Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MineSight Schedule Optimizer

Caricato da

marquezprietoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MineSight Schedule Optimizer

Caricato da

marquezprietoCopyright:

Formati disponibili

MINESIGHT

SCHEDULE OPTIMIZER

OPTIMIZE SHORT AND MEDIUM TERM PLANNING

OVERVIEW

MineSight Schedule Optimizer determines the most productive cut mining

sequence to achieve the highest project profitability while satisfying all

project quality and quantity constraints, destination capacities, equipment

resources, and economic parameters.

MineSight Schedule Optimizer generates practical short to medium term

project schedules that satisfy quality, quantity, market, and geotechnical

constraints using advanced integer programming engines to solve

optimization/blending and scheduling problems.

KEY POINTS

Shovel-level cuts

Stockpile handling

Quality/quantity constraints

Infeasibility analysis

Equipment usage

Customized charting

Semi-automatic material routing

Customized Reporting

Maximize/minimize metal contents

Maximize net present value (NPV)

KEY FEATURES

> Calculate schedules based on objectives, constraints, and economic

parameters

> Determine optimal cut mining sequence per period

> Automatically conduct infeasibility analysis to find violating constraints

> Maximize/minimize net present value (NPV), stripping ratio, or metal

contents

> Utilize available truck and shovel resources efficiently

> Import cuts from multiple models stored on reliable and secure

databases

> Define or Input:

Objective per period

Materials sent to any number of mills, leaches, pads, stockpiles, and

waste dumps

Mining, processing, marketing, and geotechnical constraints

Stockpile mining and reclaiming constraints as well as reclaiming

method

Constraints for materials sent to destinations or received from

stockpiles

Constraints for grade items, grade ratio, and stripping ratio

Bench vertical advance rates (VARs)

Constraints for shovel and truck hours

Physical relationships between phases

Material movements by mining area and by phase

Equipment usages by mining area and by phase

> Integrated with MineSight Haulage to define destinations,

capacities, opening balances, and calculate cycle time

> Calculate cut precedence between benches and phases

> Allow semi-automatic material routing

> Integrated with cuts designed by MineSight Interactive Planner and

MineSight scripts

> Read data directly from the MineSight Planning Database

> Generate customized reports and charts filtered by periods,

phases, benches, materials, cutoff grade, cut attributes, and/or

equipment hours

> Export customized reports to Microsoft Excel and CVS

> Export schedules to MineSight 3D for visualization

> Integrated with MineSight 3D end-of-period maps

> Provide flexible and customized reports and charts for pre- and

post-scheduling analysis

w w w . m i n e s i g h t . c o m

Potrebbero piacerti anche

- Bulk Material Handling: Practical Guidance for Mechanical EngineersDa EverandBulk Material Handling: Practical Guidance for Mechanical EngineersValutazione: 5 su 5 stelle5/5 (1)

- NPV Scheduler: From Geological Model To Mine PlanDocumento2 pagineNPV Scheduler: From Geological Model To Mine PlanEnrique Cruz CheccoNessuna valutazione finora

- Civil Engineering Softwares List Super Civil CDDocumento10 pagineCivil Engineering Softwares List Super Civil CDVijay Sharma100% (2)

- Production Planning and ControlDocumento25 pagineProduction Planning and ControlSharad Bharadwaj100% (1)

- BMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationDa EverandBMC Control-M 7: A Journey from Traditional Batch Scheduling to Workload AutomationNessuna valutazione finora

- How To Read An ODBC Trace FileDocumento13 pagineHow To Read An ODBC Trace FileganeshharidasNessuna valutazione finora

- Minesight EconomicsDocumento1 paginaMinesight EconomicsJean-Paul MwambaNessuna valutazione finora

- GEOVIA Minex BrochureDocumento4 pagineGEOVIA Minex BrochureMahesh Pandey100% (1)

- Maptek Vulcan Overview BrochureDocumento12 pagineMaptek Vulcan Overview BrochureStacy Oconnor100% (1)

- Introduction To MSAPDocumento26 pagineIntroduction To MSAPRCBNessuna valutazione finora

- GEOVIA MineSched BrochureDocumento4 pagineGEOVIA MineSched BrochureMahesh Pandey0% (2)

- Minemax Planner BrochureDocumento2 pagineMinemax Planner BrochureManuel AragonNessuna valutazione finora

- Strategic Mine Planning Flexible Mine Planning To Meet Changes in The Business EnvironmentDocumento18 pagineStrategic Mine Planning Flexible Mine Planning To Meet Changes in The Business Environment11804Nessuna valutazione finora

- Minemax Scheduler: Strategic Mine Schedule OptimizationDocumento3 pagineMinemax Scheduler: Strategic Mine Schedule Optimizationmining engineerNessuna valutazione finora

- Ventyx Minescape: Ventyx Intelligent Mining SolutionDocumento26 pagineVentyx Minescape: Ventyx Intelligent Mining SolutionRizal Ma'rufiNessuna valutazione finora

- Strategic Mine Planning Integrating Computer Software, Simulation, and Social ResponsibilityDocumento66 pagineStrategic Mine Planning Integrating Computer Software, Simulation, and Social ResponsibilityLuis BNessuna valutazione finora

- Gemcom MinexDocumento4 pagineGemcom Minex3wilasa pustaka50% (2)

- Going UndergroundDocumento11 pagineGoing UndergroundRicardo Contreras BNessuna valutazione finora

- OptiTekServices MiningDocumento3 pagineOptiTekServices MiningEba SitorusNessuna valutazione finora

- Maptek Vulcan Module Overview EngineeringDocumento4 pagineMaptek Vulcan Module Overview EngineeringFarouk AzzouhriNessuna valutazione finora

- SOT Schedule Optimizer ToolDocumento17 pagineSOT Schedule Optimizer Toolkluna2100% (1)

- NPVS Course Level 2Documento31 pagineNPVS Course Level 2Juan David Rondinel BulejeNessuna valutazione finora

- Perception Erp & EvmsDocumento79 paginePerception Erp & EvmsLukman Tarigan SumatraNessuna valutazione finora

- Take Complete Control Over Short-Term Production SchedulingDocumento2 pagineTake Complete Control Over Short-Term Production Scheduling9090135Nessuna valutazione finora

- Underground Coal BrochureDocumento8 pagineUnderground Coal BrochureBryanNessuna valutazione finora

- Minesight Strategic Planner V3.00: January 2011Documento4 pagineMinesight Strategic Planner V3.00: January 2011Rajesh SinghNessuna valutazione finora

- Minesight Schedule Optimizer - A New Tool: Global Mining Software Solutions Since 1970Documento28 pagineMinesight Schedule Optimizer - A New Tool: Global Mining Software Solutions Since 1970Ricardo Contreras BNessuna valutazione finora

- How To Estimate The Cost of Mechanical DredgingDocumento21 pagineHow To Estimate The Cost of Mechanical DredgingKaren LimNessuna valutazione finora

- SOT Schedule Optimizer ToolDocumento17 pagineSOT Schedule Optimizer ToolAndres GuerreroNessuna valutazione finora

- Integrating Cost Estimating Withتصميم the Ship Design Process دمج تقدير التكلفةDocumento24 pagineIntegrating Cost Estimating Withتصميم the Ship Design Process دمج تقدير التكلفةMaharAl-hasan50% (2)

- Module 04Documento16 pagineModule 04SAMRUDA SADANANDNessuna valutazione finora

- Civil StormDocumento2 pagineCivil StormBadri SeetharamanNessuna valutazione finora

- Minesight® Interactive Planner - HaulageDocumento40 pagineMinesight® Interactive Planner - HaulageRCBNessuna valutazione finora

- Mine Access Development Simulation Through Direct Mine Design Data IntegrationDocumento12 pagineMine Access Development Simulation Through Direct Mine Design Data Integrationabercon mbedziNessuna valutazione finora

- Sewergems Product Data SheetDocumento2 pagineSewergems Product Data SheetRyu Rey RogerNessuna valutazione finora

- Estimating Equipment Productivities and Unit Rates For Road Construction WorksDocumento35 pagineEstimating Equipment Productivities and Unit Rates For Road Construction WorksObinna ObiefuleNessuna valutazione finora

- 3DS GEOVIA Minex - BrochureDocumento4 pagine3DS GEOVIA Minex - Brochuresaifuddin khanNessuna valutazione finora

- Lecture - 1 - UNDERGROUND MINE DESIGNDocumento59 pagineLecture - 1 - UNDERGROUND MINE DESIGNRahat fahimNessuna valutazione finora

- MARINE CAPABILITIES-Rev2Documento4 pagineMARINE CAPABILITIES-Rev2Jaowad DabielNessuna valutazione finora

- Maptek Vulcan 9.1 Whats New PDFDocumento2 pagineMaptek Vulcan 9.1 Whats New PDFSatria Ega PutraNessuna valutazione finora

- MineScapeEngineering Brochure 230214 EN FINAL Part2Documento2 pagineMineScapeEngineering Brochure 230214 EN FINAL Part2rightful.hornet9151Nessuna valutazione finora

- Auto Desk Storm Sanitary Analysis 2015Documento15 pagineAuto Desk Storm Sanitary Analysis 2015ByhiswillNessuna valutazione finora

- Mine SchedDocumento4 pagineMine SchedJoseph Abraham33% (3)

- Cost PlanningDocumento2 pagineCost Planningjunlab0807Nessuna valutazione finora

- Strategic OpenPit Mine PlanningDocumento4 pagineStrategic OpenPit Mine PlanningLehlabile MorenaNessuna valutazione finora

- GEOVIA Surpac Quarry DS PDFDocumento4 pagineGEOVIA Surpac Quarry DS PDFarief_7Nessuna valutazione finora

- MysepDocumento16 pagineMysepsterlingNessuna valutazione finora

- The Leading Mine Scheduling SolutionDocumento6 pagineThe Leading Mine Scheduling SolutionArafat SutanNessuna valutazione finora

- Compass ™: Well PlanningDocumento2 pagineCompass ™: Well PlanningJacobsNessuna valutazione finora

- SC 401 Lecture 02-3 (Survey Equipment and Equipment Management)Documento30 pagineSC 401 Lecture 02-3 (Survey Equipment and Equipment Management)Joseph BaruhiyeNessuna valutazione finora

- Que$Tor Onshore: Oil & Gas Project Cost AnalysisDocumento4 pagineQue$Tor Onshore: Oil & Gas Project Cost AnalysisstormstoneNessuna valutazione finora

- Burrow Global - Lead Instrumentation Engineer Resume ExampleDocumento6 pagineBurrow Global - Lead Instrumentation Engineer Resume ExamplepankajskecNessuna valutazione finora

- Underground Metals BrochureDocumento8 pagineUnderground Metals BrochureBryanNessuna valutazione finora

- MCSK DeepRiser DatasheetDocumento2 pagineMCSK DeepRiser Datasheet1tmac3Nessuna valutazione finora

- Planning For ConstructionDocumento21 paginePlanning For ConstructionAnil PatelNessuna valutazione finora

- MySep Software Brochure PDFDocumento7 pagineMySep Software Brochure PDFoverlord5555Nessuna valutazione finora

- OTE Outotec CrusherMapper Eng LoresDocumento4 pagineOTE Outotec CrusherMapper Eng LoresjadetorresNessuna valutazione finora

- 1,2 - Well Planning Objective & Rig Sizing and SelectionDocumento30 pagine1,2 - Well Planning Objective & Rig Sizing and SelectionYassir Hindi100% (1)

- Construction Planning & ManagementDocumento39 pagineConstruction Planning & ManagementAnkur SrivastavaNessuna valutazione finora

- TIME SERIES FORECASTING. ARIMAX, ARCH AND GARCH MODELS FOR UNIVARIATE TIME SERIES ANALYSIS. Examples with MatlabDa EverandTIME SERIES FORECASTING. ARIMAX, ARCH AND GARCH MODELS FOR UNIVARIATE TIME SERIES ANALYSIS. Examples with MatlabNessuna valutazione finora

- DPP 01 Periodic Table JH Sir-3576 PDFDocumento5 pagineDPP 01 Periodic Table JH Sir-3576 PDFChessNessuna valutazione finora

- 截屏 2021-08-05 17.02.20Documento98 pagine截屏 2021-08-05 17.02.204WEM GTNessuna valutazione finora

- Some Observations On The Diophantine Equation Y2xa and Related ResultsDocumento12 pagineSome Observations On The Diophantine Equation Y2xa and Related ResultsJose Roberto DuarteNessuna valutazione finora

- Evaluation and Selection of Sustainable Strategy For Green Supply Chain Management ImplementationDocumento28 pagineEvaluation and Selection of Sustainable Strategy For Green Supply Chain Management ImplementationMuhammad Dzaky Alfajr DirantonaNessuna valutazione finora

- Nylon Bag BisDocumento13 pagineNylon Bag Bisbsnl.corp.pbNessuna valutazione finora

- Inorganic Chemistry - Lab Report 5Documento7 pagineInorganic Chemistry - Lab Report 5AlpNessuna valutazione finora

- How Microprocessors Work PDFDocumento2 pagineHow Microprocessors Work PDFdanielconstantin4Nessuna valutazione finora

- 1SC0 2PF Exam-Paper 20180616Documento20 pagine1SC0 2PF Exam-Paper 20180616Thasanya AlgamaNessuna valutazione finora

- Tugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)Documento4 pagineTugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)fitriani choerunnisaNessuna valutazione finora

- TB-2100 Operational and Maintenance Manual Rev C OptimiseDocumento224 pagineTB-2100 Operational and Maintenance Manual Rev C OptimisearnaudmarielNessuna valutazione finora

- Lec.5 (Prameters of OHTL Pt.2)Documento10 pagineLec.5 (Prameters of OHTL Pt.2)AbdullahNessuna valutazione finora

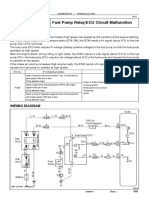

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocumento4 pagineDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNessuna valutazione finora

- Astm A106-2002Documento13 pagineAstm A106-2002henryNessuna valutazione finora

- Viscosity Measurements On Oligoesters From Terephthalic Acid and GlycoDocumento7 pagineViscosity Measurements On Oligoesters From Terephthalic Acid and GlycoMaria RincondeNessuna valutazione finora

- Caie As Computer Science 9618 Theory v3Documento20 pagineCaie As Computer Science 9618 Theory v3James HoangNessuna valutazione finora

- ITTC Surface TreatmentDocumento63 pagineITTC Surface Treatments_brizzolaraNessuna valutazione finora

- 7 - Introduction To Intelligent ControlDocumento21 pagine7 - Introduction To Intelligent ControlIsmael Espinoza100% (1)

- Wood Conserving StovesDocumento117 pagineWood Conserving Stovesalitoparana100% (1)

- Upcoming: Advisor Webcast: Oracle Database Resource ManagerDocumento41 pagineUpcoming: Advisor Webcast: Oracle Database Resource ManagerLayne MoránNessuna valutazione finora

- Register Transfer LanguageDocumento11 pagineRegister Transfer LanguageShiva IdokNessuna valutazione finora

- V-Ray For SketchUp Rendering An Exterior Scene PDFDocumento7 pagineV-Ray For SketchUp Rendering An Exterior Scene PDFDevohNessuna valutazione finora

- Mitchell-Banki Turbine Design Document PDFDocumento37 pagineMitchell-Banki Turbine Design Document PDFprojetosschillingNessuna valutazione finora

- Unit 1Documento29 pagineUnit 1Biswajit MishraNessuna valutazione finora

- Adjectives 4Documento34 pagineAdjectives 4Delia Bolasoc100% (1)

- IntegersDocumento20 pagineIntegersMahobeNessuna valutazione finora

- Cells Bio-120-Exercise-4Documento7 pagineCells Bio-120-Exercise-4Paolo TenorioNessuna valutazione finora

- Clipping Clamping CircuitsDocumento7 pagineClipping Clamping CircuitsPavan SaiNessuna valutazione finora

- Power Off Reset Reason BackupDocumento5 paginePower Off Reset Reason Backupmohamed ahmedNessuna valutazione finora

- DefaultDocumento49 pagineDefaultmaruka33100% (1)