Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Homework 7 - Due Date April 7

Caricato da

Justin DuranTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Homework 7 - Due Date April 7

Caricato da

Justin DuranCopyright:

Formati disponibili

CE 742 Pavement Systems Engineering: Spring 2014, IIT Bombay

Homework 7

Due Date: 07.04.2014

Name : ________________________________

Roll No._________________________

NOTE: Make sure to include the printout from IITPAVE wherever required and highlight critical locations.

1.

The data from the axle load survey conducted on a national highway is given in Table 1. Estimate following

values:

a. Number of Trucks

b. Number of Equivalent Single Axle

c. Number of Axles Per Vehicle

d. Vehicle Damage Factor

e. Percentage of Steering, Single, Tandem and Tridem Axles

Steering Axle

Load Range,

No.

kN

Axles

145-155

0

135-145

0

125-135

0

115-125

0

105-115

0

95-105

0

85-95

0

75-85

10

65-75

4

55-65

12

45-55

3

<45

500

2.

Single Axle

Load Range,

No.

kN

Axles

185-195

5

175-185

3

165-175

2

155-165

3

145-155

3

135-145

2

125-145

2

115-125

10

105-115

50

95-105

50

85-95

75

<85

200

Tandem Axle

Load Range,

No.

kN

Axles

390-410

2

370-390

1

350-370

2

330-350

3

310-330

2

290-310

3

270-290

2

250-270

5

230-250

7

210-230

9

190-210

10

170-190

35

<170

50

Tridem

Load Range,

No.

kN

Axles

585-615

0

555-585

0

525-555

0

495-525

1

465-495

1

435-465

2

405-435

2

375-405

1

345-375

3

315-345

5

285-315

10

255-285

15

<285

50

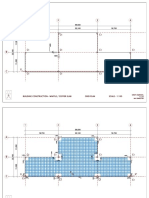

Design following different types of flexible pavements for four-lane divided national highway as per IRC 372012 and IITPAVE, for the given data. The target is successful design of a pavement without any types of

distresses (i.e., fatigue, rutting, fatigue damage in cementations layer). You should redesign a pavement until

unless you are successful. The design should be optimized therefore all the possible combinations should be

tried. Also, compare all the designed pavements in a tabular format with type of layer and thickness,

allowable and estimated tensile strains or stresses. Draw neat and clean drawing of each pavement section

with proper labelling. Comment on your results. No change in given data.

2.1 Type I: Granular Base and Granular Subbase (Fig. 10.1 in IRC 37-2012)

2.2 Type II: Cementatious Base and Cementatious Subbase with Aggregate Interlayer (Fig. 10.2 in IRC 372012): Design should also be checked for fatigue damage of cementatious base

2.3 Type III: Cementatious base and Cementatious Subbase with SAMI at the Interface of Cementatious Base

and the Bituminous Layer (Fig. 10.3 in IRC 37-2012). Design should also be checked for fatigue damage of

cementatious base.

2.4 Type IV: Foamed Bitumen/Bitumen Emulsion Treated RAP with Cementatious Base (Fig. 10.4 in IRC 372012). Design should also be checked for fatigue damage of cementatious base.

2.5 Type V: Cementatious Base and Granular Subbase with Crack Relied Layer of Aggregate Layer above the

Cementatius Base (Fig. 10.5 in IRC 37-2012). Design should also be checked for fatigue damage of

cementatious base.

Design Data (Assume other design data as per IRC 37:2012 and highlight them in your sheet)

ADT: 15,000 as per last count before start of the construction (both direction)

Truck (%): 20 as per last count before start of the construction

Construction Period: 5 Years

Truck Growth Rate: 7.5%

VDF : Estimated in Problem 1.

Design Life: 20 Years

Page 1 of 2

CE 742 Pavement Systems Engineering: Spring 2014, IIT Bombay

Directional distribution Factor: 0.5

CBR of Compacted Borrow Material 500 mm Thick: 20%

CBR of natural subgrade: 3%

Reliability of Design: 90%

No correction factor to fatigue life

Resilient Modulus of Asphalt Mix: 3000 MPa

E for Cementatious Base: 6000 MPa

E for Cementatious Subbase: 700 MPa

E for Aggregate Interlayer for Type II: 500 MPa

Resilient Modulus of RAP layer : 800 MPa

Flexural Strength of Cementatious Base: 1.4 MPa

Poisson Ratio: Asphalt mix: 0.45, Aggregate: 0.25, Soil: 0.35, Cementatious base and

subbase: 0.25, RAP Layer: 0.35

Number of axle per vehicle: Estimate from Problem 1

Axle Load Spectra: Given in Problem 1

RF = 1

Hint: For fatigue damage analysis of cementations base layer, one tandem axle is taken as two single axles and

one tridem axle is taken as three single axles carrying equal weight. This information is useful for estimating

tensile stress at bottom of cementatious layer using IITPAVE software. Check solved example in Annex- II on

page 57 in IRC 37-2012.

Page 2 of 2

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Water Tank Design Is 3370Documento103 pagineWater Tank Design Is 3370Intezaar100% (1)

- Casting of ConcreteDocumento3 pagineCasting of ConcreteoliverNessuna valutazione finora

- Irb M UpdatedDocumento398 pagineIrb M UpdatedAnonymous cYcLLOmmk8Nessuna valutazione finora

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocumento1 paginaRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- Nomination EmptyDocumento159 pagineNomination EmptyJustin DuranNessuna valutazione finora

- Homework 8 - Due Date April 10Documento2 pagineHomework 8 - Due Date April 10Justin DuranNessuna valutazione finora

- Office of The DyDocumento1 paginaOffice of The DyJustin DuranNessuna valutazione finora

- PlayerDocumento4 paginePlayerJustin DuranNessuna valutazione finora

- Assignment 09Documento7 pagineAssignment 09Justin DuranNessuna valutazione finora

- AssignmentDocumento6 pagineAssignmentJustin DuranNessuna valutazione finora

- PHEROLSDocumento14 paginePHEROLS520219005 AnweshaMrokNessuna valutazione finora

- Iqwq KD WPWRK D7 1109 - 0Documento76 pagineIqwq KD WPWRK D7 1109 - 0Suresh MahalingamNessuna valutazione finora

- Case Study: Sheraton Hotel, Bilbao, SpainDocumento13 pagineCase Study: Sheraton Hotel, Bilbao, Spainfloi dNessuna valutazione finora

- Analysis of Beams and Frames: Theory of Structure - IDocumento20 pagineAnalysis of Beams and Frames: Theory of Structure - IMuhammad UsmanNessuna valutazione finora

- Grid Plan Building Construction - Waffle / Coffer Slab SCALE - 1:100Documento3 pagineGrid Plan Building Construction - Waffle / Coffer Slab SCALE - 1:100Dristi KejriwalNessuna valutazione finora

- Types of Piles: Classification of Piles On The Basis of Load TransferDocumento4 pagineTypes of Piles: Classification of Piles On The Basis of Load TransferAnkush PendhariNessuna valutazione finora

- Modal and Harmonic Analysis of A Cantilver Beam With Differrent Cross-SectionsDocumento6 pagineModal and Harmonic Analysis of A Cantilver Beam With Differrent Cross-SectionsTJPRC PublicationsNessuna valutazione finora

- Structural Analysis and Design Report of Cum Residential BuildingDocumento38 pagineStructural Analysis and Design Report of Cum Residential BuildingSabeen budhathokiNessuna valutazione finora

- BucklingDocumento15 pagineBucklingAbhijeet SahuNessuna valutazione finora

- Tunis MallDocumento16 pagineTunis Mallعبدالمجيد اشرف عادل مجيدNessuna valutazione finora

- Earthquake LectureDocumento210 pagineEarthquake LectureJeff DatinguinooNessuna valutazione finora

- Materials: Performance Characterization of Semi-Flexible Composite MixtureDocumento13 pagineMaterials: Performance Characterization of Semi-Flexible Composite Mixturethanhnhat5521Nessuna valutazione finora

- MACE60035 Principles of Structural Engineering Design 18-19Documento12 pagineMACE60035 Principles of Structural Engineering Design 18-19KrisNessuna valutazione finora

- Methodical Approach To Repair BuildingsDocumento12 pagineMethodical Approach To Repair BuildingsSri vaishnavaNessuna valutazione finora

- Evaluasi Seismik Gedung Bertingkat EksisDocumento10 pagineEvaluasi Seismik Gedung Bertingkat EksisDonny. B TampubolonNessuna valutazione finora

- BQ KCT Per Wall PrefabDocumento17 pagineBQ KCT Per Wall PrefabDaniel EvansNessuna valutazione finora

- Hooks in Beams Stirrups: Column Tie Hook DetailsDocumento1 paginaHooks in Beams Stirrups: Column Tie Hook DetailsDesign explorer olomizanaNessuna valutazione finora

- The Nelson System Catalouge Version 2 2017 Shear StudsDocumento8 pagineThe Nelson System Catalouge Version 2 2017 Shear StudsMacNessuna valutazione finora

- Beam To Column'S Flange Fixed Connection - Bcff-2: Design DataDocumento5 pagineBeam To Column'S Flange Fixed Connection - Bcff-2: Design DataAchmad RifaiNessuna valutazione finora

- Cutting List RoofingDocumento2 pagineCutting List RoofingCzarinaCanarAguilarNessuna valutazione finora

- Tupi NHSDocumento6 pagineTupi NHSRimar LiguanNessuna valutazione finora

- Lewis Fixing and InstallationDocumento2 pagineLewis Fixing and InstallationVengatesh NJNessuna valutazione finora

- Brick WorkDocumento2 pagineBrick WorkvinitbardeNessuna valutazione finora

- A Review Study On Effect of Steel Fibre and Marble Dust With Strength of Pavement Quality ConcreteDocumento4 pagineA Review Study On Effect of Steel Fibre and Marble Dust With Strength of Pavement Quality ConcreteEditor IJTSRDNessuna valutazione finora

- Structural MembersDocumento37 pagineStructural Membersmario gadianoNessuna valutazione finora

- Design Calculation For Watch Tower - R00 - 20200615Documento3 pagineDesign Calculation For Watch Tower - R00 - 20200615Raviraj Thorat100% (1)