Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sample Work Pack

Caricato da

renjithv_4Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sample Work Pack

Caricato da

renjithv_4Copyright:

Formati disponibili

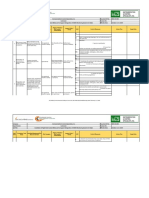

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

WORK O/No.:

LIME PLANT AREA 5

MAINTENANCE AND

SHUT-DOWN TASK

STANDARD TASK

INSTRUCTION:

LKM10

and 11

WORK PACK No.:

LKM10

and 11

ORIGINATOR:

NICAS

SCOPE OF WORK:

Remove and Overhaul Reversal Traps DATE:

EQUIPMENT DESCRIPTION:

Reversal Trap and Stack

EQUIPMENT REGISTER No:

K662-1

ITEM

1.

01.08.08

TECHNICIAN

SIGNATURE

TASK DESCRIPTION DETAILS

DATE

Obtain Permit to Work as per GPM 63.1 standard

tagout procedure.

Check and confirm Isolation(s).

2.

Review Standard Task Instruction and sign.

(Ensure all personnel are aware of tasks and risks.)

3.

Erect barricade below the proposed work and lift

areas to prevent personnel from entering.

Erect sign to advise of danger.

4.

Remove guard from Reversal Trap.

5.

Instrumentation/Electrical personnel to disconnect all

electrical connections to limit switches and electrical

components to facilitate repairs to Reversal Trap.

6.

Disconnect and Cap all hydraulic lines, fittings etc.

7.

Inspect all Hydraulic lines and fittings.

Replace as necessary.

8.

Scaffold Personnel to erect scaffold as instructed by

the Area co-ordinator.

9.

Remove Saddle from stack as shown in figure 3.0.

10.

Position 90 tonne crane and the 140 tonne crane and

prepare for lift and Reversal Trap removal task.

90 tonne crane to be used with Mancage.

140 tonne crane to perform lifts.

Note: Use only authorised rigging personnel,

techniques and equipment.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

1 of 24

GPM-xxx-xxx

Reversal Trap K662-1

ITEM

Lime Plant Area 5 Maintenance and Shut-down Task

TECHNICIAN

SIGNATURE

TASK DESCRIPTION DETAILS

11.

Remove stack Flange Mounting Bolts.

12.

Remove Stack and lower to ground.

13.

Support Combustion Air Ducting as shown in Figure

3.0.

DATE

Note: Use only authorised rigging personnel,

techniques and equipment.

14.

Unbolt and remove Combustion Air Ducting section

and lower to the top of SL662-3, 900 tonne burnt lime

storage silo.

15.

Ensure duct is safe, secure and not fouling walkway.

16.

Support Trouser Leg as shown in Figure 4.0 using

chain block and slings.

17.

Unbolt Lower Flange at trouser leg.

18.

Unbolt Lower Flange of reversal trap.

19.

Remove Reversal Trap and lower to ground.

Note: Insert a 17mm thick Marine Ply section over

the opening left by the removal of the Reversal Trap.

Note: Use only authorised rigging personnel,

techniques and equipment.

20.

Arrange truck and rigging crew to collect Reversal

Trap and transport to workshop for inspection and

repair.

21.

NDT personnel to carry out inspections to the

Reversal Trap and advise of required welding repairs

and procedures.

All welding repairs to be undertaken in site

fabrication shop.

22.

At the completion of welding repairs, the Reversal

Trap is to be transported to the Machine Shop.

23.

Planned Maintenance to inspect reversal and closing

trap Shaft Bearings.

Replace as necessary.

24.

Inspect and replace reversal and closing Trap Seals.

Page:

2 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

ITEM

Reversal Trap K662-1

TECHNICIAN

SIGNATURE

TASK DESCRIPTION DETAILS

25.

Inspect, repair, and replace as necessary, reversal and

closing trap Sealing Plate and Pivot Arm.

26.

Inspect reversal and closing trap counterweight for

wear or damage.

DATE

Repair or replace as necessary.

27.

Inspect Access Door Hinges for wear or damage.

Repair or replace hinges as necessary.

28.

Pressure Test Reversal Trap in workshop.

29.

Test correct operation and function of reversal trap.

30.

Inspect Reversal Trap Stack Refractory for damage or

wear.

Note: The inspections and repairs should be carried

out by suitably qualified Refractory Personnel

31.

Inspect the Inverted Witches Hat for corrosion and

wear.

Repair Inverted Witches Hat as necessary.

32.

Install Inspection Port in each of the Reversal Trap

Stacks. (Modification)

Details of modification to be provided by the Area

Engineer.

33.

Prepare and clean all parts, gasket surfaces, nuts and

bolts etc for the installment of Reversal Traps to the

Kiln.

34.

HOLD POINT. Area Co-ordinator to confirm and

authorise timing of reinstatement of Reversal Trap.

35.

Position 90 tonne crane and the 140 tonne crane.

Prepare for lift and reinstatement of Reversal Trap.

90 tonne crane to be used with Mancage.

140 tonne crane to perform lifts.

Note: Use only authorised rigging personnel,

techniques and equipment.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

3 of 24

GPM-xxx-xxx

Reversal Trap K662-1

ITEM

36.

Lime Plant Area 5 Maintenance and Shut-down Task

TECHNICIAN

SIGNATURE

TASK DESCRIPTION DETAILS

DATE

Raise Reversal Trap to correct level on Kiln.

Note: Use only authorised rigging personnel,

techniques and equipment.

37.

Rig and install Reversal Trap into correct position.

38.

Install bolts to lower flange of Reversal Trap and

tension. (Insert correct bolt tension here)

39.

Install bolts to lower flange at Trouser Leg and

tension. (Insert correct bolt tension here)

40.

Remove chain block and sling support from Trouser

Leg as shown in Figure 4.0.

41.

Raise and affix Combustion Air Ducting section in

correct position. Fit flange bolts and tighten.

90 tonne crane to be used with Mancage.

140 tonne crane to perform lifts.

Note: Use only authorised rigging personnel,

techniques and equipment.

42.

Reinstate Stack to reversal trap.

Note: Use only Authorised rigging personnel,

techniques and equipment.

43.

Reinstate Stack Flange mounting bolts and tension.

(Insert correct bolt tension here)

44.

Inspect and repair/replace as necessary lubrication

lines, purge lubrication points.

Replace automatic lubricator pods as necessary.

45.

Replace hydraulic cylinder with new or reconditioned

unit.

46.

Refit hydraulic hoses to hydraulic cylinder.

47.

Scaffold Personnel to remove scaffold as instructed

by the Area Co-ordinator.

48.

Instrumentation/Electrical personnel to re-connect all

electrical connections and test/check correct function

of limit switches.

49.

Reinstate guard to reversal trap.

Page:

4 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

ITEM

Reversal Trap K662-1

TECHNICIAN

SIGNATURE

TASK DESCRIPTION DETAILS

50.

All areas worked in to be left clean and safe.

51.

Remove Personal Danger Tag and sign off Standard

Clearance Certificate.

RECORD TOTAL HOURS TAKEN TO COMPLETE TASK.

POSITION

JOB TECHNICIAN

DATE

_____________ HOURS

JOB SUPERVISOR

CO-ORDINATOR

Print Name:

Signature:

Date:

IN EVENT OF EMERGENCY

PHONE 222 OR

RADIO CHANNEL 1

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

5 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

Fitters Comments:

Name:

Supervisors Comments:

Name:

Page:

6 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

Reversal Trap K662-1

There are two reversal traps, one located on either side of the Lime Kiln as shown in

Figure 1.0 below.

Figure 1.0: Showing the location of the Reversal Traps

Caution

Erect barricade below the proposed work and lift areas

Erect sign to advise of Danger.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

7 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

Remove the guard from the Reversal Trap.

Instrumentation/Electrical personnel to disconnect all limit switches and electrical

connections to facilitate removal of the Reversal Trap.

Disconnect and cap all hydraulic lines and fittings.

Figure 2.0: Showing the Reversal Trap Guard, Hydraulic Cylinder

and Electrical Equipment

Page:

8 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

Remove the saddle from the stack as shown in Figure 3.0 below.

Position the 90 tonne crane and the 140 tonne crane to prepare for lift and task.

Figure 3.0: Showing the Reversal Trap, Trap Stack and

Combustion Air Ducting

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

9 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

Support the Trouser Leg as shown in Figure 4.0 below using chain block and slings.

Unbolt the lower flange at the trouser leg.

Figure 4.0: Showing Reversal Trap and Trouser Leg

Page:

10 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

Unbolt lower flange mounting bolts of reversal trap as shown below in Figure 5.0.

Rig and prepare to remove the Reversal Trap.

Remove the trap using the 140 tonne crane and lower to the ground.

Figure 5.0: Showing Reversal Trap Lower Mounting Support Bolts

Caution

Insert a 17mm thick Marine Plywood section over the opening

left by the removal of the Reversal Trap.

Secure the plywood to prevent falling or the possibility of it

being blown away and to prevent personnel, tools or other

items falling into the opening.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

11 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

Page:

12 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

STANDARD TASK INSTRUCTION

STI NUMBER:

STI-LKM10

TASK:

WORK GROUP:

Production Maintenance

PREPARED BY:

AREA:

Lime Plant 662

DATE:

Remove and Overhaul Reversal Trap and Stack

CRITICAL TASK? (YES/NO)

REVISON NUMBER:

01.08.2001

Initial Issue

REVISION DATE:

This STI shall be reviewed for correctness and understanding prior to commencement of this particular task and after each Revision.

At these times, all members of the STI team shall sign off over the page.

All new starters on this task shall review this STI with the Supervisor and sign off over the page.

All revisions to this STI must be agreed to by all members of the STI team and recorded on this STI form with the Revision number date upgraded.

SAFETY GEAR, TOOLS, EQUIPMENT, INSTRUCTIONS, PRE-REQUISITES AND COMPETENCIES SPECIFIC TO THIS TASK.

Work Permit Requirements

Confined Space

Personal Protective Equipment (PPE) Requirements

Vessel Entry

Excavation

Hot Work

Electrical Isolation

High Voltage

Scaffolding

Radiation

Personnel Cage

Safe Work

Gas Test

Isolation

Face Shield

Monogoggles

Respirator

Dust Masks

Safety Helmet

Safety Harness

Commissioning

Life Vest

Job Specific Resources

Barricading

Signs

Sentry & Sentry Board

Fire Blankets

Extinguishers

Two-way Radio/

Mobile Phone

Running Water

Life Ring

Voltage Reducer

Standard PPE

Competencies Required

Operator

Boilermaker

USM

Fitter

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

Hearing Protection

Gloves

Sun Protection

Equip./Machinery Required (List)

Elect/Instrt Fitter

140 and 90 tonne Cranes with Mancage Facility

Crane Driver

Rigger

Refractory Personnel

Rigging Equipment, Slings, Shackles, Chain

blocks

Mechanic

SAMPLE WORK PACK

Page:

DocID:

13 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

CTA SCORING

No.

SPECIFIC JOB STEPS

HAZARDS

HAZARD CONTROLS

S

1.

Obtain Permit to Work as per GPM 63.1

standard tagout procedure.

EX

TOTAL

Working on incorrect

equipment.

Check and confirm

isolation(s), correct equipment.

Check and confirm Isolation(s).

2.

Review Standard Task Instruction and

sign. (Ensure all personnel are aware of

tasks and risks.)

Unaware of safety and task

requirements.

Understand safety and task

requirements.

3.

Erect barricade below the proposed work

and lift areas to prevent personnel from

entering. Erect sign to advise of danger.

Sprain, strains.

Use correct lifting techniques.

4.

Remove guard from Reversal Trap.

Cuts and abrasions.

Correct area PPE, wear gloves.

5.

Instrumentation/Electrical personnel to

disconnect all electrical connections to

limit switches and electrical components to

facilitate removal of Reversal Traps.

Electrocution.

Ensure correct isolation before

commencement of task.

Test circuits to ensure isolation

6.

Disconnect and cap all hydraulic lines,

fittings etc.

Oil spill

Slip, fall.

Clean and contain oil spillage

immediately.

7.

Inspect all hydraulic lines and fittings.

Replace as necessary.

Oil spill

Slip, fall.

Clean and contain oil spillage

immediately.

Page:

14 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

8.

9.

10.

11.

Scaffold personnel to erect scaffold as

instructed from the Area co-ordinator.

Remove saddle from stack as shown in

Figure 3.0.

Position 90 tonne crane and the 140 tonne

crane to prepare for lift and Reversal Trap

removal task.

Remove stack flange mounting bolts.

Reversal Trap K662-1

Working at heights

Sprain, strains.

Ensure area below is

barricaded.

Ensure no personnel enter

barricaded area.

Use correct lifting techniques.

Working at heights

Ensure area below is

barricaded.

Ensure no personnel enter

barricaded area.

Sprain, strains

90 tonne crane to be used with

Mancage. 140 tonne crane to

perform lifts.

Use only authorised rigging

personnel, techniques and

equipment

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

15 of 24

GPM-xxx-xxx

Reversal Trap K662-1

12.

13.

Lime Plant Area 5 Maintenance and Shut-down Task

Remove stack and lower to ground using

140 tonne crane.

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

Sprain, strains

Use correct lifting techniques.

Support combustion air ducting as shown

in Figure 3.0.

Note: Use only authorised rigging

personnel, techniques and equipment.

14.

Unbolt and remove combustion air ducting

section and lower to the top of SL662-3,

900 tonne burnt lime storage silo.

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

15.

Ensure duct is safe, secure and not fouling

walkway.

Sprain, strains

Trip, fall.

Use correct lifting techniques.

Good housekeeping.

Page:

16 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

16.

Support trouser leg as shown in Figure 4.0

using chain block and slings.

Sprain, strains.

Use only authorised rigging

personnel, techniques and

equipment.

17.

Unbolt lower flange at trouser leg.

Sprain, strains.

Use correct lifting techniques.

18.

Unbolt lower flange of reversal trap.

Sprain, strains.

Use correct lifting techniques.

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

Remove Reversal trap and lower to

ground.

19.

Note: Insert a 17mm thick Marine Ply

section over the opening left by the

removal of the Reversal Trap.

20.

Arrange truck and rigging crew to collect

Reversal Trap and transport to workshop

for inspection and repair.

Sprain, strains.

Use only authorised rigging

personnel, techniques and

equipment.

21.

NDT personnel to carry out inspections to

the Reversal Trap and advise of required

welding repairs and procedures.

All welding repairs to be undertaken in site

fabrication shop.

Cuts and abrasions

Noise from grinder

Welding flashes to eyes.

Wear gloves.

Wear hearing protection.

Erect weld barricade if

required.

22.

At the completion of welding repairs, the

Reversal Trap is to be transported to the

Machine Shop.

Sprain, strains.

Use correct lifting techniques.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

17 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

23.

Planned Maintenance to inspect reversal

and closing trap Shaft Bearings.

Replace as necessary.

Cuts and abrasions.

Correct area PPE, wear gloves.

24.

Inspect and replace reversal and closing

Trap Seals.

Cuts and abrasions.

Correct area PPE, wear gloves.

25.

Inspect, repair, and replace as necessary,

reversal and closing trap sealing plate and

pivot arm.

Cuts and abrasions.

Correct area PPE, wear gloves.

26.

Inspect reversal and closing trap

Counterweight for wear or damage.

Repair or replace as necessary.

Cuts and abrasions.

Correct area PPE, wear gloves.

27.

Inspect access door hinges for wear or

damage.

Repair or replace hinges as necessary.

Cuts and abrasions.

Correct area PPE, wear gloves.

28.

Pressure test Reversal Trap in workshop.

Cuts and abrasions.

Correct area PPE, wear gloves.

29.

Test correct operation and function of

reversal trap.

Cuts and abrasions.

Correct area PPE, wear gloves.

30.

Inspect Reversal Trap Stack Refractory for

damage or wear.

Cuts and abrasions.

Correct area PPE, wear gloves.

31.

Inspect the inverted witches hat for

corrosion and wear.

Repair inverted witches hat as necessary.

Cuts and abrasions.

Correct area PPE, wear gloves.

Page:

18 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

32.

Install inspection port in each of the

Reversal Trap Stacks. (Modification)

Details of modification to be provided by

the Area Engineer.

Cuts and abrasions.

Correct area PPE, wear gloves.

33.

Prepare and clean all parts, gasket

surfaces, nuts and bolts etc for the

installment of Reversal Traps to the Kiln.

Cuts and abrasions.

Correct area PPE, wear gloves.

34.

HOLD POINT Area Co-ordinator to

confirm and authorise timing of

reinstatement of Reversal Trap.

Sprain, strains

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

35.

36.

Position 90 tonne crane and the 140 tonne

crane and prepare for lift and reinstatement

of Reversal Trap.

Raise Reversal Trap to correct level on

Kiln.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

19 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

37.

Rig and install Reversal Trap into correct

position.

Sprain, strains

Use only authorised rigging

personnel, techniques and

equipment.

38.

Install bolts to lower flange of reversal trap

and tension. (Insert correct tension)

Cuts and abrasions

Correct area PPE, wear gloves.

39.

Install bolts to lower flange at trouser leg

and tension. (Insert correct tension)

Cuts and abrasions

Correct area PPE, wear gloves.

40.

Remove chain block and sling support

from trouser leg as shown in Figure 4.0.

Sprain, strains

Use only authorised rigging

personnel, techniques and

equipment.

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

41.

Raise and affix combustion air ducting

section in correct position. Fit flange bolts

and tighten.

Note: 90 tonne crane to be used with

Mancage. 140 tonne crane to perform

lifts.

42.

Reinstate stack to Reversal Trap.

Page:

20 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

43.

Reinstate stack flange mounting bolts and

tension. (Insert correct tension)

Working at heights

Falling objects.

Ensure area below is

barricaded.

Ensure no personnel enter

crane working radius or

barricaded area.

Use only authorised rigging

personnel, techniques and

equipment.

44.

Inspect and repair/replace as necessary

lubrication lines, purge lubrication points.

Replace automatic lubricator pods as

necessary.

Sprain, strains

Cuts and abrasions.

Use correct lifting techniques.

Correct area PPE, wear gloves

45.

Replace hydraulic cylinder with new or

reconditioned unit.

Sprain, strains.

Use correct lifting techniques.

Correct area PPE, wear gloves.

46.

Refit hydraulic hoses to hydraulic cylinder.

Sprain, strains.

Use correct lifting techniques.

Correct area PPE, wear gloves.

47.

Scaffold Personnel to remove scaffold as

instructed by the Area co-ordinator.

Working at heights

Sprain, strains.

Ensure area below is

barricaded.

Ensure no personnel enter

barricaded area.

Use correct lifting techniques.

48.

Instrumentation/Electrical personnel to

re-connect all electrical connections and

test/check correct function of limit

switches.

Electrocution.

Authorised personnel only.

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

SAMPLE WORK PACK

Page:

DocID:

21 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

49.

Reinstate guard to reversal trap.

Cuts and abrasions.

Use correct lifting techniques.

Correct area PPE, wear gloves.

50.

All areas worked in to be left clean and

safe.

Trip, fall

Good housekeeping.

51.

Remove Personal Danger Tag and sign off

Standard Clearance Certificate.

SCORING: S = Severity EX = Exposure P = Probability.

Task steps are measured on a scale of 10 for Severity, Exposure and Probability.

Critical steps are level 7 or higher. They are denoted by a red criticality rating within a red hexagon and the critical step is surrounded by double red

thick and thin lines.

Page:

22 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Lime Plant Area 5 Maintenance and Shut-down Task

Reversal Trap K662-1

I HAVE REVIEWED THIS STANDARD TASK INSTRUCTION

This STI shall be reviewed for correctness and understanding prior to commencement of this particular task. All members of this task MUST SIGN in the presence of the Job Supervisor.

I confirm that I have read and understand the Tasks, Risks and Hazards associated with this Maintenance Task.

NAME

DATE

NAME

Issued:

01.08.2001

Filename:

Document Owner:

Area Mgr

Authorised:

DATE

SAMPLE WORK PACK

NAME

Page:

DocID:

DATE

23 of 24

GPM-xxx-xxx

Reversal Trap K662-1

Lime Plant Area 5 Maintenance and Shut-down Task

Table 1.0: APL Listing for Reversal Trap K662-1

Page:

24 of 24

Filename:

DocID:

GPM-xxx-xxx

Authorised:

SAMPLE WORK PACK

Issued:

Document Owner:

01.08.2001

Area Mgr

Potrebbero piacerti anche

- Piping Design To AS4041 & ASME B31.3Documento3 paginePiping Design To AS4041 & ASME B31.3Roozbeh PNessuna valutazione finora

- 01.05.2021 Method Statement For Electrical & InstrumentationDocumento6 pagine01.05.2021 Method Statement For Electrical & InstrumentationPangky Abasolo100% (1)

- Bordwell NarrationDocumento22 pagineBordwell NarrationRoozbeh PNessuna valutazione finora

- E100 Wash Water Tie-In (TAR)Documento128 pagineE100 Wash Water Tie-In (TAR)Murtadda MohammedNessuna valutazione finora

- FM 200 Maintenance ProcedureDocumento2 pagineFM 200 Maintenance Procedureultrasonic81Nessuna valutazione finora

- Lifting & Installation Pipes Plan - Romp 05Documento6 pagineLifting & Installation Pipes Plan - Romp 05syed khaja misbhuddinNessuna valutazione finora

- KP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksDocumento7 pagineKP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksUtku Can KılıçNessuna valutazione finora

- SHEM-SP-08.10 Work Permits ProcedureDocumento74 pagineSHEM-SP-08.10 Work Permits ProcedureAjith Kumar AjithNessuna valutazione finora

- Grating Decking and Floor Removal FormDocumento2 pagineGrating Decking and Floor Removal FormMohamed Abd ElhaleemNessuna valutazione finora

- Testing and Commissioning Procedure: 2017 EDITIONDocumento26 pagineTesting and Commissioning Procedure: 2017 EDITIONvin ssNessuna valutazione finora

- Roteq Capability StatementDocumento10 pagineRoteq Capability StatementRoozbeh PNessuna valutazione finora

- Work Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1Documento8 pagineWork Pack - Guide For Reviewing Mechanical Engineering Work Packs - Rev1mkash028100% (4)

- Value Of Work Done A Complete Guide - 2020 EditionDa EverandValue Of Work Done A Complete Guide - 2020 EditionNessuna valutazione finora

- Structural Inspection Checklist For FactoryDocumento1 paginaStructural Inspection Checklist For FactoryAnonymous FD64zqL6S100% (1)

- LDIP-P1-Site Daily Report-SECM&E-June 24 2013Documento3 pagineLDIP-P1-Site Daily Report-SECM&E-June 24 2013Giang Cao Tho100% (1)

- FinFan Technical InfoDocumento15 pagineFinFan Technical InfoRoozbeh PNessuna valutazione finora

- Advanced Oilfield Technology Company LLC: Work ProcedureDocumento6 pagineAdvanced Oilfield Technology Company LLC: Work ProcedureAhmed M. AbdelazizNessuna valutazione finora

- Bathroom VentilationDocumento3 pagineBathroom VentilationRoozbeh PNessuna valutazione finora

- Sop Installing PumpDocumento4 pagineSop Installing Pumpilham100% (1)

- Attendance ListDocumento2 pagineAttendance ListYusup MulyanaNessuna valutazione finora

- Control and Operation of Centrifugal Gas CompressorsDocumento6 pagineControl and Operation of Centrifugal Gas CompressorsRoozbeh PNessuna valutazione finora

- Testing and Commissioning Procedure FOR Catering Equipment Installation IN Government Buildings OF The Hong Kong Special Administrative RegionDocumento29 pagineTesting and Commissioning Procedure FOR Catering Equipment Installation IN Government Buildings OF The Hong Kong Special Administrative RegionAzam Faiez MokhtarNessuna valutazione finora

- ITR-C (Instrument) 16cDocumento1 paginaITR-C (Instrument) 16cMomo ItachiNessuna valutazione finora

- Planned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyDocumento1 paginaPlanned Preventive Maintenance Task Sheet: PPM No PPM Equipment Dish Washer Frequency QuarterlyMdrahaman Mithu100% (2)

- Setia Precast SDN BHD: Emergency Response and Preparedness PlanDocumento20 pagineSetia Precast SDN BHD: Emergency Response and Preparedness PlanAisamuddin Rohaizai100% (1)

- Method Statement For LPG DismantlingDocumento8 pagineMethod Statement For LPG DismantlingHusain abidiNessuna valutazione finora

- Achieve Operations Reliability With APMDocumento11 pagineAchieve Operations Reliability With APMRoozbeh PNessuna valutazione finora

- Sample WorkpackDocumento9 pagineSample WorkpackKhairun Mohamad IshakNessuna valutazione finora

- Flygt IOM 3153-095Documento72 pagineFlygt IOM 3153-095jose03Nessuna valutazione finora

- CRSE-SA-T-775 Monthly Quality Management Report For The Month of July 2020Documento65 pagineCRSE-SA-T-775 Monthly Quality Management Report For The Month of July 2020Ahmad Assad mrednNessuna valutazione finora

- Template-Post Shutdown ReportDocumento3 pagineTemplate-Post Shutdown Reportarief bayuNessuna valutazione finora

- Site Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Documento16 pagineSite Acceptance Test Contract No.: 537856: 863013-VPS-PQM-E-DS-0002Andry YanuarNessuna valutazione finora

- Checklist For Pressure Testing Safely 2Documento2 pagineChecklist For Pressure Testing Safely 2Jonathan CambaNessuna valutazione finora

- ITP For Hydraulic BarrierDocumento4 pagineITP For Hydraulic Barriermoytabura96Nessuna valutazione finora

- Nma100776 O&m-Section 1 PDFDocumento23 pagineNma100776 O&m-Section 1 PDFMichael CaoNessuna valutazione finora

- Method Statement For Ultrasonic Testing: DCSM Project 2019Documento5 pagineMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenNessuna valutazione finora

- Pre-Mobilisation Assurance Checklist BackupDocumento7 paginePre-Mobilisation Assurance Checklist BackupNazrin SHONessuna valutazione finora

- FAT & SAT For Electrical System in Utility EndDocumento16 pagineFAT & SAT For Electrical System in Utility EndBabuNessuna valutazione finora

- Section 712-Mechanical-Commissioning Spare Part Rev.0 PDFDocumento2 pagineSection 712-Mechanical-Commissioning Spare Part Rev.0 PDFKari SmithNessuna valutazione finora

- PETI ChecklistDocumento1 paginaPETI Checklistwan nazeriNessuna valutazione finora

- Example Workpack For AodDocumento63 pagineExample Workpack For Aodapi-3745449100% (3)

- Safety Inspection Report: KLL (I)Documento1 paginaSafety Inspection Report: KLL (I)Ega NugrahaNessuna valutazione finora

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocumento1 paginaAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairNessuna valutazione finora

- PDO SP-2275 Specification For Lifting and Hoisting Equipment Inspection and Testing Requirements. Version 01.Documento1 paginaPDO SP-2275 Specification For Lifting and Hoisting Equipment Inspection and Testing Requirements. Version 01.Quality controller100% (1)

- 7 QC ToolsDocumento155 pagine7 QC Toolswintoday01Nessuna valutazione finora

- PPI - Personal Protective Equipment Issue - Version 3 September 2014Documento2 paginePPI - Personal Protective Equipment Issue - Version 3 September 2014chelios20% (1)

- PTW MatrixDocumento1 paginaPTW Matrixjinyuan74100% (1)

- Confined Space Rescue Plan: Description of The WorkDocumento2 pagineConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Documento11 pagineJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNessuna valutazione finora

- Transmittal SampleDocumento1 paginaTransmittal SamplekokocdfNessuna valutazione finora

- BFP Oil FlushingDocumento19 pagineBFP Oil FlushingParthiban KarunaNessuna valutazione finora

- 43 - Checklist of Pumps For Monthly PMDocumento6 pagine43 - Checklist of Pumps For Monthly PMSiraj AhmedNessuna valutazione finora

- Cooling Tower TNCDocumento6 pagineCooling Tower TNCAarol Hatta100% (1)

- Mset Engineering SDN BHD: Door End Closure Replacement MLNG (PL 291)Documento3 pagineMset Engineering SDN BHD: Door End Closure Replacement MLNG (PL 291)BhisamS SallehNessuna valutazione finora

- S5134 Ethernet IO Modules: 8 Channels Universal AI, 8 Channels AO 8 Channels DO, 3channels DIDocumento10 pagineS5134 Ethernet IO Modules: 8 Channels Universal AI, 8 Channels AO 8 Channels DO, 3channels DIanaklurah siniNessuna valutazione finora

- JSA - Winstar Pipeline CrossingDocumento6 pagineJSA - Winstar Pipeline CrossingRidha BennasrNessuna valutazione finora

- NCR Form ExampleDocumento1 paginaNCR Form ExampleFrank BarnesNessuna valutazione finora

- Bearing Housing Assembly Procedure EXTERNALDocumento10 pagineBearing Housing Assembly Procedure EXTERNALAlejandroZegarraNessuna valutazione finora

- Catalogo Chaglin YZ12HDDocumento4 pagineCatalogo Chaglin YZ12HDIwa RizaNessuna valutazione finora

- Punch List - Substation 2 - ELEDocumento1 paginaPunch List - Substation 2 - ELExu tao daiNessuna valutazione finora

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocumento8 pagineMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNessuna valutazione finora

- ITP Plan - FF PDFDocumento7 pagineITP Plan - FF PDFAltaf KhanNessuna valutazione finora

- AYC IC & ITP - GRP Shade InstallationDocumento7 pagineAYC IC & ITP - GRP Shade Installationmoytabura96Nessuna valutazione finora

- ITCC in Riyadh Residential Complex J10-13300 11172 - 1 Garbage CompactorDocumento5 pagineITCC in Riyadh Residential Complex J10-13300 11172 - 1 Garbage CompactoruddinnadeemNessuna valutazione finora

- Exhibit A-Scope of Work1 - 230315 - 122413Documento11 pagineExhibit A-Scope of Work1 - 230315 - 122413Nada AmmarNessuna valutazione finora

- LDO Unloading PumpDocumento3 pagineLDO Unloading PumpSamNessuna valutazione finora

- Energies: Experimental Fitting of The Re-Scaled Balje Maps For Low-Reynolds Radial TurbomachineryDocumento15 pagineEnergies: Experimental Fitting of The Re-Scaled Balje Maps For Low-Reynolds Radial TurbomachineryRoozbeh PNessuna valutazione finora

- Amtrol Extrol Expantion Tank SpecsDocumento8 pagineAmtrol Extrol Expantion Tank SpecsRoozbeh PNessuna valutazione finora

- DOE Fact Sheet Manufacturing RD - 0Documento1 paginaDOE Fact Sheet Manufacturing RD - 0Roozbeh PNessuna valutazione finora

- Scada and Telemetry in Gas Transmission SystemsDocumento4 pagineScada and Telemetry in Gas Transmission SystemsRoozbeh PNessuna valutazione finora

- Ampeak 2015Documento12 pagineAmpeak 2015Roozbeh PNessuna valutazione finora

- Advances in High Strength Technology For Natural Gas TransmissionDocumento1 paginaAdvances in High Strength Technology For Natural Gas TransmissionRoozbeh PNessuna valutazione finora

- Marg-E Ivan IlychDocumento9 pagineMarg-E Ivan IlychRoozbeh PNessuna valutazione finora

- LNG SummitDocumento19 pagineLNG SummitRoozbeh PNessuna valutazione finora

- Compressed Air Ref EngDocumento118 pagineCompressed Air Ref Engchidambaram kasiNessuna valutazione finora