Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LPI Stormaster ESE Air Terminal

Caricato da

eekamaleshCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LPI Stormaster ESE Air Terminal

Caricato da

eekamaleshCopyright:

Formati disponibili

Lightning Protection System

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

Active in Industry

PROUD AUSTRALIAN MANUFACTURER

The LPI story

Lightning Protection International Pty Ltd

(LPI) is a fully Australian owned manufacturer and supplier of direct strike lightning

protection, transient voltage surge suppression and earthing/grounding solutions.

For many years, LPI have been providing

specialist lightning protection advice to

customers in some of the most lightning

prone areas of the world. Our personnel

have extensive experience in risk management, system design, training, installation,

certification and commissioning of systems

in a wide variety of industry groups.

LIGHTNING

LPI maintains a third party Quality Management System to AS/NZS ISO 9001:2008.

Our extensive experience has involved

risk management, system design,

training, certification and installation

and commissioning in key industry groups

such as:

Telecommunications & Broadcasting

LPIs range of products and services are

exported from its head office and research

facility (in Tasmania, Australia) and via

regional offices worldwide.

Petrochemical, Oil & Gas

Highrise buildings and hotels

The company has been recognized within

Australia for its outstanding export successes and has been awarded several

prestigious export awards.

P R OT E CT I O N

I N T E R N AT I O N A L

all types of structures

Sporting centre and grounds

Golf courses, race tracks, stadiums

Aviation Civil & Military

Mining Coal, Gold, Nickel, Iron,

Copper, Bauxite, etc.

Industrial facilities of all kinds

Defence communications, surveillance and storage of armaments

Power generation and distribution

Rail / transport systems

Monuments / Ecological sites

PTY

LT D .

>>

www.lpi .com .au

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

Lightning & the need of safety

Lightning is one of the most devastating natural phenomena. There are many discharges during lightning storms and some of them can

even reach hundreds of kilo amperes. The electrical discharges are a great hazard to people, animal, buildings and electronic equipments.

The economic consequences of lightning are also very important; it can cause fire, stop production of a factory or interrupt critical processes. A direct lightning discharge lasts a very short time but the intensity is enough to provoke electrocution resulting in heart failure and

causing burns of different degrees to the human beings. Lightning is a constant hazard where the buildings and equipments are becoming

more complex and sensitive every day. One lightning strike discharge can damage the buildings and cause failures to the electronic devices

inside the building and sometimes it may even results in fire and important economical losses.

Until now, there is no device that can prevent lightning formation or lightning strikes. However, it is possible to create a path (divert) for

the lightning discharge to the ground which will minimise the damage to the environment through a well designed Lightning Protection

System (LPS). The lightning protection should be considered preferably during the initial stage of the building/structure design which has

4 basic objectives:

Capture lightning.

Disperse lightning current in the

ground quickly and safely.

Conduct lightning current to

earth avoiding damage.

Avoid the secondary effects of

lightning (surge/temperory overvoltages)

The phenomena of lightning

During the formation of a cumulonimbus

(cloud forming a towering mass with a flat

base at fairly low altitude and often a flat

top, as in thunderstorms), there is an increase

of ionisation and a potential difference is

generated between the thunder cloud and the

ground, which gives rise to small discharges.

between the cloud and the ground. This

object/structure will be hit with the lightning

strike. The cloud charge will try to find the

straightest/shortest path to earth and if this

path is not controlled, damages can be severe.

FIGURE 1

Negatively charged

stepped leader moves

towards ground

Launch of upstreamer

from highest ground

point as field

intensification

rises

Electrical effects: Damages/destruction to the

electrical & electronic equipments. Abnormal

rise in ground voltage and surges/transients

can damage all the equipment connected to

the electrical network.

As the electric field gains in strength, the

descending leader breaks up the dielectric field

in the air.

Ultimately, this may break through the layers

of dielectric field in the air and strike the surface via the upward propagating tracer from

the surface.

In normal conditions there is a balance

between positive and negative charges in the

atmosphere, where the ground is more negatively charged than the air and the elements

placed on the ground.

However, the formation of storm clouds creates a charge polarization; usually, the lower

part of the cloud is charged negatively, inducing then a positive charge at the ground and

other elements on it. The electric field at the

atmosphere can reach kilovolts in a short span

of time.

When the electric field is high enough,

the cloud starts discharging towards the

ground. The path formed by this discharge

is called downward leader and produces

a very sharp variation of the electric field,

causing the corona effect. One of these

objects/structure will be forming the upward

leader, which will move towards the downward leader thus forming the discharge path

LIGHTNING

P R OT E CT I O N

Electrodynamical effects: Structure/building

damages. The conductors & equipments which

falls within the vicinity of the flow of lightning

current are submitted to mechanical strengths

due to the magnetic field originated. This may

cause deformations and rupture the conductors & equipments.

FIGURE 2

Stepped leader

progresses towards

ground

Upstreamer is

attracted towards

stepped leader

Thermal effects: Lightning strikes can lead to

fires. Heat dissipation by the Joule effect can

even cause fires.

Effects on living beings: Electrocutions and

burns. Currents passing through during a short

lapse are enough for electrocution risk by

respiratory or cardiac arrest. Further burn risk

appears.

FIGURE 3

Induction effects: Within a variable electromagnetic field, induced currents appear in

every conductor.

Leader and streamer

meet to form ionised

path for lightning

discharge

I N T E R N AT I O N A L

The consequences of all these effects are

important economical losses because of the

damages in buildings and equipment due to

lightning strike. Lightning can cause service

interruptions, stops production processes or

force to switch off and on again the utility

machinery if the control equipment is affected

by lightning.

PTY

LT D .

>>

www.lpi .com .au

LPI STORMASTER ESE AIR TERMINAL

LPI 4-Step Approach to

Lightning Protection

The Stormaster ESE range

LPI Early Streamer Emission (ESE) air

terminals in both Anodised Aluminium

and Stainless Steel.

It is the strategic aim of our company

to be able to provide a complete packaged solution. LPI has identified 4 key

steps when considering the complete

approach to lightning protection, ask

for our LPI 4 Step approach to lightning

protection.

Ordering Code:

XX: Available in 15,30,50 and 60

YY: Bank for Gold (anodised aluminium)

model, SS for stainless steel model.

ZZ: Blank for standard model

(to FRP Mast), GI for 2 inch BSP

GI Pipe adaptor.

Our System design

approach includes

Definition and provision of area

protection

Certified Performance

As one of the leading companies in

the field of lighting protection, LPI has

invested heavily in field and laboratory

testing as part of its ongoing commitment to research and development.

Creation of a bonded earthing

system

Protection of mains power lines

Protection of signal, data and

communication lines:

LPI Stormaster ESE

The LPI Stormaster (Early Streamer Emission) range of terminals provides a safe

and efficient system for the protection of

your facility from direct lightning strikes.

How does the LPI

Stormaster ESE Terminal

work?

Throughout the product development

of the Stormaster ESE the proto-type

models were subjected to intense

testing under high voltage conditions.

Following further refinements the

Stormaster terminals were subjected

to final testing by an independently

accredited test laboratory which com-

The LPI Stormaster ESE terminal captures The Stormaster ESE air terminal uses

the lightning energy at a preferred point. the naturally occurring electrical field to

complete the timely release of an upward

streamer. This process provides for a safe

and efficient method of controlling dangerous lightning energy at a preferred point.

As a thunderstorm gathers overhead, the

ambient electrical field surrounding the

Stormaster ESE begins to rise in voltage.

Upon the approach of a downward leader

towards the protected area, there is a rapid

increase in the electric field which initiates

the triggering of an upward streamer from

the Stormaster ESE terminal. The early

initiation allows for a larger or enhanced

area of protection to be provided by the

Stormaster ESE in comparison to a

conventional rod, in accordance with

NF C 17-102.

With the release of the upward streamer

from the finial tip earlier than other competing structural points, the Stormaster ESE

terminal becomes a preferred point for the

capture of the lightning discharge within

the protected area.

LIGHTNING

P R OT E CT I O N

I N T E R N AT I O N A L

pleted testing in full compliance with

the French National Standard

NF C 17-102. The final testing of

Stormaster ESE terminals showed

effective performance as defined in

this Standard.

LPI Stormaster ESE lightning air

terminal is tested & certified from CPRI

(Central Power Research Institute),

Bangalore, Government of India.

PTY

LT D .

>>

www.lpi .com .au

LPI STORMASTER ESE AIR TERMINAL

Protection

Performance

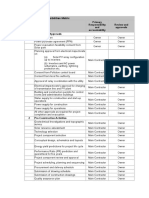

PROTECTION RADIUS (M) - (Rp)

h = height of Stormaster terminal

h(2D - h) +

10

15 20 45 60

Stormaster 15 SS

13

25

32

32 33

34 35 35 35

Stormaster 30 SS

19

28

48

48 49

50 50 50 50

Stormaster 50 SS

28

55

68

69 69

70 70 70 70

Stormaster 60 SS

32

64

79

79 79

80 80 80 80

above area to be protected (m)

The protection radius (Rp) of

a Stormaster ESE terminal is

calculated using the following

formula as defined by the

French National Standard NF C

17-102.

Rp (h) =

Protection Level 1 (High Protection)

T(2D + T) for h 5m where:

The following key parameters determine the calculation of Rp.

Protection Level 2 (Medium Protection)

Stormaster 15 SS

18

36

45

46 49

52 55 60 60

Stormaster 30 SS

25

50

63

64 66

68 71 75 75

Stormaster 50 SS

35

69

86

87 88

90 92 95 95

Stormaster 60 SS

40

78

97

97 99 101 102 105 105

Stormaster 15 SS

20

41

51

52 56

60 63 73 75

Stormaster 30 SS

28

57

71

72 75

77 81 89 90

Stormaster 50 SS

38

76

95

96 98 100 102 110 110

Stormaster 60 SS

44

87 107 107 109 111 113 120 120

T as established during the test.

Stormaster - ESE-15 SS = T (s) 15

Stormaster - ESE-30 SS = T (s) 30

Stormaster - ESE-50 SS = T (s) 50

Stormaster - ESE-60 SS = T (s) 60

h = actual height of Stormaster terminal above the area to be

protected (m).

D (in m) depends on the selected level of protection, protection

levels are specified in annex B of the standard NF C 17-102.

D = 20m for protection level 1 (High Protection)

D = 45m for protection level 2 (Medium protection)

D = 60m for protection level 3 (Standard protection)

Advantages of the Stormaster

ESE Terminal

Lightning Strike Recorder (LSR1)

A typical Stormaster ESE installation consists of a single Stormaster

ESE terminal with an enhanced area of protection and downconductors connected to a dedicated earthing system designed to

have a low inpedance to lightning.

1.

LPIs Stormaster ESE system is simple to install and requires no

special maintenance.

2.

LPIs Stormaster ESE system is a cost effective solution for

providing your lightning protection whilst providing superior

safety.

3.

The Stormaster ESE range of terminals have been fully

tested in accordance with NF C 17-102 in a high voltage

laboratory.

LPI personnel and its associates have been involved

in a number of field trials

throughout lightning prone

regions of the world. This

experience has extended

throughout such countries

as Australia, India, Indonesia, Sri Lanka, USA and

South Korea.

P R OT E CT I O N

LPI have developed a LSR

which is designed for easy

mounting on a downconductor to effectively count the

number of lightning srikes

captured by the Stormaster

ESE Terminal.

When the lightning rod receive

an impact of the lightning

strike, discharge counter detects the energy dissipated by

the down conductor, thereby

incrementing the number.

The LSR1 operates by sensing current by means of an inductive

pick up loop. With the voltage impulse detected by the current

transformer (CT) a trigger to the pulse counter then turns the

counter to register the lightning event.

LPI has an ongoing commitment to Research and Development.

LIGHTNING

Protection Level 3 (Standard Protection)

The equipment does not require either external or internal power

supply, as it is electromechanical and uses the power of the

induced current dissipated through the down conductor.

It must be placed on the down-conductor above the control/testlink joint and, in all cases, 2mtrs above the ground. Its use is not

obligatory but is highly recommended by NF C 17-102 standard.

Features

I N T E R N AT I O N A L

PTY

7 Digits

Up to 9,999,999 counts

IP 67 enclosure

Testable using LSR-Tester

LT D .

>>

www.lpi .com .au

LPI STORMASTER ESE AIR TERMINAL

IMPORTANT:

Stormaster ESE

terminal to be a

minimum of 2

metres above the

highest point of

the building.

Recommended

clearance height

= 5 metres

LPI GUY KIT

ORDERING CODE: GUYKIT-4M

GUYKIT-4M-SS

GUYKIT-7M

GUYKIT-7M-SS

LPI CABLE TIES

ORDERING CODE: SS-CABTIE-STD

SS-CABTIES-L

If installing either a radial

25mm x 3mm

Earth Rods clamped to

earthing system or grid

Copper Tape

Copper Tape

type earthing system it

Tape Clamp

is recommended that all

earthing conductors be

installed at a depth of

Earth Pit

between 500mm and

750mm (recommended)

Earth Rods

Each Radial Trench

Clamp

with a maximum depth

is treated with

of 1000mm. In order

Earth Enhancing

Compound

to further assist in

LPI Copper Tape 25 x 3mm

improving the earth

typically 3 Radial lengths of 10m,

resistance of the system,

500mm depth with a maximum depth of 1000m

it is recommended that

the excavated soil of

poor quality (rocky/sandy) shall be replaced with the soil of a good quality (garden

loam) prior to backfilling the trench.

LPI HIGH VOLTAGE SHIELDED CABLE

ORDERING CODE: HVSC-PM

Key components of a lightning earth include:

LPI STORMASTER ESE AIR TERMINAL

ORDERING CODE: STORMASTER-ESE-60

STORMASTER-ESE-50

STORMASTER-ESE-30

STORMASTER-ESE-15

ADD-GI TO END OF

PRODUCT CODE FOR

CONNECTION TO 2 BSP

LPI UPPER TERMINATION KIT

ORDERING CODE: UTERMKIT-Mk2

UTERM-FACTOUTSIDE-Mk2

LPI SUPPORT MAST

ORDERING CODE: FRP-2M

FRP-3M

FRP-4M

LPI INLINE COUPLING

ORDERING CODE: ILCOUPLING

LPI LOWER MAST ASSEMBLY WITH BASE

ORDERING CODE: ALUMB-3M

ALUMB-4M

ALUMB-5M

ALUMB-6M

Earth Rods

Copper bonded (threaded or unthreaded),

Solid Copper or Stainless Steel

LPI Resistance Lowering Compound (LPI RESLO)

The requirement for a low resistance is extremely

important with the installation of any earthing system.

LPIs RESLO provides the ability to dramatically reduce

soil resistivity even in soils with average electrical

conductivity. LPI RESLO is supplied in 10 Kgs packaged

bags to suit the site application.

LPI SADDLES AND FIXINGS

ORDERING CODE: SAD FIX

LPI HIGH VOLTAGE SHIELDED CABLE

ORDERING CODE: HVSC-PM

LPI LIGHTING STRIKE RECORDER

ORDERING CODE: LSR1

LPI INSPECTION PIT

ORDERING CODE: EPIT-P

EPIT-D

EPIT-C

LPI LOWER TERMINATION KIT

ORDERING CODE: LTERMKIT

EARTH

ENHANCING

COMPOUND

ORDERING CODE:

GRIP-10

RESLO-10

LOW EARTH-20

LPI EARTHING SYSTEM

TYPICAL PRODUCTS

REQUIRED FOR RADIAL

LP EARTH (EG):

4 X CBER1214

4 X RTC253

1 X EPIT-P

1 X GRIP-10

20 X FL6T253C

Lightning Protection

Earthing

The installation of a radial earthing arrangement

is recommended for each lightning protection

earth, the radial earthing configuration provides

an effective means for the safe dissipation of

the lightning energy into the ground mass.

All individual lightning earths should be

bonded together in a ring earth arrangement to

minimise ground loops and potential differences

under transient conditions. Compliance to

NF C17-102 requires an earth DC resistance

reading of less than 10 ohms for the

lightning earths.

LIGHTNING

RESLO comprises specifically selected compounds,

which possess excellent electrical conductivity. When

RESLO is mixed with water and poured around the

earthing system and surrounding soil, the powder and

water react to form a hardened mass within an earthing system. RESLO will not

wash away under seasonal conditions and therefore provides a permanent presence

in working to improve and maintain the integrity of an earthing system. Given that

RESLO does not wash away the requirement to re-treat the soil as is the case with

other enhancing compounds is eliminated.

LPI Ground Resistance Improvement Powder (LPI GRIP)

The requirement for a low resistance is extremely

important with the installation of any earthing system.

LPIs GRIP provides the ability to substantially reduce soil

resistivity in soils of the poorest electrical conductivity

such as rocky ground or sandy soils. LPI GRIP is supplied

in two kit sizes - A 10 Kgs kit comprises two 5 Kg

containers; one 5 Kg kit contains a copper compound

whilst the other 5 Kg kit holds a mix of compounds

which assist in the mixing process (Hardener).

When GRIP is mixed with water and poured around the earthing system and

surrounding soil, the powder and water react to form a gelatinous hygroscopic

mass which forms an integral part of an earthing system, this effectively increases

the surface area of the earthing system in contact with the surrounding soil.

GRIP will not wash away under seasonal conditions and therefore provides a

permanent presence in working to improve and maintain the integrity of an

earthing system. Given that GRIP does not wash away the requirement to

re-treat the soil is eliminated.

P R OT E CT I O N

I N T E R N AT I O N A L

PTY

LT D .

>>

www.lpi .com .au

LPI STORMASTER ESE AIR TERMINAL

Downconductors

NF C 17 - 102 (2011)

The New Standard

NF C17-102 (2011) requires the installation of two

downconductors for each installed ESE air terminal, with one

downconductor permitted to use electrically continuous natural

components of the structure.

NF C17 - 102 is written specifically to ensure compliance with

regard to the testing, applications and installation of ESE

terminal. The new standard issued in 2011 is deemed to be

applicable and structures of any height and for the protection

of open areas. The previous version of the standard was first

published in 1995 has been cancelled by the French standards

organisations UTE and conformity with that version ceased in

September 2012.

NF C17-102 (2011) includes much more stringent requirements when compared to the 1995 version.

The main differences are as follows:

1. There are now four protection levels rather than the

previous three levels.

2. There are two new enhanced sub-levels for protection

level I (level I+ and I++)

3. Protection of structures taller than 60 metres is now

allowed and there are special rules with regard to strike

interception and downconductors. The top 20% of the

building needs to be protected.

4. Some simple rules regarding downconductors, essentially

two are needed, but one of them can be the natural

components of the structure.

5. The earlier ban on coaxial insulated downconductors has

been removed, but any use of insulated conductors has

to follow the separation distance requirements per the

IEC 62305 standards.

High Voltage Shielded

Cable (HVSC)

Flat tapes

Bare, Tinned & PVC

Covered

Ultimate direct strike lightning protection

as installed across 65 countries around

the world

PVT Coated and bare

stranded copper

cable

Disclaimer

LPI maintains a policy of on-going product development,

specifications are subject to change without notice.

Downconductor Fixings

and Connectors

Application detail, illustrations and schematic drawings are

representative only and should be used as guides.

It should be noted that 100% protection level for direct

strike lightning, lightning detection and surge and transient

protection equipment is not possible and cannot be

provided due to the lightning discharge process being a

natural atmospheric event.

LIGHTNING

P R OT E CT I O N

I N T E R N AT I O N A L

PTY

LT D .

>>

www.lpi .com .au

OUR CLIENTS LIST

Distributed by:

ALLIED POWER SOLUTIONS

(ISO 9001:2008 & UL listed LPS installer)

T - 4, 5 & 6, Third Floor

Pankaj Plaza - 3, I.P. Extn., Patparganj

Delhi - 110 092 (INDIA)

Tel: +91 11 2224 7322

Email: info@alliedpowersolutions.com

Web: www.alliedpowersolutions.org

PO Box 379 Kingston, Tasmania, Australia 7051

49 Patriarch Drive, Huntingfield, Tasmania, Australia 7055

Telephone: Australia: 03 6281 2477

International: + 61 3 6281 2480

Facsimile: + 61 3 6229 1900

Email: info@lpi.com.au

Web: www.lpi.com.au

BENGALURU

Mob: +91 98869 63195, 98860 08218

LIGHTNING

P R OT E CT I O N

I N T E R N AT I O N A L

PTY

LT D .

>>

www.lpi .com .au

Potrebbero piacerti anche

- Price ListDocumento5 paginePrice ListSharafat AliNessuna valutazione finora

- LS G100 Quick SettingDocumento8 pagineLS G100 Quick SettingtrunghieutcNessuna valutazione finora

- Toez C736 70.1Documento27 pagineToez C736 70.1Marius BarNessuna valutazione finora

- Why Switch To Chemical Electrode Earthing ?Documento9 pagineWhy Switch To Chemical Electrode Earthing ?gohilnarendraNessuna valutazione finora

- Mitsubishi v500 VFD Instruction ManualDocumento119 pagineMitsubishi v500 VFD Instruction ManualMROstop.com100% (1)

- J AIR CONDITIONER TROUBLESHOOTING GUIDEDocumento134 pagineJ AIR CONDITIONER TROUBLESHOOTING GUIDEbenNessuna valutazione finora

- Bar Chart S CurveDocumento2 pagineBar Chart S Curvejaphet ontongNessuna valutazione finora

- EarthingDocumento17 pagineEarthingtangouzeNessuna valutazione finora

- Metal Table-2865 - 2866Documento1 paginaMetal Table-2865 - 2866kastelaninNessuna valutazione finora

- Caustic Soda Flake MSDS PDFDocumento3 pagineCaustic Soda Flake MSDS PDFFajar RamadhanNessuna valutazione finora

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocumento11 pagineOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNessuna valutazione finora

- Schedule of Loads and Computation SampleDocumento5 pagineSchedule of Loads and Computation SampleVhilly JheykNessuna valutazione finora

- Hardness ConversionDocumento11 pagineHardness ConversionSimon RisteskiNessuna valutazione finora

- Stress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanDocumento9 pagineStress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanGANESANMECH05Nessuna valutazione finora

- Air Condition Size Calculator (1.1.19)Documento5 pagineAir Condition Size Calculator (1.1.19)jiguparmar1516Nessuna valutazione finora

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Documento25 pagineTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoNessuna valutazione finora

- Datasheet - Pig Signallers: Product Description and FunctionsDocumento2 pagineDatasheet - Pig Signallers: Product Description and FunctionsMurli ramchandranNessuna valutazione finora

- Sample Load ComputationDocumento2 pagineSample Load ComputationABCD EFGNessuna valutazione finora

- SLC-Essential 2013 Catalogue (Introduction) FinalDocumento8 pagineSLC-Essential 2013 Catalogue (Introduction) FinalWaleed Mohammed FekryNessuna valutazione finora

- QuestionsDocumento9 pagineQuestionsI Gede Darma Susila100% (1)

- Dokumen - Tips Spherical Tanks Erection ProcedureDocumento9 pagineDokumen - Tips Spherical Tanks Erection ProcedureAhmad Tedjo RukmonoNessuna valutazione finora

- MAK MEP Drawing ListDocumento11 pagineMAK MEP Drawing ListkenjoshiNessuna valutazione finora

- 200 Item Answer SheetDocumento4 pagine200 Item Answer SheetFroilan EspinosaNessuna valutazione finora

- Product CatalogueDocumento6 pagineProduct CatalogueBvitalizeNessuna valutazione finora

- LV Switchboard Technical Data SheetDocumento2 pagineLV Switchboard Technical Data SheetjendrikoNessuna valutazione finora

- Distribution Substation Design Code of PracticeDocumento95 pagineDistribution Substation Design Code of PracticeKei WongNessuna valutazione finora

- Voltage Drop Calculation: Riyadh Cable Group CompanyDocumento1 paginaVoltage Drop Calculation: Riyadh Cable Group CompanyKhizer AminNessuna valutazione finora

- Distribution Board ScheduleDocumento1 paginaDistribution Board ScheduleAnonymous SrVaQYNessuna valutazione finora

- Division of Responsibilities MatrixDocumento5 pagineDivision of Responsibilities MatrixbuntysuratNessuna valutazione finora

- 400 Volts System By: Engr. Jesus C. Santos: April 6, 2013Documento1 pagina400 Volts System By: Engr. Jesus C. Santos: April 6, 2013stephen dinopolNessuna valutazione finora

- Overhead Tranmission Line DesignDocumento28 pagineOverhead Tranmission Line DesignJose ManjooranNessuna valutazione finora

- Royu Wires Devices Price List March 2016Documento6 pagineRoyu Wires Devices Price List March 2016AlrwinNessuna valutazione finora

- Commercial and Industrial LED Lighting Solutions DocumentDocumento51 pagineCommercial and Industrial LED Lighting Solutions DocumentNagesh Rao100% (1)

- 6 Illumination CalculationDocumento42 pagine6 Illumination CalculationSamant SauravNessuna valutazione finora

- Pss Sincal ProtectionDocumento4 paginePss Sincal ProtectionJoséVirgilioDeAndradeNessuna valutazione finora

- 1.4 FGD - KPCL - SchedulesDocumento22 pagine1.4 FGD - KPCL - SchedulesKoushik DeyNessuna valutazione finora

- Electrical Boq for Sulphuric Handling at EnclosureDocumento2 pagineElectrical Boq for Sulphuric Handling at EnclosureKrishNessuna valutazione finora

- Note For Electrical & Civil WorkDocumento5 pagineNote For Electrical & Civil WorkNitin SharmaNessuna valutazione finora

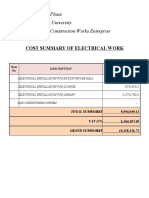

- Cost Summary of Electrical WorkDocumento138 pagineCost Summary of Electrical WorkGada RobaleNessuna valutazione finora

- Erection BOQ - ChamparanDocumento170 pagineErection BOQ - ChamparanPrasanna kumar subudhiNessuna valutazione finora

- Load Calculation 3Documento21 pagineLoad Calculation 3Royce PaladaNessuna valutazione finora

- Chapter - E15: Site Testing and CommissioningDocumento2 pagineChapter - E15: Site Testing and CommissioningvenkateshbitraNessuna valutazione finora

- EDS 06-0001 Earthing Standard PDFDocumento11 pagineEDS 06-0001 Earthing Standard PDFMittapalli SaikiranNessuna valutazione finora

- 000 EE 153 CAD For EEE PDFDocumento35 pagine000 EE 153 CAD For EEE PDFStampinusStephanoNessuna valutazione finora

- Busbar Rating TableDocumento1 paginaBusbar Rating TableRa ArNessuna valutazione finora

- Cable Schedule For GSPC REV P1Documento8 pagineCable Schedule For GSPC REV P1jhakg_169712275Nessuna valutazione finora

- 3x200KVA UPS System Technical SpecificationsDocumento46 pagine3x200KVA UPS System Technical Specificationspradeep.selvarajanNessuna valutazione finora

- Cable alley and panel door elevation viewsDocumento1 paginaCable alley and panel door elevation viewsHytech Pvt. Ltd.Nessuna valutazione finora

- Submit Drawings & Documents for SEWA Inspection & File OpeningDocumento1 paginaSubmit Drawings & Documents for SEWA Inspection & File Openingrize1159Nessuna valutazione finora

- HVAC Excel SheetDocumento8 pagineHVAC Excel Sheettuong buiNessuna valutazione finora

- Annexure E - Division of ResponisbilityDocumento4 pagineAnnexure E - Division of Responisbilityshaikhsajid242Nessuna valutazione finora

- Eci Lab ManulDocumento118 pagineEci Lab ManulGP Siva KumarNessuna valutazione finora

- HFDSR - 1500kw 6kv Drwg.Documento4 pagineHFDSR - 1500kw 6kv Drwg.Sulistyono SulistyonoNessuna valutazione finora

- Lugs & GlandsDocumento1 paginaLugs & GlandsElectrical RadicalNessuna valutazione finora

- Circuit Breaker RatingsDocumento75 pagineCircuit Breaker Ratingsyibelta abebeNessuna valutazione finora

- 896-BECC-Q-2019R8.1 Quotation For MEP Works For The Heirs of Jomaa Al Qubaisi-MilestoneDocumento8 pagine896-BECC-Q-2019R8.1 Quotation For MEP Works For The Heirs of Jomaa Al Qubaisi-MilestonePalwasha GulNessuna valutazione finora

- Metering & H.T. Substation Equipment: Client: ProjectDocumento3 pagineMetering & H.T. Substation Equipment: Client: Projectganesh gundNessuna valutazione finora

- External Protection LightningDocumento100 pagineExternal Protection LightningvalicanNessuna valutazione finora

- Lightning Protection TechnologyDocumento48 pagineLightning Protection TechnologyNguyen Phu LocNessuna valutazione finora

- Dokumen - Tips - Lightning Discharge and Fundamentals of Lightning ProtectionDocumento18 pagineDokumen - Tips - Lightning Discharge and Fundamentals of Lightning ProtectionBlazing RaysNessuna valutazione finora

- H14.72.HR.090702.PE Data SheetDocumento5 pagineH14.72.HR.090702.PE Data SheeteekamaleshNessuna valutazione finora

- Eng2eje v3Documento1 paginaEng2eje v3eekamaleshNessuna valutazione finora

- Book 1Documento2 pagineBook 1eekamaleshNessuna valutazione finora

- App Ground SoilResistivityDocumento7 pagineApp Ground SoilResistivityPrashanth Reddy GouniNessuna valutazione finora

- Pages From NEC 2011Documento1 paginaPages From NEC 2011eekamaleshNessuna valutazione finora

- Retscreen International: Clean Energy Project AnalysisDocumento48 pagineRetscreen International: Clean Energy Project Analysiswrgrant11Nessuna valutazione finora

- Is 3043 1987Documento95 pagineIs 3043 1987suresh kumarNessuna valutazione finora

- Eng1eje v3Documento1 paginaEng1eje v3eekamaleshNessuna valutazione finora

- Abb MaterialDocumento64 pagineAbb Materialvijayakanthc100% (1)

- Trafo SelectionDocumento2 pagineTrafo SelectioneekamaleshNessuna valutazione finora

- Is 13235 Calculation of The Effects of Short-Circuit Currents 1991 EdDocumento32 pagineIs 13235 Calculation of The Effects of Short-Circuit Currents 1991 Edcustomerx100% (1)

- Russia 1Documento4 pagineRussia 1eekamaleshNessuna valutazione finora

- PV Power SystemsDocumento72 paginePV Power SystemsMarcell TirtaNessuna valutazione finora

- 1 Tutorial Handouts 150Documento80 pagine1 Tutorial Handouts 150GokulGopiNessuna valutazione finora

- KEI Recommendations For Current RatingsDocumento1 paginaKEI Recommendations For Current RatingseekamaleshNessuna valutazione finora

- Ampacity StudiesDocumento22 pagineAmpacity StudiesnithinNessuna valutazione finora

- JibhugDocumento202 pagineJibhugeekamalesh0% (1)

- VRLA Tech Manual - IndiaDocumento22 pagineVRLA Tech Manual - IndiaDrig PanditNessuna valutazione finora

- 4 Hyundai Hijgh Speed Elevator Catalogue - Speed Up To 6 MPSDocumento15 pagine4 Hyundai Hijgh Speed Elevator Catalogue - Speed Up To 6 MPSeekamaleshNessuna valutazione finora

- 2012 Linear PolyDocumento1 pagina2012 Linear PolyeekamaleshNessuna valutazione finora

- KeidDocumento6 pagineKeideekamaleshNessuna valutazione finora

- SkipperDocumento25 pagineSkipperMayank MishraNessuna valutazione finora

- Micom S1 Studio: Micom Ied Support SoftwareDocumento2 pagineMicom S1 Studio: Micom Ied Support SoftwareeekamaleshNessuna valutazione finora

- KeidDocumento6 pagineKeideekamaleshNessuna valutazione finora

- Bitronics 70 Series: Measurement SystemDocumento8 pagineBitronics 70 Series: Measurement SystemeekamaleshNessuna valutazione finora

- 1 Tutorial Handouts 150Documento80 pagine1 Tutorial Handouts 150GokulGopiNessuna valutazione finora

- KeidDocumento6 pagineKeideekamaleshNessuna valutazione finora

- Micom S1 Studio: Micom Ied Support SoftwareDocumento2 pagineMicom S1 Studio: Micom Ied Support SoftwareeekamaleshNessuna valutazione finora

- Rdso Specification (Annexure-Ix)Documento29 pagineRdso Specification (Annexure-Ix)eekamaleshNessuna valutazione finora

- Thermal_Physics_-_Revision__Documento5 pagineThermal_Physics_-_Revision__jainamjainNessuna valutazione finora

- NCSE 2015 Integrated ScienceDocumento20 pagineNCSE 2015 Integrated ScienceMath Class90% (10)

- Vaccuperm VGS 147, 148Documento20 pagineVaccuperm VGS 147, 148Sreenubabu Kandru0% (1)

- CO2 Conversion and Utilization-American Chemical Society (2002)Documento427 pagineCO2 Conversion and Utilization-American Chemical Society (2002)Nguyen TrangNessuna valutazione finora

- Lecture One Power PlantDocumento38 pagineLecture One Power PlantEmmanuel Anosisye MwangomoNessuna valutazione finora

- Al11 Weekend Worksheet 16Documento4 pagineAl11 Weekend Worksheet 16ulusoy2005Nessuna valutazione finora

- Introduction To Heat TransferDocumento15 pagineIntroduction To Heat TransferRishabh KumarNessuna valutazione finora

- CHEM 101 LECTURE EXCERCISE 2 On Mass Spectrometer and Quantum Theory - E. N DIM-1-1Documento4 pagineCHEM 101 LECTURE EXCERCISE 2 On Mass Spectrometer and Quantum Theory - E. N DIM-1-1Ekene Agwu100% (1)

- Solar Powered Cathodic ProtectionDocumento2 pagineSolar Powered Cathodic ProtectionncharalaNessuna valutazione finora

- Work, Energy & PowerDocumento18 pagineWork, Energy & PowerSiva Chaitanya SunkuNessuna valutazione finora

- Environmental Impact of Cement ProductionDocumento2 pagineEnvironmental Impact of Cement ProductionRahul SainiNessuna valutazione finora

- Ecotherm Solar WHDocumento60 pagineEcotherm Solar WHvrsub80Nessuna valutazione finora

- Statements of the Second Law ExplainedDocumento45 pagineStatements of the Second Law ExplainedSindhu KemburuNessuna valutazione finora

- Challenges of DR Industry in Me Emirates SteelDocumento11 pagineChallenges of DR Industry in Me Emirates SteelJose Hurtado OjedaNessuna valutazione finora

- Franco, Reinier M.: Me 405 - Alternative Sources of Energy - Me41S1 Topic: Biomass EnergyDocumento2 pagineFranco, Reinier M.: Me 405 - Alternative Sources of Energy - Me41S1 Topic: Biomass EnergyReinier FrancoNessuna valutazione finora

- Newtons Laws of MotionDocumento50 pagineNewtons Laws of MotionJoshua MeraNessuna valutazione finora

- St. Ignacia High School 1st Preliminary Exam in Science 10Documento12 pagineSt. Ignacia High School 1st Preliminary Exam in Science 10Mira VeranoNessuna valutazione finora

- Class 4 Worksheet on Tenses, Conversion, Rights and Duties, MatterDocumento7 pagineClass 4 Worksheet on Tenses, Conversion, Rights and Duties, MatterTech trixNessuna valutazione finora

- Chapter - 17 Static ElectricityDocumento54 pagineChapter - 17 Static ElectricityNayeem HakimNessuna valutazione finora

- Environmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006Documento34 pagineEnvironmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006enviroNessuna valutazione finora

- Planetary Atmospheric ElectricityDocumento521 paginePlanetary Atmospheric ElectricityArmando Heilmann100% (1)

- Activity 9.1: OIL Eeming With IFEDocumento16 pagineActivity 9.1: OIL Eeming With IFEAlisha ChopraNessuna valutazione finora

- Wood Wide WebDocumento6 pagineWood Wide WebGurleen Hora100% (1)

- Prabharani Public SchoolDocumento30 paginePrabharani Public SchoolMainak RayNessuna valutazione finora

- Climate Change 11 FactsDocumento4 pagineClimate Change 11 Factsfahadraja78Nessuna valutazione finora

- Notes On CeramicsDocumento11 pagineNotes On Ceramicsleebrown21082003Nessuna valutazione finora

- Poultry Meal MSDSDocumento7 paginePoultry Meal MSDSyousria.ahmed46Nessuna valutazione finora

- Thermal KineticsDocumento37 pagineThermal KineticsgowthamiNessuna valutazione finora

- Thermo ChemistryDocumento27 pagineThermo ChemistryhannahNessuna valutazione finora

- Blackbody Radiation History & LawsDocumento2 pagineBlackbody Radiation History & LawsMinoGerminaNessuna valutazione finora