Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

14

Caricato da

Akhil TiwariCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

14

Caricato da

Akhil TiwariCopyright:

Formati disponibili

NPTEL Chemical Mass Transfer Operation 1

MODULE 3: MASS TRANSFER COEFFICIENTS

LECTURE NO. 6

3.5.2 Penetration theory

Most of the industrial processes of mass transfer is unsteady state process. In

such cases, the contact time between phases is too short to achieve a stationary

state. This non stationary phenomenon is not generally taken into account by the

film model. In the absorption of gases from bubbles or absorption by wetted-wall

columns, the mass transfer surface is formed instantaneously and transient

diffusion of the material takes place. Figure 3.4 demonstrates the schematic of

penetration model.

Basic assumptions of the penetration theory are as follows:

1) Unsteady state mass transfer occurs to a liquid element so long it is in

contact with the bubbles or other phase

2) Equilibrium exists at gas-liquid interface

3) Each of liquid elements stays in contact with the gas for same period of

time

Liquid elements

are sliding down

Rising gas

bubble

Figure 3.4: Schematic of penetration model.

Joint initiative of IITs and IISc Funded by MHRD

Page 1 of 5

NPTEL Chemical Mass Transfer Operation 1

Under these circumstances, the convective terms in the diffusion can be

neglected and the unsteady state mass transfer of gas (penetration) to the liquid

element can be written as:

c

2c

DAB

t

Z 2

(3.60)

The boundary conditions are: t = 0, Z > 0 : c = c Ab and t > 0, Z = 0 : c = cAi.

The term cAb is the concentration of solute at infinite distance from the surface

and cAi is the concentration of solute at the surface. The solution of the partial

differential equation for the above boundary conditions is given by the following

equation:

Z

c Ai c

erf

2 D t

c Ai c Ab

AB

(3.61)

Where erf(x) is the error function defined by

x

exp( Z

erf ( x)

)dZ

(3.62)

If the process of mass transfer is a unidirectional diffusion and the surface

concentration is very low (cAb~0), the mass flux of component A, NA [kg m2 s1],

can be estimated by the following equation:

NA

DAB

1 c Ab

c

c

Z Z 0

Z Z 0

(3.63)

Substituting Equation (3.61) into Equation (3.63), the rate of mass transfer at

time t is given by the following equation:

N A (t )

D AB

(c Ai c Ab )

t

(3.64)

Then the mass transfer coefficient is given by

k L (t )

DAB

t

(3.65)

The average mass transfer coefficient during a time interval tc is then obtained by

integrating Equation (3.61) as

Joint initiative of IITs and IISc Funded by MHRD

Page 2 of 5

NPTEL Chemical Mass Transfer Operation 1

k L ,av

1 c

DAB

k (t )dt 2

tc 0

tc

(3.66)

So from the above equation, the mass transfer coefficient is proportional to the

square root of the diffusivity. This was first proposed by R. Higbie in 1935 and the

theory is called Higbies penetration theory.

3.5.3 Surface Renewal Theory

For the mass transfer in liquid phase, Danckwert (1951) modified the Higbies

penetration theory. He stated that a portion of the mass transfer surface is

replaced with a new surface by the motion of eddies near the surface and

proposed the following assumptions:

1) The liquid elements at the interface are being randomly swapped by fresh

elements from bulk

2) At any moment, each of the liquid elements at the surface has the same

probability of being substituted by fresh element

3) Unsteady state mass transfer takes place to an element during its stay at

the interface.

Hence, average molar flux, NA,av

N A,av (C Ai C Ab ) s DAB

(3.67)

Comparing Equation (3.67) with Equation (3.8) we get

k L,av s DAB

(3.68)

where s is fraction of the surface renewed in unit time, i.e., the rate of surface

renewal [s-1].

3.5.4 Boundary Layer Theory

Boundary layer theory takes into account the hydrodynamics/flow field that

characterizes a system and gives a realistic picture of the way mass transfer at a

phase boundary. A schematic of concentration boundary layer is shown in Figure

3.5.

Joint initiative of IITs and IISc Funded by MHRD

Page 3 of 5

NPTEL Chemical Mass Transfer Operation 1

U

CAb

u U

CA=CAi-0.99(CAi-CAb)

(x) m(x)

x

Flat plate

Figure 3.5: Schematic of concentration boundary layer.

When (x)u=Uand when m(x) u=0.99U distance over which solute

concentration drops by 99% of (CAi-CAb).

Shx

x.k L , x

D AB

0.332(Re) 0.5 ( Sc) 0.33

(3.69)

where, x is the distance of a point from the leading edge of the plate; kL,x is the

local mass transfer coefficient.

Shav

l.k L, x

D AB

0.664(Re) 0.5 ( Sc) 0.33

(3.70)

where, l is the length of the plate.

Example problem 3.2: Zakauskas (Adv. Heat Transfer, 8, 93, 1972) proposed

the following correlation for the heat-transfer coefficient in a staggered tube bank

arrangement:

Nu 0.453 Re 0.568 Pr 0.36 ,

where 10 Re ( u g d / ) 10 6 and 0.7 Pr 500

Estimate the mass-transfer coefficient by using the mass and heat transfer

analogy if to be expected for evaporation of n-propyl alcohol into carbon dioxide

for the same geometrical arrangement of tube diameter (d) of 38 mm when the

carbon dioxide flows at a maximum velocity (ug) of 10 m/s at 300 K and 1 atm.

Properties of dilute mixtures of propyl alcohol in carbon dioxide at 300 K and 1

atm are: Molecular weight (M) = 44 gm/mole, density () = 1.8 kg/m 3, Viscosity

() = 1.4910-5 kg/m.s, diffusivity (DAB) = 7.610-6 m2/s and universal gas

Joint initiative of IITs and IISc Funded by MHRD

Page 4 of 5

NPTEL Chemical Mass Transfer Operation 1

constant (R) = 8.314 J/mole.K. Sherwood number is defined based on diameter

of the tube as k G RTd / DAB

Solution 3.2: Re = 1.8*10*0.038/1.4910-5 = 45906.04

Sc = (1.4910-5)/(1.8* 7.610-6) = 1.08

Analogy to heat transfer

Sh 0.453 Re 0.568 Sc 0.36 = 207.68

So, k G RTd / DAB = 207.68

Therefore kG = (207.68*DAB)/(RTd) = 1.66510-05 mole/m2.s.Pa

Joint initiative of IITs and IISc Funded by MHRD

Page 5 of 5

Potrebbero piacerti anche

- Chapter 5, Separator and Distillation ColumnDocumento71 pagineChapter 5, Separator and Distillation ColumnSyukri ZainuddinNessuna valutazione finora

- Chapter 3 - Distillation Column Design PDFDocumento54 pagineChapter 3 - Distillation Column Design PDFSyukri Zainuddin100% (6)

- Chapter 5.T-102 (5.4) PDFDocumento51 pagineChapter 5.T-102 (5.4) PDFSyukri ZainuddinNessuna valutazione finora

- 12Documento119 pagine12Salihin FhooziNessuna valutazione finora

- Chapter 5 - Chemical DSGNDocumento126 pagineChapter 5 - Chemical DSGNSyukri ZainuddinNessuna valutazione finora

- Chapter 8Documento44 pagineChapter 8Syukri ZainuddinNessuna valutazione finora

- Chapter 2 DCDocumento52 pagineChapter 2 DCSyukri ZainuddinNessuna valutazione finora

- Report Duty FormDocumento1 paginaReport Duty FormSyukri ZainuddinNessuna valutazione finora

- Molecules: Biological and Nutritional Properties of Palm Oil and Palmitic Acid: Effects On HealthDocumento23 pagineMolecules: Biological and Nutritional Properties of Palm Oil and Palmitic Acid: Effects On HealthHyung Sholahuddin AlayNessuna valutazione finora

- Salaries & Wages Survey Report, Malaysia, 2015Documento3 pagineSalaries & Wages Survey Report, Malaysia, 2015Syukri ZainuddinNessuna valutazione finora

- Workbook: Case (Main) : Streams 1Documento10 pagineWorkbook: Case (Main) : Streams 1Syukri ZainuddinNessuna valutazione finora

- Dampak Used OilDocumento1 paginaDampak Used OildaralextianyNessuna valutazione finora

- Rubrics For Dp2-StudentsDocumento15 pagineRubrics For Dp2-StudentsAddison JuttieNessuna valutazione finora

- Walther 2016Documento50 pagineWalther 2016Syukri ZainuddinNessuna valutazione finora

- Nikhi SharmaDocumento17 pagineNikhi SharmaSyukri ZainuddinNessuna valutazione finora

- N-Propanol M5579 2016 05Documento4 pagineN-Propanol M5579 2016 05Syukri ZainuddinNessuna valutazione finora

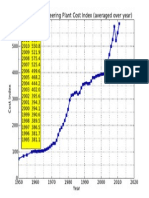

- Cepci 2011 PyDocumento1 paginaCepci 2011 PyRISTAARISRIYANTONessuna valutazione finora

- 19 (1985) 219-223 Elsevier Science Publishers V., Amsterdam - Printed in The Netherlands 219Documento5 pagine19 (1985) 219-223 Elsevier Science Publishers V., Amsterdam - Printed in The Netherlands 219Syukri ZainuddinNessuna valutazione finora

- Unit: Aduan Date: 6/8/2017 - 10/8/2017 Officers:: Week 4 (Department of Environment)Documento1 paginaUnit: Aduan Date: 6/8/2017 - 10/8/2017 Officers:: Week 4 (Department of Environment)Syukri ZainuddinNessuna valutazione finora

- Payback Period TemplateDocumento5 paginePayback Period TemplateSyukri ZainuddinNessuna valutazione finora

- PropanolDocumento8 paginePropanolSyukri ZainuddinNessuna valutazione finora

- Unit: Punca Tetap (PT) Date: 20/8/2017 - 24/8/2017 OfficersDocumento3 pagineUnit: Punca Tetap (PT) Date: 20/8/2017 - 24/8/2017 OfficersSyukri ZainuddinNessuna valutazione finora

- Petrochemical Industry in MalaysiaDocumento25 paginePetrochemical Industry in MalaysiahahaNessuna valutazione finora

- Week 5 EIADocumento6 pagineWeek 5 EIASyukri ZainuddinNessuna valutazione finora

- 1403231561-Guidelines For Packaging Labelling and Storage of Scheduled Wastes in Malaysia PDFDocumento34 pagine1403231561-Guidelines For Packaging Labelling and Storage of Scheduled Wastes in Malaysia PDFknabpshoNessuna valutazione finora

- BiogasDocumento4 pagineBiogasSyukri ZainuddinNessuna valutazione finora

- Week 1 & 2 GinaDocumento4 pagineWeek 1 & 2 GinaSyukri ZainuddinNessuna valutazione finora

- Unit: Pendidikan & BT Date: 1/8/2017 - 3/8/2017: Week 3 (Department of Environment)Documento1 paginaUnit: Pendidikan & BT Date: 1/8/2017 - 3/8/2017: Week 3 (Department of Environment)Syukri ZainuddinNessuna valutazione finora

- Chin Et Al. 2013-RSERDocumento11 pagineChin Et Al. 2013-RSERSyukri ZainuddinNessuna valutazione finora

- Biotechnological UtilisationDocumento291 pagineBiotechnological UtilisationSyukri ZainuddinNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)