./sq. in. (.865 in.W.C.)

(See note* for 2)

Maximum Setting w/o Modification:

(Pressure)

(Vacuum)**

2:.............................................. 18 oz./sq. in. 8 oz./sq. in.

3: ............................................. 18 oz./sq. in. 9 oz./sq. in.

4: ............................................. 18 oz./sq. in. 11 oz./sq. in.

6: ............................................. 12 oz./sq. in. 12 oz./sq. in.

8: ............................................. 10 oz./sq. in. 14 oz./sq. in.

10: ........................................... 8 oz./sq. in. 17 oz./sq. in.

12: ........................................... 6 oz./sq. in. 21 oz./sq. in.

Service and Body Material:

Normal:...................................... Cast Low Copper Aluminum

Low Temperature: . ................... Cast Low Copper Aluminum

Severe: ..................................... Cast Iron, Ductile Iron, Cast

Steel, Cast 316 Stainless Steel

Type of Flange Connection:

Screwed or flanged for: .......................... 2 & 3 sizes

Flanged for: ............................................ 4, 6, 8 ,10 & 12

sizes

Raised face flange available, except for aluminum

body material.

Temperature Range: Body and Seal....... -400F to 2200F

Options for Process Temperature Ranges of

-3000F to 5000F

Options available:

Flame Snuffer for all sizes (open vent) and material, except low

temperature service. Closed vent for all sizes and materials.

Material substitutions as required. Cleaning for LOX/LIN

service.

Notes:

Expanda-Seal Vent only:

Expanda-Seal Pressure Setting: 1.5 oz./sq. in. Minimum

Integral Seats:........................... Same as body; AL, 316 SS,

(Consult Factory for lower settings)

CS with 316 SS seat overlay

Replaceable Seats:

Ryton for: .................................. 2 size

** Modifications may be required to vacuum port for

Phenolic for:.............................. 3 Thru 12 sizes

installations where product contamination may occur.

Aluminum for:............................ 2, 3, 4, 6, 8, 10 & 12 sizes See figure 4 for Principle of Operation. Caution

316 Stainless Steel for:............. 2, 3, 4, 6, 8, 10 & 12 sizes any obstruction to vacuum port may alter the set point.

Teflon for:................................... 2, 3, 4, 6, 8 sizes

SS Teflon Coated for:................ 2, 3, 4, 6, 8, 10 & 12 sizes

Component

Standard

Materials

of

Construction

Severe

Normal Aluminum

Low Temperature

Body

CA

CA

CI/DI

CS

Cover

CA

CA

CS

CS

Hood

18-8SS, PA1

AL

AL2

AL

SS

316SS

GI

GI

316SS

316SS

Seats3

Stem Guide

316SS

316SS

18-8SS, PA1 18-8SS, PA1

316SS

316SS

316SS

316SS

AL

AL

316SS

316SS

Pressure Stem

316SS

316SS

316SS

316SS

316SS

Vacuum Stem

AL4

304SS

316SS

316SS

316SS

Screens

AL4

GS

304SS

304SS

316SS

Retainer

AL

AL

316SS

316SS

316SS

Hardware

ZS

316SS

316SS

ZS

316SS

FEP

FEP

FEP

FEP

FEP

Pallets

Diaphragms

NOTES: 1. 18-8SS for 2, 3, 4, 6 & 8 sizes; spun alum. for 10 & 12 sizes.

2. 2, 3, 4, 6, 8, 10 & 12 sizes ; alum. enclosure w/flapper.

3. Material same as body except CI and DI.

4. 316SS for elevated settings.

Material Legend:

AL Aluminum

CA Cast Aluminum

Cl Cast Iron

CS

DI

Gl

GS

Cast Steel

Ductile Iron

Galvanized Iron

Galvanized Steel

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

PDS94020-2D

E-mail: sales@ljtechnologies.com

PA Spun Aluminum

FEP FEP Teflon

ZS Zinc Plated Steel

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

21

94020

Conservation Vent

PRODUCT DATA SHEET

(Pressure/Vacuum)

Principle of Operation

Fig. 1

Fig. 2

Figures 1 and 3 show the relation of the pressure or vacuum

pallet assembly to the seat when atmospheric and tank

pressures are equal. The wrap around effect of the resilient

diaphragm on the edge of the seat and the resulting high ratio

of seating force to seating area affords a tight seal.

As the pressure or vacuum increases, the pallet begins to

rise. Because there is still a wrap-around effect on the edge

of the seat, good sealing is maintained. Teflon diaphragm

memory and lapped seating surface further enhance sealing

characteristics.

As increasing pressure or vacuum continues to lift the pallet,

the diaphragm is held in close proximity to the seat by the

flat plane memory of the diaphragm material.

As set pressure or vacuum is reached the diaphragm leaves

the seat (see Figures 2 and 4) and the escaping vapor lifts

the pallet even further.

Fig. 3

Fig. 4

The vacuum pallet is guided in the same manner as the

pressure pallet. Both are pallet stem and pallet side guided

for smooth movement.

STEAM JACKETED OPTION:

Designed for use on tanks containing liquids whose vapors

crystallize at ambient temperatures. Stainless steel pressure

and vacuum pallets are cased in a steam heated jacket

ensuring the valves will be free from plugging. The jacket is

steel or stainless steel construction. The standard jacket can

withstand steam pressures up to 100 psig. Higher pressure

ratings are available.

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

22

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

PDS94020-2D

94020

Conservation Vent

PRODUCT DATA SHEET

(Pressure/Vacuum)

6, 8, 10 & 12

Cryogenic

Hood Model

Dimensions in Inches

Vent Size*

(In.)

6

8

10

12

30

34 1/2

41

44 1/2

12 1/8

14 11/16

17 1/2

19 3/4

5 5/8

7 3/8

8 3/8

10

8 1/8

9 5/8

11 3/8

12 5/8

8 1/2

10

11 5/8

13

11 1/2

12 1/2

14 3/16

15 3/8

17 1/16

21 1/4

25 1/2

29 7/8

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

PDS94020-2D

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

23

94020

Conservation Vent

PRODUCT DATA SHEET

(Pressure/Vacuum)

94020 Closed Vent

Outlet

"Size"

Valve

Size

Outlet

Size

"H"

"J"

"K"

"L"

2"

2"

13

11 1/8

5 1/32

4 1/4

2"

3"

13

11 1/8

5 1/32

4 1/4

3"

3"

16 3/8

13 1/4

5 9/16

5 1/4

3"

4"

16 3/16

13 3/4

5 31/32

5 1/4

4"

4"

20

20 3/8

6 1/2

4"

6"

19 1/4

15 3/4

7 1/32

5 15/16

6"

6"

26 1/4

21 1/4

9 3/8

8 3/8

6"

8"

26 3/16

21 1/4

10 11/32

8 1/4

8"

8"

31 5/8

25 1/2

11 11/16

9 3/4

8"

10"

31 5/8

26 3/16 12 23/32

10"

10"

37 7/8

10"

12"

37 7/8

30 1/4

12"

12"

43 3/8

33 7/8

12"

14"

43 3/8

33 7/8

Connection

*

*

"J"

*

*

"K"

*

*

Valve Inlet

"Size"

Connection

"L"

"B"

"H"

*Table D option 5 for same size inlet and outlet

connections has been obsoleted and replaced by

Table D option 6. Dimensions do not match. Consult

Factory for replacement valve.

30

13 7/8

9 3/4

11 19/32

14 29/32 11 19/32

16 1/4

12 13/16

16 29/32 12 13/16

NOTES:

1.

2.

3.

Connection size matches ANSI, DIN & JIS.

Mounting Holes straddle centerline except: 2

& 3 sizes; holes are on centerline.

Optional NPT Adapter available for 2 & 3.

94020 Open Vent

"F"

Valve

Size

2"

3"

4"

6"

8"

10"

12"

"E"

Valve

"Size"

Connection

"B"

"D"

"B"

"D"

"E"

9

11 1/8

13 1/2

17 15/16

21 7/8

26 1/4

30 9/16

15 1/4

17 15/16

21 1/2

28 1/2

31 3/16

40 5/8

44 5/8

11 1/8

13 3/4

15 3/4

18 3/4

21 1/4

28 1/8

32 1/4

Diameter

"F"

12 7/8

13 9/16

15 15/16

18 5/8

18 5/8

25 9/16

29 7/8

NOTES:

1.

2.

3.

Connection size matches ANSI, DIN & JIS.

Mounting Holes straddle centerline except: 2

& 3 sizes; holes are on centerline.

Optional NPT Adapter available for 2 & 3.

All designs subject to change. Certified dimensions and specifications available upon request

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

24

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

PDS94020-2D

94020

Conservation Vent

ORDERING GUIDE

(Pressure/Vacuum)

The CONSERVATION VENTS provide tank venting and breathing with high efficiency, maximum flow

capacity and minimum leakage. Standard materials of construction include low copper aluminum,

cast iron, ductile iron, cast steel, and 316 Stainless Steel. The 94020 comes in open or closed vent

versions, and in sizes 2 through 12. Cryogenic hoods, flame snuffers, limit switches and steam

jacketing and steam tracing are available.

*Low copper aluminum alloy construction reduces need for special materials in corrosive and extreme temperature service

*Peripheral and stem guided pressure pallet assures smooth lift and closure.

*Unique floating diaphragm construction assures positive seal and minimal blowdown, thus conserving valuable tank content

*Capacity certified in accordance with API standards

*Expanda-Seal diaphram for reduced leakage

MODEL NUMBER SELECTION:

The model number will consist of a base number 94020 followed by a dash and 8 numbers.

94020 AB CD EF GH

Special Cleaning

ATEX, CE

Size and Body Material

Seat and Pallet Material

Vent and Flange Type

Pressure Range and Weight Material

Seal Type and Softgood Material

ORDERING INFORMATION

Specify:

1. Model 94020 Conservation Vent

2. Size and Body Material

3. Screwed or Flanged Connection on 2 and 3 Size

4. Closed Vent or Vent to Atmosphere (With or without flame snuffer)

5. Pressure and Vacuum Settings (if other than normal setting)

6. Type of Cleaning (if for oxygen service)

7. Optional Materials of Construction, as Required

8. To Specify CE for Ordinary EU Locations use

94020C AB CD EF GH

9. To Specify ATEX Certification for Group IIB, IIA EU Locations

use 94020A AB CD EF GH. ATEX Certification includes CE Mark.

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

PDS94020-2D

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

25

94020

Conservation Vent

ORDERING GUIDE

(Pressure/Vacuum)

TABLE (AB) - SIZE AND BODY MATERIAL

TABLE I - (AB) SIZE, MATERIAL & TYPE OF CONNECTION

Option AB

Size

11

12

21

22

*31/41

*32/42

51

52

71

72

13

14

23

24

*33/43

*34/44

53

54

73

74

15

25

2"

2"

2"

2"

2"

2"

2"

2"

2"

2"

3"

3"

3"

3"

3"

3"

3"

3"

3"

3"

4"

4"

* 3X = Cast Iron

4X = Ductile Iron

TYPE OF

CONNECTION

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

NPT**

Flanged

Flanged

Flanged

BODY

MATERIAL

ALUM

ALUM

ALUM CRYO HOOD

ALUM CRYO HOOD

CI/DI

CI/DI

CS

CS

SS 316

SS 316

ALUM

ALUM

ALUM CRYO HOOD

ALUM CRYO HOOD

CI/DI

CI/DI

CS

CS

SS 316

SS 316

ALUM

ALUM CRYO HOOD

**For NPT Connections,

Specify Table C0

Option AB

SIZE

*35/45

55

75

16

26

*36/46

56

76

17

27

*37/47

57

77

18

28

*38/48

58

78

19

29

*39/49

59

79

4"

4"

4"

6"

6"

6"

6"

6"

8"

8"

8"

8"

8"

10"

10"

10"

10"

10"

12"

12"

12"

12"

12"

TYPE OF

CONNECTION

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

Flanged

BODY

MATERIAL

CI/DI

CS

SS 316

ALUM

ALUM CRYO HOOD

CI/DI

CS

SS 316

ALUM

ALUM CRYO HOOD

CI/DI

CS

SS 316

ALUM

ALUM CRYO HOOD

CI/DI

CS

SS 316

ALUM

ALUM CRYO HOOD

CI/DI

CS

SS 316

TABLE (C) - FLANGE TYPE

OPTION#

DESCRIPTION

0

FF ANSI 150 lb

1

RF ANSI 150 lb*

2

DIN 2633 PN 16 FF

3

DIN 2633 PN 16 RF*

4

JIS 10K FF

5

JIS 10K RF*

* RF Not available in aluminum

TABLE (D) - VENT TYPE

OPTION #

1

2

3

4

6

DESCRIPTION

Open Vent

Open Vent w/ Flame Snuffer-Not Available with ATEX (H5, H6, or H7)

Closed, Standard Outlet>Inlet*

Closed, P&V C.F.

Closed, Same Size Inlet, Outlet, Seat**

* Standard closed vent (outlet is one size larger than the inlet)

Ex. - 2 Inlet X 3 Outlet, 6 Inlet X 8 Outlet

**Note: Replaced Option 5. Dimensions are not identical.

Consult Factory if replacement valve is required.

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

26

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

PDS94020-2D

94020

Conservation Vent

ORDERING GUIDE

(Pressure/Vacuum)

TABLE (E) - SEAL TYPE AND SOFTGOODS

OPTION E

DESCRIPTION

0

Normal FEP / N8090

1

Expanda Seal FEP / N8090

2

Normal FEP (all)

3

Expanda FEP (all)

4

Normal Viton

5

Expanda Viton

6

Normal PTFE

8

Normal Buna

9

Expanda Buna

TABLE (F) - PRESSURE RANGE & LOAD WEIGHT MATERIAL

OPTION F

DESCRIPTION

MATERIAL

1

Standard Pressure and Vacuum Setting**= .5 oz/sq. in

2

Over 2.9 oz/sq. in., to max. setting

3

>Standard to 2.9 oz/sq.in.

4

Standard Setting**

5

Over 2.9 oz/sq. in., to max. setting

6

>Standard to 2.9 oz/sq.in.

** Expanda-Seal min. pressure setting: 1.5 oz/sq. in.

TABLE (G) - SEAT & PALLET MATERIAL

Option G

0

+ 1

2

+ 3

4

5

Seat

STD*

Teflon

AL

Phenolic

SS

Teflon Coated SS

Pallet

STD*

STD*

STD*

STD*

STD*

STD*

A

+ B

C

+ D

E

F

STD*

Teflon

AL

Phenolic

SS

Teflon Coated SS

316SS

316SS

316SS

316SS

316SS

316SS

* See Materials of Construction

+ These Options not Available with ATEX Models

Lead

Lead

Lead

316 SS

316 SS

316 SS

TABLE (H) - LOX (Liquid Oxygen) & LIN

(Liquid Nitrogen) Cleaning, Trim

Option H

0

1

2

5

6

7

8

9

A

Cleaning

Normal

LOX

LIN

Normal

LOX

LIN

Normal

LOX

LIN

Trim

STD

STD

STD

316SS

316SS

316SS

Monel

Monel

Monel

For an ATEX Certified Valve choose Option 5, 6, 7.

Trim includes Stem, Stem Guides, Side Guides,

Nuts,Bolts, and Screen.

NOTE: LOX/LIN cleaning for Cryogenic Breathers

of aluminum construction includes degreasing before

assembly only!

5911 Butterfield Road, Hillside, Illinois 60162

an L&J Technologies Company

PDS94020-2D

E-mail: sales@ljtechnologies.com

Phone: (708) 236-6000

http:\\www.ljtechnologies.com

Fax: (708)236-6006

ISO 9001 Registered

27

Potrebbero piacerti anche

- Shand - Jurs Conservation Vent 94020-3CDocumento8 pagineShand - Jurs Conservation Vent 94020-3CRuban PaulNessuna valutazione finora

- SBF LongdDocumento10 pagineSBF LongdcatalineulaNessuna valutazione finora

- Conservation Vent (Pressure & Vacuum)Documento8 pagineConservation Vent (Pressure & Vacuum)SudhirNessuna valutazione finora

- Velan Forged Steel CatalogueDocumento26 pagineVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezNessuna valutazione finora

- Breather Valve 94020-3HDocumento8 pagineBreather Valve 94020-3Hbuzz cmkyNessuna valutazione finora

- Conservation Vent (Pressure & Vacuum)Documento8 pagineConservation Vent (Pressure & Vacuum)Bureau VeritasNessuna valutazione finora

- Velan Valve KatalogDocumento22 pagineVelan Valve KatalogAinurizal HilmiNessuna valutazione finora

- Flow Safe - F84L - CatalogueDocumento12 pagineFlow Safe - F84L - CataloguecookienutNessuna valutazione finora

- Triton XR-70 HZP R2 FinalDocumento16 pagineTriton XR-70 HZP R2 FinalErcan YilmazNessuna valutazione finora

- Disc ValvesDocumento8 pagineDisc ValvesMahesh KumarNessuna valutazione finora

- L&J 94020-2BDocumento8 pagineL&J 94020-2BBureau VeritasNessuna valutazione finora

- 15 Metal Seated Butterfly ValvesDocumento8 pagine15 Metal Seated Butterfly ValvesrajfmcNessuna valutazione finora

- Series 7400Documento22 pagineSeries 7400zekha87Nessuna valutazione finora

- Broady 3500 BrochureDocumento12 pagineBroady 3500 Brochureahmedm2020Nessuna valutazione finora

- Conservation Vent (Pressure & Vacuum)Documento8 pagineConservation Vent (Pressure & Vacuum)Mustafa PardawalaNessuna valutazione finora

- G209 IDocumento8 pagineG209 IJaider CamachoNessuna valutazione finora

- Tyco Vanessa DatasheetDocumento16 pagineTyco Vanessa DatasheetJack ChavanNessuna valutazione finora

- L&T ButterflyValves Triple OffsetDocumento16 pagineL&T ButterflyValves Triple OffsetvarathapandianNessuna valutazione finora

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocumento12 pagineAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNessuna valutazione finora

- Gasket Catalog SEPCODocumento12 pagineGasket Catalog SEPCOJaime Lozano GonzálezNessuna valutazione finora

- Cokebuster: A Proven SolutionDocumento11 pagineCokebuster: A Proven Solutionengg_mech77Nessuna valutazione finora

- Pressure Releif ValveDocumento24 paginePressure Releif Valvemtalha_loveNessuna valutazione finora

- Top Guide Control ValveDocumento32 pagineTop Guide Control Valveachari_swapnilNessuna valutazione finora

- Velan Ball Valve 1 PDFDocumento9 pagineVelan Ball Valve 1 PDFMilena Lemus FonsecaNessuna valutazione finora

- ASME Class 150 and 300Documento12 pagineASME Class 150 and 300pca97Nessuna valutazione finora

- E-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortDocumento16 pagineE-Series Flanged Ball Valves: ANSI 150 and 300 Regular and Full-PortAhmed RashiedNessuna valutazione finora

- GWC Valve International Cast Steel ValvesDocumento32 pagineGWC Valve International Cast Steel ValvesGWC Valve International100% (1)

- Ball ValeDocumento36 pagineBall Valelouiswang1964Nessuna valutazione finora

- I Nnov at IV e Solut Ions: Innovative SolutionsDocumento12 pagineI Nnov at IV e Solut Ions: Innovative Solutionsleandroperao5374Nessuna valutazione finora

- VX Butterfly Bray 40Documento10 pagineVX Butterfly Bray 40jpcrivariNessuna valutazione finora

- Gulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsDocumento6 pagineGulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsRiyas UdheenNessuna valutazione finora

- Airknife Drying Systems & ComponentsDocumento12 pagineAirknife Drying Systems & Componentsfagb1978Nessuna valutazione finora

- Hydro SafetyReliefValves Series15002500Documento12 pagineHydro SafetyReliefValves Series15002500HGuruGuruHNessuna valutazione finora

- AD00839V Butterfly Valves Broch - LRDocumento44 pagineAD00839V Butterfly Valves Broch - LRMaulia SabrinaNessuna valutazione finora

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDocumento14 pagineKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNessuna valutazione finora

- Vacuum ChambersDocumento20 pagineVacuum Chamberselloco1031Nessuna valutazione finora

- W01 358 7143Documento29 pagineW01 358 7143MROstop.comNessuna valutazione finora

- Static Data Description Assembly Order NoDocumento29 pagineStatic Data Description Assembly Order NoMROstop.comNessuna valutazione finora

- Tech Pneumatic AccDocumento1 paginaTech Pneumatic AccAlexandru StănucNessuna valutazione finora

- Static Data Description Assembly Order NoDocumento29 pagineStatic Data Description Assembly Order NoMROstop.comNessuna valutazione finora

- Static Data Description Assembly Order NoDocumento29 pagineStatic Data Description Assembly Order NoMROstop.comNessuna valutazione finora

- Ad00912v Wkmsaf T SealDocumento36 pagineAd00912v Wkmsaf T SealJulia WadeNessuna valutazione finora

- Slade GasketsDocumento3 pagineSlade Gasketsjontylee87Nessuna valutazione finora

- Fisher Valve EzDocumento28 pagineFisher Valve EzGrant BloxomNessuna valutazione finora

- High Performance Butterfly ValvesDocumento8 pagineHigh Performance Butterfly ValvesTejas JasaniNessuna valutazione finora

- 7800 Spec PDFDocumento2 pagine7800 Spec PDFxnbsxNessuna valutazione finora

- Breather Valve - Pressure-Vaccuem Relief ValveDocumento2 pagineBreather Valve - Pressure-Vaccuem Relief Valvevphor85Nessuna valutazione finora

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocumento8 pagineTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Nessuna valutazione finora

- Vacuum Breaker SubmittalDocumento4 pagineVacuum Breaker Submittalcarismendy428Nessuna valutazione finora

- Parker MA Series PDFDocumento17 pagineParker MA Series PDFhaggNessuna valutazione finora

- Series 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Documento12 pagineSeries 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Gopinath GunasekaranNessuna valutazione finora

- W01 358 9106Documento29 pagineW01 358 9106MROstop.comNessuna valutazione finora

- Rising DiscDocumento8 pagineRising DiscwenigmaNessuna valutazione finora

- Grove G9 Wafer Gate ValveDocumento9 pagineGrove G9 Wafer Gate Valvetxlucky80Nessuna valutazione finora

- Formed-Cylinders 2007-04 LoDocumento14 pagineFormed-Cylinders 2007-04 LomartinvandoornNessuna valutazione finora

- kfp3 Ball ValvesDocumento20 paginekfp3 Ball ValvesKristy DavisNessuna valutazione finora

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Da EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Valutazione: 5 su 5 stelle5/5 (2)

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Da EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168Nessuna valutazione finora

- Y-Type and Basket Strainer: Valve GroupDocumento3 pagineY-Type and Basket Strainer: Valve Groupxaaabbb_550464353Nessuna valutazione finora

- Msds AcetoneDocumento9 pagineMsds Acetonenapster386Nessuna valutazione finora

- Lehe0439 01Documento6 pagineLehe0439 01ddzoningcomNessuna valutazione finora

- Y-Type and Basket Strainer: Valve GroupDocumento3 pagineY-Type and Basket Strainer: Valve Groupxaaabbb_550464353Nessuna valutazione finora

- PAUT Advantages Set1Documento1 paginaPAUT Advantages Set1napster386Nessuna valutazione finora

- Process Piping Equations Set 1Documento2 pagineProcess Piping Equations Set 1napster386Nessuna valutazione finora

- Why Use Washers PDFDocumento2 pagineWhy Use Washers PDFnapster386Nessuna valutazione finora

- Application OpenAccount Form 4 PDFAgreementDocumento8 pagineApplication OpenAccount Form 4 PDFAgreementnapster386Nessuna valutazione finora

- Total Dynamic HeadDocumento2 pagineTotal Dynamic Headrajbhar_sNessuna valutazione finora

- MCC Vicinity MapDocumento1 paginaMCC Vicinity Mapnapster386Nessuna valutazione finora

- Angping AddressDocumento1 paginaAngping Addressnapster386Nessuna valutazione finora

- A516 NormalizedDocumento3 pagineA516 Normalizediran1362Nessuna valutazione finora

- Ultimate Scoring WorkoutDocumento2 pagineUltimate Scoring WorkoutrcdpreludeNessuna valutazione finora

- Dynapocket: Pocket-Size Hardness Tester Standardized To ASTM A 956Documento4 pagineDynapocket: Pocket-Size Hardness Tester Standardized To ASTM A 956napster386Nessuna valutazione finora

- LEAD ME LORD CHORDS by Gary Valenciano at Ultimate-GuitarDocumento2 pagineLEAD ME LORD CHORDS by Gary Valenciano at Ultimate-Guitarnapster386Nessuna valutazione finora

- My Maid Invests in The Stock Market by Bo SanchezDocumento29 pagineMy Maid Invests in The Stock Market by Bo SanchezGerald Magno100% (1)

- Angping AddressDocumento1 paginaAngping Addressnapster386Nessuna valutazione finora

- Total Dynamic HeadDocumento2 pagineTotal Dynamic Headrajbhar_sNessuna valutazione finora

- AutomatedListProfits PLR License PDFDocumento3 pagineAutomatedListProfits PLR License PDFCarlos HenryNessuna valutazione finora

- Ammonia MSDSDocumento3 pagineAmmonia MSDSnapster386Nessuna valutazione finora

- Activity 3Documento26 pagineActivity 3napster386Nessuna valutazione finora

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Documento17 pagineStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Petroleum Products MSDSDocumento2 paginePetroleum Products MSDSnapster386Nessuna valutazione finora

- Chlor TestDocumento1 paginaChlor Testnapster386Nessuna valutazione finora

- Paint DefectsDocumento129 paginePaint Defectsmohammad100% (6)

- Material Safety Data Sheet: CAUSTIC SODA SOLUTION: Chemicals and Vinyls, LLCDocumento9 pagineMaterial Safety Data Sheet: CAUSTIC SODA SOLUTION: Chemicals and Vinyls, LLCganukaniNessuna valutazione finora

- Velocity and Pressure Drop in PipesDocumento5 pagineVelocity and Pressure Drop in Pipeskiran9285Nessuna valutazione finora

- Engineering Design Guideline Pump Rev3Documento14 pagineEngineering Design Guideline Pump Rev3hclsvw67% (3)

- How To Connect Your Laptop To The TVDocumento8 pagineHow To Connect Your Laptop To The TVnapster386Nessuna valutazione finora

- Sharp AR-C172M ServiceM EN PDFDocumento308 pagineSharp AR-C172M ServiceM EN PDFpiaggio_nrgNessuna valutazione finora

- Installation Instructions: LRM1070, LRM1080Documento2 pagineInstallation Instructions: LRM1070, LRM1080Stefan JovanovicNessuna valutazione finora

- Linux Memory ExplainedDocumento60 pagineLinux Memory ExplainedRaphael AraujoNessuna valutazione finora

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocumento1 paginaDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyNessuna valutazione finora

- Books Confirmation - Sem VII - 2020-2021 PDFDocumento17 pagineBooks Confirmation - Sem VII - 2020-2021 PDFRaj Kothari MNessuna valutazione finora

- Ass2 mkt1009Documento11 pagineAss2 mkt1009thang5423Nessuna valutazione finora

- Project Execution and Control: Lunar International College July, 2021Documento35 pagineProject Execution and Control: Lunar International College July, 2021getahun tesfayeNessuna valutazione finora

- OOAD Documentation (Superstore)Documento15 pagineOOAD Documentation (Superstore)Umâir KhanNessuna valutazione finora

- XC3000 Series Motion Control System of Laser Cutting Commissioning Manual TextDocumento138 pagineXC3000 Series Motion Control System of Laser Cutting Commissioning Manual Textgerardo.reynosoNessuna valutazione finora

- Primal Grow Pro Supplement Review - Does It Work or Scam?Documento3 paginePrimal Grow Pro Supplement Review - Does It Work or Scam?Rakib0% (1)

- Theory and Practice AssignmentDocumento12 pagineTheory and Practice AssignmentMelikteNessuna valutazione finora

- SLA707xM Series: 2-Phase Unipolar Stepper Motor DriverDocumento20 pagineSLA707xM Series: 2-Phase Unipolar Stepper Motor DriverKatherine EsperillaNessuna valutazione finora

- UST G N 2011: Banking Laws # I. The New Central Bank Act (Ra 7653)Documento20 pagineUST G N 2011: Banking Laws # I. The New Central Bank Act (Ra 7653)Clauds GadzzNessuna valutazione finora

- Nagpur Company List 2Documento10 pagineNagpur Company List 2Kaushik BachanNessuna valutazione finora

- Presentation 2Documento32 paginePresentation 2Jackie LeeNessuna valutazione finora

- Quote Generator DocumentDocumento47 pagineQuote Generator DocumentPrajwal KumbarNessuna valutazione finora

- The Dell Direct Model: What It Means For Customers (Users) : - ProsDocumento12 pagineThe Dell Direct Model: What It Means For Customers (Users) : - ProsAbhinandan MattelaNessuna valutazione finora

- Review Accounting NotesDocumento9 pagineReview Accounting NotesJasin LujayaNessuna valutazione finora

- Iwcf Section OneDocumento20 pagineIwcf Section OnesuifengniliuNessuna valutazione finora

- Piston EffectDocumento11 paginePiston EffectBK180Nessuna valutazione finora

- Cover LetterDocumento16 pagineCover LetterAjmal RafiqueNessuna valutazione finora

- Rule: Steel Import Monitoring and Analysis SystemDocumento8 pagineRule: Steel Import Monitoring and Analysis SystemJustia.comNessuna valutazione finora

- Offer LetterDocumento8 pagineOffer LetterMadhavi Latha100% (3)

- Crisostomo Vs Courts of Appeal G.R. No. 138334 August 25, 2003Documento5 pagineCrisostomo Vs Courts of Appeal G.R. No. 138334 August 25, 2003RGIQNessuna valutazione finora

- DAR Vol1-2013Documento744 pagineDAR Vol1-2013chitransh2002Nessuna valutazione finora

- Design Calculation of Braking System (Landcruiser) : AbstractDocumento4 pagineDesign Calculation of Braking System (Landcruiser) : AbstractDr. Aung Ko LattNessuna valutazione finora

- Bureau of Indian Standards Conformity Assessment Scheme For Milk and Milk ProductsDocumento51 pagineBureau of Indian Standards Conformity Assessment Scheme For Milk and Milk Productsatvenu16160Nessuna valutazione finora

- Gcm02-Mt-Ing4 New1 PDFDocumento57 pagineGcm02-Mt-Ing4 New1 PDFabdel jabbar67% (3)

- GM1. Intro To FunctionsDocumento5 pagineGM1. Intro To FunctionsGabriel Benedict DacanayNessuna valutazione finora