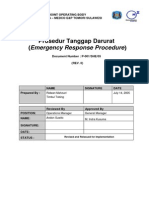

Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cementing Plugs AND Ancillary Equipment

Caricato da

Teguh Akbar HarahapTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cementing Plugs AND Ancillary Equipment

Caricato da

Teguh Akbar HarahapCopyright:

Formati disponibili

Sir William Smith Road, Kirkton Industrial Estate,

Arbroath, Angus, Scotland, U.K. DD11 3RD

Tel: +44 (0) 1241 877776. Fax: +44 (0) 1241 871037

E-mail: sales@pioneeroiltools.com

Website: www.pioneeroiltools.com

CEMENTING PLUGS

AND

ANCILLARY EQUIPMENT

CP 07/05

Copyright 2005

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

CONTENTS

Table of contents

Page

Content

01

Contents page

02

Introduction

0304

Surface Launched Anti-rotational plugs

0506

Subsea Launched Standard plugs

0708

Subsea Launched Anti-rotational plugs

0910

High Pressure High Temperature system

11

Ancillary equipment

12

Launching darts and balls

13

Float collars and shoes

14

Cementing heads

When time is of the essence, Pioneer delivers

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

INTRODUCTION

Pioneer Oil Tools Ltd is pleased to provide a range of products related to the downhole cementing

process. These are mostly-rubber products and standard availability is in the following.

Standard materials:

Nitrile Butadiene Rubber (NBR) or

Hydrogenated Acryonitrile Butadiene Rubber (HNBR)

The selection of the material is dependent on the operating environment in the hole and the

physical and chemical characteristics required from the equipment item. Other materials may

be specied by customer.

Material selection

Material

Description

Temperature limits

NBR

High Nitrile (Acrylonitrile content 35 to 45%). Excellent resistance -45C to +100C(can go to 120C

to mineral based uids and hydrocarbon fuels. Strength and with special processsing)

resilience is reasonable but low temperature performance is

poor.

Medium Nitrile (Acrylonitrile content 27 to 34%). Resistance

to mineral based uids is excellent, but resistance to fuels is

moderate.

Low Nitrile (Acrylonitrile content 18 to 25%). Strength, resilience

and abrasion resistance is reasonable, and resistance to

mineral based uids is also reasonable. This material has a low

temperature capability.

HNBR

General performance as for NBR but better abrasion and ozone -45C to +175C

resistance. It has good resistance to Crude oil, Hydrogen

Sulphide and Amines: another feature of HNBR over NBR is its

higher temperature range.

Pioneer has comprehensive experience in the design and manufacture of various types of oilindustry tools. If your requirements are not covered in this brochure, please contact us. Our

sales and design team are anxious to demonstrate our range of products and versatility, by

solving your tooling problems.

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

SURFACE LAUNCHED

ANTI-ROTATIONAL PLUGS

Pioneer Oil Tools Ltd surface launched anti-rotational cementing plugs are designed to provide

a rm wiping action on the casing walls, a good seal for the cement when being pumped (to

avoid contamination) and are easily drillable.

Operation of the plugs is simple: the bottom plug is loaded, followed by the cement and then

the top plug. The plug set is then pumped down to the required location. The bottom plug

latches at the required level into a bafe joint or oat collar. Pressure is applied to the top plug

resulting in the shear disc in the bottom plug bursting. The cement then extrudes through the

bottom plug until the top plug closes and latches with the bottom plug. The cement is then

allowed to set.

Pioneers high quality cementing plugs are constructed from nitrile rubber, bronze and nylon.

The plugs incorporate toothed anti-rotational devices that mesh between the top and bottom

plugs and between the bottom plug and the receiver. In conjunction with its nylon core, these

anti-rotational measures ensure that the plugs can be drilled through easily with a PDC bit.

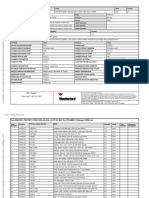

SLNT0963T / SLNB0963T

SLNT1338T / SLNB1338T

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

SURFACE LAUNCHED

ANTI-ROTATIONAL PLUGS (Contd)

The plugs are manufactured from two colours of rubber for easy identication of the top and

bottom plugs and to determine when the lower plug has been drilled through. Top plugs are

moulded from black rubber, bottom plugs from red. Cementing plugs come in a range of sizes

and are capable of accepting different pressures. Specifying details are as follows, with T

indicating top plug and B for bottom plug:

Surface launched anti-rotational plugs

Product

code

Size

Max

pressure

SLNT

SLNB

20 x 18

2000 PSI

SLNT

SLNB

16

2700 PSI

SLNT1338T

SLNB1338T

14 x 13

6000 PSI

175

SLNT0963T

SLNB0963T

10 x 9

8000 PSI

175

7 x 7

8000 PSI

SLNT

SLNB

When ordering specify the following:

Diameter of plug required.

Minimum constraint to plug travel.

Working pressure and temperature.

Shear disc pressure required.

Max

temperature

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

SUBSEA LAUNCHED

STANDARD PLUGS

Pioneer Oil Tools Ltds subsea launched standard cementing

plugs are designed to provide a rm wiping action on the casing

walls, a good seal for the cement (to avoid contamination)

and are made of materials that are easily drillable with a PDC

bit.

CPN2000E

Operation of the plugs is simple but effective. The plug set

is connected to the cementing stinger on the drill pipe and

lowered to the correct position. A ball is dropped down the

drill pipe followed by cement. The ball seats itself in the

bottom plug sealing off the lower plug bore. Subsequent

pressurisation of the cement column results in the shear

pins of the bottom plug shearing, releasing the bottom plug

and cement to travel to a plug receiver (also available from

Pioneer Oil Tools Ltd).

When sufcient cement has been pumped, a dart is released

which latches itself into the top plug. Applying pressure

results in the top plug shear pins shearing, releasing the top

plug. The top plug can then transmit pump pressure through

the column of cement; this pressure squeezes the ball into

the lower chamber of the bottom plug allowing the cement

to extrude out through the plugs bottom ports. The cement

is then allowed to set before drilling through.

The high quality cementing plugs are made of nitrile rubber,

aluminium, PVC and nylon ensuring that the plugs can be

drilled through easily.

CPND1338E

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

SUBSEA LAUNCHED

STANDARD PLUGS (Contd)

The plugs are manufactured in two colours of rubber (for

easy identication and to allow operators to gauge which

plug they are drilling through) top plugs in black, bottom

plugs in red.

CPND0963E

Cementing plugs come in a range of sizes and capable of

accepting different pressures. Specifying details are as

follows:

Subsea launched standard plugs

Product

code

Size

Max

pressure

Max

temperature

20 x 18

1500 PSI

65C

CPND1600E

16

2000 PSI

65C

CPND1338E

14 x 13

4000 PSI

170C

CPND0963E

10 x 9

5000 PSI

170C

CPND2000E

CPND0700E

7 x 7

5000 PSI

170C

The code letter D indicates a set of plugs and can be omitted if single plugs are

required.

CPND0700E

When ordering specify the following:

Diameter of plug required.

Minimum constraint to plug travel.

Working pressure and temperature.

Connection requirements for top plug.

Pioneer would be pleased to supply associated equipment of

darts and balls for these items.

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

SUBSEA LAUNCHED

ANTI-ROTATIONAL PLUGS

Pioneer Oil Tools Ltd subsea launched standard cementing

plugs are designed to provide a rm wiping action on the casing

walls, a good seal for the cement (to avoid contamination)

and made of materials that are easily drillable with a PDC

bit. These plugs also have the additional feature of antirotational teeth between the plugs to facilitate drilling.

CPN2000T

The operation of the subsea anti-rotational plugs is very

similar to the standard type. Placement is by the drill string,

utilising darts and balls to control the operations of the plugs

and the placing of cement.

The high quality cementing plugs are constructed from

nitrile rubber, aluminium, PVC and nylon. The materials

ensure that the plugs can be drilled through easily. The plugs

are manufactured from red and black rubber, to make easy

identication of the top and bottom plugs and to aid drilling

operators in identifying which plug they are drilling through.

Plugs are supplied as a set or as single top plugs.

CPN1338T

CPND1338T

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

SUBSEA LAUNCHED

ANTI-ROTATIONAL PLUGS (Contd)

Cementing plugs come in a range of sizes and capable of

accepting different pressures. Specifying details are as

follows:

CPND0963T

Subsea launched anti-rotational plugs

Product

code

Size

Max pressure

Max

temperature

CPND2000T

20 x 18

2000 PSI

65C

CPND1600T

16

2700 PSI

65C

CPND1338T

14 x 13

6000 PSI

175C

CPND0963T

10 x 9

8000 PSI

175C

CPND0700T

7 x 7

8000 PSI

175C

The code letter D indicates a set of plugs and can be omitted if single plugs are

required.

When ordering specify the following:

Diameter of plug required.

Minimum constraint to plug travel.

Working pressure and temperature.

Pioneer would be pleased to supply associated equipment

of darts and balls for these items. The plugs are compatible

with the BJ Launch System.

CPN0963T

CPND0700T

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

HPHT SYSTEM

High Pressure High Temperature

The HPHT system is designed to operate in more difcult

environmental conditions of high temperature and pressure

(up to 175C and up to 15,000 psi).

CPHD1338ST

The plugs are made for surface launching and have operating

characteristics similar to the standard surface launched plug

for good wiping of the casing, a good seal for the cement

when being pumped (to avoid contamination) and made of

materials that are easily drillable with a PDC bit.

The use of an aluminium core allows the plug to be used

at higher pressures than the standard plug. The other high

quality materials from which the plug is manufactured are

HNBR rubber and a bronze shear disc in the bottom plug.

The plugs are made from red and black rubber for easy

identication.

The plugs have optional receiving mechanisms for the

bottom plug and can be made with either a solid aluminium

top to the top plug or tted with an aluminium poppet valve

to control pressure between the plugs.

Plugs may be supplied as a set of top and bottom plug or as

an individual plug.

CPHD0963ST

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

HPHT SYSTEM (Contd)

Cementing plugs come in a range of sizes from 7 to 14.

Specifying details are as follows:

CPHD0963ST-PV

HPHT system

Product code

Size

CPHD1338ST

14 x 13

CPHD0963ST

10 x 9

CPHD0700ST

7 x 7

The code letter D indicates a set of plugs and can be omitted if single plugs are

required. If a poppet valve is required a PV code should be used at the end of the

item code.

When ordering the following should be specied:

Diameter of plug required.

Minimum constraint to plug travel.

Working pressure and temperature.

Receiver connection requirements.

Poppet Valve required or not.

Pioneer would be pleased to supply associated equipment

(cement heads, etc) with this equipment if required.

CPH0700ST-PV

CPH0963ST-PV

10

CPHD0700ST-PV

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

ANCILLARY EQUIPMENT

Pioneer Oil Tools Ltd is able to supply a range of ancillary equipment associated with cementing

plugs and the cementing process. These items include

Darts

Balls

Float valves and shoes

Cementing Heads

All items are made from similar high quality materials as the plugs with nitrile rubber, aluminium

and nylon parts where items are for downhole use and need to be PDC drillable.

When specifying requirements ensure that the whole system is compatible dimensionally and

in operating environment parameters.

11

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

ANCILLARY EQUIPMENT

LAUNCHING DARTS AND BALLS

Pioneer Oil Tools Ltd Launching Darts and Balls are

compatible with the associated range of subsea launched

cementing plugs and are to industry standard dimensions.

Customer-specied dimensions can also be accomodated.

The Launch Darts can be supplied with different latching

mechanisms, the capability to operate under high pressure

conditions if required and a poppet valve feature.

LD0500

The Launching Darts and Balls are made from high quality

nitrile rubber and aluminium latching mechanism on the

darts to ensure that they are PDC drillable.

The design of the Launch Darts ensures that they remain

stable in the casing during their path to the top cement plug

and then latch easily into the plug.

LD0663A

LB0225

12

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

ANCILLARY EQUIPMENT

FLOAT COLLARS AND SHOES

Pioneer produces a range of dependable oat collars for a

variety of casing sizes for use with Pioneer cement plugs.

The primary feature of all pioneer oat collars is the nonreturn valve. This mechanism allows wellbore/drilling uids

and back-owing cement to be excluded from the casing

string.

This feature gives the tool its name as each joint run above

the valve displaces its own volume of drilling uid and hence

allows the string to partially oat, mitigating a portion of

the weight of the string.

The oat collar also incorporates an anti-rotational feature, a

quality that permits the easy drilling of Pioneer anti-rotational

cementing plugs.

In addition a range of oat shoes is available to match each

oat collar.

13

PVN0963B

CEMENTING PLUGS AND

ANCILLARY EQUIPMENT

ANCILLARY EQUIPMENT

CEMENT HEADS

Pioneer Oil Tools Ltd has a series of cement heads to be used

in conjunction with the range of cement plugs and darts or

with other suppliers equipment.

10 Cement Head

These cement heads feature a quick release mechanism that

permits rapid connection/disconnection of the cement head

from the string.

The cement heads are made from high quality materials and

are pressure tested.

14 Cement Head

Product

14 Cement Head

14

Cement heads

Tested

pressure

Working

pressure

11250 PSI

7500 PSI

Sir William Smith Road, Kirkton Industrial Estate,

Arbroath, Angus, Scotland, U.K. DD11 3RD

Tel: +44 (0) 1241 877776. Fax: +44 (0) 1241 871037

E-mail: sales@pioneeroiltools.com

Website: www.pioneeroiltools.com

CEMENTING PLUGS

AND

ANCILLARY EQUIPMENT

CP 07/05

As the policy of Pioneer Oil Tools Ltd is one of continual improvement,

we reserve the right to change designs or specications without notice. Copyright 2005

Potrebbero piacerti anche

- BS StandardsDocumento13 pagineBS StandardsShyam Prasad K S100% (3)

- Bimbar Inflatable PDFDocumento36 pagineBimbar Inflatable PDFcarlosdh_03Nessuna valutazione finora

- MH Hyd Tac Tm-353!01!3Documento6 pagineMH Hyd Tac Tm-353!01!3David MannNessuna valutazione finora

- TU-045 - AS-RBP - 9-5.8 inDocumento4 pagineTU-045 - AS-RBP - 9-5.8 inAtom InsideNessuna valutazione finora

- 0620000008Documento6 pagine0620000008mahsaNessuna valutazione finora

- Parveen PRHP Packer: Downhole Completion EquipmentDocumento5 pagineParveen PRHP Packer: Downhole Completion EquipmentsambhajiNessuna valutazione finora

- Polar RB (Regular Bore) Seal Bore PackerDocumento3 paginePolar RB (Regular Bore) Seal Bore PackerAlexander KlmNessuna valutazione finora

- Control Unit Model: WC-CUDocumento3 pagineControl Unit Model: WC-CUmahsaNessuna valutazione finora

- A Type PerforatorDocumento0 pagineA Type PerforatorLazaro DhNessuna valutazione finora

- ELDER IX 5 5 X 2 375Documento8 pagineELDER IX 5 5 X 2 375crni rokoNessuna valutazione finora

- 7.000 X 2.875 DLH Packer With J-Release (17-26) 938-7000-028 Rev ADocumento5 pagine7.000 X 2.875 DLH Packer With J-Release (17-26) 938-7000-028 Rev ANorbey Ashley Gasca AlzateNessuna valutazione finora

- Permanent PKR Eline/Hydraulic Setting Tool Signature: AdvantagesDocumento18 paginePermanent PKR Eline/Hydraulic Setting Tool Signature: Advantagesjulio RDLRNessuna valutazione finora

- Sect 06 Full-Opening EquipmentDocumento44 pagineSect 06 Full-Opening EquipmentpaimanNessuna valutazione finora

- Sect 08 Plug CatchersDocumento14 pagineSect 08 Plug CatcherspaimanNessuna valutazione finora

- Ps 0412 0600obh WDocumento1 paginaPs 0412 0600obh WHunterNessuna valutazione finora

- Assy Vol IDocumento4 pagineAssy Vol IFernando CastelblancoNessuna valutazione finora

- Ps 0412 0612obh WDocumento1 paginaPs 0412 0612obh WHunterNessuna valutazione finora

- XDT Taz A4 Datasheet WebDocumento2 pagineXDT Taz A4 Datasheet WebClOudyo VirgílioNessuna valutazione finora

- Schlumbergerblue Pack PBR & PBR PKR Ret Tool: 33/8" 5 3/4" 4 1/2" Left Hand Thread 3 15/16"Documento1 paginaSchlumbergerblue Pack PBR & PBR PKR Ret Tool: 33/8" 5 3/4" 4 1/2" Left Hand Thread 3 15/16"yasirismNessuna valutazione finora

- Champ IV Packers With Parts ListsDocumento82 pagineChamp IV Packers With Parts ListsMohamed ShafieNessuna valutazione finora

- Annexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFDocumento7 pagineAnnexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFMehdi NorouziNessuna valutazione finora

- Two-Way Swivel Redress Kit Assembly InstructionsDocumento10 pagineTwo-Way Swivel Redress Kit Assembly InstructionsEvolution Oil ToolsNessuna valutazione finora

- Liner PackersDocumento1 paginaLiner PackersMohamed ElabbasyNessuna valutazione finora

- Arrow-Pak 7.0 X 4Documento9 pagineArrow-Pak 7.0 X 4Tech AlfaNessuna valutazione finora

- C2™ Liner Setting Sleeve With Tieback ExtensionDocumento5 pagineC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Junk Catcher AssembliesDocumento10 pagineJunk Catcher AssembliesMicNessuna valutazione finora

- DDocumento26 pagineDBalkis FatihaNessuna valutazione finora

- 4.000 Locator Seal Assembly Product: 15-802-0400-00-00: Item Description QTY Part Number 1 2 A B C D 3 Parts ListDocumento1 pagina4.000 Locator Seal Assembly Product: 15-802-0400-00-00: Item Description QTY Part Number 1 2 A B C D 3 Parts ListJhonathan MirandaNessuna valutazione finora

- Packer Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2Documento4 paginePacker Systems Technical Unit Model "M" Expansion Joint, Sizes 2-3/8, 2-7/8, 3-1/2, and 4-1/2eberthson hernandezNessuna valutazione finora

- BTU Retreivable PlugDocumento1 paginaBTU Retreivable Plugbrunolb1Nessuna valutazione finora

- 7 000 X 2 875 Stradasnap 645-7000-020 2008-04-01Documento5 pagine7 000 X 2 875 Stradasnap 645-7000-020 2008-04-01Roberto Andres Sizas ReyNessuna valutazione finora

- 2023 10.75 TST-2 Service PackerDocumento15 pagine2023 10.75 TST-2 Service PackerDhenny FarialNessuna valutazione finora

- GR - WRDSP - Tech LiteratureDocumento7 pagineGR - WRDSP - Tech LiteratureDigger Downhole ToolsNessuna valutazione finora

- Sur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitDocumento3 pagineSur-Set™ Selective Seating Nipples: Flow Control Systems Technical UnitTamer Hesham AhmedNessuna valutazione finora

- 9.625'' Inspection SheetDocumento3 pagine9.625'' Inspection SheetMohamed Mahmoud Rezk DimoNessuna valutazione finora

- BakerDocumento4 pagineBakerWilliam EvansNessuna valutazione finora

- Descriptio: Model GXA Sliding SleeveDocumento4 pagineDescriptio: Model GXA Sliding SleevefelipeNessuna valutazione finora

- Sliding SleveDocumento4 pagineSliding SleveMarceloNessuna valutazione finora

- New BDMI L 4.5 HE0Documento6 pagineNew BDMI L 4.5 HE0Natanael SaputraNessuna valutazione finora

- Ah Hydraulic Setting ToolDocumento12 pagineAh Hydraulic Setting ToolCarlos HolguinNessuna valutazione finora

- Half Mule Shoe Guide 88050307Documento2 pagineHalf Mule Shoe Guide 88050307satyendraNessuna valutazione finora

- Packer CupDocumento2 paginePacker Cupmiguel mendozaNessuna valutazione finora

- 9.625x4 Arrow-Pak (265-94)Documento3 pagine9.625x4 Arrow-Pak (265-94)Tech AlfaNessuna valutazione finora

- Type 680 Hydraulic Stage CollarDocumento6 pagineType 680 Hydraulic Stage Collar唐辉Nessuna valutazione finora

- D601005184 Man 001Documento17 pagineD601005184 Man 001Riski Kurniawan100% (1)

- Completion Schematic #1: Stimulate and Test ZonesDocumento1 paginaCompletion Schematic #1: Stimulate and Test Zonesasset_kulmagambetovNessuna valutazione finora

- Lock-Set, J-LokDocumento3 pagineLock-Set, J-LokYaqoob IbrahimNessuna valutazione finora

- PCK para Limpiar PunzadosDocumento19 paginePCK para Limpiar PunzadosRodolfo RiderNessuna valutazione finora

- 15 800 7040 00 00 PLDocumento1 pagina15 800 7040 00 00 PLJhonathan MirandaNessuna valutazione finora

- Arrow-Pak RT 266-45Documento3 pagineArrow-Pak RT 266-45Tech AlfaNessuna valutazione finora

- NCS Liner HangersDocumento5 pagineNCS Liner Hangerssmithyry2014Nessuna valutazione finora

- Packer HP 6 Technical LiteratureDocumento7 paginePacker HP 6 Technical LiteratureRaul Diaz100% (1)

- WH6 2005Documento19 pagineWH6 2005annNessuna valutazione finora

- R Selective Test Tool PDFDocumento5 pagineR Selective Test Tool PDFazze bouzNessuna valutazione finora

- 616-35000 Assembly DrawingDocumento1 pagina616-35000 Assembly DrawingAl KautsarNessuna valutazione finora

- D&L Double Grip Pkr-Asi-Xpacker1c PDFDocumento2 pagineD&L Double Grip Pkr-Asi-Xpacker1c PDFMoh Syamsul BahriNessuna valutazione finora

- Complete CatalogueDocumento67 pagineComplete Cataloguejarrod lyonNessuna valutazione finora

- Kline General CatalogDocumento30 pagineKline General CatalogservicemenruNessuna valutazione finora

- Api Plan 11Documento6 pagineApi Plan 11johnsaballaNessuna valutazione finora

- Orifice PlatesDocumento12 pagineOrifice PlatesPhaitoon PudsriNessuna valutazione finora

- Rhino Grating PDFDocumento16 pagineRhino Grating PDFoluomo1Nessuna valutazione finora

- PerforationDocumento3 paginePerforationTeguh Akbar HarahapNessuna valutazione finora

- Oil Spill 2Documento43 pagineOil Spill 2Teguh Akbar HarahapNessuna valutazione finora

- Cohesion: Cause and Effect ContrastDocumento12 pagineCohesion: Cause and Effect ContrastTeguh Akbar HarahapNessuna valutazione finora

- About Recycle: Oleh: Septian Teguh Akbar Novian Shafrial Eka P Muhammad ZulkarnainDocumento7 pagineAbout Recycle: Oleh: Septian Teguh Akbar Novian Shafrial Eka P Muhammad ZulkarnainTeguh Akbar HarahapNessuna valutazione finora

- 3 PDF Covariance VariogramDocumento22 pagine3 PDF Covariance VariogramTeguh Akbar HarahapNessuna valutazione finora

- Lock Set PackerDocumento2 pagineLock Set PackerTeguh Akbar HarahapNessuna valutazione finora

- Service Tools RBPDocumento26 pagineService Tools RBPTeguh Akbar HarahapNessuna valutazione finora

- TutorialDocumento80 pagineTutorialTeguh Akbar Harahap100% (4)

- Construction Contract & Law (Ceng 6107)Documento50 pagineConstruction Contract & Law (Ceng 6107)bilisuma seboka100% (1)

- 2022-2023 Fall CE371 HW4 PDFDocumento3 pagine2022-2023 Fall CE371 HW4 PDFMurat EnginNessuna valutazione finora

- NTN Bearings CatalogueDocumento412 pagineNTN Bearings Cataloguemfulgosi1231Nessuna valutazione finora

- Baroda Mumbai Express HighwayDocumento319 pagineBaroda Mumbai Express HighwayBRIJNessuna valutazione finora

- Unique & Latest Civil Engineering Project, Seminar, Thesis & Presentation Topics - CivilDigital PDFDocumento6 pagineUnique & Latest Civil Engineering Project, Seminar, Thesis & Presentation Topics - CivilDigital PDFAlfredo L. PenachosNessuna valutazione finora

- Submitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliDocumento46 pagineSubmitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliBipinNessuna valutazione finora

- Day Reference Contents Industrial Training in Telecom Tower ConstructionDocumento2 pagineDay Reference Contents Industrial Training in Telecom Tower ConstructionHjNessuna valutazione finora

- Renderoc TgxtraDocumento2 pagineRenderoc TgxtraBalasubramanian Ananth100% (3)

- SSCF StainlessSteel Shell and TubeDocumento7 pagineSSCF StainlessSteel Shell and TubeTom GuyetteNessuna valutazione finora

- RubberDocumento36 pagineRubbermohanad ghanimNessuna valutazione finora

- Manual For Design Using Etabs PDFDocumento46 pagineManual For Design Using Etabs PDFPankaj Sardana100% (1)

- General Principles of Foundation Design: To Prepare A Plan of The Base of The StructureDocumento119 pagineGeneral Principles of Foundation Design: To Prepare A Plan of The Base of The StructureTashi TamangNessuna valutazione finora

- Design For Manufacturability For CNC MachiningDocumento4 pagineDesign For Manufacturability For CNC Machiningviorelu99Nessuna valutazione finora

- Ucan CPL PDFDocumento40 pagineUcan CPL PDFMark VargasNessuna valutazione finora

- Why Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuresDocumento5 pagineWhy Don't We Deduct The Steel Volume While Calculating The Concrete Volume in RCC StructuressitaracommercialcomplexNessuna valutazione finora

- 31003Documento4 pagine31003Elliott RussellNessuna valutazione finora

- FEM Analysis On Concrete Columns Confined With CFRP Sheets by AnsysDocumento3 pagineFEM Analysis On Concrete Columns Confined With CFRP Sheets by AnsysVikramNessuna valutazione finora

- Lecture 23Documento83 pagineLecture 23Robert Andy WoodNessuna valutazione finora

- A B C D E: Laboratory Building Ground Floor PlanDocumento1 paginaA B C D E: Laboratory Building Ground Floor PlanEmre ÇilNessuna valutazione finora

- Terminology of StairDocumento8 pagineTerminology of StairGaiKONessuna valutazione finora

- Daikin VRV III Heat Pump Sound Pressure Page 181Documento13 pagineDaikin VRV III Heat Pump Sound Pressure Page 181Octavian BumbescuNessuna valutazione finora

- Prestress ConcreteDocumento19 paginePrestress ConcreteAbdulrhman Abduelgassim OsmanNessuna valutazione finora

- ICSE X-Selina-solution-Ch09-Household CircuitsDocumento27 pagineICSE X-Selina-solution-Ch09-Household CircuitsSHERWIN FFNessuna valutazione finora

- BM Dri-Design 6pp WEBDocumento2 pagineBM Dri-Design 6pp WEBBerinaNessuna valutazione finora

- 3889-Article Text-8520-1-10-20180712Documento17 pagine3889-Article Text-8520-1-10-20180712JohnNessuna valutazione finora

- Peri Up Flex Stairs 75 Instructions For Assembly and UseDocumento64 paginePeri Up Flex Stairs 75 Instructions For Assembly and UseswathiNessuna valutazione finora

- HVAC BOQ - HOSPITAL at KozhikkodeDocumento7 pagineHVAC BOQ - HOSPITAL at KozhikkodeVysakhan KrishnanNessuna valutazione finora

- Single-Chamber Type, Inlet and Outlet Area Have The Same SizeDocumento6 pagineSingle-Chamber Type, Inlet and Outlet Area Have The Same SizeSathishkumarNessuna valutazione finora

- Reinforced Concrete Design (RCD - 1) Introduction and Theory III Lecture NotesDocumento26 pagineReinforced Concrete Design (RCD - 1) Introduction and Theory III Lecture NotesColene GammadNessuna valutazione finora