Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Virgo Evs Valve Brochure

Caricato da

shashikanth79Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Virgo Evs Valve Brochure

Caricato da

shashikanth79Copyright:

Formati disponibili

Understanding expectations, delivering satisfaction!

Experience You Can Trust

Metal seated ball valves have proven to be the valves of choice in Severe Service applications where

critical shut-off or isolation of flow must be achieved due to safety, environmental or maintenance

concerns. With the demand for energy increasing globally and investment in production capacities

skyrocketing, the demand for Severe Service valve technology has increased. We at EVS are fully

prepared to meet the challenges of serving our customers. Our business strategy is based on trust

and respect, ensuring our customers needs always come first.

Industry Focus

Below is a general overview of the major industries with Severe Service applications where metal

seated technology can increase production, decrease down-time and enhance safety. There are

many new applications emerging today; from processes to reduce fugitive emissions, to new

methods to produce energy from natural resources. Severe applications include temperatures to

1500F, pressures to 4500 psi, abrasives, corrosives and solids. Other criteria include high cycles

and viscous or sticky service media. EVS has a wide range of Severe Service valve options to

choose from.

Power Generation

Refining

Chemical and Petrochemical

Oil and Gas

Mining

Pulp and Paper

Food and Beverage

Gasification

Synfuels

Miscellaneous Specialty Industries

**For specific application and valve selection, please contact one of our design application specialists.

Key Features & Benefits

Full range of designs to meet customer and industry specifications

Wide selection of body and trim materials to cover any process condition

Hard coating technologies selected based on service media

Quarter turn operation for quick opening/closing

Many standard sizes/materials are stocked for immediate availability

Lever, manual or automated options with ISO mounting pad

Smooth transitioned flow paths for optimum flow rates

Full service automation capabilities for one source responsibility and ownership

Parts are repairable, reducing turnaround and maintenance cost

Temperature ranges from -150F to 1500F

Pressure ranges from vacuum to 4500 Class

Copyright 2008 by EVS Valves all rights reserved

Metal Seated Product Range

Model EVS-FHP (Floating Ball with Integral Seat Design for Severe Service Water/Steam)

1/2 to 3, 1500, 2500, 4500 ASME Class, A105, F22 and F91 Forged Body Materials, Hard Coated Ball, Socketweld or Butt-weld end connections. (1/2 to 2-1/2, 1500 and 2500 ASME Class are stocked. Additional sizes/

classes/materials/end connections are available upon request).

Model EVS-FS (Floating Ball with Integral Seat Design for Severe Service Temperatures, Pressures and Service Media)

1/2 to 36 150 to 2500 ASME Class, Carbon Steel, Chrome Moly, Stainless Steel and exotic body materials, with

various trim/coating options or end connections available to fit customer specifications.

Model EVS-FC (Floating Ball Design for Moderate to Severe Temperatures, Pressures and Service Media)

2 to 8, 150, 300, 600 ASME Class, Carbon Steel, Chrome Moly, and Stainless Steel body materials with

410SS/316SS hard faced ball, with various end connections available to fit customer specifications.

Model EVS-TC (Trunnion Ball Design for Moderate to Severe Temperatures, Pressures and Service Media)

6 to 16, 150, 300, 600 ASME Class, Carbon Steel, Chrome Moly, and Stainless Steel body materials with

410SS/316SS hard faced ball, with various end connections available to fit customer specifications.

Model EVS-TOV (Triple Offset Zero Leakage Design for Severe Service Temperatures, Pressures and Service Media)

3 to 24, 150, 300, 600 ASME Class, Triple Offset Valve, Carbon Steel, and Stainless Steel body materials

with Stellite 21 alloy seat, Duplex SS seal ring, with Flanged and Lugged end connections available.

Basic Components for Integral Seat Models

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

DESCRIPTION

Ball

Seat Surface

Upstream seat

Disc Spring

Body

End Adaptor/Integral Seat

Stem

Body Gasket

Body Stud

Body Nut

Packing Gland

Stem Packing

Gland Stud

Gland Nut

Gland Live Loaded Springs

Quality, Testing and Service

Valves comply to ASME B16.34 and other national standards, see individual valve data sheets

for complete list of standards and codes.

Valves for steam service are tested to API 598 with water and nitrogen for zero leakage.

Service is a vital part of our business with 24 hour access to our EVS quick response team.

Copyright 2008 by EVS Valves all rights reserved

Introduction to EVS

As part of a growing International Valve Group, EVS brings forth a new era in Metal Seated Ball Valve

technology. Evolving from a proven team with over 80 years combined expertise; EVS understands your

Severe Service application challenges, and appreciates your need to increase efficiency and production.

The Engineering and Technology Department is directed by Marvin Beasley, P.E., a pioneer in the

development of Severe Service valve technology and a respected expert in this field. Along with his

experienced colleagues, this team is ready to tackle your harshest Severe Service application needs.

EVS valves are manufactured, assembled and tested in the companys new state of the art manufacturing

facility located in Stafford, Texas, USA.

EVS evolves from deep Virgo roots

EVS is a wholly-owned subsidiary of the Virgo

Engineers Group, a globally successful valve and

automation company servicing over 70 countries

world-wide. Virgo Engineers is one of the fastest

growing valve companies in the world. Virgo

product designs are the result of decades of

experience and innovation in the Oil & Gas process

industry. Our designs are proven performers in the

most severe environments. Virgo brand signifies

quality and reliability. To learn more about Virgo

please visit the website at www.virgoengineers.com

EVS Mission Statement

We at EVS will strive to understand difficult flow isolation or control applications faced by our customers

and will work with them to provide a reliable valve solution using sound engineering practices and our

extensive industry experience. EVS team members will attain customer satisfaction without compromising

good business ethics and our core values.

Please contact EVS Valves Inc. at:

10225 Mula Road, Suite 130 Stafford, Texas 77477

Phone: 281-933-3100 Fax: 281-933-3110

Website: www.evsvalves.com E-mail: sales@evsvalves.com

Copyright 2009 by EVS Valves all rights reserved

Potrebbero piacerti anche

- Case Study SentinelDocumento2 pagineCase Study Sentinelashumishra007Nessuna valutazione finora

- Section 3 Gas Turbines Start SystemsDocumento14 pagineSection 3 Gas Turbines Start SystemsPodeh AspriyantoNessuna valutazione finora

- 01 220043enc Routine Turbine MaintenanceDocumento8 pagine01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- Er-96-0-7-1 - Piston Rod Runout CorrectionDocumento3 pagineEr-96-0-7-1 - Piston Rod Runout CorrectionJeff LNessuna valutazione finora

- NIC 13.20 Rev.01Documento15 pagineNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- Especificação Técnica RM7800L1087 PDFDocumento36 pagineEspecificação Técnica RM7800L1087 PDFpedro netoNessuna valutazione finora

- المستندDocumento5 pagineالمستندMahdi HassanNessuna valutazione finora

- pmp1000 Pump InstallationDocumento7 paginepmp1000 Pump InstallationPitipong SunkhongNessuna valutazione finora

- 334.00-11 The Turning Gear PDFDocumento3 pagine334.00-11 The Turning Gear PDFOleg ShkolnikNessuna valutazione finora

- Ariel-Er-105 1 1Documento9 pagineAriel-Er-105 1 1gustavofx21Nessuna valutazione finora

- Babbitt Pro Service Goulds PumpDocumento2 pagineBabbitt Pro Service Goulds PumpKepin ShethNessuna valutazione finora

- Boilermate Boiler BookDocumento6 pagineBoilermate Boiler Bookhamidrezaee008Nessuna valutazione finora

- Compressor Over-Lubrication PresentationDocumento38 pagineCompressor Over-Lubrication Presentation1mmahoneyNessuna valutazione finora

- IOPTC PLC4TurbineDocumento4 pagineIOPTC PLC4TurbineStarlightbrightNessuna valutazione finora

- The Steam Turbine: 7.3.3 Rotor BalancingDocumento2 pagineThe Steam Turbine: 7.3.3 Rotor BalancingBhavana KewlaniNessuna valutazione finora

- Compressor FS604 Data SheetDocumento4 pagineCompressor FS604 Data SheetprimmughalNessuna valutazione finora

- Ariel J. Lubrication System-03 04 04Documento43 pagineAriel J. Lubrication System-03 04 04Manuel LiñeiroNessuna valutazione finora

- Long Weld Necks 300 PDFDocumento1 paginaLong Weld Necks 300 PDFPedro Montes MarinNessuna valutazione finora

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocumento1 paginaSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementmohammadNessuna valutazione finora

- Report Vibrasi Plant CP-2Documento13 pagineReport Vibrasi Plant CP-2hafiz_hayat_44190215Nessuna valutazione finora

- 00-Superior Compressor Student Guide-ToCDocumento1 pagina00-Superior Compressor Student Guide-ToCTu PhamNessuna valutazione finora

- MC HighPressureStageCasingPump E10026Documento6 pagineMC HighPressureStageCasingPump E10026govindkaniNessuna valutazione finora

- Piping ClassDocumento29 paginePiping Classvikas verma1Nessuna valutazione finora

- A-VIP Compressor BrochureDocumento6 pagineA-VIP Compressor BrochureAvrinFakherniaNessuna valutazione finora

- As Operating and Installation InstructionsDocumento12 pagineAs Operating and Installation InstructionsmedjebNessuna valutazione finora

- Sonceboz Chart Recorder Motor Spec SheetDocumento2 pagineSonceboz Chart Recorder Motor Spec Sheetjesdcp7Nessuna valutazione finora

- Mechanical Seals Piping Plans API 628Documento3 pagineMechanical Seals Piping Plans API 628Pedro ViegasNessuna valutazione finora

- HOSS ProductDescriptionDocumento6 pagineHOSS ProductDescriptionmath62210Nessuna valutazione finora

- Product Overview-WH FramesDocumento43 pagineProduct Overview-WH FramesArzyman100% (1)

- HOS (Heavy Oilfield Separable Compressor) BrochureDocumento6 pagineHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriNessuna valutazione finora

- Piping Lube OilOilconsole - enDocumento8 paginePiping Lube OilOilconsole - engopojiNessuna valutazione finora

- Psib 20130524aDocumento1 paginaPsib 20130524aLéandre Ettekri NdriNessuna valutazione finora

- TG 611 GovernorDocumento4 pagineTG 611 Governorveer_sNessuna valutazione finora

- Automation of Reciprocating Gas Engine Compressor Packages UsingDocumento7 pagineAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- Manual Caja Lufkin NF2019DDocumento46 pagineManual Caja Lufkin NF2019DLuis Romero100% (1)

- Case Study Vibration Problem of Steam Condensate Pump-ADocumento39 pagineCase Study Vibration Problem of Steam Condensate Pump-Akirany58100% (1)

- Peppers Catalogue PDFDocumento64 paginePeppers Catalogue PDFStone123456789Nessuna valutazione finora

- Allison 501 KB CompressorDocumento3 pagineAllison 501 KB CompressortaghiNessuna valutazione finora

- Mnit001 Meter Manual PDFDocumento9 pagineMnit001 Meter Manual PDFSergio Andres Rivera JaramilloNessuna valutazione finora

- Single-Stage Steam TurbinesDocumento8 pagineSingle-Stage Steam Turbinesfouzi gherNessuna valutazione finora

- Rod ReversalDocumento21 pagineRod ReversalandresNessuna valutazione finora

- 01 - SSE Academy BoolDocumento65 pagine01 - SSE Academy BoolAmmar AltamimyNessuna valutazione finora

- Nooter Eriksen HRSG AdvantagesDocumento3 pagineNooter Eriksen HRSG Advantagesaliscribd46Nessuna valutazione finora

- Vag Riko Plunger Valve: Operating and Maintenance InstructionsDocumento12 pagineVag Riko Plunger Valve: Operating and Maintenance InstructionsMuzamil Maqbool Rather100% (1)

- DDDocumento3 pagineDDAnkush Sehgal100% (1)

- Valvulas PDFDocumento32 pagineValvulas PDFMilena Lemus FonsecaNessuna valutazione finora

- Ansaldo Thomassen - CMU (2014)Documento4 pagineAnsaldo Thomassen - CMU (2014)guerrezNessuna valutazione finora

- Generon CatalogDocumento11 pagineGeneron CatalogDonovan BonnerNessuna valutazione finora

- gt24 XL Gas Turbine Upgrade PDFDocumento4 paginegt24 XL Gas Turbine Upgrade PDFkmishra80Nessuna valutazione finora

- KS3-Steam Turbine Over Speed Trip SystemsDocumento8 pagineKS3-Steam Turbine Over Speed Trip SystemsArul Kumaran Kothandapani100% (1)

- CCI Control Valves For Fossil ApplicationsDocumento2 pagineCCI Control Valves For Fossil ApplicationsGabrieldiazNessuna valutazione finora

- GT24/GT26 Operation Training Module: Jacking Oil SystemDocumento15 pagineGT24/GT26 Operation Training Module: Jacking Oil SystemAli HegaigNessuna valutazione finora

- Compressor Magazine March 2014Documento97 pagineCompressor Magazine March 2014Leon SanchezNessuna valutazione finora

- General Valve 4wayDocumento12 pagineGeneral Valve 4wayMargaret DaughertyNessuna valutazione finora

- ACHE Windmill DraftguardDocumento5 pagineACHE Windmill DraftguardTIKSHALANessuna valutazione finora

- InstallationOperationMaintenance 3600 enDocumento110 pagineInstallationOperationMaintenance 3600 enStaman1988Nessuna valutazione finora

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocumento8 pagineMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNessuna valutazione finora

- Mechanical Qa/Qc Inspector: ObjectivesDocumento6 pagineMechanical Qa/Qc Inspector: ObjectivesmohdNessuna valutazione finora

- VAAS General CatalogueDocumento14 pagineVAAS General CataloguenaughtyguymNessuna valutazione finora

- Complete Valve Solutions: For The Refining and Petrochemical IndustriesDocumento16 pagineComplete Valve Solutions: For The Refining and Petrochemical Industriesfranz_passariniNessuna valutazione finora

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Documento1 paginaGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79Nessuna valutazione finora

- Gate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12Documento1 paginaGate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12shashikanth79Nessuna valutazione finora

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Documento1 paginaGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79Nessuna valutazione finora

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Documento1 paginaGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79Nessuna valutazione finora

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Documento1 paginaGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79Nessuna valutazione finora

- Globe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12Documento1 paginaGlobe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12shashikanth79Nessuna valutazione finora

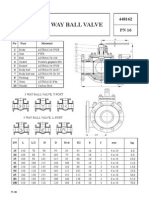

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Check Valve: 472452 472451 PN 16 PN 10Documento1 paginaBall Check Valve: 472452 472451 PN 16 PN 10shashikanth79Nessuna valutazione finora

- Resilient Seated Gate Valve: 620302 620301 PN 16 PN 10Documento1 paginaResilient Seated Gate Valve: 620302 620301 PN 16 PN 10shashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Compact: No MaterialDocumento1 paginaBall Valve Full Bore - Compact: No Materialshashikanth79Nessuna valutazione finora

- 3-Way Gland Cock: 1 No MaterialDocumento1 pagina3-Way Gland Cock: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Check Valve: 4740 47401 PN 16 PN 10Documento1 paginaBall Check Valve: 4740 47401 PN 16 PN 10shashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Flanged End: 1 Body No MaterialDocumento1 paginaBall Valve Full Bore - Flanged End: 1 Body No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Flanged End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Flanged End: No MaterialDocumento1 paginaBall Valve Full Bore - Flanged End: No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Screwed End: No MaterialDocumento1 paginaBall Valve Full Bore - Screwed End: No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Butt Weld End: No MaterialDocumento1 paginaBall Valve Full Bore - Butt Weld End: No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Screwed End: 442013 PN 30 PN 20Documento1 paginaBall Valve Full Bore - Screwed End: 442013 PN 30 PN 20shashikanth79Nessuna valutazione finora

- Ball Valve Screwed or Welded End Fire SafeDocumento1 paginaBall Valve Screwed or Welded End Fire Safeshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79Nessuna valutazione finora

- 3-Way Gland Cock: 1 No MaterialDocumento1 pagina3-Way Gland Cock: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Screwed End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79Nessuna valutazione finora

- Ball Valve Full Bore - Butt Weld End: 1 No MaterialDocumento1 paginaBall Valve Full Bore - Butt Weld End: 1 No Materialshashikanth79Nessuna valutazione finora

- 3-Way Ball Valve Full Bore - Screwed End: No MaterialDocumento1 pagina3-Way Ball Valve Full Bore - Screwed End: No Materialshashikanth79Nessuna valutazione finora

- 3-Way Gland Cock: No Material 1Documento1 pagina3-Way Gland Cock: No Material 1shashikanth79Nessuna valutazione finora

- 3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10Documento1 pagina3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79Nessuna valutazione finora

- 3-Way Ball Valve Full Bore - Flanged End: 1 No MaterialDocumento1 pagina3-Way Ball Valve Full Bore - Flanged End: 1 No Materialshashikanth79Nessuna valutazione finora

- 3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10Documento1 pagina3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79Nessuna valutazione finora

- SULTANS OF SWING - Dire Straits (Impresión)Documento1 paginaSULTANS OF SWING - Dire Straits (Impresión)fabio.mattos.tkd100% (1)

- Different Types of Classrooms in An Architecture FacultyDocumento21 pagineDifferent Types of Classrooms in An Architecture FacultyLisseth GrandaNessuna valutazione finora

- Purposeful Activity in Psychiatric Rehabilitation: Is Neurogenesis A Key Player?Documento6 paginePurposeful Activity in Psychiatric Rehabilitation: Is Neurogenesis A Key Player?Utiru UtiruNessuna valutazione finora

- APICS-Houston Newsletter Sept 2012Documento16 pagineAPICS-Houston Newsletter Sept 2012Christopher SeifertNessuna valutazione finora

- Apple Festival Program 2017Documento3 pagineApple Festival Program 2017Elizabeth JanneyNessuna valutazione finora

- Irregular Verbs-1Documento1 paginaIrregular Verbs-1timas2Nessuna valutazione finora

- Visual Images of America in The Sixteenth Century: Elaine BrennanDocumento24 pagineVisual Images of America in The Sixteenth Century: Elaine Brennanjoerg_spickerNessuna valutazione finora

- Intro To EthicsDocumento4 pagineIntro To EthicsChris Jay RamosNessuna valutazione finora

- Final ReflectionDocumento4 pagineFinal Reflectionapi-314231777Nessuna valutazione finora

- Veritas CloudPoint Administrator's GuideDocumento294 pagineVeritas CloudPoint Administrator's Guidebalamurali_aNessuna valutazione finora

- Maule M7 ChecklistDocumento2 pagineMaule M7 ChecklistRameez33Nessuna valutazione finora

- Monastery in Buddhist ArchitectureDocumento8 pagineMonastery in Buddhist ArchitectureabdulNessuna valutazione finora

- Impact Grammar Book Foundation Unit 1Documento3 pagineImpact Grammar Book Foundation Unit 1Domingo Juan de LeónNessuna valutazione finora

- 23 East 4Th Street NEW YORK, NY 10003 Orchard Enterprises Ny, IncDocumento2 pagine23 East 4Th Street NEW YORK, NY 10003 Orchard Enterprises Ny, IncPamelaNessuna valutazione finora

- An Etymological Dictionary of The Scottivol 2Documento737 pagineAn Etymological Dictionary of The Scottivol 2vstrohmeNessuna valutazione finora

- Pediatric ECG Survival Guide - 2nd - May 2019Documento27 paginePediatric ECG Survival Guide - 2nd - May 2019Marcos Chusin MontesdeocaNessuna valutazione finora

- Europe Landmarks Reading Comprehension Activity - Ver - 1Documento12 pagineEurope Landmarks Reading Comprehension Activity - Ver - 1Plamenna Pavlova100% (1)

- On The Linguistic Turn in Philosophy - Stenlund2002 PDFDocumento40 pagineOn The Linguistic Turn in Philosophy - Stenlund2002 PDFPablo BarbosaNessuna valutazione finora

- Curriculum Vitae: Personal InformationDocumento3 pagineCurriculum Vitae: Personal InformationMira ChenNessuna valutazione finora

- Introduction To Control SystemDocumento9 pagineIntroduction To Control SystemAbdulhakam Abubakar YusufNessuna valutazione finora

- BirdLife South Africa Checklist of Birds 2023 ExcelDocumento96 pagineBirdLife South Africa Checklist of Birds 2023 ExcelAkash AnandrajNessuna valutazione finora

- Employer'S Virtual Pag-Ibig Enrollment Form: Address and Contact DetailsDocumento2 pagineEmployer'S Virtual Pag-Ibig Enrollment Form: Address and Contact DetailstheffNessuna valutazione finora

- Michael M. Lombardo, Robert W. Eichinger - Preventing Derailmet - What To Do Before It's Too Late (Technical Report Series - No. 138g) - Center For Creative Leadership (1989)Documento55 pagineMichael M. Lombardo, Robert W. Eichinger - Preventing Derailmet - What To Do Before It's Too Late (Technical Report Series - No. 138g) - Center For Creative Leadership (1989)Sosa VelazquezNessuna valutazione finora

- Steel and Timber Design: Arch 415Documento35 pagineSteel and Timber Design: Arch 415Glennson BalacanaoNessuna valutazione finora

- IBM Unit 3 - The Entrepreneur by Kulbhushan (Krazy Kaksha & KK World)Documento4 pagineIBM Unit 3 - The Entrepreneur by Kulbhushan (Krazy Kaksha & KK World)Sunny VarshneyNessuna valutazione finora

- Student Worksheet Task 1 - Long Reading: Fanny Blankers-KoenDocumento2 pagineStudent Worksheet Task 1 - Long Reading: Fanny Blankers-KoenDANIELA SIMONELLINessuna valutazione finora

- Narrative ReportDocumento6 pagineNarrative ReportAlyssa Marie AsuncionNessuna valutazione finora

- Lista Agentiilor de Turism Licentiate Actualizare 16.09.2022Documento498 pagineLista Agentiilor de Turism Licentiate Actualizare 16.09.2022LucianNessuna valutazione finora

- Atelierul Digital Pentru Programatori: Java (30 H)Documento5 pagineAtelierul Digital Pentru Programatori: Java (30 H)Cristian DiblaruNessuna valutazione finora

- Trenching Shoring SafetyDocumento29 pagineTrenching Shoring SafetyMullapudi Satish KumarNessuna valutazione finora