Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Selonoid

Caricato da

Anthony MayTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Selonoid

Caricato da

Anthony MayCopyright:

Formati disponibili

www.atos.

com

Table E001-9/E

Solenoid directional valves: users guidelines

due stadi, pilotate, dimensioni ISO/Cetop 07 e 08

Atos solenoid valves have been designed and tested with innovative concepts to satisfy the advanced needs of modern machines: rapid or damped

switching, quiet operation, reduced power absorbed, versatility, reliability and safety of use.

This table gives engineers, in condensed form, a series of useful information for the choice and the use of modern solenoid valves.

DESCRIPTION OF FUNCTION

Solenoid directional valves are used for

changing flow direction in hydraulic systems.

Main features are:

1.1 New integrated design between hydraulic and electrical parts with more compact construction and better efficiencies.

1.2 Wet solenoids for maximum reliability,

also available in flame-proof, intrinsically

safe and stainless steel execution.

1.3 All seals are static and all the moving

parts are protected and lubricated by

the fluid.

1.4 Smoother switching with effective regulation thanks to optional switching control devices.

1.5 Plastic encapsulated coils easily interchangeable and UL certified.

1.6 Electric or electronic connectors, depending on the application and on electric

control board interface.

1.7 Cored oil passages with low pressure

drops.

1.8 Interchangeable spools for various

directional functions.

2

. .

1.6

SPOOLS CHARACTERISTICS

Standard interchangeable spools are available in a wide range of configurations, as indicated in table 3.

Specific spools to reduce water hammershocks during switching: variants 1/1, 4/8

and 5/1. Their special shape reduces water

hammer-shocks during switching. Use of

these spools is not recommended with maximum flow greater than 80% of the nominal

values, because of higher pressure drops

generated in the valve.

Response times and control of switching

time: direct operated solenoid valves.

The solenoid valve response times can be

controlled by the use of specific devices

(option L); associated with the spools */1

and */8 it is possible to control smooth

acceleration/deceleration of the connected

actuator. The L* devices allow an effective

control of the solenoid valve switching time,

slowing down the spool speed without reducing the solenoid force.

They are available in different configurations.

For correct use a slight backpressure (2 bar)

on solenoid valve T port is recommended.

Valve response time is also influenced by

operating conditions (oil characteristics and

temperature), elasticity of the hydraulic circuit and by use of electronic connectors.

Response time and control of switching

time: pilot operated solenoid valves.

The response time of the piloted valves can

be adjusted by means of the options /H

(meter-out control) or /H9 (meter-in control).

This options provide the installation between

the main stage and the pilot valve of a modular throttle valve, type HQ-*/U specific for fine

pilot flow control.

Associated with */1 and */8 spools, smooth

acceleration/deceleration can be controlled

on loads.

1.8

1.2

1.3

. .

.

A

1.4

1.1

1.5

B

1.7

Fig. 1 Cross-section of direct operated solenoid valve

SOLENOID IDENTITY

According to European Convention solenoid

A is close to A port and solenoid B is

close to B port of the direct operated valves.

When pilot operated, the solenoids are identified according to following practice: solenoid

A is at port A end of pilot valve and solenoid

B at port B end, independent of main stage

valve port location or spool type.

3

P

A

B

T

Solenoid A

Solenoid B

Fig. 2 Solenoid identification

Type

Scheme

Intermediate passages

0

1

2

3

4

5

58

6

7

8

0/2

1/2

2/2

16

17

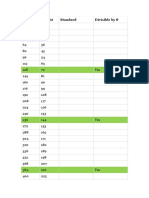

Table 3 Basic spools, schemes and intermediate passages between central and external positions.

The spools are not available for all the directional valves. For their availability see

the relevant valve table.

E001

*P spools for direct operated solenoid valves to reduce leakage.

They are normally used on pilot valve for

pressure and directional control valves, for

cartridge valves and systems with specific

requirements.

Use of these spools is not recommended

with maximum flow greater than 70% of the

nominal values, because of the higher pressure drops generated in the valve.

Following types available: 1P, 3P, 1/2 P, 8P

(for ISO size 06 valves).

COIL CHARACTERISTICS

Table 3.2 Spools to reduce water hammer shocks associated with switching

Type

Intermediate passages

0/1

1/1

3/1

4/8

Table 3.3 Specific spools for special uses or in regenerative circuits

Solenoid valves are available both with DC and

AC coils. Three main solenoids for use with following supply for DH* valves:

OI solenoid for AC and DC supply (only

replacing coil);

OU and OO solenoid for DC supply only;

The solenoid OO can be used also with AC

supply: in this case it must be coupled with

the connector SP-669 having the rectifier

bridge.

Coils are fully encapsulated; they are easily

replaceable without aid of tools in DHI and

DHU valves. AC and DC solenoids are available for DKE* valves. The DC solenoids can

be also fed with AC supply, by using SP-669

connector. The coils with different nominal

voltages can be interchanged on the same

solenoid type.

ELECTRICAL CONNECTORS TO

ISO 4400 (DIN 43650)

The cable entry on electrical plugs can be fitted at 90 intervals by reassembling the contact holder relative to the plug housing.

The cable entry is Pg. 11 suitable for cable

6-10 mm.

Following types are available:

Standard connectors, IP65 protection degree

(SP-666);

Connectors with built in LED (SP-667);

Connectors with built in rectifier bridge (SP669) to supply DC coils by alternating current AC.

In addition to the above DIN connectors,

other type of electrical interfaces are available on request:

- Lead Wire connection

- Deutsch connector DT-04-2P (IP67)

- AMP Junior Timer connector (IP67)

Scheme

Type

Scheme

Intermediate passages

09

90

19

91

39

93

49

94

ELECTRONIC CONNECTORS

Operational principle

E-SE for direct current power supply on DC

coils with reduction of power consumption and increase of performance;

E-SD to eliminate electric disturbances when

solenoids are deenergized;

E-SR to pilot the solenoid valves with a low

power signal (20 mA max);

E-SE main characteristics

They allow a modulation of the power supply

voltage and thus an effective control of the

solenoid force to obtain increased performance and reduction of power consumption.

The use of electronic E-SE connector allows

a considerable increase in solenoid valve

performance.

OPERATING NOTES

Tightening of the fixing screws to the subplates

and of the plastic coil ring-nut.

It is particularly important to check that the

tightening of the fixing screws respects the

torque limits indicated in table 5.

Hi g h e r v a l u e s m a y c a u se a n o m a lo u s

deformations of the body and prevent sliding

of the spool. 12.9 class fixing screws are

recommended. The plastic coil ring-nuts will

be fixed on the solenoid with a torque 3Nm:

this deforms properly the seals and protects

against external particles and water.

Operation in circuits with flow exceeding

the nominal valve flow

In circuits with flow rates greater than the

nominal values and in circuits with accumulators, where the instantaneous flow can exceed

nominal values, is recommended a throttle

valve on P port of solenoid valve to limit the

03/07

maximum flow on the valve.

Dilatation and contraction of flexible hoses

subjected to variations of system pressure

can generate high instantaneous flow rates.

The version indicated in fig. 6 can be directly

inserted into P port of the valve but also in

other valve ports.

Where throttle valve may be required they can

be supplied with following codes:

SP-PLUG H-** (for DH* valves)

SP-PLUG K-** (for DKE* valves)

** the double asterisk identifies the dimension

in tenths of a millimeter.

Example: SP-PLUG H-05 = 0,5 mm diameter

24 VDC

PNP

TRANSISTOR

E-SE

Limits on two-way and three-way operation

for direct operated solenoid valves.

When used as two-way and three-way valves

with P, A or B ports blocked or not subject to

flow, or with flow much lower than flow on

other ports, maximum catalogue performance

cannot be assured.

Minimum pilot pressure for pilot operated

solenoid valves.

A minimum pressure value must be guaranteed

for piloting the valve. This value is 8 bar (or 10

bar in the case of valves with hydraulic centering). In case of circuits with lower pilot pressure on P port, the option /R should be used.

Operation combined with hydraulic cylinders with high section ratios.

Operational limits may occur with cylinders

with section ratios (piston/rod) greater than

1.25. In these cases multiplications or demultiplications of flow and pressure may disturb

the correct operation of the solenoid valve.

8

SPECIAL VERSION SOLENOID VALVES

COIL

Fig. 4 E-SE electrical connection

Table 5

Recommended torque for the fixing screws

Valve type

Fixing screws

class 12.9

Torque

DH*

M5

8 Nm

DKE*

M6

15 Nm

DP**-2

M10 and M6

70 Nm and 15 Nm

DP**-3

M12

125 Nm

DP**-6

M20

600 Nm

for explosion-proof environments

for intrinsically safe operation

stainless steel execution for marine or

aggressive environments

for operation beyond the allowed temperature limits.

Fig. 6 Throttle valve which can be inserted in

port P (or A and B) of the solenoid

valve to limit the flow.

Potrebbero piacerti anche

- G 3CPF 1331 952 0001 - 0Documento1 paginaG 3CPF 1331 952 0001 - 0Anthony MayNessuna valutazione finora

- G 3CPF 1331 955 0302 - 0Documento1 paginaG 3CPF 1331 955 0302 - 0Anthony MayNessuna valutazione finora

- L&T Hydrocarbon Engineering: Approved For ConstructionDocumento6 pagineL&T Hydrocarbon Engineering: Approved For ConstructionAnthony MayNessuna valutazione finora

- RPT ComputersDocumento4 pagineRPT ComputersAnthony MayNessuna valutazione finora

- 110 T 8069Documento8 pagine110 T 8069Anthony MayNessuna valutazione finora

- Z03 AersqDocumento6 pagineZ03 AersqAnthony MayNessuna valutazione finora

- Equipment Service Manuals DIS201: Frame 9fa Gas Turbine Pulse Filtration System A040Documento46 pagineEquipment Service Manuals DIS201: Frame 9fa Gas Turbine Pulse Filtration System A040Anthony MayNessuna valutazione finora

- Alignment Module.Documento64 pagineAlignment Module.Anthony MayNessuna valutazione finora

- ADR ColdStartDocumento1 paginaADR ColdStartAnthony MayNessuna valutazione finora

- Fi Chier 0005Documento7 pagineFi Chier 0005Anthony MayNessuna valutazione finora

- Mechanical Seals ModuleDocumento93 pagineMechanical Seals ModuleAnthony May100% (1)

- Lubrication and Bearing Module.Documento64 pagineLubrication and Bearing Module.Anthony MayNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Avr 555Documento5 pagineAvr 555makroumNessuna valutazione finora

- 1KW Project in On GrideDocumento5 pagine1KW Project in On GrideRAKESH PRADHANNessuna valutazione finora

- MisII Manual PageDocumento21 pagineMisII Manual PageMorgan PeemanNessuna valutazione finora

- Lastexception 63715991441Documento1.051 pagineLastexception 63715991441Hannah KimNessuna valutazione finora

- Ccna4 Chapter 1 Intro WANsDocumento71 pagineCcna4 Chapter 1 Intro WANsdjqriusgeorgeNessuna valutazione finora

- RC Infant Flow Sipap Operator Manual UG enDocumento80 pagineRC Infant Flow Sipap Operator Manual UG enpericopepeNessuna valutazione finora

- Cisco Netacad Chapter 5Documento59 pagineCisco Netacad Chapter 5Carlos IzaNessuna valutazione finora

- Remote Field Testing: HapterDocumento20 pagineRemote Field Testing: HapterKalai VananNessuna valutazione finora

- RTCDocumento12 pagineRTCAsim Idrees OsmanNessuna valutazione finora

- TL-MR3020 V1 Datasheet 1Documento2 pagineTL-MR3020 V1 Datasheet 1hman3636Nessuna valutazione finora

- Plug Power Supply: MCPLG SeriesDocumento3 paginePlug Power Supply: MCPLG SerieswisnuNessuna valutazione finora

- A - ATG - PR 2014 0006 GB - HyPower Geko OCT - BR - K1 02 2015 - 150dpi PDFDocumento16 pagineA - ATG - PR 2014 0006 GB - HyPower Geko OCT - BR - K1 02 2015 - 150dpi PDFionutenacheNessuna valutazione finora

- Bright Sign Touchscreen Tech NoteDocumento1 paginaBright Sign Touchscreen Tech NotemauroboteroNessuna valutazione finora

- Free Chlorine Analyser (Swan)Documento2 pagineFree Chlorine Analyser (Swan)Văn Tuấn NguyễnNessuna valutazione finora

- Assignment Switch Gear and Protection (3360901)Documento2 pagineAssignment Switch Gear and Protection (3360901)Madhuri chavanNessuna valutazione finora

- List of True 16 9 ResolutionsDocumento19 pagineList of True 16 9 ResolutionsryuNessuna valutazione finora

- TP of AutomobileDocumento20 pagineTP of AutomobileHicham Salahdine100% (1)

- Lista Chint ExelDocumento27 pagineLista Chint ExelRodolfo Calvo0% (1)

- Jdsu 6000a ManualDocumento744 pagineJdsu 6000a Manualabc100% (1)

- Turbidimetry: I. PurposeDocumento14 pagineTurbidimetry: I. PurposeMiftahul Jannah0% (1)

- MC770 / MC780 MPS3537mc / MPS4242mc Maintenance ManualDocumento217 pagineMC770 / MC780 MPS3537mc / MPS4242mc Maintenance ManualPon ThephavongNessuna valutazione finora

- ClimateMaster Troubleshooting Info Revised 10-04-11Documento5 pagineClimateMaster Troubleshooting Info Revised 10-04-11Daniel VeraNessuna valutazione finora

- FSP180 60savDocumento1 paginaFSP180 60savlth126Nessuna valutazione finora

- Eee589 Analog-ic-Design Eth 2.00 Ac29Documento2 pagineEee589 Analog-ic-Design Eth 2.00 Ac29dileshwarNessuna valutazione finora

- Brocade Bottel Neck CMDDocumento32 pagineBrocade Bottel Neck CMDragservNessuna valutazione finora

- 1a455 Quanta fx5 0504 A00-03 PDFDocumento50 pagine1a455 Quanta fx5 0504 A00-03 PDFdigenioNessuna valutazione finora

- Welding: Instruction Manual & Owners GuideDocumento36 pagineWelding: Instruction Manual & Owners Guidekdm004xx75% (8)

- Voltage Monitoring Series SM 501Documento5 pagineVoltage Monitoring Series SM 501srinivasgateNessuna valutazione finora

- Ade Lab ManualDocumento73 pagineAde Lab ManualAshutosh PatilNessuna valutazione finora