Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality Planning For The Manufacturing Supply Chain

Caricato da

joannakamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quality Planning For The Manufacturing Supply Chain

Caricato da

joannakamCopyright:

Formati disponibili

Quality Planning for the Manufacturing Supply Chain

Batson, Robert G;McGough, Karen D

The Quality Management Journal; Jan 2006; 13, 1; ABI/INFORM Research

pg. 33

Quality Planning for the

Manufacturing Supply Chain

ROBERT G. BATSON AND KAREN D. MCGOUGH

THE UNIVERSITY OF ALABAMA

2006, ASQ

QualiZJ' as a suppz1 chain performance measure bas

110! been adequately e.\plored in either the supply

cbain or quality management literature. P!amzing for

qualiZJ' in the manufacturing supp(1 chain requires a

context, and begins uith documented customer needs.

An original schematic model depicting the interrelationsbip betueen strategic production pla1111i11g a11d

strategic supply cbain planning prol'ides Ibis context.

Another result is a listing of the departmental customers for the manufacturing supp(1 chain and their

respectil'e needs. The quality requirements for each

supplied part or module. derived from these needs.

should become critical criteria in supplier selection

and other sourcing decisions ll'ben starti11g up a neu

plant. Although supply chains are being created today

using planning processes that focus primariz1 on logistics and production planning. dril'en by cost and

schedule considerations. the autbors argue that there is

a need to formally ''jJlan qualiZJ' in" as uell.

Key l/'Ords: quality function deployment. quality

planning. strategic production planning. strategic

supNJ' chain planning. supp(J' chain management

INTRODUCTION

The manufacturing supply chain uses production

and delivery processes to provide raw materials, parts,

and subassemblies to the point of product assembly.

More generally, "A company's supply chain comprises

geographically dispersed facilities where raw materials, intermediate products, or finished products are

acquired, transformed, stored, or sold and transportation links that connect facilities along which products

flow" (Shapiro 2001). Chopra and Meindl (2001) list

four main drivers that determine the performance of a

supply chain: inventory, transportation, facilities, and

information. When planning a supply chain, these

four main drivers have to be evaluated and optimized

in terms of flexibility, delivery performance, cost, and

quality. Quality is a supply chain performance measure that has not been adequately explored in either

the supply chain or quality management literature.

Miller (2002) says, "We need the same (or better) levels

of planning and communications with key suppliers

as we have enjoyed inside the organization, in order

to meet or exceed end-customer expectations for cost,

lead times, quality, and demand flexibility." The

focus of this article is planning for quality in the

manufacturing supply chain.

Supply Chain Quality

Management

In Juran (1989), quality management is defined as

the application of the managerial processes of Juran's

Quality Trilogy: quality planning, quality control,

and quality improvement. The planning phase of

supply chain quality management is the activity of

www.asq.org 33

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

identifying supply chain customer needs and analyzing

and developing a sourcing strategy to meet those needs.

The focus is on identifying the supply chain customers

and assessing the needs of these customers. The output

of this phase is a set of quality-related requirements, at

the original equipment manufacturer (OEM) and

each supplier, for production and delivery subsystems.

The derived quality requirements for each supplied

part or module should be critical criteria in supplier

selection and supplier plant site selection decisions

during the sourcing process. Without quality planning,

these quality requirements are subordinated to cost

and schedule, and may even be taken for granted.

At least two assembly industries, automotive and

electronics, "have institutionalized quality management practices into the way their business is conducted," according to Choi and Rungtusanatham (1999).

Strategic quality planning and the method of advanced

product quality planning (APQP) are two examples of

common practices in the automotive industry. But

when OEMs establish new plants as part of their

strategic plan, they need to apply strategic supply

chain quality planning to minimize quality-related

problems at production start up.

The control phase of Juran's Quality Trilogy, as

applied to the supply chain, involves evaluating supplier

performance and acting to bring supplier performance in line with expectations, expressed both in

technical specifications and business-related documents and verbal understandings. The improvement

phase of Juran's Quality Trilogy, applied to the supply

chain, has an objective of developing a supply chain

that acts as a single, well-performing entity. Showing

the supplier the effect of poor quality on product costs

and sales may be necessary to stimulate action by the

supplier. Once the need for improvement is known,

some problems can be solved by the supplier, while

others may require joint quality improvement teams

(Batson 2002).

It has been found that the responsibility for supplier

quality lies mostly with a company's purchasing

department. Purchasing departments have shifted their

focus from transaction to process management, and

are now facilitators of the sourcing process. One of the

activities required to facilitate the interface between

suppliers and end users is quality planning. Gryna

(1988) mentions that joint quality planning that

occurs after the supplier has been selected should

include joint economic planning, joint technological

planning, and joint managerial planning. Quality

planning that occurs before supplier selection is "the

activity of identifying customer needs and analyzing

and developing a sourcing strategy to meet those

needs" (Donovan and Maresca 1999). In this article,

the authors identify the customers for the manufacturing supply chain and their categories of need, and

show how quality planning may be viewed as a key

activity within strategic supply chain planning.

Problem Statement

Although supply chains are being created using planning processes that focus primarily on logistics and

production planning and scheduling, there is a need

to "plan for quality" in supply chain operations. A

definition and concept of supply chain quality is

needed, followed by a method that could be used by a

corporation during the early stages of establishing a

new manufacturing plant to plan for quality in the

supply chain supporting the plant.

Research Objective and Scope

The scope of this research is restricted to the earliest

planning stages for a manufacturing supply chain,

which will serve a hypothetical OEM manufacturer of

an assembled product. While it is necessary to discuss

strategic production planning, the focus of this

research is strategic supply chain planning and,

in particular, the quality aspects that have received

little attention. An original schematic model depicting the interrelationship between strategic production

planning and supply chain planning is developed.

Then, an original listing of the OEM's departmental

customers and their needs is developed. These needs

are the input for supply chain quality planning to

be conducted in parallel with other supply chain

planning activities depicted in the model.

34 QMJ VOL. 13, NO. 1/ 2006, ASQ

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

LITERATLiRE REVIEW

In the introduction, the authors reviewed Juran 's

Quality Trilogy and planning for supplier relations.

When applied to the supply chain, the trilogy implies

that effort expended on planning for quality in supply chain operations will more than pay for itself in

avoidance of costly controls and unnecessary

improvement activities. Planning for supplier relations helps establish the informational, contractual.

and other business relationships between customer

and supplier, but does not assure good quality-the

processes embodied in joint quality planning and

Juran's Quality Planning Roadmap are needed. Joint

quality planning enhances communication between

the customer and supplier, and results in cooperative

decisions that optimize overall supply chain costs.

As mentioned previously, there are three areas of joint

quality planning: joint economic planning, joint

technological planning, and joint managerial planning. These are fully explained by Gryna (1988).

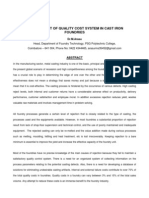

Juran's Quality Planning Roadmap (see Figure 1)

can be applied to derive quality-related requirements

for production and delivery subsystems, at both

the OEM and supplier plants, to be demonstrated in

this article.

ISO 9001 Production

Realization

ISO 9001 defines product realization as that "sequence

of processes and subprocesses needed to achieve the

required product or service." Clause 7, Product

Realization, contains Clause 7.1 "Planning of product

realization," which states that the organization shall

plan and develop the processes needed for product

realization. Clearly, the manufacturing supply chain is

a system of such processes. In ISO 9001, a document

specifying the processes of the quality management

system and the resources to be applied to a specific

product, project, or contract, can be referred to as a

quality plan.

Quality plans in ISO 9001 may refer to raw materials, modules and parts, or the final assembly. Quality

Figure 1 Juran's quality planning roadmap .

Subject matter of planning

ldent;fy ; ..tome"

list of customers

Discover customers' needs

Customers' needs (in their language)

r..,.,1+ need

Customers' needs (in our language)

Develop product features

Product features

Develo~

pn><e"

Process features (process ready to produce)

Transfer to operations

plans include supply chain considerations such as

quality requirements, inspection equipment, packaging, and product identification, handling, and delivery.

Therefore, OEMs certified to the ISO 9001 standard

may provide for some aspects of supply chain quality

planning in their existing processes. If certification

extends to their first-tier suppliers, there is a basis for

confidence that much of what the authors term

"strategic supply chain planning" and quality planning in that context, are occurring.

The six-step models of strategic production and

supply chain planning presented in the next two

subsections of this article constitute generic models

of a planning method for two key product realization

systems: the production system and the supply chain.

The level of detail to be presented in these sections is

restricted to the assembled product and its modules

(subassemblies).

www.osq.org 35

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

STRATEGIC PRODUCTION

PLANNING

OEMs use market research and competitive analysis

to identify a new product to be produced and sold.

Product form, function, and performance dictate the

capabilities required at the OEM plant site. Demand for

the product by location in the worldwide market often

dictates potential locations if a new plant is warranted.

This is because plant location determines distribution

cost directly, and often influences sales volumes and, to

some extent, unit manufacturing cost. As stated by

Bowersox, Closs, and Cooper (2002), "The unique

nature of each manufacturing process and the market

served limit the practical range of alternative strategies."

Because the production department at the OEM is the

major customer for the product's supply chain, the

authors are interested in this subsection and the next in

describing strategic production planning and strategic

supply chain planning. In the next section, they propose a model that depicts the interlocking nature of

these two elements of strategic planning.

Bowersox, Closs, and Cooper (2002) state that

"The most common manufacturing strategies are

make-to-plan (MTP), make-to-order (MTO), and

assemble-to-order (ATO)." Because MTP strategies

exploit economy of scale that results from long production runs, and these strategies are not appropriate for

OEM equipment manufacturers, the authors focus on

MTO strategies. ATO product finalization is performed

in distribution warehouses; "Product components are

manufactured in anticipation of future customer

orders; however, products are not fully assembled or

customized until a customer's order is received"

(Bowersox, Closs, and Cooper 2002). Dell Computers

is an example of a company that has succeeded with

an ATO strategy. All automotive OEMs follow an MTO,

market-pull production strategy today.

Just-in-time (JIT) techniques have naturally been

highlighted in recent textbooks on supply chain

management. Terms such as JIT purchasing, JIT

delivery, and JIT production are common and well

understood. Bowersox, Closs, and Cooper (2002)

state, "The objective of JIT is to time-phase activities

so that purchased materials and components arrive at

the manufacturing or assembly point just at the time

they are required for the transformation process." Akey

point in a JIT supply chain is that the nodes and links

in the chain are organized and scheduled in such a

way that the timing requirements are met, even though

the demand for components and materials depends on

the finalized production schedule at the OEM.

Regarding quality of supplies and logistics, Bowersox,

Closs, and Cooper (2002) observed:

"It is necessary to deal with suppliers who have

high and consistent levels of quality, as their components will go directly into the finished product.

Absolutely reliable logistical performance is

required and eliminates, or at least reduces, the

need for stocks of materials. JIT concepts have

evolved from MTP manufacturing to accommodate MTO and ATO manufacturing as well."

The previous statement provides a rationale for

this study of supply chain quality planning, because

planning is the avenue to "high and consistent levels

of quality" in the product, and to "absolutely reliable

logistical performance." The authors assume a JIT

environment at their hypothetical OEM and in the

required first-tier suppliers' delivery processes.

Furthermore, if supplied components or modules are

preidentified to a specific customer's equipment item,

the authors call the delivery process just-in-sequence.

The term modular design means that the OEM

consciously designs the product for assembly by joining major subassemblies known as modules. These

subassemblies are manufactured off-site and are

delivered to the OEM in a just-in-sequence manner to

match the sequence of final products being produced.

Modular design and assembly offers cost and time

savings, and is typical of OEM automotive manufacturing. The authors assume their hypothetical product

is modular in design and use the term "module" to

mean a major subassembly, ready to install in the

product.

The model of strategic production planning the

authors developed in this research includes the following

steps:

36 QMJ VOL. 13, NO. 1/ 2006, ASQ

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

1. Identify product to be manufactured and sold

2. Forecast demand quantity: by location of customer

sale or by options to be requested

3. Group product components into modules for

potential outsourcing

4. Conduct a make-to-buy decision for each module

5. Identify quality requirements and delivery quantities and schedules for each module

6. Synthesize a product assembly and delivery model,

using the flows of respective modules to the OEM

plant as submodels.

The sixth step links the supply chain function of

providing required modules from external sources with

the production function of delivering finished products

to customers on time, and exactly as they ordered. As

Bowersox, Closs, and Cooper (2002) observed: The

efficient and effective coordination of manufacturing

strategy with the procurement of materials and components ultimately relies on logistics ... logistics link

the supplier base with manufacturing processes.

The next section reviews strategic supply chain

planning, and provides a six-step process for this planning that the authors' research suggests must be carried

out in parallel with strategic production planning. This

parallel (or concurrent) planning provides the best

opportunity for seamless integration, high-quality

supplies, logistics and products, and minimum cost.

STRATEGIC SUPPLY CHAIN

PLANNING

Strategic supply chain planning involves the longterm decisions about a company's supply chain.

These are decisions on how a company's overall

internal and external linkages are organized, not just

one with one supplier. For example, Shapiro (2001)

presents a "Framework for Manufacturing Strategy

Formulation." In this model, he sees product competitiveness as resting on supply chain design, in addition

to product cost and differentiation (long recognized as

the two key dimensions along which firms compete).

In fact, since supply chain design in part determines

the unit manufacturing cost, and because product

quality is a source of differentiation, the authors' focus

on strategic supply chain planning for quality is timely. Shapiro (2001) defines supply chain design as

"decisions regarding the facilities owned and operated

by the company, and the company's relationship with

its suppliers."

The model of strategic supply chain planning

developed in this research incorporates the following

six steps:

1. Define capabilities required of the OEM plant

2. Identify OEM plant site and production rate

3. Define capabilities for each module supplier,

including production rate

4. Select supplier for each outsourced module

5. Simultaneously select supplier locations, mode of

module transportation from supplier to OEM, and

shipment frequency

6. Synthesize a network model of the flow of modules

from first-tier suppliers to OEM, using the OEM

assembly schedule as the driver

There are three planning approaches to this problem:

the operations research (OR) approach, the network

simulation approach, and the quality planning

approach.

The OR approach uses optimization algorithms to

identify the optimal network structure, using OEM

total cost of supplies as the objective function. A

mixed integer linear programming model is used to

formulate the problem. The output of this model will

determine which warehouses, factories, and suppliers

will be chosen, their locations, and the mode of transportation between them, among other decisions. This

provides a minimal cost network capable of meeting

product demand, production and delivery efficiency,

and other management constraints. The deterministic

solution to the decisions listed in step 5 provides the

network structural details.

Anetwork simulation model predicts how a certain

supply chain design will operate under specific conditions over time. This allows for different supply chain

design alternatives to be evaluated, with random

processes (probabilistic events over time) included to

add realism and dynamics. Therefore, step 6 is the

www.asq.org 37

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

Figure 2 Parallel strategic planning processes for production and the supply chain.

Identify product to be assembled and sold

Define capabilities required at the OEM plant

Forecast demand quantity

By location of customer sale

By options

Identify OEM plant site and production rate

Group product components into modules for

potential outsourcing

Define capabilities for each module supplier,

including production rate, quality, and cost

thresholds

Make or buy decision, for each module

Select supplier for each outsourced module

Identify delivery schedule and quality

requirements for each module

Simultaneously, select supplier locations,

mode of module transportation from supplier

to OEM, and shipment frequency

Synthesize a product assembly and delivery

model, using the flows of respective modules

as submodels

"

Synthesize a network of the flow of modules

from first-tier suppliers to OEM, using the

OEM assembly schedule as the driver

place where risks and uncertainties in the supply

chain can have their individual and combined effects

measured, discerned in the performance statistics

provided by a well-planned simulation experiment.

Supply chain designers can propose actions to mitigate

these effects and test them using a revised simulation.

Persson and Olhager (2002) evaluated alternative

supply chain designs using simulation with respect to

quality, lead times, and cost. One objective of their

simulation was to "increase the understanding of the

interrelationships among these and other parameters,

relevant for the design and operations of a supply

chain." The optimal model depicted how costs depend

on quality levels and lead times, and how lead time is

a function of quality levels and the supply chain

structure.

Neither of these approaches specifically tackles the

quality planning aspect of strategic supply chain management. When applying quality planning in addition

to the two planning approaches mentioned previously,

additional quality-related issues are surfaced. Though

the OR and network simulation approaches can

determine the best solution with regard to cost, time,

demand, and so forth, they do not explicitly plan to

meet customers' needs and quality standards. Without

quality planning layered over existing supply chain

planning approaches, the result might be an efficient

supply chain, but one that cannot deliver on quality

expectations without the addition of extensive controls

or improvements. Quality planning approaches, such

as Juran's Quality Planning Roadmap, highlight

th ~se issues to supply chain planners at the time

supply chain structural and logistics decisions are

being made.

MODEL DEVELOPMENT

Based on the discussion in the previous two sections,

this section integrates the two six-step strategic planning processes into a model (see Figure 2), showing

38 QMJ VOL. 13, NO. l/ 2006, ASQ

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

how closely linked supply chain planning is to production planning. Interfaces that carry information

across the boundary between the two processes are

shown as arrows. The parallel, interdependent nature

of the two processes is evident. Viewing the direction of

the cross-boundary arrows clearly shows that production planning decisions (for example, plant location,

make-or-buy) drive supply chain planning. This same

relationship, where production plans drive supply

chain plans at the tactical and operational levels, has

been noted by others.

Hicks 0999) has observed that "Supply chain

planning problems encompass industrial production

process design, inventory control policy, transportation management, supply procurement, and demand

planning ... Although the first step of enterprise analysis is to reduce the problem to a manageable size by

examining only one aspect (link) in the supply chain,

it is now common knowledge that. .. simplifying the

supply chain planning problem, or reducing it to

parts, often renders the analysis itself moot. It is the

complexity and interdependence of the operational

links that result in the areas of interest for the typical

industrial decision maker."

Hicks 0999) goes on to propose a four-step

methodology for using optimization, simulation, and

robust design technologies in strategic supply chain

planning. Step 1 concerns itself with the proposed

supply chain's structure, with structural elements

such as products, sites, shipments, transportation

assets, machines, and workers. He proposes network

optimization as a tool, and an "optimal" supply

chain structure as a result of step 1 then states, "In

order to predict exactly how a proposed supply chain

design will operate, the design must be simulated in

step 2." These two steps match the last two steps the

authors have indicated in the strategic supply chain

planning model of Figure 2. The only difference is

that the authors are not prescribing network optimization and network simulation as the tools to plan

quality into the supply chain. In fact, the authors

believe Juran's Quality Planning Roadmap (or its

Japanese-originated equivalent, quality function

deployment (QFD)) is the best tool. This will be

demonstrated in the next section. Hicks goes on to

recommend policy optimization and design for

robustness to complete his four-step methodology.

These methods optimize network behavior and minimize risk due to uncontrolled factors. Considering

risk in supply chain design has been described before.

There is a paper by Davis 0993) in which risk factors

in supply chain management are described, for

example, the variation in delivery times, quality, and

condition of supplier parts. The paper addresses

strategic issues in that entire product families at

Hewlett-Packard were reevaluated for uncertainty in

their supply and distribution chains. The methodology

could be adapted to start-up of new manufacturing

supply chains.

Shapiro's (2001) view of strategic supply chain

planning, like Hicks' 0999), ignores quality planning. Shapiro states, "Once the options associated

with the supply chain design have been identified, the

company must quantify and integrate them (with

marketing and production strategies) when analyzing its supply chain strategy." He believes that supply

chain modeling incorporates concepts from several

management disciplines:

Strategy formation and the theory of the firm

Logistics, production, and inventory management

Management accounting

Demand forecasting

Operations research

The relevance and application of each of these is

discussed in Shapiro's text (2001). The research

reported here focuses on the role of quality management, and, in particular, quality planning, in supply

chain strategic planning.

QUALITY PLANNING APPLIED

TO THE MANUFACTURING

SUPPLY CHAIN

An organizing model for supply chain strategic plan-

ning was introduced in the previous section. Here, the

authors illustrate how to layer quality planning steps

over the supply chain planning activities depicted in

www.osq.org 39

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

Figure 2, by flowing down quality requirements as

each strategic decision about the supply chain is

made. This will be done using a series of interlocking

matrices, as suggested in Juran's writings and similar

to QFD, the Japanese-originated equivalent of Juran's

Quality Planning Roadmap. QFD "is a method for

structured product planning and development that

enables a development team to specify clearly the

customer's wants and needs, and then to evaluate

each proposed product or service capability systematically in terms of its impact on meeting those needs"

(Cohen 1995).

In order to begin the requirements flow down

process, a few assumptions must first be made. These

are:

Discrete-part assembled product

MTO manufacturing strategy

JIT production and delivery system

Product consists of modules, many produced by

tier 1 suppliers.

Who Are the Customers for

the Supply Chain~

The first step in the Juran quality planning process

is to determine "Who are the customers?" This section

discusses the customers of the supply chain and how

they relate to the supply chain. The customers of the

supply chain are: production, purchasing, production

planning and scheduling, supplier quality engineering, logistics personnel, and the plant manager or

president.

The main customer of the supply chain is the

production department. This department consumes

what the supply chain delivers. The production

department is responsible for assembling the product.

It cannot complete products unless all supplies (for

example, modules and parts) arrive on time, in the

right quantity and type, with perfect quality, and are

ready to use in assembly.

The purchasing department is another customer

of the supply chain. This department identifies the

possible sources of the parts needed to be supplied.

From those sources, the best source is selected and

becomes the sole supplier for that part. Once the supplier has been selected, the purchasing department

negotiates and enforces the terms of the contract with

the supplier. Purchasing may also advise the supplier

on the selection of their plant site.

Production planning and scheduling (PP&S) is

responsible for informing the suppliers of what exactly

is needed and when it is needed. PP&S personnel are

often involved in logistics planning, coordination,

and control. PP&S often tracks inventory location and

quantity, whether in transit or in stock (off or on site).

They may select the mode of transportation and

source (for example, truck line) of transportation of

supplies.

Supplier quality engineering (SQE) interprets

quality requirements to each of the suppliers. They

assure that suppliers can produce acceptable quality

at the rate of production and that packaging and

handling do not affect the quality of supplied parts.

SQE tracks the quality of delivered parts and investigates issues with delivered parts that cannot be

assembled, or fail in assembly.

Logistics personnel include the logistics system engineers or planners, cross-company logistics personnel,

internal logistics personnel, packaging engineers, the

maintainers of parts' containers and racks, and,

finally, the internal conveyance engineers. Crosscompany logistics personnel are people such as drivers,

loaders, and unloaders. Internal logistics personnel are

the packaging, unpackaging, and conveyance personnel (for example, drivers). The conveyance engineers

are those responsible for the design and installation of

the means of conveying parts and materials within

the plant.

Finally, the plant manager or president is a customer of the supply chain. For the OEM, the plant

manager or president is a customer because the aforementioned functions listed report to him or her, and

affect the plant's success. As for the supplier, he or she

is a customer because timely and safe delivery of his

or her production output depends on the supply chain.

Once the supply chain customers and their needs

have been determined (see Appendix), it is up to the

40 QMJ VOL. 13, NO. l/ 2006, ASQ

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supp Iv Chain

OD1 user of the authors supply chain planning

model (see Figure 2) to apply Juran 's Quality

Planning Roadmap (or QFD) to derive and document

the quality requirements that should influence key

decisions. such as:

OEM plant site location

OEM production and delivery system design

Supplier selection and plant site location

Supplier production and delivery system design

Strategic supply chain quality planning, which

determines and documents quality requirements in

parallel with other supply chain planning activities,

naturally supports such sourcing and site selection

decisions.

CONCLUSIONS

The objective of this research was to create a method

that could be used by a corporation during the early

stages of establishing a new manufacturing plant, to

plan for quality in the supply chain supporting the

plant. The focus was strategic supply chain planning,

especially the quality aspects that have received little

attention. An original schematic model was developed,

depicting the interrelationship between strategic production planning and strategic supply chain planning.

Then, following juran's Quality Planning Roadmap

approach, supply chain customers and their needs

were documented for the first time.

REFERENCES

Batson, Robert G. 2002. Getting started in a supplier improvement

initiative. 2002 ASQ 56th annual quality congress proceedings.

Milwaukee: American Society for Quality.

Bowersox, Donald J., David J. Closs, and M. Bixby Cooper.

2002. Supply chain logistics management. Boston: McGrawHill/Irwin.

Choi, Thomas Y., and Manus Rungtusanatham. 1999.

Comparison of quality management practices: Across the supply

chain and industries. Journal of Supply Chain Management 35,

no. l.

Chopra, Sunil, and Peter Meindl. 2001. Supply chain management:

strategy, planning, and operation. Upper Saddle River, N. J.:

Prentice-Hall, Inc.

Cohen, Lou. 1995. Quality function deployment: how to make QFD

work for you. Reading, Mass.: Addison-Wesley Longman, Inc.

Davis, Tom. 1993. Effective supply chain management. Sloan

Management Review 34, no. 4: 35-46.

Donovan, John A., and Frank P. Maresca. 1999. Supplier relations.

In Juran's quality handbook, 5th ed., ed. J.M. Juran and A. Blanton

Godfrey. New York: McGraw-Hill.

Gryna, Frank M. 1988. Supplier relations. In Juran's quality control

handbook, 4th ed., ed. J. M. Juran and Frank M. Gryna. New York:

McGraw-Hill.

Hicks, Donald A. 1999. A four-step methodology for using simulation and optimization technologies in strategic supply chain

planning. 1999 Winter Simulation Conference Proceedings,

Volume 2. Atlanta: Institute of Industrial Engineers.

Juran, J. M. 1989. Juran on leadership for quality: an executive

handbook. New York: The Free Press.

Miller, Charles R. 2002. Competing through supply chains: the

rise of integrated supply chain management. Journal of the

Reliability Analysis Center l 0, no. 3: l -4.

Persson, Fredrik, and Jon Olhager. 2002. Performance simulation of supply chain designs. International Journal of Production

Economics 77, no. 3: 231-245.

Shapiro, Jeremy F. 200 l. Modeling the supply chain. Pacific

Grove, Calif.: Duxbury.

Simchi-Levi, David, Philip Kaminsky, and Edith Simchi-Levi.

2000. Designing and managing the supply chain: concepts,

strategies, and case studies. Boston: McGraw-Hill/Irwin.

BIOGRAPHIES

Robert Batson is a professor of industrial engineering at the

University of Alabama (UA), where he teaches and performs

research in quality engineering and operations research. In 21

years at Alabama, he has held research contracts and grants

worth more than $2 million with organizations such as BellSouth,

Mercedes-Benz, NASA, Army Materiel Command, and the FAA.

Prior to joining UA, he worked for five years as a systems engineer with Lockheed Corporation. He received a master's degree in

mathematics from Florido State in 1974, and two degrees from

Alabama in 1979: a doctorate in mothemotics and a master's

in industrial engineering. Botson is o Registered Professional

Engineer in California, and an ASQ Fellow. He can be reached

by e-mail at rbatson@coe.eng.ua.edu .

Karen McGough is a research engineer with the Naval Surface

Warfare Center in Panama City, Fla. At the time of this research,

she was a graduate research assistant in industrial engjneering

at the University of Alabama, where she received the master's

degree in industrial engineering in 2004, and a bachelor's

degree in mathematics in 2002. She may be contacted by e-mail

atkaren.mcgough@navy.mil .

www.asq.org 41

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Quality Planning for the Manufacturing Supply Chain

APPENDIX

Supply Chain Customer Needs

The following is an original list of the needs for each

customer in terms of the supply chain.

Production Needs

Modules/parts/fluids needs:

Meet specifications (form, fit, finish, function)

Are identifiable

Available when needed, and in sequence if required

Available in right quantity and type

Are undamaged by shipment or handling

Are essentially ready to use

Containers/pallets/racks needs:

Compatible with material handling systems within

production

Compatible with space allocated for parts within

the plant

Do not contribute to supply damage while in use

Actual arrival time of orders

Back orders and their status

Lost orders and their status

Returned orders and their status

Containers/pallets/racks needs:

Location of each, and under control of whom?

Properly identified

Undamaged or damaged properly repaired

Logistics (Internal and External)

Needs

Unit loads compatible with transportation

equipment

Unit loads compatible with material handling

equipment

Transportation equipment with driver, at right

location at right time

Material handling equipment with automatic

controller or driver

Pick-up and delivery schedule, with description of

the cargo

Protective packaging/wrapping needs:

Easy to remove prior to assembly

Supplier Quality Engineering

Needs

Easy to dispose of or recycle

Quality requirements for each module/part/fluid

Prevent damage/deterioration of parts in transit or

inventory

Production Planning and

Scheduling Needs

Modules/parts/fluids needs:

Location of each order, under control of whom?

Completeness of each order

Estimated arrival time of orders

Amethod of measuring conformance to requirement

Amethod of sorting, labeling, and tracking defective

units

An advanced product quality plan for each part

Apre-production acceptance plan for each part

Traceability of a defective module or part to lower

levels in supply-chain, methods and materials

used, and so on.

42 QMJ VOL. 13, NO. 1/ 2006, ASQ

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

Potrebbero piacerti anche

- Gateway 2nd Edition C1 Teacher's BookDocumento115 pagineGateway 2nd Edition C1 Teacher's BookBrittan Ian Peter78% (36)

- Competitive Strategies in Retailing An Investigation of The Applicability of Porter's Framework For Food RetailersDocumento13 pagineCompetitive Strategies in Retailing An Investigation of The Applicability of Porter's Framework For Food Retailersjoannakam0% (1)

- Feminist TheoryDocumento12 pagineFeminist TheoryJelly Bean80% (5)

- Deped K To 12 - English Session GuideDocumento3 pagineDeped K To 12 - English Session Guideyachiru121100% (13)

- Quality Function DeploymentDocumento8 pagineQuality Function Deploymentoglenk_nfNessuna valutazione finora

- 20-MBA-Fundamentals of Logistics and Supply Management-Unit 3Documento44 pagine20-MBA-Fundamentals of Logistics and Supply Management-Unit 3Rahul GoudaNessuna valutazione finora

- Identification of Performance Measures For Establishing A Framework For Performance Measurement in Supply ChainsDocumento33 pagineIdentification of Performance Measures For Establishing A Framework For Performance Measurement in Supply Chainssymphs88Nessuna valutazione finora

- Quality Improvement Using Statistical Process Control in Automotive Ancillary: A Case StudyDocumento5 pagineQuality Improvement Using Statistical Process Control in Automotive Ancillary: A Case Studymushtaq789Nessuna valutazione finora

- 2016 - CoQ Implementation Methodology-A Case Study in Medium Size MFG Enterprise - PRINTDocumento6 pagine2016 - CoQ Implementation Methodology-A Case Study in Medium Size MFG Enterprise - PRINTwuri rahardjoNessuna valutazione finora

- Models For Optimization of Supply ChainDocumento17 pagineModels For Optimization of Supply Chaindon mcleanNessuna valutazione finora

- Group - 3, Managing Quality in De-Centralised Supply ChainDocumento21 pagineGroup - 3, Managing Quality in De-Centralised Supply ChainASTHA AKRITINessuna valutazione finora

- Role and Application of Supply Chain Performance Measurement SystemDocumento10 pagineRole and Application of Supply Chain Performance Measurement SystemSami Ur RehmanNessuna valutazione finora

- 6-A Model For Supply Chain Design Considering Cost of QualityDocumento16 pagine6-A Model For Supply Chain Design Considering Cost of QualityIslamSharafNessuna valutazione finora

- Putri 2019 IOP Conf. Ser. Mater. Sci. Eng. 505 012011Documento7 paginePutri 2019 IOP Conf. Ser. Mater. Sci. Eng. 505 012011rezaNessuna valutazione finora

- Kevin - Artículo 1Documento7 pagineKevin - Artículo 1kevin alexander salguero lopezNessuna valutazione finora

- Metodos de Control de Calidad en La FabricaciónDocumento9 pagineMetodos de Control de Calidad en La FabricaciónOscar GomezNessuna valutazione finora

- The Procurement ProcessDocumento7 pagineThe Procurement ProcessXtianPNessuna valutazione finora

- DR - Alaa Mashiel: Report About Quality AssuranceDocumento13 pagineDR - Alaa Mashiel: Report About Quality Assuranceحسين ميثم سعيد مهديNessuna valutazione finora

- Best Practices in Supplier Quality ManagementDocumento4 pagineBest Practices in Supplier Quality ManagementAnonymous 3tOWlL6L0UNessuna valutazione finora

- Production Operations Management Muhammad Hammad Alam Bs64 8004 Capacity PlanningDocumento2 pagineProduction Operations Management Muhammad Hammad Alam Bs64 8004 Capacity PlanningHammad AlamNessuna valutazione finora

- Scor ModelDocumento8 pagineScor ModelDerbel WalidNessuna valutazione finora

- Dissertation - Quality in Supply Chain ManagementDocumento30 pagineDissertation - Quality in Supply Chain ManagementAbhishek JainNessuna valutazione finora

- Emma WorkDocumento7 pagineEmma Workoluwasegunnathaniel0Nessuna valutazione finora

- Quality Costs in A Manufacturing Industry: A Gateway For ImprovementDocumento11 pagineQuality Costs in A Manufacturing Industry: A Gateway For ImprovementDih LimaNessuna valutazione finora

- The Structural Influence of Supply Chain Management On Product Quality and Business PerformanceDocumento7 pagineThe Structural Influence of Supply Chain Management On Product Quality and Business PerformanceGodfred TakyiNessuna valutazione finora

- Impact Quality Management Practices On Performance and Competitive AdvantageDocumento34 pagineImpact Quality Management Practices On Performance and Competitive Advantagejust justNessuna valutazione finora

- Building A Customer Requirement Based Supplier Quality Management SystemDocumento3 pagineBuilding A Customer Requirement Based Supplier Quality Management SystemP Singh KarkiNessuna valutazione finora

- Benefits of Six Sigma in Supply Chain MaDocumento8 pagineBenefits of Six Sigma in Supply Chain MaAjayi AugustineNessuna valutazione finora

- 18-Quality Costing An Effecient Measurement For ImprovementDocumento8 pagine18-Quality Costing An Effecient Measurement For ImprovementIslamSharafNessuna valutazione finora

- PRR ReportDocumento4 paginePRR ReportAkash SawantNessuna valutazione finora

- Adopting The Product Lifecycle ApproachDocumento4 pagineAdopting The Product Lifecycle Approach刘朝阳Nessuna valutazione finora

- Montg ManualDocumento20 pagineMontg ManualMaryam ShirbanNessuna valutazione finora

- Core ToolsDocumento15 pagineCore ToolsUn-peu de-toutNessuna valutazione finora

- Measuring Retail Supply Chain Performance - Theoretical Model Using Key Performance Indicators (KPIs)Documento34 pagineMeasuring Retail Supply Chain Performance - Theoretical Model Using Key Performance Indicators (KPIs)shradha_DAIMSRNessuna valutazione finora

- Cost of Quality Section ADocumento46 pagineCost of Quality Section APranav ShandilNessuna valutazione finora

- Putri 2019 IOP Conf. Ser. Mater. Sci. Eng. 505 012011Documento7 paginePutri 2019 IOP Conf. Ser. Mater. Sci. Eng. 505 012011NATURENessuna valutazione finora

- D ScoreDocumento7 pagineD ScoreDenny SheatsNessuna valutazione finora

- Accepted Manuscript: Computers & Industrial EngineeringDocumento33 pagineAccepted Manuscript: Computers & Industrial EngineeringLourdes Valera ReaNessuna valutazione finora

- UCT SCM M8U3 NotesDocumento9 pagineUCT SCM M8U3 Notesgaolebe lucasNessuna valutazione finora

- The Role of Engineering in Supply Chain Management William K. Hoehn, Ph.D. Raytheon Systems Company Tucson, ArizonaDocumento6 pagineThe Role of Engineering in Supply Chain Management William K. Hoehn, Ph.D. Raytheon Systems Company Tucson, Arizonacsrajmohan2924Nessuna valutazione finora

- Development of Supplier Quality Performances in A Semiconductor Company FDocumento5 pagineDevelopment of Supplier Quality Performances in A Semiconductor Company Fmobassher01866044145Nessuna valutazione finora

- Introduction and Purpose of The Selected Article-1Documento6 pagineIntroduction and Purpose of The Selected Article-1Sudip ThapaNessuna valutazione finora

- Computational ThinkingDocumento10 pagineComputational ThinkingHà Vi ĐinhNessuna valutazione finora

- Super PaperDocumento11 pagineSuper Paperrathish14uNessuna valutazione finora

- INDM4210-Rahul Kothari - Graduate Term PaDocumento25 pagineINDM4210-Rahul Kothari - Graduate Term PaJean Lucas Haag AbbudNessuna valutazione finora

- Cost of Quality As A Driver For Continuous Improvement - Case Study - Company XDocumento8 pagineCost of Quality As A Driver For Continuous Improvement - Case Study - Company XAbdur Rahman UsamaNessuna valutazione finora

- The Supply Chain Management Article4Documento24 pagineThe Supply Chain Management Article4Elzein Amir ElzeinNessuna valutazione finora

- PDF 18 Dec 12Documento8 paginePDF 18 Dec 12Khtb AshrafNessuna valutazione finora

- Maximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)Documento10 pagineMaximizing Efficiency and Compliance: Essential Tips For Conducting An Effective Annual Product Quality Review (APQR)aniaaa220Nessuna valutazione finora

- Pharmaceutical Industry Deviation Management Case StudyDocumento8 paginePharmaceutical Industry Deviation Management Case StudytrinhtreeNessuna valutazione finora

- S ChainDocumento4 pagineS Chainsisay.d234Nessuna valutazione finora

- Oil & Gas Supply Chain - Key FindingsDocumento18 pagineOil & Gas Supply Chain - Key FindingsAchu F AchamNessuna valutazione finora

- Module 3Documento47 pagineModule 3ashir807Nessuna valutazione finora

- Building & Leveraging The Metrics Framework For Driving Enterprise Performance Management (EPM) - A Supply Chain Management ViewDocumento13 pagineBuilding & Leveraging The Metrics Framework For Driving Enterprise Performance Management (EPM) - A Supply Chain Management ViewSameerNagnurNessuna valutazione finora

- Managing Suppliers For Continuous Improvement: White PaperDocumento6 pagineManaging Suppliers For Continuous Improvement: White Papervenkat raNessuna valutazione finora

- Lean Supply Chain Performance Evaluation Method: June 2012Documento16 pagineLean Supply Chain Performance Evaluation Method: June 2012Carlos Delgado NietoNessuna valutazione finora

- Internal Test - III Part - ADocumento9 pagineInternal Test - III Part - AramNessuna valutazione finora

- Chapter Five Quality Management and Control 5.1. Overview of Total Quality Management and Quality SpecificationDocumento7 pagineChapter Five Quality Management and Control 5.1. Overview of Total Quality Management and Quality SpecificationGebrekiros ArayaNessuna valutazione finora

- Supplied ChainDocumento81 pagineSupplied ChainEslam A. FahmyNessuna valutazione finora

- Report Ilim PDFDocumento16 pagineReport Ilim PDFKumarNessuna valutazione finora

- Process Monitoring and Improvement HandbookDa EverandProcess Monitoring and Improvement HandbookNessuna valutazione finora

- Pharmaceutical Quality Management System (QMS) Questions and AnswersDa EverandPharmaceutical Quality Management System (QMS) Questions and AnswersNessuna valutazione finora

- The Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyDocumento12 pagineThe Effects of Corporate Brand Attributes On Attitudinal and Behavioural Consumer LoyaltyjoannakamNessuna valutazione finora

- A Path Analytic Model of Store Loyalty Involving Self-Concept, Store Image...Documento27 pagineA Path Analytic Model of Store Loyalty Involving Self-Concept, Store Image...joannakamNessuna valutazione finora

- (Ehrenberg & Goodhardt 2000) New Brands Near Instant LoyaltyDocumento8 pagine(Ehrenberg & Goodhardt 2000) New Brands Near Instant LoyaltyjoannakamNessuna valutazione finora

- Impact of Brand Image, Service Quality and Price On Customer Satisfaction in Pakistan Telecommunication SectorDocumento7 pagineImpact of Brand Image, Service Quality and Price On Customer Satisfaction in Pakistan Telecommunication SectorCorinne MooreNessuna valutazione finora

- Testing An Expanded Attitude Model of Goal-Directed Behavior in A Loyalty ContextDocumento22 pagineTesting An Expanded Attitude Model of Goal-Directed Behavior in A Loyalty ContextjoannakamNessuna valutazione finora

- Customer Retention, Loyalty, and Satisfaction in The German Mobile Cellular Telecommunications MarketDocumento21 pagineCustomer Retention, Loyalty, and Satisfaction in The German Mobile Cellular Telecommunications Marketjoannakam100% (1)

- The Impact of Brand Image On Consumer Behavior A Literature ReviewDocumento6 pagineThe Impact of Brand Image On Consumer Behavior A Literature ReviewjoannakamNessuna valutazione finora

- An Examination of The Effect of Product Performance On Brand Reputation, Satisfaction and LoyaltyDocumento17 pagineAn Examination of The Effect of Product Performance On Brand Reputation, Satisfaction and Loyaltyjoannakam0% (1)

- The Relationship Between Customer Satisfaction and Loyalty Cross-Industry DifferencesDocumento6 pagineThe Relationship Between Customer Satisfaction and Loyalty Cross-Industry DifferencesjoannakamNessuna valutazione finora

- Customer Loyalty The Future of Hospitality MarketingDocumento26 pagineCustomer Loyalty The Future of Hospitality MarketingjoannakamNessuna valutazione finora

- Customer Satisfaction in The Hong Kong Mobile Phone IndustryDocumento13 pagineCustomer Satisfaction in The Hong Kong Mobile Phone IndustryjoannakamNessuna valutazione finora

- Customer Loyalty in The Hotel Industry The Role of Customer Satisfaction and ImageDocumento5 pagineCustomer Loyalty in The Hotel Industry The Role of Customer Satisfaction and ImagejoannakamNessuna valutazione finora

- A National Customer Satisfaction Barometer The Swedish ExpeDocumento16 pagineA National Customer Satisfaction Barometer The Swedish Expejoannakam100% (1)

- Customer Satisfaction and Loyalty Start With The Product, Culminate With The BrandDocumento13 pagineCustomer Satisfaction and Loyalty Start With The Product, Culminate With The BrandjoannakamNessuna valutazione finora

- Brand Loyalty vs. Repeat Purchasing BehaviorDocumento9 pagineBrand Loyalty vs. Repeat Purchasing BehaviorjoannakamNessuna valutazione finora

- Understanding Customer Loyalty Through System Dynamics The Case of A Public Sports Service in SpainDocumento23 pagineUnderstanding Customer Loyalty Through System Dynamics The Case of A Public Sports Service in SpainjoannakamNessuna valutazione finora

- Customer Loyalty Toward An Integrated Conceptual FrameworkDocumento16 pagineCustomer Loyalty Toward An Integrated Conceptual FrameworkjoannakamNessuna valutazione finora

- (Park, Jaworski & MacInnis 1986) Strategic Brand Concept-ImageDocumento11 pagine(Park, Jaworski & MacInnis 1986) Strategic Brand Concept-ImagejoannakamNessuna valutazione finora

- Strategies For Assessing and Managing Organizational StakeholdersDocumento15 pagineStrategies For Assessing and Managing Organizational StakeholdersjoannakamNessuna valutazione finora

- M. Phil & Masters ProgrammesDocumento23 pagineM. Phil & Masters ProgrammesShilpa SahuNessuna valutazione finora

- Moving To A New Country British English Student Ver2Documento4 pagineMoving To A New Country British English Student Ver2Paula LyrioNessuna valutazione finora

- Basic Information NewDocumento4 pagineBasic Information NewOBASEKINessuna valutazione finora

- Artikel QualitatifDocumento18 pagineArtikel QualitatifJuliana RahmawatiNessuna valutazione finora

- LKS Chapter 5 Dan 6 Kelas 7Documento36 pagineLKS Chapter 5 Dan 6 Kelas 7PINAWATINessuna valutazione finora

- Minutes of Meeting Science Quiz BeeDocumento5 pagineMinutes of Meeting Science Quiz BeeOhm PawatNessuna valutazione finora

- Health Seeking Behaviour and Healthcare Services in Rajasthan, India A Tribal Community's PerspectiveDocumento25 pagineHealth Seeking Behaviour and Healthcare Services in Rajasthan, India A Tribal Community's PerspectiveThe IIHMR UniversityNessuna valutazione finora

- Math Notes by Sunil Khrub (Gossc - In)Documento305 pagineMath Notes by Sunil Khrub (Gossc - In)RohitNessuna valutazione finora

- Diploma in Engineering and Technology: Curriculum Development Centre, DOTEDocumento219 pagineDiploma in Engineering and Technology: Curriculum Development Centre, DOTEMECHANICAL TOOL & DIENessuna valutazione finora

- Feb2018Documento226 pagineFeb2018Mioara RoscaNessuna valutazione finora

- Book Review FormatDocumento3 pagineBook Review FormatJayson MercadoNessuna valutazione finora

- Breast Cancer Diagnosis Using MachineDocumento11 pagineBreast Cancer Diagnosis Using Machinenguyenhaminh36Nessuna valutazione finora

- WPS Dongle2 User Manual enDocumento38 pagineWPS Dongle2 User Manual ennias144Nessuna valutazione finora

- Nguyen Hoang Bao Vinh ResumeDocumento1 paginaNguyen Hoang Bao Vinh Resumenghbvinh19Nessuna valutazione finora

- Episode 1 FS 2Documento9 pagineEpisode 1 FS 2Daniela RiosNessuna valutazione finora

- Short Term Plan Grade 8: Number Present: AbsentDocumento22 pagineShort Term Plan Grade 8: Number Present: AbsentDinara TolegenovaNessuna valutazione finora

- Information Management Module 1Documento7 pagineInformation Management Module 1ML MariaWengNessuna valutazione finora

- Assignment 2 LastDocumento34 pagineAssignment 2 Lastapi-455660717Nessuna valutazione finora

- BANKAL ES CIGPs 4th QuarterDocumento7 pagineBANKAL ES CIGPs 4th Quarterma.louregie l. bonielNessuna valutazione finora

- Educ102 ExamDocumento13 pagineEduc102 ExamRonibe B MalinginNessuna valutazione finora

- 006 DEW Kaltarbeitsstahl GBDocumento96 pagine006 DEW Kaltarbeitsstahl GBhelderfsnNessuna valutazione finora

- International Society For Soil Mechanics and Geotechnical EngineeringDocumento5 pagineInternational Society For Soil Mechanics and Geotechnical EngineeringALANG CANDRA MARSUDIANTONessuna valutazione finora

- Search Algorithms in Artificial IntelligenceDocumento13 pagineSearch Algorithms in Artificial IntelligencenandhiniNessuna valutazione finora

- Chapter 16 Transforming Shapes Scheme of Work: Marshall Cavendish Maths Stage 6Documento2 pagineChapter 16 Transforming Shapes Scheme of Work: Marshall Cavendish Maths Stage 6rightwayNessuna valutazione finora

- wsc2018 Schedule WebDocumento46 paginewsc2018 Schedule WebAndrea AcriNessuna valutazione finora

- Bridging Between LanguagesDocumento14 pagineBridging Between Languagestrisha abad80% (5)

- My Technology Lesson PlanDocumento2 pagineMy Technology Lesson PlansaraNessuna valutazione finora