Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

14 PDF

Caricato da

Autof FerreiraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

14 PDF

Caricato da

Autof FerreiraCopyright:

Formati disponibili

14-1

ENGINE

COOLING

CONTENTS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 2

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 2

14109000208

Engine Coolant Replacement . . . . . . . . . . . . . . . . . 10

Concentration Measurement . . . . . . . . . . . . . . . . . . 11

Fan Controller Check . . . . . . . . . . . . . . . . . . . . . . . . 12

LUBRICANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Fan Control Relay Continuity Check . . . . . . . . . . 12

SEALANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

WATER PUMP

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . 3

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 9

Engine Coolant Leak Checking . . . . . . . . . . . . . . . . 9

Radiator Cap Opening Pressure

Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

<4G6> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

<6A1> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

<4D6> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

WATER HOSE AND WATER PIPE . . . . . . . . 19

RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14-2

ENGINE COOLING -

General Information/

Service Specifications/Lubricant/Sealants

GENERAL INFORMATION

14100010217

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.

The water pump is of the centrifugal type and is

driven by the timing belt or drive belt from the

crankshaft.

The radiator is the corrugated fin, down flow type

and is cooled by the electrical radiator fan.

The cooling fans are controlled by a fan controller

and the engine-ECU depending on driving

conditions.

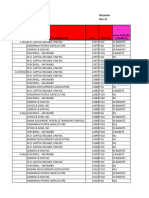

Items

Specifications

Radiator

Performance kJ/h

A/T oil cooler

Performance kJ/h

4G6

175,800

6A1

200,900

4D6

213,500

4G6

5,700

6A1, 4D6

7,100

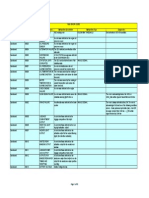

SERVICE SPECIFICATIONS

14100030091

Items

Standard value

Limit

Radiator cap opening pressure kPa

74 - 103

64

Range of coolant antifreeze concentration of radiator %

30 - 60

Valve opening temperature of thermostat _C

82 1.5

Full-opening temperature of thermostat _C

95

Valve lift (at 95_C) mm

8.5 or more

Thermostat

LUBRICANT

14100040148

Items

HIGH QUALITY ETHYLENE GLYCOL

ANTIFREEZE COOLANT

Quantity L

4G6, 6A1

4D6

SEALANTS

14100050172

Items

Specified sealant

Remarks

Cylinder block drain plug

3M Nut Locking Part No. 4171 or equivalent

Drying sealant

Water pump <6A1>,

Thermostat case assembly <4G6, 4D6>,

Water outlet fitting <4D6>

Mitsubishi Genuine Parts No. MD970389 or

equivalent

Semi-drying sealant

14-3

ENGINE COOLING - Special Tool/Troubleshooting

SPECIAL TOOL

Tool

A

14100060038

Number

Name

Use

MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222

Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: probe

Measurement of terminal voltage

A: Connector pin contact pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester connection

TROUBLESHOOTING

14100560019

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptoms

Inspection procedure

No.

Reference page

Radiator fan and condenser fan do not operate. <Vehicles with A/C>

Radiator fan does not operate. <Vehicles without A/C>

14-3

Radiator fan and condenser fan do not change speed or stop.

<Vehicles with A/C>

Radiator fan does not change speed or stop. <Vehicles without A/C>

14-6

Radiator fan does not operate. <Vehicles with A/C>

14-8

Condenser fan does not operate. <Vehicles with A/C>

14-8

INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Inspection Procedure 1

Radiator fan and condenser fan do not operate.

<Vehicles with A/C>

Radiator fan does not operate. <Vehicles without A/C>

Probable cause

The cause could be a malfunction of the fan controller power supply or earth circuit.

The cause could also be a malfunction of the fan controller or the engine-ECU.

D

D

D

D

D

Malfunction

Malfunction

Malfunction

Malfunction

Malfunction

of

of

of

of

of

fusible link

fan control relay

fan controller

engine-ECU

wiring harness or connector

14-4

ENGINE COOLING - Troubleshooting

<Vehicles with A/C>

D

D

Fusible links (4) and (7) check

Fan control relay check (Refer to P.14-12.)

NG

Replace

OK

1. NG

Measure at the fan control relay connector B-20X.

D Remove the relay, and measure at the harness side connector.

1. Voltage between 4 and body earth

2. NG

OK: Battery voltage

2. Voltage between 3 and body earth (Ignition switch: ON)

OK: Battery voltage

3. NG

3. Continuity between 1 and body earth

OK: Continuity

OK

1. NG

Measure at the fan controller connector A-22.

D Disconnect the connector, and measure at the harness side

connector.

2. NG

1. Voltage between 3 and body earth (Ignition switch: ON)

OK: Battery voltage

2. Continuity between 1 and body earth

OK: Continuity

OK

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Voltage between 21 and body earth

(Engine: idling, A/C switch: ON)

OK: 0.7 V or more (When A/C compressor is operating)

<4D6>

D Voltage between 18 and body earth

(Engine: idling, A/C switch: ON)

OK: 0.7 V or more (When A/C compressor is operating)

OK

NG

Check the harness wire between fan control relay and fusible link

(4), and repair if necessary.

Check the harness wire between fan control relay and fusible link

(7), and repair if necessary.

Check the harness wire between fan control relay and body earth,

and repair if necessary.

Check the harness wire between fan controller and fan control

relay, and repair if necessary.

Check the harness wire between fan controller and body earth,

and repair if necessary.

Check the harness wire between fan controller and engine-ECU.

OK

NG

Repair

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NG

OK

Replace

Check the automatic compressor-ECU <manual air conditioner>

or A/C-ECU <automatic air conditioner>, and repair if necessary.

(Refer to GROUP 55 - Troubleshooting.)

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Pull out the terminal No.21 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor and condenser fan motor operate.

<4D6>

D Pull out the terminal No.18 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor and condenser fan motor operate.

YES

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NOTE

*1: 4G6

*2: 6A1

*3: 4D6

NO

Replace the radiator fan motor and fan controller assembly.

14-5

ENGINE COOLING - Troubleshooting

<Vehicles without A/C>

D

D

Fusible links (4) and (7) check

Fan control relay check (Refer to P.14-12.)

NG

Replace

OK

1. NG

Measure at the fan control relay connector B-20X.

D Remove the relay, and measure at the harness side connector.

1. Voltage between 4 and body earth

2. NG

OK: Battery voltage

2. Voltage between 3 and body earth (Ignition switch: ON)

OK: Battery voltage

3. NG

3. Continuity between 1 and body earth

OK: Continuity

OK

1. NG

Measure at the fan controller connector A-22.

D Disconnect the connector, and measure at the harness side

connector.

2. NG

1. Voltage between 3 and body earth (Ignition switch: ON)

OK: Battery voltage

2. Continuity between 1 and body earth

OK: Continuity

OK

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Voltage between 21 and body earth (Engine: idling)

OK: 0.7 V or more (When radiator fan is operating)

<4D6>

D Voltage between 18 and body earth (Engine: idling)

OK: 0.7 V or more (When radiator fan is operating)

NG

Check the harness wire between fan control relay and fusible link

(4), and repair if necessary.

Check the harness wire between fan control relay and fusible link

(7), and repair if necessary.

Check the harness wire between fan control relay and body earth,

and repair if necessary.

Check the harness wire between fan controller and fan control

relay, and repair if necessary.

Check the harness wire between fan controller and body earth,

and repair if necessary.

Check the harness wire between fan controller and engine-ECU.

OK

NG

Repair

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

OK

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Pull out the terminal No.21 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor operates.

<4D6>

D Pull out the terminal No.18 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor operates.

YES

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NOTE

*1: 4G6

*2: 6A1

*3: 4D6

NO

Replace the radiator fan motor and fan controller assembly.

14-6

ENGINE COOLING - Troubleshooting

Inspection Procedure 2

Radiator fan and condenser fan do not change speed or

stop. <Vehicles with A/C>

Radiator fan does not change speed or stop.

<Vehicles without A/C>

Probable cause

The fan controller carries out step-free control of the radiator fan motor and the condenser

fan motor speeds using signals transmitted from the engine-ECU.

D

D

D

D

Malfunction

Malfunction

Malfunction

Malfunction

of

of

of

of

fan control relay

fan controller

engine-ECU

wiring harness or connector

<Vehicles with A/C>

Fan control relay check (Refer to P.14-12.)

NG

Replace

OK

D

D

D

Check the harness wire between fan control relay and fusible

link (7).

Check the harness wire between fan control relay and body

earth.

Check the harness wire between fan control relay and fan

controller.

OK

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Voltage between 21 and body earth

(Engine: idling, engine coolant temperature: 80_C or less)

OK: 0 - 0.3 V (Engine: idling, A/C switch: ON)

OK: 0.7 V or more (When A/C compressor is operating)

<4D6>

D Voltage between 18 and body earth

(Engine: idling, engine coolant temperature: 80_C or less)

OK: 0 - 0.3 V (Engine: idling, A/C switch: ON)

OK: 0.7 V or more (When A/C compressor is operating)

NG

NG

Check the harness wire between fan controller and engine-ECU.

NG

OK

Repair

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NG

OK

Replace

Check the automatic compressor-ECU <manual air conditioner>

or A/C-ECU <automatic air conditioner>, and repair if necessary.

(Refer to GROUP 55 - Troubleshooting.)

OK

Fan controller check (Refer to P.14-12.)

OK

Repair

NG

Replace the radiator fan motor and fan controller assembly.

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Pull out the terminal No.21 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor and condenser fan motor operate.

D Connect the terminal No.21 to the body earth (Ignition switch: ON)

OK: The radiator fan motor and condenser fan motor stop.

<4D6>

D Pull out the terminal No.18 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor and condenser fan motor operate.

D Connect the terminal No.18 to the body earth (Ignition switch: ON)

OK: The radiator fan motor and condenser fan motor stop.

YES

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NOTE

*1: 4G6

*2: 6A1

*3: 4D6

NO

Replace the radiator fan motor and fan controller assembly.

14-7

ENGINE COOLING - Troubleshooting

<Vehicles without A/C>

Fan control relay check (Refer to P.14-12.)

NG

Replace

OK

D

D

D

Check the harness wire between fan control relay and fusible

link (7).

Check the harness wire between fan control relay and body

earth.

Check the harness wire between fan control relay and fan

controller.

OK

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Voltage between 21 and body earth

(Engine: idling, engine coolant temperature: 80_C or less)

OK: 0 - 0.3 V (Engine: idling)

OK: 0.7 V or more (When radiator fan is operating)

<4D6>

D Voltage between 18 and body earth

(Engine: idling, engine coolant temperature: 80_C or less)

OK: 0 - 0.3 V (Engine: idling)

OK: 0.7 V or more (When radiator fan is operating)

OK

Fan controller check (Refer to P.14-12.)

NG

NG

Repair

Check the harness wire between fan controller and engine-ECU.

OK

NG

Repair

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NG

Replace the radiator fan motor and fan controller assembly.

OK

Measure at the engine-ECU connectors C-34*1, C-33*2, C-53*3.

D Connect the connector.

<Except 4D6>

D Pull out the terminal No.21 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor operates.

D Connect the terminal No.21 to the body earth (Ignition switch: ON)

OK: The radiator fan motor stops.

<4D6>

D Pull out the terminal No.18 to disconnect it (Ignition switch: ON)

OK: The radiator fan motor operates.

D Connect the terminal No.18 to the body earth (Ignition switch: ON)

OK: The radiator fan motor stops.

YES

Engine-ECU terminal voltage check (Refer to GROUP 13A - Troubleshooting.)

NOTE

*1: 4G6

*2: 6A1

*3: 4D6

NO

Replace the radiator fan motor and fan controller assembly.

14-8

ENGINE COOLING - Troubleshooting

Inspection Procedure 3

Radiator fan does not operate. <Vehicles with A/C>

Probable cause

The cause could be a malfunction of the radiator fan motor or an open circuit between

the fan controller and the radiator fan motor.

D

D

Malfunction of radiator fan motor

Open circuit between fan controller and radiator fan

motor

Replace the radiator fan motor and fan controller assembly.

Inspection Procedure 4

Condenser fan does not operate. <Vehicles with A/C>

Probable cause

The cause could be a malfunction of the condenser fan motor or of the fan controller.

D

D

D

Condenser fan motor check (Refer to

GROUP 55.)

OK

Replace the radiator fan motor and fan

controller assembly.

NG

Condenser fan motor connector

OK

Check the trouble symptom.

Malfunction of condenser fan motor

Malfunction of fan controller

Malfunction of wiring harness or connector

NG

NG

Repair

Replace the condenser fan motor.

ENGINE COOLING - On-vehicle Service

ON-VEHICLE SERVICE

Cap adapter

Adapter

14-9

14100100136

ENGINE COOLANT LEAK CHECKING

1. Confirm that the coolant level is up to the filler neck.

Install a radiator cap tester and apply 160 kPa pressure,

and then check for leakage from the radiator hose or

connections.

Caution

(1) Be sure to completely clean away any moisture

from the places checked.

(2) When the tester is taken out, be careful not to

spill any coolant from it.

(3) Be careful, when installing and removing the tester

and when testing, not to deform the filler neck

of the radiator.

2. If there is leakage, repair or replace the appropriate part.

RADIATOR CAP OPENING PRESSURE CHECK

14100130159

Cap adapter

1. Use a cap adapter to attach the cap to the tester.

2. Increase the pressure until the indicator of the gauge

stops moving.

Limit: 64 kPa

Standard value: 74 - 103 kPa

3. Replace the radiator cap if the reading does not remain

at or above the limit.

NOTE

Be sure that the cap is clean before testing, since rust

or other foreign material on the cap seal will cause an

improper indication.

14-10

ENGINE COOLING - On-vehicle Service

ENGINE COOLANT REPLACEMENT

14100120231

1. Drain the engine coolant by removing the drain plug and

then the radiator cap.

2. Remove the drain plug from the cylinder block to drain

the engine coolant.

Cylinder block drain plug

<4G6>

<4D6>

<6A1> Front bank

<6A1> Rear bank

3. Remove the reserve tank to drain the engine coolant.

4. When the engine coolant has drained, pour in water from

the radiator cap to clean the engine coolant line.

<6A1>

<4G6, 4D6>

5. Coat the thread of the cylinder block drain plug with the

specified sealant and tighten to the specified torque.

Specified sealant:

3M Nut Locking Part No. 4171 or equivalent

6. Securely tighten the radiator drain plug.

7. Install the reserve tank.

39 Nm

44 Nm

14-11

ENGINE COOLING - On-vehicle Service

<6A1>

Water outlet

fitting

Air bleed bolt

12 - 15 Nm

8. Remove the air bleed bolt and replace the seal washer.

9. Fill the radiator until the engine coolant flows from the

air bleed bolt section, and then close the air bleed bolt.

Seal washer

10. Slowly pour the engine coolant into the mouth of the

radiator until the radiator is full, and pour also into the

reserve tank up to the FULL line.

Recommended antifreeze:

HIGH QUALITY ETHYLENE GLYCOL ANTIFREEZE

COOLANT

Quantity:

<4G6, 6A1> 6 L

<4D6> 8 L

NOTE

For Norway, the non-amine type of antifreeze should be

used.

11. Install the radiator cap securely.

12. Start the engine and warm the engine until the thermostat

opens. (Touch the radiator hose with your hand to check

that warm water is flowing.)

13. After the thermostat opens, race the engine several times,

and then stop the engine.

14. Cool down the engine, and then pour engine coolant

into the reserve tank until the level reaches the FULL

line. If the level is low, repeat the operation from step

11.

CONCENTRATION MEASUREMENT

14100110146

Measure the temperature and specific gravity of the engine

coolant to check the antifreeze concentration.

Standard value: 30 - 60 % (allowable concentration range)

RECOMMENDED ANTIFREEZE

Antifreeze

Allowable concentration

HIGH QUALITY ETHYLENE

GLYCOL ANTIFREEZE COOLANT

30 - 60 %

Caution

If the concentration of the antifreeze is below 30 %, the

anti-corrosion property will be adversely affected. In

addition, if the concentration is above 60 %, both the

anti-freezing and engine cooling properties will decrease,

affecting the engine adversely. For these reasons, be

sure to maintain the concentration level within the

specified range.

14-12

ENGINE COOLING - On-vehicle Service

FAN CONTROLLER CHECK

Fan controller

14100610011

1. Remove the fan controller mounting bolt, and then

disconnect the condenser fan motor connector.

2. Start the engine and run it at idle.

3. Turn the A/C switch to ON and maintain the coolant

temperature at 80_C or less.

4. When measuring the voltage between the fan

controller-side connector terminals, check that the value

changes repeatedly as indicated by (1) - (3) below.

(1) 0 V

(2) <4G6> 8.2 2.6 V

<Except 4G6> 6.8 2.6 V

(3) Battery voltage 2.6 V

5. If the voltage does not repeatedly change as indicated,

replace the radiator fan motor and the fan controller

assembly.

FAN CONTROL RELAY CONTINUITY CHECK

14100620014

Fan control relay

Battery voltage

Terminal No.

1

When current is not

supplied

When current

supplied

is

14-13

ENGINE COOLING - Thermostat

THERMOSTAT

14100240265

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Engine Coolant Draining and Supplying

(Refer to P.14-10.)

D Air Cleaner and Air Intake Hose Assembly Removal

and Installation

<4G6>

Air Hose and Air Pipe Assembly Removal and

Installation <4D6> (Refer to P.14-21.)

4

13 Nm

6

7

3

<6A1>

4

17 - 20 Nm

6

7

3

<4D6>

12 - 15 Nm

13 Nm

12 - 15 Nm

6

1

Removal steps

1. Heater hose connection <4D6>

2. Water hose connection <4D6>

AA" "BA 3. Radiator lower hose connection

4. Control wiring harness mounting

bolt

5. Fuel pipe mounting bolt <4D6>

6. Water inlet fitting

"AA 7. Thermostat

14-14

ENGINE COOLING - Thermostat

REMOVAL SERVICE POINT

AA" RADIATOR LOWER HOSE DISCONNECTION

After making mating marks on the radiator hose and the hose

clamp, disconnect the radiator hose.

INSTALLATION SERVICE POINTS

Jiggle valve

"AA THERMOSTAT INSTALLATION

Install the thermostat so that the jiggle valve is facing straight

up.

Caution

Make absolutely sure that no oil is adhering to the rubber

ring of the thermostat. In addition, be careful not to fold

over or scratch the rubber ring when inserting. If the

rubber ring is damaged, replace the thermostat.

Rubber ring

"BA RADIATOR LOWER HOSE CONNECTION

1. Insert each hose as far as the projection of the water

inlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

14100250275

THERMOSTAT CHECK

1. Immerse the thermostat in water, and heat the water while

stirring. Check the thermostat valve opening temperature.

Standard value:

Valve opening temperature: 821.5_C

2. Check that the amount of valve lift is at the standard

value when the water is at the full-opening temperature.

Standard value:

Full-opening temperature: 95_C

Amount of valve lift: 8.5 mm or more

Valve lift

NOTE

Measure the valve height when the thermostat is fully

closed, and use this measurement to calculate the valve

height when the thermostat is fully open.

14-15

ENGINE COOLING - Water Pump <4G6>

WATER PUMP <4G6>

14100270363

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Engine Coolant Draining and Supplying

(Refer to P.14-10.)

D Timing Belt Tensioner Pulley Removal

Installation (Refer to GROUP 11.)

and

Bolt specifications

8 60

8 22

1

8 14

8 25

3

20 - 25 Nm

2

24 Nm

2

8 22

Screw diameter length mm

12 - 15 Nm

Removal steps

1. Alternator brace

2. Water pump

3. Water pump gasket

"AA 4. O-ring

INSTALLATION SERVICE POINT

Water pump

O-ring

Water inlet pipe assembly

"AA O-RING INSTALLATION

Insert the O-ring to the water inlet pipe assembly, and coat

the outer circumference of the O-ring with water or engine

coolant.

Caution

Do not allow engine oil or other greases to adhere to

the O-ring

14-16

ENGINE COOLING - Water Pump <6A1>

WATER PUMP <6A1>

14100270370

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Engine Coolant Draining and Supplying

(Refer to P.14-10.)

D Power Steering Fluid Draining and Supplying

(Refer to GROUP 37A - On-vehicle Service.)

D Radiator Removal and Installation (Refer to P.14-24.)

D A/C Compressor Removal and Installation

(Refer to GROUP 55.)

D

D

Timing Belt Removal and Installation

(Refer to GROUP 11.)

Engine Mount Bracket Removal and Installation (Refer

to GROUP 32.)

Bolt specifications

8 30

8 25

8 25

8 20

39 Nm

24 Nm

4

5

8 30

8 30

Screw diameter length mm

49 Nm

f3mm

5

3

12 Nm

8 25

39 Nm

18 Nm

Sealant:

Mitsubishi Genuine Part

MD970389 or equivalent

AA"

Removal steps

1. Pressure tube connection

2. Power steering oil pump assembly

3. Power steering oil pump bracket

4. Engine support bracket

"AA 5. Water pump

No.

ENGINE COOLING - Water Pump <6A1>

14-17

REMOVAL SERVICE POINT

AA" POWER STEERING OIL PUMP ASSEMBLY

REMOVAL

Remove the power steering oil pump assembly with the hoses

still attached.

NOTE

Secure the removed oil pump with rope, etc. in a place where

it will not be in the way when removing and installing the

power steering oil pump bracket.

INSTALLATION SERVICE POINT

"AA WATER PUMP INSTALLATION

Squeeze out the sealant from the tube evenly and apply

it so that there is not too much sealant and no places without

sealant.

Specified Sealant:

Mitsubishi Genuine Part No. MD970389 or equivalent

14-18

ENGINE COOLING - Water Pump <4D6>

WATER PUMP <4D6>

14100270387

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Engine Coolant Draining and Supplying

(Refer to P.14-10.)

D Timing Belt Idler Pulley Removal and Installation

(Refer to GROUP 11.)

4

24 Nm

Bolt specifications

8 25

8 22

3

8 65

24 Nm

8 20

12 - 15 Nm

8 22

Screw diameter length mm

Removal steps

1. Alternator brace

2. Water pump

3. Water pump gasket

"AA 4. O-ring

Water pump

O-ring

Water inlet pipe assembly

INSTALLATION SERVICE POINT

"AA O-RING INSTALLATION

Insert the O-ring to the water inlet pipe assembly, and coat

the outer circumference of the O-ring with water or engine

coolant.

Caution

Do not allow engine oil or other greases to adhere to

the O-ring

ENGINE COOLING - Water Hose and Water Pipe

WATER HOSE AND WATER PIPE

14-19

14100330306

REMOVAL AND INSTALLATION

<4G6>

Pre-removal and Post-installation Operation

D Engine Coolant Draining and Suppling

(Refer to P.14-10.)

D Air Cleaner and Air Intake Hose Assembly Removal

and Installation

4

2

24 Nm

13 Nm

5

7

10

1

13 Nm

7

12

11

9

f3mm

Sealant:

Mitsubishi Genuine Part No.

MD970389 or equivalent

Removal steps

AA" "CA 1. Radiator lower hose connection

2. Control wiring harness mounting

bolt

3. Water inlet fitting

4. Engine coolant temperature gauge

unit connector

5. Water hose

6. Heater hose connection

"BA 7. Thermostat case assembly

"AA 8. O-ring

9. Heater hose connection

10. Water hose

11. Water inlet pipe assembly

"AA 12. O-ring

14-20

ENGINE COOLING - Water Hose and Water Pipe

<6A1>

Pre-removal and Post-installation Operation

D Engine Coolant Draining and Supplying

(Refer to P.14-10.)

D Air Cleaner and Air Intake Hose Assembly Removal

and Installation

Distributor Removal and Installation

(Refer to GROUP 16.)

10 - 12 Nm

22 - 25 Nm

8

1

7

6

13

10

11

4

12 - 15 Nm

16

14

22 - 25 Nm

15

12

12 - 15 Nm

22 Nm

19

39 Nm

17

18

27 - 33 Nm

Removal steps

1. Control wiring harness mounting

bolt

2. Spark plug cable clamp mounting

bolt

AA" "CA 3. Radiator upper hose connection

AA" "CA 4. Radiator lower hose connection

5. Engine coolant temperature sensor

connector

6. Engine coolant temperature gauge

unit connector

7. Water hose

8. Water hose

9.

10.

"AA 11.

12.

13.

"AA 14.

15.

"AA 16.

17.

18.

19.

Heater hose connection

Heater pipe assembly

O-ring

Water hose

Thermostat case assembly

O-ring

Water inlet pipe assembly

O-ring

Water hose

Water pipe assembly

Water pipe joint

14-21

ENGINE COOLING - Water Hose and Water Pipe

<4D6>

Pre-removal operation

D Engine Coolant Draining (Refer to P.14-10.)

D Air Cleaner and Air Intake Hose Assembly Removal

Post-installation Operation

D Engine Coolant Supplying (Refer to P.14-10.)

D Engine Oil Supplying and Checking (Refer to

GROUP 11 - On-vehicle Service.)

D Air Cleaner and Air Intake hose Assembly

Installation

17 Nm

11

9

7

10

1

17 Nm

20 - 25 Nm

45 Nm

6 Nm

2

6 Nm

10 - 12 Nm

9 Nm

10 - 13 Nm

12 - 15 Nm

5

4

12 - 15 Nm

12

12 - 15 Nm

10 - 12 Nm

13

12 - 15 Nm

Removal steps

1. Air hose and air pipe assembly

AA" "CA 2. Radiator upper hose connection

AA" "CA 3. Radiator lower hose connection

4. Heater hose connection

5. Turbocharger heat protector

6. Oil return hose and pipe assembly

7. Vacuum hose connection

8.

9.

10.

11.

12.

Air pipe bracket stay

Oil pipe assembly

Oil pipe assembly

Vacuum pump assembly

Control wiring harness mounting

bolt

13. Fuel pipe mounting bolt

14-22

ENGINE COOLING - Water Hose and Water Pipe

24 Nm

10 Nm

18

14

17

27 - 33 Nm

15

16

23

27 - 33 Nm

24

24 Nm

19

13 Nm

13 Nm

22

21

20

10 Nm

17

18

f3mm

f3mm

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalent

14.

15.

16.

"BA 17.

"BA 18.

"AA 19.

Water pipe assembly (A)

Water hose

Water inlet fitting

Thermostat case assembly

Water outlet fitting

O-ring

20.

21.

22.

23.

"AA 24.

Heater hose connection

Water hose

Water pipe assembly (B)

Water inlet pipe assembly

O-ring

ENGINE COOLING - Water Hose and Water Pipe

14-23

REMOVAL SERVICE POINT

AA" RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE DISCONNECTION

After making mating marks on the radiator hose and the hose

clamp, disconnect the radiator hose.

Thermostat case assembly,

water pump or cylinder block

O-ring

Water inlet pipe assembly or

heater pipe assembly

INSTALLATION SERVICE POINTS

"AA O-RING INSTALLATION

Insert the O-ring to the water inlet pipe assembly or the heater

pipe assembly and coat the outer circumference of the O-ring

with water or engine coolant.

Caution

Do not allow engine oil or other greases to adhere to

the O-ring

"BA WATER OUTLET FITTING/THERMOSTAT CASE

ASSEMBLY INSTALLATION

Squeeze out the sealant from the tube evenly and apply

it so that there is not too much sealant and no places without

sealant.

Specified Sealant:

Mitsubishi Genuine Parts No. MD970389 or equivalent

"CA RADIATOR LOWER HOSE/RADIATOR UPPER

HOSE CONNECTION

1. Insert each hose as far as the projection of the water

inlet fitting or water outlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

INSPECTION

14100340118

WATER PIPE AND HOSE CHECK

Check the water pipe and hose for cracks, damage, clog

and replace them if necessary.

14-24

ENGINE COOLING - Radiator

RADIATOR

14100150285

REMOVAL AND INSTALLATION

Pre-removal operation

D Engine Coolant Draining (Refer to P.14-10.)

D Air Cleaner and Air Intake Hose Assembly Removal

Post-installation Operation

D Engine Coolant Supplying (Refer to P.14-10.)

D A/T Fluid Supplying and Checking (Refer to GROUP

23 - On-vehicle Service.)

D Air Cleaner and Air Intake Hose Assembly

Installation

12 Nm

12 Nm

11

17

18

20

11

19

12

12 Nm

1

5 Nm

9

5

8

16

10

14

5 Nm

15

5 Nm

13

13

Radiator removal steps

1. Drain plug

2. Radiator cap

3. Overflow hose

4. Reserve tank

5. Reserve tank bracket

AA" "AA 6. Radiator upper hose

AA" "AA 7. Radiator lower hose

8. Clamp <6A1 - A/T>

AB"

9. Transmission fluid cooler hose connection <A/T>

10. Engine oil cooler hose mounting

bolt <4D6>

11. Upper insulator

12. Radiator assembly

13. Lower insulator

14. Bolt <A/T>

AB"

15. Transmission fluid cooler hose and

pipe assembly <A/T>

16. Condenser fan motor assembly

<Vehicle with A/C>

17. Radiator fan motor assembly

Radiator fan motor and fan

controller assembly removal steps

AA" "AA 6. Radiator upper hose

8. Clamp <6A1 - A/T>

14. Bolt <A/T>

17. Radiator fan motor assembly

18. Fan

19. Radiator fan motor and fan controller assembly

20. Shroud

ENGINE COOLING - Radiator

14-25

REMOVAL SERVICE POINTS

AA" RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE DISCONNECTION

After making mating marks on the radiator hose and the hose

clamp, disconnect the radiator hose.

AB" TRANSMISSION FLUID COOLER HOSE AND PIPE

ASSEMBLY REMOVAL

After disconnecting the hoses from the radiator and the

transmission, plug all of the pipes and hoses to prevent dirt

and other foreign objects from getting inside.

INSTALLATION SERVICE POINT

"AA RADIATOR LOWER HOSE/RADIATOR UPPER HOSE

CONNECTION

1. Insert each hose as far as the projection of the water

inlet fitting.

2. Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

NOTES

Potrebbero piacerti anche

- F430 Error CodesDocumento63 pagineF430 Error CodesIsrael Negrete Dominguez100% (2)

- BMW 03 CIP ProgrammingDocumento20 pagineBMW 03 CIP ProgrammingSalisburNessuna valutazione finora

- Manual Cambio PDFDocumento122 pagineManual Cambio PDFrogerioNessuna valutazione finora

- Iveco Daily Euro 4 Repair Manual GuideDocumento1.132 pagineIveco Daily Euro 4 Repair Manual Guideroney82% (17)

- MOST Bus Diagnostics: Initial Print Date: 02/04 Revision DateDocumento11 pagineMOST Bus Diagnostics: Initial Print Date: 02/04 Revision DateAutof FerreiraNessuna valutazione finora

- F430 Error CodesDocumento63 pagineF430 Error CodesIsrael Negrete Dominguez100% (2)

- Powertrain ZF PDFDocumento74 paginePowertrain ZF PDFAnonymous 3rxPUo6Nessuna valutazione finora

- 04 Telephone DiagnosticsDocumento19 pagine04 Telephone DiagnosticsSalisburNessuna valutazione finora

- 01 - Passive Safety DiagnosticsDocumento3 pagine01 - Passive Safety DiagnosticsSalisburNessuna valutazione finora

- Powertrain ZF PDFDocumento74 paginePowertrain ZF PDFAnonymous 3rxPUo6Nessuna valutazione finora

- DPO Oil CheckDocumento3 pagineDPO Oil CheckAutof FerreiraNessuna valutazione finora

- Troubleshooting the 41TE Transmission in 2003-Later CaravansDocumento4 pagineTroubleshooting the 41TE Transmission in 2003-Later CaravansAutof FerreiraNessuna valutazione finora

- Service BulletinDocumento3 pagineService BulletinAutof FerreiraNessuna valutazione finora

- Service Bulletin for 1999 Mitsubishi Galant Special SpecsDocumento6 pagineService Bulletin for 1999 Mitsubishi Galant Special SpecsAutof FerreiraNessuna valutazione finora

- Service BulletinDocumento2 pagineService BulletinAutof FerreiraNessuna valutazione finora

- MSB 99e42 003eDocumento5 pagineMSB 99e42 003eAutof FerreiraNessuna valutazione finora

- MSB 99E22 001eDocumento2 pagineMSB 99E22 001eAutof FerreiraNessuna valutazione finora

- Service BulletinDocumento3 pagineService BulletinAutof FerreiraNessuna valutazione finora

- SB ListDocumento1 paginaSB ListAutof FerreiraNessuna valutazione finora

- MSB 98e54 501Documento3 pagineMSB 98e54 501Autof FerreiraNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 16+Sistema+de+Arranque,+Poleas,+Injectores,+Alternador,+EtcDocumento0 pagine16+Sistema+de+Arranque,+Poleas,+Injectores,+Alternador,+EtcrcvalNessuna valutazione finora

- 15Documento24 pagine15Autof FerreiraNessuna valutazione finora

- Engine LubricationDocumento10 pagineEngine LubricationAutof FerreiraNessuna valutazione finora

- 17 PDFDocumento52 pagine17 PDFAutof FerreiraNessuna valutazione finora

- 21 PDFDocumento8 pagine21 PDFAutof FerreiraNessuna valutazione finora

- 23Documento70 pagine23Autof FerreiraNessuna valutazione finora

- Manual TransmissionDocumento10 pagineManual TransmissionAutof FerreiraNessuna valutazione finora

- 26 PDFDocumento18 pagine26 PDFAutof FerreiraNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- JACOB ThirdDocumento16 pagineJACOB ThirdWendell ReyesNessuna valutazione finora

- p-4500 Technical InformationDocumento13 paginep-4500 Technical InformationElhoiNessuna valutazione finora

- Ofc SyllabusDocumento7 pagineOfc SyllabusARDHRA BNessuna valutazione finora

- Welcome: Bahasa Inggris Teknik I Ahmad Nusi, S. PD., M. PDDocumento11 pagineWelcome: Bahasa Inggris Teknik I Ahmad Nusi, S. PD., M. PDAsril SalongNessuna valutazione finora

- Solidworks Flow SimulationDocumento7 pagineSolidworks Flow SimulationpatrickNX94200% (1)

- ETABS Building Structure Analysis and Design ReportDocumento84 pagineETABS Building Structure Analysis and Design ReportMd Awesshadab0% (1)

- Dental Material Final ReportDocumento7 pagineDental Material Final ReportAbdullah Muhammed khaleel HassanNessuna valutazione finora

- Gpa Calculation SheetDocumento1 paginaGpa Calculation SheetIryna HoncharukNessuna valutazione finora

- Absorption QuestionsDocumento11 pagineAbsorption QuestionsRalph CastinoNessuna valutazione finora

- Mammography View ChapterDocumento60 pagineMammography View ChapterSehar GulNessuna valutazione finora

- Using Topcon GR-3 GPS for Topographic SurveysDocumento4 pagineUsing Topcon GR-3 GPS for Topographic SurveysFranco BaldiNessuna valutazione finora

- Grade 8 Diagnostic Test 2022-2023Documento2 pagineGrade 8 Diagnostic Test 2022-2023JennyNessuna valutazione finora

- Tutorial - Lecture 3 SolutionsDocumento10 pagineTutorial - Lecture 3 SolutionsBastián Olfos MárquezNessuna valutazione finora

- Matriculation Chemistry Introduction To Organic Compound Part 1 PDFDocumento24 pagineMatriculation Chemistry Introduction To Organic Compound Part 1 PDFiki292Nessuna valutazione finora

- SteganographyDocumento13 pagineSteganographyIgloo JainNessuna valutazione finora

- Weld CheckDocumento6 pagineWeld CheckArnold c ElverNessuna valutazione finora

- Matrix Inversion Note in Mathematics MagazineDocumento2 pagineMatrix Inversion Note in Mathematics Magazinejuan carlos molano toroNessuna valutazione finora

- XI-Opt. Syllabus (2023-24)Documento29 pagineXI-Opt. Syllabus (2023-24)INDERDEEPNessuna valutazione finora

- Alkali MetalsDocumento12 pagineAlkali MetalsSaki Sultana LizaNessuna valutazione finora

- Grade 6 Term1 Properties of 2-D Shapes Lesson 7Documento4 pagineGrade 6 Term1 Properties of 2-D Shapes Lesson 7Ayanda Siphesihle NdlovuNessuna valutazione finora

- Oracle Coherence Admin GuideDocumento156 pagineOracle Coherence Admin Guidegisharoy100% (1)

- Maintenance Recommendations: Operation and Maintenance ManualDocumento10 pagineMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNessuna valutazione finora

- Time Signature - WikipediaDocumento17 pagineTime Signature - WikipediaDiana GhiusNessuna valutazione finora

- Full Paper Template IRC 2020Documento3 pagineFull Paper Template IRC 2020Mobina AbdulRaufNessuna valutazione finora

- Eps Manual NissanDocumento8 pagineEps Manual Nissanjoiler pajueloNessuna valutazione finora

- LsApi PDFDocumento347 pagineLsApi PDFEduardo Martin Vega100% (2)

- List of Practical Cs With SolutionDocumento57 pagineList of Practical Cs With SolutionArjun KalaNessuna valutazione finora

- Connective TissueDocumento6 pagineConnective TissuecrtgyhujikNessuna valutazione finora

- Nov. AbwDocumento50 pagineNov. Abwjbyarkpawolo70Nessuna valutazione finora

- Service Manual (V1.22)Documento529 pagineService Manual (V1.22)JensNessuna valutazione finora