Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

H. J. Smith: Potato Cutting Machine 28 Filed 00

Caricato da

RodrigoPomaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

H. J. Smith: Potato Cutting Machine 28 Filed 00

Caricato da

RodrigoPomaCopyright:

Formati disponibili

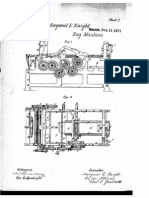

My 1 , 1924.

1,499,950

H. J. SMITH

POTATO CUTTING MACHINE

Filed 00

28

1..

I,

I

at

,

4.

Patented duty 1, 192-4.

rra areas

v. r

\VVHENRY J. SMITH, O1? IJIIN'NEAPOLIS, MINNESOTA.

POTATO-CUTTING llIAGI-IINE.

Application ?led. Gctober 28, 19255.

T 0 all whom it may concern.

Serial No. 597,691.

Within the lower part of the frame, piv

Be it known that I, HENRY J. SMITH, a oted on shafts 10 and 11 are yokes 13 and

citizen of the United States, residing at Min 14. In the upper ends of yokes 13 and 14

neapolis, in the county of Hennepin and are hearings in which revolve shafts 21 and

State of Minnesota, have invented new and 22. Securely attached to that portion of

useful Potato-Cutting Machines, of which shaft 21 which is between the bearings of

the following is a speci?cation.

yoke 14 are feeding rolls 23, 24, 25, 26, and

This invention relates particularly to hand 27, hereafter known as a set. Also attached

or power driven machines of the continuous to shaft 22 between the upper ends of yoke

operation type, or machines not dependent 13 are feeding rolls 28, 29, 30, 31, and 32,

upon plungers to force the potatoes through

the cutting knives.

15

hereafter known as a- set.

65

These two sets

of feeding rolls are so spaced upon shafts

The primary object of this invention is to 21 and 22 that there is room between them

provide a potato cutting machine in which for the stretching from one end piece 4 to

potatoes of varying size can be cut into the other end piece 5 of cutting knives 33,

pieces of a more suitable size for planting, 34, and 35. In the central portion of the

or feeding purposes and to provide a ma

frame, above and at right angles to knives

chine in which the cutting operations are 33, 34, and 35 is cutting knife 36. Knives

constant, thus providing great cutting ca 33, 34, 35, and 36 are held securely within

20

[0 Ci

acity.

the frame by their ends being provided with

\Vith the foregoing and other objects in bolts and nuts by means of which they are

View which will appear as the description

proceeds, the invention resides in the combi

nation and arrangements of parts and in the

details of construction hereinafter described

drawn taut. The two sets of feeding-rolls

are prevented from coming in contact with

each other or with knife 36 by means of stop

80

pins 37 and 38 inside of frame member 3,

and claimed, it being understood that against which the arms of yoke-s 13 and 14

changes in the precise embodiment of the in come in contact.

vention herein disclosed may be made within

The outer rims, of the individual members

the scope of what is claimed without depart of the two sets of feeding rolls are provided

ing from the spirit of the invention.

In the accompanying drawing the pre

with depressions, or corrugations of varying

depths are so held in alignment in the roll

assemblies as to provide cups or pockets

which seize the potatoes to be cut and pre

ferred form of the invention is shown.

In said drawings :-

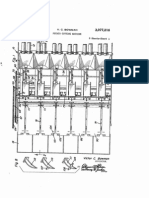

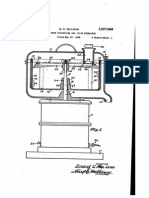

Figure 1 is a plan view of the belt or vent their slipping out of place while being

gear side of the machine with the belt pulley forced through the cutting knives. The two

removed.

sets of feeding rolls in addition to a revolv

90

Figure 2 is a top plan view of the machine ing motion also have a reciprocating motion

with the feeding rolls and cutting knife ad to or from each other by being carried in

justment in section.

yokes 13 and 14 which are pivoted at their

40

Figure 3 is a sectional end view of the

machine on the lines A,B, Figure 1.

Figure 4 is an assembly view inside of

frame member 3 of yokes 13 and 14 and

equalizing levers 15, 16 and 17 , and

lower ends, on shafts 10 and 11 inside of

frame members 2 and 3. As these two sets

of feed rolls swing to or from each other

they are kept at approximately the same

distance from knife 36 by means of equaliz

ing levers 15, 16 and 17 acting on the swing

Figure 5 is a. top view of the parts shown ing ends of yokes 13 and 14. Equalizing

in Figure 4, and shows in greater detail lever 15 being pivoted at its central portion

method of attaching the ends of connecting to frame member 3 its outer ends are by

spring 2Q.

'

levers 16 and 17 to yokes 13 and 14.

50

100

means of a rivet 49 hinged to one end of con

Referring to the ?gure by character of necting levers 16 and 17, the other ends

105

reference, 1 designates the frame which is of levers 16 and 17 being connected by means

composed of side members 2 and 3, and end of a screw to one side of yokes 13 and 14.

pieces 4 and 5. The lower side of frame The two sets of feeding rolls are caused

members 2 and 3 terminates in brackets to to revolve, at a uniform speed in opposite 110

which are bolted the supporting legs 6, 'Z, directions by there being mounted on the

8 and 9,

'

'

'

Outer ends at shafts 21 sad-22, gears: 33

1,499,950

2

and 40.

shafts, means for rigidly holding these

In consta t mesh with gears 39

and a0 are gears Lil and i2,

Gears ill and shafts within the lower ends of the swing

42 are in turn connected together by gears mg yokes, said yokes having shaft bear

Gears 4?) and 44 turn on axles ings in the upper ends, shafts free to revolve '

attached to the lower portion of frame mem within said. bearings, spaced and positively

ber 3, while gears 1l1 and 42 revolve upon driven feeding rolls securely attached to

the outer ends of shafts l0 and 11. Se said shafts and means for causing the two

curely attached to gear 44 is belt pulley sets of feeding rolls to retain a proper feed

'19. Gears 39 and 40 are enabled to have ing relationship to each other and to the

43 and 44:.

a swinging as wel as a revolving motion

cutting knives, centrally located cutting

by being connected through shafts 21 and knives operating among and between the

TO

22 to the swinging ends of yokes 13 and 14. two sets of feeding rolls.

15

20

to Oz

Potato cutting machine consisting of

The two sets of feeding rolls are caused

to revolve by being connected through shaft a frame, supported by supporting legs.

22 with crank 4L6 or through shafts 2-1 and knives within the frame, feeding rolls op

22 and gears 39, ~10, 41, l2, 43, and 4a with erated among said cutting knives, means for

belt pulley 19. The two sets of feeding driving the feeding rolls by means of a

rolls are ordinarily held in close proxim crank or a belt pull y, which drives said

ity to each other by means of an adjust rolls by means of gearing connecting said

able spring 20 being, connected to the upper rolls through their axles to each other and

ends of yokes 13 and 14 so that the necessary to the belt pulley.

4:. A. potato cutting machine, consisting

gripping pressure to enable the feeding rolls

to grasp and securely hold potatoes while of a frame, supported by supporting legs,

knives within the frame, positive driven

forcing them through the cutting knives.

In operation when the two sets of feed feedii'ig rolls operating among the knives,

ing rolls are caused to revolve toward each means for, controlling the swinging action

other by power applied either at the belt of said rolls in reference to each other and

pulley or crank if potatoes are dropped to the central cutting knife and means for

80

retaining, timing and driving gears upon

between the feeding rolls they will immedi

ately be seized by cups in the outer surface the side of said frame in proper relation to

of the feeding rolls and as they are carried each other and to the driving pulley and

10

I

i

downward they are prevented from being feeding rolls. ,

5. A potato cutting machine, consisting

crushed by their forcing apart the two sets

of feeding rolls and the extension of spring of a frame supported upon supporting legs,

20. its the potatoes pass through the cut- knives within the frame, swinging yokes

ting knives they drop into spout 4-7. Spring pivoted in the lower portion of said frame,

20 at all times maintaining a uniform grip- feeding rolls mounted within said yokes,

ill]

95

ping action on the potatoes being cut or means for holding the feeding rolls in a

returns the feeding rolls working position. close but elastic proximity to each other,

The size of the pieces into which a potato equalizing levers for controlling the swing

can be cut are dependent upon the will of ing action of said rolls in relation to the

the operator and the number of knives left central cutting knife, means for preventing

the feeding rolls from coming in contact

_

Having thus described my invention with each otheror with the central cutting

knife, means for preventing the feeding

what I claim is :

I

l. A potato cutting machine, consisting rolls from twisting within the frame, means

100

in the machine.

105

of a frame supported by supporting legs, for preventing potatoes from slipping from

between the feeding rolls or out. of posi

cutting knives stretched through the cen

tral or inner portion of said frame, means tion while passing between said rolls, and

for drawing these knives to the desired ten means for holding potatoes within a con

sion, means for holding revolving and venient distance of the operator.

In testimony that I claim the foregoing

swinging feeding rolls among the cutting

knives and means for imparting a positive as my own, l have hereto atlixed my signa

revolving motion to said feeding rolls.

27! iii

'

2. A potato cutting machine consisting

of frame supported upon supporting legs,

hearings in the lower portion of said frame,

shafts supported within said bearings, gears

free to revolve upon one outer end of said

ture in the presence of two witnesses;

HENRY J. SMITH.

\Vitnesses :

GEORGE E. SMITH,

' PAUL J. THOMPSON.

110

Potrebbero piacerti anche

- Us1223254 PDFDocumento7 pagineUs1223254 PDFRodrigoPomaNessuna valutazione finora

- Us1955360 PDFDocumento8 pagineUs1955360 PDFRodrigoPomaNessuna valutazione finora

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocumento6 pagineWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNessuna valutazione finora

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Documento3 pagineM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNessuna valutazione finora

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Documento4 pagineAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1Nessuna valutazione finora

- Us2765819 PDFDocumento8 pagineUs2765819 PDFAzri LunduNessuna valutazione finora

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Documento7 pagine"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNessuna valutazione finora

- European Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Documento13 pagineEuropean Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02Lenti TiborNessuna valutazione finora

- No. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70Documento3 pagineNo. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70AlecsandrNessuna valutazione finora

- Coco Inven PDFDocumento4 pagineCoco Inven PDFsushil-funNessuna valutazione finora

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Documento5 pagine19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNessuna valutazione finora

- US2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)Documento2 pagineUS2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)devheadbot100% (1)

- US2099314Documento3 pagineUS2099314Jhonnatan E Avendaño Florez100% (1)

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocumento7 pagineCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNessuna valutazione finora

- Apron MechanismDocumento7 pagineApron Mechanismgopalpaul0% (2)

- Braiding MachineDocumento7 pagineBraiding Machinejojaberi100% (1)

- NOV-5, 1940 - C. D. Peterson: Two Speed Forward and Two Speed Reverse TransmissionDocumento4 pagineNOV-5, 1940 - C. D. Peterson: Two Speed Forward and Two Speed Reverse TransmissionMohan RaoNessuna valutazione finora

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocumento3 pagineData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNessuna valutazione finora

- Target Kite (1944)Documento7 pagineTarget Kite (1944)CAP History LibraryNessuna valutazione finora

- US1685447Documento5 pagineUS1685447Redirecting DecoyNessuna valutazione finora

- United States Patent (191: Andersen Et A1Documento5 pagineUnited States Patent (191: Andersen Et A1khoagleNessuna valutazione finora

- Us 2120533asfafafDocumento5 pagineUs 2120533asfafafankitsarvaiyaNessuna valutazione finora

- US2128620 - Bending MachineDocumento5 pagineUS2128620 - Bending MachinedevheadbotNessuna valutazione finora

- Us 4207797Documento7 pagineUs 4207797fghdfjerNessuna valutazione finora

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocumento4 pagineMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNessuna valutazione finora

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Documento7 pagineSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNessuna valutazione finora

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Documento8 pagineApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNessuna valutazione finora

- Unidad IV Intercambiadores de CalorDocumento4 pagineUnidad IV Intercambiadores de CalorRafael CórdobaNessuna valutazione finora

- 1895 - Us570025Documento5 pagine1895 - Us570025Enrico Bruce GioloNessuna valutazione finora

- MMM-@U: H. M. SpragueDocumento4 pagineMMM-@U: H. M. SpraguedjsfNessuna valutazione finora

- Hypoid Gear CuttingDocumento9 pagineHypoid Gear CuttingHano LourensNessuna valutazione finora

- June 23, 1925.: F . I: ZacherDocumento3 pagineJune 23, 1925.: F . I: ZachershamsNessuna valutazione finora

- Us955823 PDFDocumento3 pagineUs955823 PDFSashikant SharmaNessuna valutazione finora

- Patented May 27, 1919.: S. H. GarstDocumento4 paginePatented May 27, 1919.: S. H. GarstKrozeNessuna valutazione finora

- Us2218783 PDFDocumento4 pagineUs2218783 PDFlandagoNessuna valutazione finora

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Documento6 pagineJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNessuna valutazione finora

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocumento3 pagine1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNessuna valutazione finora

- July 4, 1950 E. L. Masters 2,53,810: Filed April 10, 1946 2 Sheets-SheetDocumento5 pagineJuly 4, 1950 E. L. Masters 2,53,810: Filed April 10, 1946 2 Sheets-SheetVijayakumar G VNessuna valutazione finora

- W, B. Kidder. : Tree Climbing MotorDocumento4 pagineW, B. Kidder. : Tree Climbing Motormonem2014Nessuna valutazione finora

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Documento3 pagineUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06Nessuna valutazione finora

- United States Patent (19) : HermannsDocumento3 pagineUnited States Patent (19) : HermannsIvan ReyesNessuna valutazione finora

- Us1434007 PDFDocumento5 pagineUs1434007 PDFsebastian escobarNessuna valutazione finora

- Us 5176330Documento7 pagineUs 5176330ManivannanMudhaliarNessuna valutazione finora

- United States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991Documento6 pagineUnited States Patent (191 1111 Patent Number: 4,991,386: Dirksen (45) Date of Patent: Feb. 12, 1991James LindonNessuna valutazione finora

- Us2467764 PDFDocumento10 pagineUs2467764 PDFRodrigoPomaNessuna valutazione finora

- USRX52Documento3 pagineUSRX52nmfzkwy2rNessuna valutazione finora

- Project ASSEMBLYDocumento5 pagineProject ASSEMBLYfachrifadlurrohman8Nessuna valutazione finora

- Sept. 4, 1956 R. D. La Hayne: Adjustable Beam and Form ClampDocumento3 pagineSept. 4, 1956 R. D. La Hayne: Adjustable Beam and Form Clampkkd108Nessuna valutazione finora

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDocumento4 pagineNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroNessuna valutazione finora

- 3/ Z7 VZMZM/ZZ : V. Holek 2,216,412Documento3 pagine3/ Z7 VZMZM/ZZ : V. Holek 2,216,412wererNessuna valutazione finora

- Nun M.: BC BM 0000Documento12 pagineNun M.: BC BM 0000shdhsjkNessuna valutazione finora

- July 8, 1924. 1,500,672: Y 7%Ale/Éa-Ac6-ÉzazaDocumento3 pagineJuly 8, 1924. 1,500,672: Y 7%Ale/Éa-Ac6-Ézazakkd108Nessuna valutazione finora

- Oct. 19, 1943. W, E. Humphrey 2,331,931: / 61,4847, M M/MaaxDocumento14 pagineOct. 19, 1943. W, E. Humphrey 2,331,931: / 61,4847, M M/MaaxAulia Haq AqobyNessuna valutazione finora

- LL-LLL'LL-FLL: 31, 1940. E. C. MmleanDocumento7 pagineLL-LLL'LL-FLL: 31, 1940. E. C. MmleanKrozeNessuna valutazione finora

- April 2, 1968.: Filed Sept 26, 1966Documento7 pagineApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Engineering Vol 69 1900-03-16Documento30 pagineEngineering Vol 69 1900-03-16ian_newNessuna valutazione finora

- US2228469Documento4 pagineUS2228469George AcostaNessuna valutazione finora

- Us 3090578Documento3 pagineUs 3090578mohamad zareNessuna valutazione finora

- Feb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3Documento7 pagineFeb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3ValBMSNessuna valutazione finora

- 507 Mechanical Movements: Mechanisms and DevicesDa Everand507 Mechanical Movements: Mechanisms and DevicesValutazione: 4 su 5 stelle4/5 (28)

- 1 ChuquisacaDocumento6 pagine1 ChuquisacaRodrigoPomaNessuna valutazione finora

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocumento7 pagineNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNessuna valutazione finora

- Diagrama Bases 1Documento1 paginaDiagrama Bases 1RodrigoPomaNessuna valutazione finora

- Large Batch Hard Candy and LollipopsDocumento2 pagineLarge Batch Hard Candy and LollipopsRodrigoPomaNessuna valutazione finora

- LM 7805 RegulatorDocumento12 pagineLM 7805 RegulatorFadel BairuniNessuna valutazione finora

- Us 4106436Documento10 pagineUs 4106436RodrigoPomaNessuna valutazione finora

- United States Patent: Dreve, Jr. (45) May 16, 1972Documento6 pagineUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNessuna valutazione finora

- Us 2296645Documento4 pagineUs 2296645RodrigoPomaNessuna valutazione finora

- United States Patent: Dreve, Jr. (45) May 16, 1972Documento6 pagineUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNessuna valutazione finora

- M. Schwafel: Derrick Safety CageDocumento4 pagineM. Schwafel: Derrick Safety CageRodrigoPomaNessuna valutazione finora

- Us659197 PDFDocumento3 pagineUs659197 PDFRodrigoPomaNessuna valutazione finora

- Us2467764 PDFDocumento10 pagineUs2467764 PDFRodrigoPomaNessuna valutazione finora

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Documento6 pagineJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNessuna valutazione finora

- United States Patent (19) : Miiller (45) Date of PatentDocumento8 pagineUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNessuna valutazione finora

- United States Patent - (191: Mayeux Et AlDocumento4 pagineUnited States Patent - (191: Mayeux Et AlRodrigoPomaNessuna valutazione finora

- Us4589264 PDFDocumento6 pagineUs4589264 PDFRodrigoPomaNessuna valutazione finora

- Jan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTDocumento5 pagineJan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTRodrigoPomaNessuna valutazione finora

- United States Patent (19) : Grote Et A1Documento9 pagineUnited States Patent (19) : Grote Et A1RodrigoPomaNessuna valutazione finora

- Us2678614 PDFDocumento6 pagineUs2678614 PDFRodrigoPomaNessuna valutazione finora

- MXTVXVW PDFDocumento3 pagineMXTVXVW PDFRodrigoPomaNessuna valutazione finora

- Datasheet UA741CPDocumento19 pagineDatasheet UA741CPlcruz_86Nessuna valutazione finora

- MikroDocumento5 pagineMikroAmir Si KetengNessuna valutazione finora

- Musical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneDocumento1 paginaMusical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneHenry GutierrezNessuna valutazione finora

- A9 PDFDocumento25 pagineA9 PDFRodrigoPomaNessuna valutazione finora

- Cba The GPSDocumento7 pagineCba The GPSRodrigoPomaNessuna valutazione finora

- Us116842 PDFDocumento6 pagineUs116842 PDFRodrigoPomaNessuna valutazione finora

- 1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016Documento3 pagine1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016api-292307509Nessuna valutazione finora

- BTL Info CNC ProgrammDocumento132 pagineBTL Info CNC ProgrammdieulafaitNessuna valutazione finora

- Lecture 20Documento10 pagineLecture 20bilal5202050Nessuna valutazione finora

- Assignment On Cholera: Submitted ToDocumento17 pagineAssignment On Cholera: Submitted ToEhesanulHaqueSaifNessuna valutazione finora

- Volvo PDFDocumento218 pagineVolvo PDFNelio Lara Ricaldi0% (1)

- BHLP Year Long Plan Required English Medium 2023 24 Batch Final 991676721629413Documento3 pagineBHLP Year Long Plan Required English Medium 2023 24 Batch Final 991676721629413A V GamingNessuna valutazione finora

- Eng Pipe DesignDocumento12 pagineEng Pipe DesignEsapermana Riyan100% (1)

- Orifice Assembly With D-D2 Taps PDFDocumento1 paginaOrifice Assembly With D-D2 Taps PDFArup MondalNessuna valutazione finora

- Lcnews227 - Nexera SeriesDocumento47 pagineLcnews227 - Nexera SeriesMuhammad RohmanNessuna valutazione finora

- Welding Research Council: BulletinDocumento28 pagineWelding Research Council: BulletinRogerio Tropia GranjaNessuna valutazione finora

- Additive Manufacturing Objective QuestionsDocumento7 pagineAdditive Manufacturing Objective Questionsmohammad shaqib100% (4)

- Lab Centre of Pressure Ecw341Documento4 pagineLab Centre of Pressure Ecw341danialNessuna valutazione finora

- Schneider Modicon M580 CatalogueDocumento268 pagineSchneider Modicon M580 CatalogueKhaerul Imam HermanNessuna valutazione finora

- EASA - Design OrganisationsDocumento30 pagineEASA - Design Organisationsyingqi.yangNessuna valutazione finora

- Vintage Tavern - PrintInspectionDocumento4 pagineVintage Tavern - PrintInspectionBryce AirgoodNessuna valutazione finora

- Model: P660 Series: Differential Pressure Gauge With Diaphragm ElementDocumento6 pagineModel: P660 Series: Differential Pressure Gauge With Diaphragm ElementTÀi VÕNessuna valutazione finora

- Into The Unknown 21 Doc PDFDocumento9 pagineInto The Unknown 21 Doc PDFFernando AlbuquerqueNessuna valutazione finora

- NARS Fall 2011 Press File PDFDocumento19 pagineNARS Fall 2011 Press File PDFheather_dillowNessuna valutazione finora

- ManufactureDocumento2 pagineManufactureRahima Akter RakhiNessuna valutazione finora

- Study of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderDocumento3 pagineStudy of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderAnonymous AkoNessuna valutazione finora

- Menstrupedia Comic: The Friendly Guide To Periods For Girls (2014), by Aditi Gupta, Tuhin Paul, and Rajat MittalDocumento4 pagineMenstrupedia Comic: The Friendly Guide To Periods For Girls (2014), by Aditi Gupta, Tuhin Paul, and Rajat MittalMy Home KaviNessuna valutazione finora

- Digital Trail Camera: Instruction ManualDocumento20 pagineDigital Trail Camera: Instruction Manualdavid churaNessuna valutazione finora

- Thesis 1-15Documento15 pagineThesis 1-15hewelirNessuna valutazione finora

- Phytoremediation Acuatic PlantsDocumento120 paginePhytoremediation Acuatic PlantsFranco Portocarrero Estrada100% (1)

- z482 E3b en (3a2)Documento2 paginez482 E3b en (3a2)Gerencia General ServicesNessuna valutazione finora

- Kiss Forex How To Trade Ichimoku PDFDocumento72 pagineKiss Forex How To Trade Ichimoku PDFSastryassociates Chartered100% (3)

- NDTDocumento2 pagineNDTRoop Sathya kumarNessuna valutazione finora

- Syntorial NotesDocumento13 pagineSyntorial NotesdanNessuna valutazione finora

- Fluid Solids Operations: High HighDocumento20 pagineFluid Solids Operations: High HighPriscilaPrzNessuna valutazione finora

- General Anaesthesia MCQsDocumento5 pagineGeneral Anaesthesia MCQsWasi Khan100% (3)