Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sapphire Hi-Pressure 2 Tds

Caricato da

fahreezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sapphire Hi-Pressure 2 Tds

Caricato da

fahreezCopyright:

Formati disponibili

Technical Data

SAPPHIRE Hi-Pressure 2

High load molybdenum disulphide plain bearing grease

Product Overview

ROCOL SAPPHIRE Hi-Pressure 2 is a heavy duty

bearing grease fortified with molybdenum disulphide.

It has been designed for the effective lubrication and

protection of plain bearings and sliding surfaces used

in extreme environments, particularly in heavily

loaded, slow moving applications.

SAPPHIRE Hi-Pressure 2 combines the resilience of

a clay thickener with the addition of molybdenum

disulphide ensuring that a lubricating film exists

under the most extreme loadings where the grease

film can be squeezed out.

Features and Benefits

Wide temperature range operating from -20C

to +150C.

SAPPHIRE Hi-Pressure 2 is a non-melting

grease, fortified with molybdenum disulphide, for

excellent temperature and water resistance.

Molybdenum disulphide (MoS2) has an affinity to

metal surfaces leaving a tenacious high load

carrying film with a low coefficient of friction. This

film provides an extremely durable layer reducing

frictional heat and wear and extending

component life and lubrication intervals.

Ideal for highly loaded, applications where shock

loads and vibration can occur.

SAPPHIRE Hi-Pressure 2 offers excellent

corrosion resistance to protect in humid, damp

and even wet conditions.

SAPPHIRE Hi-Pressure 2 maintains its integrity

in arduous conditions and continues to protect

over extended lubrication intervals, reducing

equipment failure, downtime and lubricant usage.

Directions for Storage and Use

SAPPHIRE Hi-Pressure 2 can be applied

manually, by grease gun, keg pump or by other

methods suitable for dispensing NLGI No. 2

greases with solid additives.

SAPPHIRE Hi-Pressure 2 is compatible with other

clay thickened greases. However, for best results

the previous lubricant should be removed prior to

application.

Avoid mixing SAPPHIRE Hi-Pressure 2 with soap

thickened greases.

The storage temperature should be controlled

between +1C and +40C.

Shelf life is 3 years from date of manufacture.

Typical Applications

SAPPHIRE Hi-Pressure 2 is particularly suitable for

heavily loaded, slow moving applications typically

found in industries such as quarries, mining, marine,

docks, agriculture, and construction.

SAPPHIRE Hi-Pressure 2 excels in applications

such as crushers, screens, presses, loaders,

scrapers, wagons and similar applications where

plain bearings, pins, bushes, slides etc. are subjected

to extreme conditions.

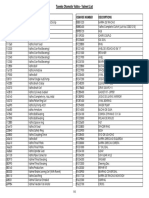

Pack Sizes

Pack Size

400g cartridge

500g

5kg

18kg

50kg

Part Code

12011

12013

12016

12024

12018

Technical Data

SAPPHIRE Hi-Pressure 2

High load molybdenum disulphide plain bearing grease

Property

Test Method

Result

Visual

Smooth blue / black grease

IP 50 ASTM D217

N/A

Severely refined mineral oil

Base Fluid Viscosity at 40C

IP 71

184cSt

Base Fluid Viscosity at 100C

IP 71

15cSt

Thickener

N/A

Organically modified clay

Solids

N/A

Molybdenum disulphide

Temperature Range

N/A

-20C to + 150C

Weld Load

IP 239 ASTM D2596

355kg

Mean Hertz Load

IP 239 ASTM D2596

68kg

IP 121

3% maximum

IP 215 ASTM D1264

0%

IP 112 ASTM D130

1a

Mild Steel

N/A

No stain

Aluminium

N/A

No stain

Appearance

NLGI No.

Base Type

4-Ball:

Oil Separation 24 hrs at +100C

Water Washout Test

Copper Corrosion:

24 hrs at +100C

Corrosion Test 24 hrs at 100C:

Values quoted above are typical and do not constitute a specification.

Safety Data Sheets

Safety data sheets are available for download from our website www.rocol.com or may be obtained from your usual

ROCOL contact.

The information in this publication is based on our experience and reports from customers. There are many factors outside our control or

knowledge which affect the use and performance of our products, for which reason it is given without responsibility.

Issue: 1

Date: 01-11

Potrebbero piacerti anche

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Maintenance PDFDocumento11 pagineMaintenance PDFMehul PatelNessuna valutazione finora

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Mobilgrease XHP 222 & Special PDSDocumento3 pagineMobilgrease XHP 222 & Special PDScatoeraleifNessuna valutazione finora

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Da EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Nessuna valutazione finora

- Mobilgrease XHP™ Mine SeriesDocumento2 pagineMobilgrease XHP™ Mine Seriesppanagos5664Nessuna valutazione finora

- NT 00035662Documento1 paginaNT 00035662sai babuNessuna valutazione finora

- Grease Catalogue Velvex - Nandan Petrochem LTDDocumento11 pagineGrease Catalogue Velvex - Nandan Petrochem LTDNandan Petrochem LtdNessuna valutazione finora

- Ceran FGDocumento2 pagineCeran FGUtkarshNessuna valutazione finora

- Chevron Starplex EP-2 MSDSDocumento2 pagineChevron Starplex EP-2 MSDSCrystal RojasNessuna valutazione finora

- GulfSea Hyperbar CS2 PDFDocumento2 pagineGulfSea Hyperbar CS2 PDFObydur RahmanNessuna valutazione finora

- GulfSea Hyperbar LCM2 PDFDocumento2 pagineGulfSea Hyperbar LCM2 PDFObydur RahmanNessuna valutazione finora

- Molylube Mill Gear GreaseDocumento2 pagineMolylube Mill Gear GreasedhowardjNessuna valutazione finora

- Mobilgrease XHP 460Documento3 pagineMobilgrease XHP 460Jaime Miloz Masle JaksicNessuna valutazione finora

- MAK Hitemp Xtra SM GreaseDocumento1 paginaMAK Hitemp Xtra SM GreaseAnand PadhiyarNessuna valutazione finora

- Mobilgrease XHP 222 Pds PDFDocumento3 pagineMobilgrease XHP 222 Pds PDFStefan Cel MareNessuna valutazione finora

- Omniguard QLT GreaseDocumento2 pagineOmniguard QLT GreaseCarlosNessuna valutazione finora

- Australia Shell Gadus S3 V460XD 2 TDSDocumento2 pagineAustralia Shell Gadus S3 V460XD 2 TDSfdpc1987Nessuna valutazione finora

- Velloils High Temperature & Speciality Grease Velloplex GreaseDocumento6 pagineVelloils High Temperature & Speciality Grease Velloplex GreaseBhusarapu SrinivasNessuna valutazione finora

- Mobiltemp Series Product Data SheetDocumento3 pagineMobiltemp Series Product Data SheetRonaldo RossiNessuna valutazione finora

- Catálogo Grasas - SinopecDocumento20 pagineCatálogo Grasas - SinopecMario GonzalesNessuna valutazione finora

- HT Mobilux Ep 2 EngDocumento2 pagineHT Mobilux Ep 2 EngdgslimaNessuna valutazione finora

- Sinopec Grease: SINOPEC Moly-Lithium Grease SINOPEC Heavy Duty LC Mining GreaseDocumento2 pagineSinopec Grease: SINOPEC Moly-Lithium Grease SINOPEC Heavy Duty LC Mining GreaseSumaya AkterNessuna valutazione finora

- Mobiltemp SHC 100 Special and 460 SpecialDocumento3 pagineMobiltemp SHC 100 Special and 460 SpecialHugo PinargoteNessuna valutazione finora

- Mobilgrease XHP 322 Special PdsDocumento2 pagineMobilgrease XHP 322 Special Pdsppanagos5664Nessuna valutazione finora

- GulfSea Synth Gear Oil Series PDFDocumento2 pagineGulfSea Synth Gear Oil Series PDFObydur RahmanNessuna valutazione finora

- Heavy Duty LC Mining GreaseDocumento2 pagineHeavy Duty LC Mining GreaseYoong TanNessuna valutazione finora

- TIME Drilling Fluid ProductsDocumento12 pagineTIME Drilling Fluid Productssc2011100% (1)

- Altis MV2 (11.12.03)Documento1 paginaAltis MV2 (11.12.03)D Wahyu BawonoNessuna valutazione finora

- PDS - Mobilgrease XHP 460 SeriesDocumento3 paginePDS - Mobilgrease XHP 460 SeriesJuanSantillanNessuna valutazione finora

- Eni Grease LCX 2-220 PDFDocumento2 pagineEni Grease LCX 2-220 PDFranjanguptNessuna valutazione finora

- Mobil Grease X HP 222Documento2 pagineMobil Grease X HP 222sapu11jagat5855Nessuna valutazione finora

- Sinopec Super Grease NLGI 2Documento2 pagineSinopec Super Grease NLGI 2Yoong TanNessuna valutazione finora

- GulfSea Synth Gear Oil PG 220 PDFDocumento2 pagineGulfSea Synth Gear Oil PG 220 PDFObydur RahmanNessuna valutazione finora

- Agip Gear Oil Pamphlet PDFDocumento4 pagineAgip Gear Oil Pamphlet PDFranjanguptNessuna valutazione finora

- TDS Energrease MP-MG 2 InfoDocumento9 pagineTDS Energrease MP-MG 2 InfoLucian IftemieNessuna valutazione finora

- Carboguard 60 LH PDSDocumento4 pagineCarboguard 60 LH PDSRicardo SantosNessuna valutazione finora

- Gpcdoc Gtds Shell Gadus s2 Og 80 (En) TdsDocumento2 pagineGpcdoc Gtds Shell Gadus s2 Og 80 (En) Tdsangel de mi guardaNessuna valutazione finora

- 643Documento20 pagine643Lokesh ModemzNessuna valutazione finora

- Characteristics (Typical Figures) Agip Grease Mu 0 1 2 3 NLGI Consistency 0 1 2 3Documento1 paginaCharacteristics (Typical Figures) Agip Grease Mu 0 1 2 3 NLGI Consistency 0 1 2 3LLNessuna valutazione finora

- Tex CladDocumento3 pagineTex Cladabdallah badrNessuna valutazione finora

- Product Information Sheet: Description: ApplicationDocumento2 pagineProduct Information Sheet: Description: ApplicationgalaxiprinceNessuna valutazione finora

- Calipsol H 443-HD 88Documento2 pagineCalipsol H 443-HD 88Oscar CabreraNessuna valutazione finora

- Lithium Grease Manufacturers in IndiaDocumento16 pagineLithium Grease Manufacturers in IndiaUnit GreaseNessuna valutazione finora

- TDS MHT GreaseDocumento2 pagineTDS MHT GreaseAntonio DávilaNessuna valutazione finora

- Ultra Grease Lithium EP2Documento12 pagineUltra Grease Lithium EP2Balaji BalaNessuna valutazione finora

- Eni Grease PHT 1,5 PDFDocumento1 paginaEni Grease PHT 1,5 PDFranjanguptNessuna valutazione finora

- Valvoline Heavy Duty TDL PRO 75W-90-PI SheetDocumento2 pagineValvoline Heavy Duty TDL PRO 75W-90-PI SheetJUAN BAUTISTANessuna valutazione finora

- Petronas Grease LiX 2-380 and MEPDocumento2 paginePetronas Grease LiX 2-380 and MEPChristianEspinal100% (1)

- Renolin CLPDocumento6 pagineRenolin CLPjacl88Nessuna valutazione finora

- Texaco Texclad.2Documento3 pagineTexaco Texclad.2Silvio RodriguezNessuna valutazione finora

- Ceran-Ad-plus TDS v171128Documento2 pagineCeran-Ad-plus TDS v171128Stefan ThomsenNessuna valutazione finora

- Ceran-Ad-Plus TDS v171128Documento2 pagineCeran-Ad-Plus TDS v171128Edgar AdamesNessuna valutazione finora

- Mobil Mobilgrease XHP222 DatasheetDocumento3 pagineMobil Mobilgrease XHP222 Datasheetphankhoa83-1Nessuna valutazione finora

- Raj Rubber ProductsDocumento35 pagineRaj Rubber Productsnaveenraj mNessuna valutazione finora

- Balmerol GreaseDocumento3 pagineBalmerol GreaselifttecNessuna valutazione finora

- OilDocumento23 pagineOilSheikh ZakirNessuna valutazione finora

- GulfSea Hyperbar Super CSDocumento2 pagineGulfSea Hyperbar Super CSObydur RahmanNessuna valutazione finora

- Exclad®: P D T T DDocumento1 paginaExclad®: P D T T DsofelsbabaNessuna valutazione finora

- IOCAENGRSMOMobilux EP 2Documento2 pagineIOCAENGRSMOMobilux EP 2mh09Nessuna valutazione finora

- Verb Patterns: (John) (Smiled) - (Nothing) (Has Happened) - (The Baby) (Was Sleeping)Documento15 pagineVerb Patterns: (John) (Smiled) - (Nothing) (Has Happened) - (The Baby) (Was Sleeping)fahreezNessuna valutazione finora

- JUMO Temperature Analog TransmitterDocumento2 pagineJUMO Temperature Analog TransmitterfahreezNessuna valutazione finora

- Asphalt Paving OperationDocumento7 pagineAsphalt Paving OperationfahreezNessuna valutazione finora

- Eye Bolts Excel Oogbout Grade 80 ALDocumento1 paginaEye Bolts Excel Oogbout Grade 80 ALfahreezNessuna valutazione finora

- Ebook AwanproDocumento8 pagineEbook AwanprofahreezNessuna valutazione finora

- A Review On Grease Lubrication in Rolling BearingsDocumento11 pagineA Review On Grease Lubrication in Rolling BearingsfahreezNessuna valutazione finora

- CSWIP Welding Inspection Notes and QuestionsDocumento132 pagineCSWIP Welding Inspection Notes and QuestionsfahreezNessuna valutazione finora

- Anti Seize Compound - TDSDocumento2 pagineAnti Seize Compound - TDSfahreezNessuna valutazione finora

- Cash Flow PisangDocumento1 paginaCash Flow PisangfahreezNessuna valutazione finora

- Anti-Seize Spray TdsDocumento2 pagineAnti-Seize Spray TdsfahreezNessuna valutazione finora

- Foodlube GREASE 2, 1 & 00: Food Grade Multi-Purpose EP Bearing Grease With PTFEDocumento2 pagineFoodlube GREASE 2, 1 & 00: Food Grade Multi-Purpose EP Bearing Grease With PTFEfahreezNessuna valutazione finora

- Viton Selection GuideDocumento16 pagineViton Selection GuidefahreezNessuna valutazione finora

- STYLE 2000: Australia New Zealand AsiaDocumento1 paginaSTYLE 2000: Australia New Zealand AsiafahreezNessuna valutazione finora

- Anti Seize 797 - TdsDocumento2 pagineAnti Seize 797 - TdsfahreezNessuna valutazione finora

- VossPac - Silica Fabric2Documento1 paginaVossPac - Silica Fabric2fahreezNessuna valutazione finora

- Dry Ptfe Spray MsdsDocumento7 pagineDry Ptfe Spray MsdsfahreezNessuna valutazione finora

- Foodlube Multipaste Spray MsdsDocumento7 pagineFoodlube Multipaste Spray MsdsfahreezNessuna valutazione finora

- VossPac - Ceramic SS FabricsDocumento1 paginaVossPac - Ceramic SS FabricsfahreezNessuna valutazione finora

- Anatomy of Centrifugal PumpsDocumento14 pagineAnatomy of Centrifugal PumpsABRAHAM ESTRADANessuna valutazione finora

- Tabla de Ajustes, Aplicaciones y ComportamientosDocumento2 pagineTabla de Ajustes, Aplicaciones y ComportamientosabacciadNessuna valutazione finora

- Apex Isfl: Horizontal End-Suction Pumps To ISO 2858 DimensionsDocumento2 pagineApex Isfl: Horizontal End-Suction Pumps To ISO 2858 DimensionsQing JyulyanNessuna valutazione finora

- Agma 6010Documento62 pagineAgma 6010Adrian Ropero100% (1)

- 译文 - 多级离心泵Multistage centrifugal pumpDocumento10 pagine译文 - 多级离心泵Multistage centrifugal pumpVocal SamirNessuna valutazione finora

- O&M Manual (Volume 2) FDPSDocumento87 pagineO&M Manual (Volume 2) FDPSShilpa GuptaNessuna valutazione finora

- Gearbox DesignDocumento6 pagineGearbox Designash1968Nessuna valutazione finora

- Installation and Maintenance Manual (Ebara Non-Submersible Pump)Documento36 pagineInstallation and Maintenance Manual (Ebara Non-Submersible Pump)tm_2075% (8)

- Internal Combustion Engine RepairDocumento8 pagineInternal Combustion Engine RepairRyan EdwardsNessuna valutazione finora

- Nasa Rolling-Element Bearings - A Review of State of ArtDocumento87 pagineNasa Rolling-Element Bearings - A Review of State of Artchetan_thakur4278100% (1)

- Long Term Protection For Your Compressed Air System: BOGE Genuine Parts.Documento4 pagineLong Term Protection For Your Compressed Air System: BOGE Genuine Parts.Air Repair, LLCNessuna valutazione finora

- Taneks Valmet-Valtra ListDocumento6 pagineTaneks Valmet-Valtra ListeCommerce SAJID AutoNessuna valutazione finora

- CIE626 Chapter 9 Seismic Isolation Systems Fall 2013Documento133 pagineCIE626 Chapter 9 Seismic Isolation Systems Fall 2013PASAR MANGGIS 2021Nessuna valutazione finora

- CENERG RR Bit Catalogue FinalDocumento12 pagineCENERG RR Bit Catalogue FinalRAJIV GandhiNessuna valutazione finora

- ABS Rules For Building and Classing Steel Vessel, 2017: AlignmentDocumento6 pagineABS Rules For Building and Classing Steel Vessel, 2017: AlignmentDavid MestanzaNessuna valutazione finora

- IXIN Angular Contact Ball BearingDocumento0 pagineIXIN Angular Contact Ball BearingMohamed AbdouNessuna valutazione finora

- Leaflet Bearing Replacement Jan2022Documento3 pagineLeaflet Bearing Replacement Jan2022Jasony PadasianNessuna valutazione finora

- 31.29.60.31-Special Purpose Steam TurbineDocumento29 pagine31.29.60.31-Special Purpose Steam Turbinemansih457Nessuna valutazione finora

- Schrittmotoren Anwenderhandbuch 2.0 enDocumento120 pagineSchrittmotoren Anwenderhandbuch 2.0 enEmil ZaevNessuna valutazione finora

- C2R Compressor & Turbine ShutdownDocumento10 pagineC2R Compressor & Turbine ShutdownfvaefaNessuna valutazione finora

- High Performance and Hi-Load Elevators Maintenance Check ListDocumento1 paginaHigh Performance and Hi-Load Elevators Maintenance Check ListDwi April YantoNessuna valutazione finora

- Orbit Plot Analysis: For Checking Condition of A MachineDocumento24 pagineOrbit Plot Analysis: For Checking Condition of A MachineRAKOTONDRAMPARANY Ndimby Njara StephaneNessuna valutazione finora

- Intermediate Bearing: Case Study 4Documento1 paginaIntermediate Bearing: Case Study 4thiha aungNessuna valutazione finora

- Dremel 16" Scroll SawDocumento21 pagineDremel 16" Scroll SawTink EretteNessuna valutazione finora

- CAK50 MechanicalDocumento37 pagineCAK50 Mechanicals_barriosNessuna valutazione finora

- The Highest Efficiency Turbo Blower: Oilless Gearless Vibrationless StainlessDocumento13 pagineThe Highest Efficiency Turbo Blower: Oilless Gearless Vibrationless Stainlessxiong du100% (1)

- TDocumento39 pagineTayush093Nessuna valutazione finora

- Manual de Servicio Nissan Qr25deDocumento218 pagineManual de Servicio Nissan Qr25deWuilberth AriasNessuna valutazione finora

- Meeka Brochure HoistDocumento16 pagineMeeka Brochure HoistMeeka Machinery Pvt. Ltd.Nessuna valutazione finora

- FagDocumento198 pagineFagHamza NoumanNessuna valutazione finora

- University of Chicago Press Fall 2009 CatalogueDa EverandUniversity of Chicago Press Fall 2009 CatalogueValutazione: 5 su 5 stelle5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDa EverandUniversity of Chicago Press Fall 2009 Distributed TitlesValutazione: 1 su 5 stelle1/5 (1)