Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manual Transmission

Caricato da

Autof FerreiraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manual Transmission

Caricato da

Autof FerreiraCopyright:

Formati disponibili

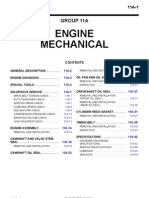

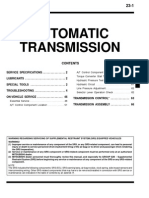

22-1

MANUAL

TRANSMISSION

CONTENTS

22109000319

LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Transmission Oil Replacement . . . . . . . . . . . . . . . . 3

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TRANSMISSION CONTROL* . . . . . . . . . . . . . . . . 4

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 3

TRANSMISSION ASSEMBLY . . . . . . . . . . . . . . . . 6

Transmission Oil Check . . . . . . . . . . . . . . . . . . . . . . . 3

WARNING REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICULES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring, side impact sensors and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

22-2

MANUAL TRANSMISSION - Lubricant/Special Tools

LUBRICANT

22100040242

Item

Specified lubricant

Quantity L

Transmission oil

Hypoid gear oil SAE 75W - 90 or 75W - 85W

conforming to API GL-4

2.2

SPECIAL TOOLS

Tool

22100060187

Number

Name

Use

MB990635 or

MB991113

Steering linkage

puller

Ball joint disconnection

GENERAL

SERVICE

TOOL

MZ203827

Engine lifter

Supporting the engine assembly during

removal and installation of the transmission

MB991453

Engine hanger

MANUAL TRANSMISSION - On-vehicle Service

ON-VEHICLE SERVICE

22-3

22100090124

TRANSMISSION OIL CHECK

Transmission oil

Filler plug hole

(1) Remove the oil filler plug.

(2) Oil level should be at the lower portion of the filler plug

hole.

(3) Check that the transmission oil is not noticeably dirty,

and that it has a suitable viscosity.

(4) Tighten the filler plug to the specified torque.

Tightening torque: 32 Nm

TRANSMISSION OIL REPLACEMENT

Filler plug

22100100247

(1) Remove the drain plug to drain oil.

(2) Tighten the drain plug to the specified torque.

(3) Remove the filler plug and fill with specified oil till the

level comes to the lower portion of filler plug hole.

Transmission oil

32 Nm

Drain plug

Specified oil:

Hypoid gear oil SAE 75W - 90 or 75W - 85W

conforming to API GL-4

Quantity: 2.2 L

(4) Tighten the filler plug to the specified torque.

22-4

MANUAL TRANSMISSION - Transmission Control

TRANSMISSION CONTROL

22100380238

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Air Cleaner Assembly Removal and Installation

D Battery and Battery Tray Removal and Installation

Caution: SRS

Be careful not to subject the SRS-ECU to any

shocks during removal and installation of the

shift cable and select cable assembly.

8

12 Nm

1

8

5

10

11

2

3

12 Nm

12

14

13

"BA

"BA

"BA

"AA

"AA

"AA

Shift cable and select cable

assembly removal steps

D Lower cover and side cover (Refer

to GROUP 52A - Instrument Panel.)

1. Shift knob

2. Spring washer

3. Nut

D Floor console box

(Refer to GROUP 52A.)

4. Snap pin

5. Select cable connection

(Shift lever side)

6. Clip

7. Shift cable connection

(Shift lever side)

8. Snap pin

9. Select cable connection

(Transmission side)

10. Shift cable connection

(Transmission side)

11. Shift cable and select cable

assembly

Shift lever assembly removal steps

"BA 1. Shift knob

"BA 2. Spring washer

"BA 3. Nut

D Floor console box

(Refer to GROUP 52A.)

4. Snap pin

5. Select cable connection

(Shift lever side)

6. Clip

7. Shift cable connection

(Shift lever side)

12. Shift lever assembly

13. Distance piece

14. Bushing

MANUAL TRANSMISSION - Transmission Control

22-5

INSTALLATION SERVICE POINTS

Shift lever

"AA SHIFT CABLE AND SELECT CABLE ASSEMBLY/

SHIFT CABLE CONNECTION/SELECT CABLE

CONNECTION

(1) Set the transmission side shift lever and the passenger

compartment side shift lever to the neutral position.

Neutral position

(2) For the transmission side, the white and yellow paint

marks on the shift and select cable ends should face

the snap pins.

(3) Move the shift lever to all positions and check that the

operation is smooth.

"BA NUT/SPRING WASHER/SHIFT KNOB

INSTALLATION

(1) Screw in the nut all the way by hand, turn back half

a turn, and then insert the spring washer.

(2) Screw in the shift knob until it touches the spring washer,

and make one more turn. Then turn more to adjust the

shift pattern on the shift knob.

(3) If the above steps are impossible, you can turn back

the shift knob by one turn at most after screwing in all

the way to adjust the shift pattern.

22-6

MANUAL TRANSMISSION - Transmission Control

SHIFT LEVER ASSEMBLY

DISASSEMBLY AND REASSEMBLY

22100400101

5 Nm

9

6

6 Nm

7

3

3

1

4

5

Disassembly steps

1. Bolt

2. Select lever

3. Bushing

4. Return spring

5. Collar

10

6.

7.

8.

9.

10.

Cap

Spacer

Shift lever

Shift lever bushing

Lever bracket

22-7

MANUAL TRANSMISSION - Transmission Assembly

TRANSMISSION ASSEMBLY

22100270290

REMOVAL AND INSTALLATION

Pre-removal Operation

D Transmission Oil Draining (Refer to P.22-3.)

D Under Cover Removal

D Battery and Battery Tray Removal

D Air Cleaner Assembly Removal

Post-installation Operation

D Air Cleaner Assembly Installation

D Battery and Battery Tray Installation

D Under Cover Installation

D Transmission Oil Supplying (Refer to P.22-3.)

D Check the Dust Cover for Cracks or Damage by

Pushing it with Finger.

D Shift Lever Operation Check

D Speedometer Operation Check

D Wheel Alignment Adjustment

(Refer to GROUP 33A - On-vehicle Service.)

5 <4G6>

19 Nm

5 <4D6, 6A1>

19 Nm

1

103 Nm

19 Nm

44 Nm

9

88

Nm*1

98 - 118 Nm*1

10

8

15

15

10 - 12 Nm

81 Nm

12

30 Nm

11

30 Nm

24 - 33 Nm

81 Nm

67 - 78 Nm

14

13

88 Nm

98 - 118 Nm

AA"

Removal steps

1. Select cable connection

2. Shift cable connection

3. Backup lamp switch connector

4. Vehicle speed sensor connector

5. Clutch release cylinder connection

6. Clutch fluid line damper connection

7. Starter motor <6A1>

8. Tie rod end connection

9. Stabilizer link connection

10. Damper fork

AB"

AC"

11.

12.

13.

14.

15.

No.2 stay

Lateral lower arm connection

No.3 stay

Compression lower arm connection

Drive shaft

Caution

*1: Indicates parts which should be temporarily

tightened, and then fully tightened with the

vehicle on the ground in the unladen condition.

22-8

MANUAL TRANSMISSION - Transmission Assembly

57 Nm

16

18

81 Nm*2

49 Nm

19

17

25

19

30 Nm

24

10 - 12 Nm

24 49 Nm

22

25 Nm

49 Nm

57 Nm*2

23

44 Nm

7 Nm

20

10Nm <Flange bolts>

9Nm <Washer assembled bolts>

21

69 Nm

93 Nm

69 - 78 Nm

16. Starter motor <4G6, 4D6>

17. Transmission assembly upper part

coupling bolts

AD"

18. Transmission mount bracket

"AA 19. Transmission mount stopper

AE"

D Engine and transmission assembly

supporting

20. Centermember assembly

21. Rear roll stopper

22. Bell housing cover <4G6, 4D6>

AF"

AF"

23. Cover <6A1>

24. Transmission assembly lower part

coupling bolts

25. Transmission assembly

Caution

Mounting locations marked by *2 should be

provisionally tightened, and then fully tightened after

placing the vehicle horizontally and loading the full

weight of the engine on the vehicle body.

MANUAL TRANSMISSION - Transmission Assembly

22-9

REMOVAL SERVICE POINTS

Cord

AA" TIE ROD END DISCONNECTION

Ball joint

MB990635 or

MB991113

Caution

1. Use the special tool to loosen the tie rod end mounting

nut. Only loosen the nut; do not remove it from the

ball joint.

2. Support the special tool with a cord, etc. not to let

it come off.

Nut

AB" NO.3 STAY REMOVAL

No.3 stay is tightened together with the crossmember.

Therefore, after removing No.3 stay, install the nut and bolt

to the crossmember provisionally.

No.3 stay

Crossmember

Transmission

side

Pry bar

AC" DRIVE SHAFT DISCONNECTION

(1) Insert a pry bar between the transmission case and the

drive shaft as shown to remove the drive shaft.

NOTE

Do not remove the hub and knuckle from the drive shaft.

Caution

Always use a pry bar, or the TJ will be damaged.

(2) Suspend the removed drive shaft with a wire so that

there are no sharp bends in any of the joints.

(3) Use a shop towel to cover the transmission case not

to let foreign material get into it.

AD" TRANSMISSION MOUNT BRACKET REMOVAL

Jack up the transmission assembly gently with a garage jack,

and then remove the transmission mount bracket.

22-10

MANUAL TRANSMISSION - Transmission Assembly

MZ203827

AE" ENGINE AND TRANSMISSION ASSEMBLY

SUPPORTING

Set the special tool to the vehicle to support the engine and

transmission assembly.

MB991453

Flywheel

Bolt

AF" TRANSMISSION ASSEMBLY LOWER PART

COUPLING BOLTS/TRANSMISSION ASSEMBLY

REMOVAL

1. Support the transmission assembly with a transmission

jack.

2. Remove the transmission assembly lower part coupling

bolts, and lower the transmission assembly to remove.

Caution

Do not remove the flywheel mounting bolt shown in

the illustration. If this bolt is removed, the flywheel

will become out of balance and damaged.

INSTALLATION SERVICE POINTS

Engine side

"AA TRANSMISSION MOUNT STOPPER INSTALLATION

Install the transmission mount stopper so that the arrow points

as shown in the illustration.

Arrow

Transmission

mount

bracket

Transmission

mount

stopper

Potrebbero piacerti anche

- 4L60E Overhaul ManualDocumento185 pagine4L60E Overhaul Manualanon_89043510089% (56)

- Nissan Navara Workshop Manual CLDocumento22 pagineNissan Navara Workshop Manual CLbdsisira89% (9)

- Subaru - Impreza - Workshop Manual - 1999 - 2002Documento8.373 pagineSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- A 240Documento89 pagineA 240Mario Diaz Lopez100% (1)

- Toyota Corolla+c52 Shift ManualDocumento221 pagineToyota Corolla+c52 Shift Manualdaswine100% (4)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Repair ManualDocumento132 pagineRepair Manualicechieff96% (24)

- Steering System Service ManualDocumento36 pagineSteering System Service Manualmybdt1691Nessuna valutazione finora

- Powershit CatDocumento36 paginePowershit CatFrancisco Mariños100% (1)

- Ax 5 TransDocumento33 pagineAx 5 TransCarlos Gabriel EstergaardNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Automotive Air Conditioning and Climate Control SystemsDa EverandAutomotive Air Conditioning and Climate Control SystemsValutazione: 4 su 5 stelle4/5 (6)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorDa EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- Mitsubishi 4 g63 Turbo PDFDocumento48 pagineMitsubishi 4 g63 Turbo PDFAlexandru UngureanuNessuna valutazione finora

- DP0 / AL4 Technical NoteDocumento58 pagineDP0 / AL4 Technical NoteSimone C89% (9)

- Dynamometer: Theory and Application to Engine TestingDa EverandDynamometer: Theory and Application to Engine TestingNessuna valutazione finora

- Omd Graviner Mk6 ManualDocumento90 pagineOmd Graviner Mk6 ManualChristis SavvaNessuna valutazione finora

- Engine Lubrication System: SectionDocumento23 pagineEngine Lubrication System: Sectiontomallor101Nessuna valutazione finora

- Fuel System: SectionDocumento13 pagineFuel System: Sectiontomallor101Nessuna valutazione finora

- Rear AxleDocumento6 pagineRear AxleThomas A. EDISSONNessuna valutazione finora

- Clutch: SectionDocumento22 pagineClutch: SectionMatea Virgil SorinNessuna valutazione finora

- Engine Lubrication System: SectionDocumento32 pagineEngine Lubrication System: Sectionfrank1220uNessuna valutazione finora

- Pajero Timing BeltDocumento44 paginePajero Timing Beltguzzi1100100% (2)

- GR00000700 11C PDFDocumento52 pagineGR00000700 11C PDFNicu PascalutaNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Payment InstructionDocumento2 paginePayment InstructionNeel PatelNessuna valutazione finora

- Pruebas y Ajustes Trannmision 928gDocumento23 paginePruebas y Ajustes Trannmision 928gManuel RamosNessuna valutazione finora

- QA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #Documento3 pagineQA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #deva017Nessuna valutazione finora

- Content Analysis in The Social Sciences From Manual To Automated ApproachesDocumento75 pagineContent Analysis in The Social Sciences From Manual To Automated Approachesdiablero999Nessuna valutazione finora

- Tranny 722 RepairDocumento159 pagineTranny 722 Repairpaschov100% (3)

- Subsea Pipeline Engineering (Indonesia) - ElisaDocumento5 pagineSubsea Pipeline Engineering (Indonesia) - ElisaMheErdiantoNessuna valutazione finora

- NessusDocumento23 pagineNessusShivaprakash TimmapurNessuna valutazione finora

- What Are The Good Research QuestionDocumento26 pagineWhat Are The Good Research Questionkavindukarunarathna100% (2)

- GR00004900 22a PDFDocumento18 pagineGR00004900 22a PDFNicu PascalutaNessuna valutazione finora

- 22sPACE WAGONDocumento16 pagine22sPACE WAGONrafaelcruzgjaNessuna valutazione finora

- Manual TransmissionDocumento16 pagineManual TransmissionKalGeorgeNessuna valutazione finora

- 2g MT OverhaulDocumento148 pagine2g MT OverhaulMatt BushnellNessuna valutazione finora

- GR00002000 15 PDFDocumento12 pagineGR00002000 15 PDFNicu PascalutaNessuna valutazione finora

- 23A Automatic TransaxleDocumento81 pagine23A Automatic Transaxletakedashinden100% (1)

- Intake and ExhaustDocumento8 pagineIntake and ExhaustAlexandre Da Silva PintoNessuna valutazione finora

- Ajustes de Transmision CaterpillarDocumento23 pagineAjustes de Transmision CaterpillarPlstina RamsNessuna valutazione finora

- GR00006300 35a PDFDocumento26 pagineGR00006300 35a PDFNicu PascalutaNessuna valutazione finora

- F5M42 Transmission Service ManualDocumento54 pagineF5M42 Transmission Service ManualTim Zimmer100% (4)

- Clutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .Documento8 pagineClutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - .rafaelcruzgjaNessuna valutazione finora

- MANUAL TRANSM Mitsu PDFDocumento20 pagineMANUAL TRANSM Mitsu PDFtanotopNessuna valutazione finora

- Accelerator Control System: SectionDocumento8 pagineAccelerator Control System: SectionRichard Wilson Mera JaimeNessuna valutazione finora

- Subaru-Legacy 2005 EN Manual de Taller Sistema Transmision Embrague Caja Automatica 1dbe02a483Documento45 pagineSubaru-Legacy 2005 EN Manual de Taller Sistema Transmision Embrague Caja Automatica 1dbe02a483miguelNessuna valutazione finora

- 41 Manual Transmission TransaxleDocumento85 pagine41 Manual Transmission TransaxleTung NguyenNessuna valutazione finora

- Power Steering: Group 37Documento50 paginePower Steering: Group 37Yago BgNessuna valutazione finora

- SLK Trans RemovalDocumento3 pagineSLK Trans RemovalMarl Dominic M. BonbonNessuna valutazione finora

- FL PDFDocumento19 pagineFL PDFSantiago LopezNessuna valutazione finora

- Desmontaje Caja Manual TucsonDocumento13 pagineDesmontaje Caja Manual TucsonJose Luis BastidasNessuna valutazione finora

- Desmontaje de Motor OutlanderDocumento8 pagineDesmontaje de Motor OutlanderErick Mauricio Chavez Neira100% (1)

- Improvement of Seal To Prevent Oil Leaks From Seal Transmission D85ESS-2 (AJ20004A)Documento8 pagineImprovement of Seal To Prevent Oil Leaks From Seal Transmission D85ESS-2 (AJ20004A)ary guswantoroNessuna valutazione finora

- Fuel System: SectionDocumento15 pagineFuel System: SectionRonildo GirardiNessuna valutazione finora

- Manual Eclipse 06Documento68 pagineManual Eclipse 06Ángel PastranaNessuna valutazione finora

- Clutch: SectionDocumento16 pagineClutch: Sectiontomallor101Nessuna valutazione finora

- Clutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - . .Documento8 pagineClutch Master Cylinder 7 - . - . - . - . - . - . - . - . - . - . - . .Alexandre Da Silva PintoNessuna valutazione finora

- M34b Master Cylinder PDFDocumento9 pagineM34b Master Cylinder PDFLuis MarquezNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Troubleshooting: Troubleshooting The 604 (41TE) The 604 (41TE)Documento4 pagineTroubleshooting: Troubleshooting The 604 (41TE) The 604 (41TE)Autof FerreiraNessuna valutazione finora

- MOST Bus Diagnostics: Initial Print Date: 02/04 Revision DateDocumento11 pagineMOST Bus Diagnostics: Initial Print Date: 02/04 Revision DateAutof FerreiraNessuna valutazione finora

- MSB 99e00 002eDocumento6 pagineMSB 99e00 002eAutof FerreiraNessuna valutazione finora

- MSB 99e42 003eDocumento5 pagineMSB 99e42 003eAutof FerreiraNessuna valutazione finora

- Service BulletinDocumento3 pagineService BulletinAutof FerreiraNessuna valutazione finora

- Service BulletinDocumento3 pagineService BulletinAutof FerreiraNessuna valutazione finora

- Service BulletinDocumento2 pagineService BulletinAutof FerreiraNessuna valutazione finora

- 23Documento70 pagine23Autof FerreiraNessuna valutazione finora

- SB ListDocumento1 paginaSB ListAutof FerreiraNessuna valutazione finora

- Engine LubricationDocumento10 pagineEngine LubricationAutof FerreiraNessuna valutazione finora

- MSB 98e54 501Documento3 pagineMSB 98e54 501Autof FerreiraNessuna valutazione finora

- MSB 97e55 001 PDFDocumento12 pagineMSB 97e55 001 PDFAutof FerreiraNessuna valutazione finora

- MSB 97e17 502 PDFDocumento10 pagineMSB 97e17 502 PDFAutof FerreiraNessuna valutazione finora

- Braemar ApplicationDocumento2 pagineBraemar Applicationjoemedia0% (1)

- Face Recognition Using Back Propagation Neural NetworkDocumento1 paginaFace Recognition Using Back Propagation Neural NetworkMayank OnkarNessuna valutazione finora

- Kalkhoff Users ManualDocumento148 pagineKalkhoff Users Manualanonms_accNessuna valutazione finora

- FE Yeet GUIDocumento3 pagineFE Yeet GUINobodyNessuna valutazione finora

- Terminal - Exam - Section 4A-4B - Signal & System FA14 COMSATDocumento3 pagineTerminal - Exam - Section 4A-4B - Signal & System FA14 COMSATAli RazaNessuna valutazione finora

- Final Project Miguel Santana GallegoDocumento44 pagineFinal Project Miguel Santana GallegoDaniel PereiraNessuna valutazione finora

- A Car Parking Guard Circuit Using Infrared SensorDocumento9 pagineA Car Parking Guard Circuit Using Infrared Sensorhamed razaNessuna valutazione finora

- Arun Et al-2019-ChemistrySelectDocumento8 pagineArun Et al-2019-ChemistrySelectRavi Kumar ARunNessuna valutazione finora

- Applies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)Documento5 pagineApplies To:: The Beginner's Guide To Oracle Solaris Patching (ID 1005835.1)apletonprinceNessuna valutazione finora

- Fi SlingDocumento4 pagineFi SlingSony TogatoropNessuna valutazione finora

- Split Panasonic Cspc18dkqDocumento16 pagineSplit Panasonic Cspc18dkqMaria de VillalobosNessuna valutazione finora

- An Introduction To Error-Correcting Codes: The Virtues of RedundancyDocumento38 pagineAn Introduction To Error-Correcting Codes: The Virtues of RedundancyKrish Cs20Nessuna valutazione finora

- WEdu Abroad - Study Abroad E-GuidebookDocumento111 pagineWEdu Abroad - Study Abroad E-GuidebookRithyKhouyNessuna valutazione finora

- If Then ElseDocumento10 pagineIf Then Elseapi-297910907Nessuna valutazione finora

- The Dilemma of The Last FilipinoDocumento12 pagineThe Dilemma of The Last FilipinoEunice Delos SantosNessuna valutazione finora

- Brosur Hari GuruDocumento8 pagineBrosur Hari GuruFitri SharifNessuna valutazione finora

- Technology and Culture - ReadingDocumento3 pagineTechnology and Culture - ReadingBraulio Pezantes100% (1)

- Whirlpool SPIW318A2WF Air ConditionerDocumento324 pagineWhirlpool SPIW318A2WF Air ConditionerAxxNessuna valutazione finora

- ResumeDocumento3 pagineResumeabreddy2003Nessuna valutazione finora

- Sky Spark White PaperDocumento7 pagineSky Spark White PaperJohn KablerNessuna valutazione finora

- Patrick C Hall@yahoo - com-TruthfinderReportDocumento13 paginePatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithNessuna valutazione finora

- En 10268Documento4 pagineEn 10268Alex LacerdaNessuna valutazione finora

- Uniport Data Capture PortalDocumento1 paginaUniport Data Capture PortalPrince AdieNessuna valutazione finora