Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cement Plant Operations Handbook, Preview

Caricato da

emad sabriTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cement Plant Operations Handbook, Preview

Caricato da

emad sabriCopyright:

Formati disponibili

The Cement Plant

Operations Handbook

for Dry-Process Plants

Sixth Edition

January 2014

Philip A Alsop,

PhD

Tradeship

Publications Ltd

Cement Plant

Operations Handbook

Sixth Edition

Contents

Section A

Process summaries

1. Introduction

10

1. The basics of cement manufacture-2. History of cement manufacture-3. Portland cement in

today's world

2. Raw materials

14

milling

1. Raw

milling

2.

3. Raw

and

Blending

Crushing-5. Drying

6.

1. Raw materials-2. Raw mix-3. Reserves-4.

Pre-blending- 7. Storage and handling

blending

26

3. Kiln feed

Physics of combustion 4. Burner design 5. Cement kiln burners

8. Modelling

9. Fuel storage and firing systems in practice

10.

-

Alternative and waste fuels

and

cooling

60

and shutdown

12. Plant control

cooling

11.

bypass

Emergency

94

-

Storage of clinker and other components 2. Cement milling

storage-6. Cement dispatch 7. Distribution

7.

10. Kiln mechanical

systems

control -5. Cement

(classifiers) 4. Ball mill circuit

Quality assurance and customer service

3. Separators

-8.

Quality control

2. Chemical

114

Cement and Concrete

analysis 3. Particle size analysis 4. Thermal analysis 5. Microscopy 6. Virtual

Testing Laboratory (VCCTL) 7. Calorimetry 8. Burnability 9. Grindability 10. Physical

testing 11. Process control analysis 12. Chromate passivation 13. Cement quality 14. Setting time 15.

ASTM cement types and specifications

16. European EN 197 cement specification

17. Composite cements

(intergrinds) 18. Supersulphated cement 19. Calcium aluminate cement (CAC) 20. Shrinkage-compensating

21. ISO 9001:2000 Quality management system

22. Concrete problems

cements (SCC)

Sampling

1.

Kiln control -5. Volatiles in the kiln -6. Kiln

9. Clinker

milling

6. Cement

1.

burning-4.

8. Kiln refractories

power

startup

7. Kiln

Burning

1. Chemical reactions-2. Process variants-3. Kiln

-

3.

5.

-11.

2. Fuels

7. Pollutant formation

Insufflation

Chemistry of combustion

6. Heat transfer

34

1.

-

4. Flames and fuels

8.

Maintenance

144

1. Maintenance benefits and costs

2. Failure modes

3. Computerised Maintenance Management Systems

4. Reliability-Centred Maintenance (RCM)

5. Maintenance cost management

6. Maintenance

(CMMS)

organisation 7. Role, planning and control 8. Mobile equipment maintenance 9. People and indicators

-

1. Dust collection

2. Pollution control

9. Environment and pollution control

-

3. ISO 14000

4. Sustainable

154

development and climate change

Contents

Plant

-9. Plant

stage

4. Deceleration

stage

172

reporting 5. Miscellaneous reporting

Typical equipment downtime report

-

4. Downtime

process summary data

Typical

8.

7.

manning

Accounting

2. Investment

justification

3.

Capacity

increase

by

process

change

5. Financial statements

13. Technical and process audits

-

power consumption

5.

194

2. Kiln specific fuel consumption

3. Cement mill specific

Debottlenecking 6. Project audit 7. Risk assessment

Historical performance

4. Other systems

1.

capacity summary

20.

17. Process

18.

16. Maintenance

4.

13.

Quarry 5. Drying 6.

Quality control 14.

Materials analysis -19. Plant

12. Cement

11. Finish mill

15. Dust collectors

3. Communication with stakeholders

10. Clinker

Storage capacity

plant construction

15. Cement

1. New

9. Fuel

202

distribution

8. Kiln

Blending

-

7.

Administration and commercial

2.

milling

Packing and

Raw

14. Plant assessment list

1. General

management accounting

or

Project cost estimation

1. Cost

182

-

12.

3. Acceleration

3. Inventories ard feeders

Typical daily production report

2. List of reports

1. Definitions

stage

168

reporting

-

II.

4.

2. Induction or dormant

stage

I. Initial

6.

of Portland cement

Hydration

10.

plant construction

2.

Project management

and valuation

3. Cement

plant

212

investment costs

Project phases

4.

5. Plant valuation

Section B

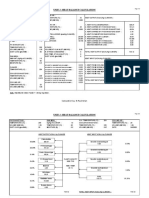

Process calculations

and

MISCELLANEOUS DATA

Bl. Power

4. Motor power output

handling

5. Peak

3.

Impeller build-up 4. Gas properties 5. Plant air distribution 6. Pitots,

loading 9. Stack draught 10. Dewpoint of moist air at atmospheric

-

8. Dust

False air

233

7.

2. Fan mechanical

1. Fan laws

Three-phase power

B2. Fans and air

orifices and Venturis

3.

Specific power consumption 2. Power conservation

power tariffs 6. Power generation 7. Cogeneration

-

1.

231

pressure -11. Spray cooling of gas -12. Abrasion resistance

B3.

Conveying

238

1. Com parative power consumption for lift 2. Pneu matic conveyi ng 3. Bucket elevator power 4. Belt conveyor

power 5. Screw conveyor power-6. Airslide-7. Drag chain power-8. Tube belt conveyor-9. Air-supported belt

-

10. Sandwich conveyor

11. Modified belt conveyor

conveyor

12.

Capsule conveyor

13. Water pump power

Cement Plant

Circulating

load

3. Classifier recovery

Maximum ball size

B5. Kilns

Cement

parameters

required -11. Measurement of wear

and

4.

Tromp curve

8. Mill power

5. Mill

-

critical speed 6. Charge volume

10.

weight and surface area

9. Ball

2.

7. Grace factor and other ball mill

loading

241

-

1. Sieve sizes

1.

Sixth Edition

Milling

-

B4.

Operations Handbook

Effects of gypsum upon setting time

12.

burning

compounds and

247

ratios-2.

Theoretical heat of formation of clinker

-

Coating tendency-3. Burnability factor-4. Required burning temperature

6. Kiln gas velocities

7. Kiln heat balance

8. Kiln specific heat

loading (SHL) 9. Kiln retention time 10. Kiln volume loading 11. Kiln capacity vs diameter 12. Kiln drive

power 13. Cooler efficiency 14. Kiln exhaust gas (coal) -15. Circulation of volatile components -16. Estimation

5.

of kiln

bypass -17.

Other kiln types

B6. Fuels

1.

259

Typical data for solid fuels

B7.

2.

Typical data for liquid fuels

3.

Typical data for gaseous fuels

Materials

261

-

1. Bulk densities of materials for silo storage

2. Specific gravities and grindabilities

3. Solubilities of sulphates

4. Rates of dissolution of different forms of caicium sulphate at 20C

5. Influence of temperature on the

-

solubilities of various

sulphate forms

6. Chemical formula

weights

7. Coefficients of linear

expansion

B8. Statistics

264

B9. Miscellaneous data

269

Atmospheric pressure and density vs altitude (0C) 2. pH and normality 3. Laboratory reagents (aqueous

solutions) 4. Seawater composition 5. Abundance of elements in earth's crust 6. Hardness of materials

7. Earthquake scales 8. Beaufort wind scale

9. World cement production -10. Regional cement consumption

data -11. EU Environmental legislation -12. Ship and truck capacities -13. Patents

1.

3. Pressure

4.

Weight

5. Area

6.

Density

7.

Energy

8. Force

2. Volume

Length

275

-

1.

Conversion tables

-

BIO.

9. Miscellaneous

References

276

Index

287

Advertisers' index

290

Potrebbero piacerti anche

- Thermos Design of Rotary Kiln For Reduction of Radiantion LossesDocumento20 pagineThermos Design of Rotary Kiln For Reduction of Radiantion LossesMadhav Krishna MNessuna valutazione finora

- Rotary KilnDocumento7 pagineRotary KilnhangarrodNessuna valutazione finora

- Cement Plant VIPDocumento51 pagineCement Plant VIPengr kazamNessuna valutazione finora

- Cement Plant Thermal EnergyDocumento7 pagineCement Plant Thermal Energytsrinivasan5083Nessuna valutazione finora

- Cement IndustryDocumento27 pagineCement IndustryAhmed Mahmoud100% (1)

- Bypass SystemsDocumento17 pagineBypass SystemsNael100% (1)

- Mod 4Documento58 pagineMod 4mkpqNessuna valutazione finora

- Rotary Kiln SimulatorDocumento10 pagineRotary Kiln SimulatorPassmore DubeNessuna valutazione finora

- AirslidesDocumento3 pagineAirslidesVisnu SankarNessuna valutazione finora

- Holcim Material Bulk Density PDFDocumento1 paginaHolcim Material Bulk Density PDFEdgar Raul RomeroNessuna valutazione finora

- Abccoolerinleta4 (Air Blast Controlled Cooler Inlet) .AshxDocumento4 pagineAbccoolerinleta4 (Air Blast Controlled Cooler Inlet) .Ashxabosede2013Nessuna valutazione finora

- Mean Residence Time and Hold-Up of Solids in Rotary KilnsDocumento6 pagineMean Residence Time and Hold-Up of Solids in Rotary KilnsAnonymous NxpnI6jCNessuna valutazione finora

- 1Documento5 pagine1Dee HsNessuna valutazione finora

- Loesche Grinding Plants For Coal GasificationDocumento45 pagineLoesche Grinding Plants For Coal GasificationMaxim Polevoy100% (1)

- CPB Brochure Diaphragms en 2Documento12 pagineCPB Brochure Diaphragms en 2ebrahimNessuna valutazione finora

- Optimization of Kiln Plants: Activities and Technical DetailsDocumento10 pagineOptimization of Kiln Plants: Activities and Technical DetailsPaulo VidasNessuna valutazione finora

- Ball Mill InspectionDocumento9 pagineBall Mill InspectionmahantmtechNessuna valutazione finora

- PG 1591-1634 Chap5-RawMealHomogenization TextDocumento44 paginePG 1591-1634 Chap5-RawMealHomogenization TextMKPashaPasha100% (3)

- Mechanical Training PreheatDocumento15 pagineMechanical Training Preheattricky777100% (1)

- Brochure 154 Loesche-Mills For Cement Raw Material EN PDFDocumento24 pagineBrochure 154 Loesche-Mills For Cement Raw Material EN PDFMohammed AbdoNessuna valutazione finora

- New Hardware Grinding Aid - ECOFORDocumento5 pagineNew Hardware Grinding Aid - ECOFORlovjnxNessuna valutazione finora

- Boulder Formation in Cement Silos by Chettinad Cement CoDocumento11 pagineBoulder Formation in Cement Silos by Chettinad Cement CoWaka OngetiNessuna valutazione finora

- Maintenence in Cement Industry ProjectDocumento25 pagineMaintenence in Cement Industry ProjectSUMIT SHARMA95% (19)

- Cement Seminars and Courses 2016Documento68 pagineCement Seminars and Courses 2016Lucas Araújo100% (1)

- Cement ProcessingDocumento28 pagineCement ProcessingRish-ab KanwarNessuna valutazione finora

- Design Guide For Air Slide ConveyorDocumento4 pagineDesign Guide For Air Slide Conveyordoh16810% (1)

- Collaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurDocumento4 pagineCollaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurjmpbarrosNessuna valutazione finora

- Ikn Bee - Meet Ikni r12Documento28 pagineIkn Bee - Meet Ikni r12Junaid MazharNessuna valutazione finora

- KHD Pyroclon EnglDocumento4 pagineKHD Pyroclon Englkresimir.mikoc9765100% (1)

- CSI Guidelines For Co-Processing Fuels and Raw Materials in Cement Manufacturing - v2 PDFDocumento36 pagineCSI Guidelines For Co-Processing Fuels and Raw Materials in Cement Manufacturing - v2 PDFnaldsonNessuna valutazione finora

- Coolax CoolerDocumento19 pagineCoolax Cooleremad sabriNessuna valutazione finora

- Process Costing LafargeDocumento23 pagineProcess Costing LafargeGbrnr Ia AndrntNessuna valutazione finora

- Equip. Name:-RAW MILL Equip. TAG No. 300 RM-1Documento1 paginaEquip. Name:-RAW MILL Equip. TAG No. 300 RM-1vinodsnNessuna valutazione finora

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Documento1 paginaAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaNessuna valutazione finora

- Cement MagazineDocumento31 pagineCement Magazinedexter1850Nessuna valutazione finora

- Cyclone Separators: Learner GuideDocumento14 pagineCyclone Separators: Learner GuideRobson DE Freitas WerlingNessuna valutazione finora

- Raw MillDocumento6 pagineRaw MillRohmi SafitriNessuna valutazione finora

- Burning The Mix 1Documento11 pagineBurning The Mix 1John GiannakopoulosNessuna valutazione finora

- Combustion CalculationesDocumento3 pagineCombustion CalculationesSatish KumarNessuna valutazione finora

- By-Pass Calculation Method - DocbDocumento2 pagineBy-Pass Calculation Method - DocbElwathig BakhietNessuna valutazione finora

- Ball MillDocumento23 pagineBall MillSajjad Rasool ChaudhryNessuna valutazione finora

- 3500TPD Cement Plant Heat BalanceDocumento2 pagine3500TPD Cement Plant Heat BalanceIrshad HussainNessuna valutazione finora

- Kiln Doctor FAQDocumento3 pagineKiln Doctor FAQgvrr1954Nessuna valutazione finora

- RIETVELD TC Champions Training Outline April 2006 V0 280206Documento6 pagineRIETVELD TC Champions Training Outline April 2006 V0 280206Tarek FennicheNessuna valutazione finora

- Gujarat Sidhee Cement Limited-SmitDocumento26 pagineGujarat Sidhee Cement Limited-SmitHimadri MahatoNessuna valutazione finora

- Cement ProcessDocumento14 pagineCement ProcessChristian RuedaNessuna valutazione finora

- Raw MealDocumento48 pagineRaw Mealrashmiranjan1110Nessuna valutazione finora

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDocumento8 pagineSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- Click Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelDocumento26 pagineClick Here To Download Holcim, , Lafarge, Most Importnant Manuals, Most Important ExcelhamedNessuna valutazione finora

- V6 EngineeringDocumento252 pagineV6 EngineeringRRHH100% (1)

- Rotary Kilns: Transport Phenomena and Transport ProcessesDa EverandRotary Kilns: Transport Phenomena and Transport ProcessesValutazione: 4.5 su 5 stelle4.5/5 (4)

- Preview-Cement Plant Operations HandbookDocumento4 paginePreview-Cement Plant Operations Handbookemad sabri0% (1)

- Cpoh6 ContentsDocumento3 pagineCpoh6 ContentsSTABNessuna valutazione finora

- 09-The Cement Plant Operations Handbook, 7th Edition PDFDocumento287 pagine09-The Cement Plant Operations Handbook, 7th Edition PDFNguyen Thanh100% (10)

- Seventh Edition Cement Hand BookDocumento6 pagineSeventh Edition Cement Hand Booksatfas50% (2)

- Cpoh6 Contents PDFDocumento3 pagineCpoh6 Contents PDFHazem DiabNessuna valutazione finora

- Cement Plant Operations Handbook, 5th Edition, PreviewDocumento3 pagineCement Plant Operations Handbook, 5th Edition, Previewemad sabriNessuna valutazione finora

- Cement PlantDocumento232 pagineCement PlantAnonymous iI88Lt100% (1)

- Year 4 Course Brief SPFDocumento4 pagineYear 4 Course Brief SPFMichel IsereNessuna valutazione finora

- Cement Plant Operation HandbookDocumento232 pagineCement Plant Operation HandbookFu_John91% (23)

- Glossary of Conveyor Belt TermsDocumento8 pagineGlossary of Conveyor Belt Termsemad sabriNessuna valutazione finora

- Effective MaintenanceDocumento19 pagineEffective Maintenanceemad sabri100% (1)

- Alternative Fuels in Cement IndustryDocumento25 pagineAlternative Fuels in Cement Industryemad sabri100% (1)

- Alternative Fuels in Cement IndustryDocumento25 pagineAlternative Fuels in Cement Industryemad sabri100% (1)

- 2013 Plant Info Summary Sample PDFDocumento38 pagine2013 Plant Info Summary Sample PDFemad sabriNessuna valutazione finora

- Maintenance Audit SampleDocumento4 pagineMaintenance Audit Sampleemad sabriNessuna valutazione finora

- CementDocumento24 pagineCementanshuldoc9100% (2)

- The Most Important Books of The Cement IndustryDocumento3 pagineThe Most Important Books of The Cement Industryemad sabriNessuna valutazione finora

- IEEE IASPCA 2012 Conference Plant Tours at TXI Hunter Cement PlantDocumento2 pagineIEEE IASPCA 2012 Conference Plant Tours at TXI Hunter Cement Plantemad sabriNessuna valutazione finora

- Operations: The PlantDocumento4 pagineOperations: The Plantemad sabriNessuna valutazione finora

- Alignment StandardsDocumento6 pagineAlignment StandardsFidelFornolles100% (2)

- Chapter 5 - The Role of Tribology in Engineering Materials: Friction, Lubrication and WearDocumento40 pagineChapter 5 - The Role of Tribology in Engineering Materials: Friction, Lubrication and Wearemad sabriNessuna valutazione finora

- The Role of Tribology in Engineering Materials: Friction, Lubrication and WearDocumento40 pagineThe Role of Tribology in Engineering Materials: Friction, Lubrication and Wearemad sabri100% (1)

- Lubrication, Friction and Wear PDFDocumento31 pagineLubrication, Friction and Wear PDFemad sabriNessuna valutazione finora

- Tribology (Surface Roughness and Measurements)Documento12 pagineTribology (Surface Roughness and Measurements)emad sabriNessuna valutazione finora

- Symptoms Causes Remedies: Rolling Bearing DamageDocumento1 paginaSymptoms Causes Remedies: Rolling Bearing Damageemad sabriNessuna valutazione finora

- The Economics of HardfacingDocumento6 pagineThe Economics of Hardfacingemad sabri100% (1)

- Shell InspectionDocumento23 pagineShell Inspectionemad sabri100% (1)

- Factors Affecting PerformanceDocumento33 pagineFactors Affecting Performanceemad sabri100% (1)

- ME-255 Principles of Tribology: Gamit Vipul M.E. (08214) Mechanical Engg - Dept. IiscDocumento14 pagineME-255 Principles of Tribology: Gamit Vipul M.E. (08214) Mechanical Engg - Dept. Iiscemad sabriNessuna valutazione finora

- Arguments and FallaciesDocumento18 pagineArguments and FallaciesSarah Mae Peñaflor Baldon-IlaganNessuna valutazione finora

- Good Parenting 1Documento6 pagineGood Parenting 1honey13Nessuna valutazione finora

- L-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Documento63 pagineL-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Hidayat Ullah100% (3)

- Reaction PaperDocumento2 pagineReaction PaperMisna Blasco Zurbano50% (2)

- Assignment On Training & Development Process of Uniliver BangladeshDocumento9 pagineAssignment On Training & Development Process of Uniliver BangladeshMohaiminul Islam50% (2)

- Segway v1 04 Eng Segway Atv Snarler Manual t3b L7eDocumento192 pagineSegway v1 04 Eng Segway Atv Snarler Manual t3b L7eMarouane LASRYNessuna valutazione finora

- MLA 7th Edition Formatting and Style GuideDocumento14 pagineMLA 7th Edition Formatting and Style Guideapi-301781586Nessuna valutazione finora

- How To Query Asham Tele Points (Telebirr)Documento13 pagineHow To Query Asham Tele Points (Telebirr)Fayisa ETNessuna valutazione finora

- Artikel Jurnal Siti Tsuwaibatul ADocumento11 pagineArtikel Jurnal Siti Tsuwaibatul Aaslamiyah1024Nessuna valutazione finora

- Transco Summary Gudinace For Work Method Statements R 0 300912Documento12 pagineTransco Summary Gudinace For Work Method Statements R 0 300912kla_alk100% (2)

- SP Post ListDocumento54 pagineSP Post ListJoel Eljo Enciso SaraviaNessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityShruti BiradarNessuna valutazione finora

- Banksy Responses Done With A Partner 655512Documento122 pagineBanksy Responses Done With A Partner 655512api-569248887Nessuna valutazione finora

- Reports On TECHNICAL ASSISTANCE PROVIDED by The Teachers To The Learners / Learning FacilitatorsDocumento2 pagineReports On TECHNICAL ASSISTANCE PROVIDED by The Teachers To The Learners / Learning FacilitatorsJerv AlferezNessuna valutazione finora

- 0404 eDocumento80 pagine0404 eFrancisco MisleNessuna valutazione finora

- Questionaire Abusive Supervision SurveyDocumento2 pagineQuestionaire Abusive Supervision SurveyAabee SyedNessuna valutazione finora

- 02.03.05.06.01 - Manage Sales Rebate AgreementDocumento11 pagine02.03.05.06.01 - Manage Sales Rebate AgreementVinoth100% (1)

- 2020-21 Series Test 1 QPDocumento1 pagina2020-21 Series Test 1 QPred18ggmuNessuna valutazione finora

- APTET 2014 Social Question Paper II With Solutions PDFDocumento47 pagineAPTET 2014 Social Question Paper II With Solutions PDFgayathriNessuna valutazione finora

- How To ComboDocumento15 pagineHow To Combosapabapjava2012Nessuna valutazione finora

- Introduction EthicsDocumento26 pagineIntroduction EthicsLawrence MarquezNessuna valutazione finora

- Current Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Documento11 pagineCurrent Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Manoj Digi Loans100% (1)

- Tutorial Probability and Statistics: SolutionsDocumento3 pagineTutorial Probability and Statistics: SolutionsAdnanNessuna valutazione finora

- S&S PDFDocumento224 pagineS&S PDFMohammed MateenNessuna valutazione finora

- Hatton National Bank PLC: Instance Type and TransmissionDocumento2 pagineHatton National Bank PLC: Instance Type and TransmissiontaraNessuna valutazione finora

- Diagram 1 Shows An AbacusDocumento11 pagineDiagram 1 Shows An AbacusHema BalasubramaniamNessuna valutazione finora

- CasDocumento2 pagineCasJamesalbert KingNessuna valutazione finora

- Remembering Thanu Padmanabhan - The HinduDocumento3 pagineRemembering Thanu Padmanabhan - The HinduIucaa libraryNessuna valutazione finora

- Criteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysDocumento5 pagineCriteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysProduction DepartmentNessuna valutazione finora

- Control System Engineering: Topic Block Diagram RepresentationDocumento24 pagineControl System Engineering: Topic Block Diagram RepresentationWaqas AfzalNessuna valutazione finora