Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

POH JS 32 - 02 Airframe and Flying Controls ATA 53 & 27

Caricato da

Aviacion Jlp100%(1)Il 100% ha trovato utile questo documento (1 voto)

44 visualizzazioni24 pagineMaterial de Apoyo para cursantes del Curso para Piloto Comercial CIA Helica

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMaterial de Apoyo para cursantes del Curso para Piloto Comercial CIA Helica

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

44 visualizzazioni24 paginePOH JS 32 - 02 Airframe and Flying Controls ATA 53 & 27

Caricato da

Aviacion JlpMaterial de Apoyo para cursantes del Curso para Piloto Comercial CIA Helica

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 24

erence asposmace

JSETSTF

EAT

‘Senies 3200

MANUFACTURERS OPERATING MANUAL PART 2

CHAPTER 2 AIRFRAME & FLYING CONTROLS

CHAPTER

SECTION

SUBJECT

LIST OF EFFECTIVE PAGES

TABLE OF CONTENTS

a-1

401723

OF EI Wi

PAGE

NE @vouewNH H

HPeerAnEewne

Printed inthe U.K

A

DATE

Aug

Aug

Aug

aug

Aug

Aug

Aug

Aug

Oct

oct

Nov

Aug

Aug

Aug

Aug

May

Aug

Aug

Aug

Aug

Aug

Aug

15/95

15/95

15/90

15/90

15/90

15/95

15/90

15/90

15/93

15/90

19/94

15/95

15/90

15/90

15/95

15/95

15/90

15/90

15/90

15/90

15/90

15/90

2-EFFECTIVE PAGES

Page 1

Aug 15/95

JETSTREAM

‘Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

AIRERI 53 AND 27

LIST_OF CONTENTS

LIST OF EFFECTIVE PAGES

DESCRIPTION AND OPERATION

General. .

Fuselage.

Tail Unit

Wings

Baggage Pod.

Entrance/Exit Boor.

Cabin Escape Hatches.

Cabin Windows :

Flight Deck Windows.

Flight Deck Seats

Passenger Seats

Flight Controls

Stall Protection

Rererererererererererer res

vee ee

Sek oboe sw AEE

SCHEMATIC DTAGRAMS

Plight Control system.

Stall Protection and Recovery system.

oe

CONTROL AND INDICATION

Trim Control and Indication

Plight Control (Gust) Lock

stall Protection Control and Indication.

Right Hand Crew Seat.

Entrance Door

Emergency Escape Hatches.

Direct Vision Window.

Crew Biteryeucy Escape

Baggage Compartment. Door.

Baggage Pod Indication.

boatadsune

CHAPTER 2 CONTENTS

Page 1

H01276 Printed inthe UK. Aug 15/95

YETSTREAM

‘Senies 3200

MANUFACTURERS OPERATING MANUAL PART 2

CHAPTER 2

AIRFRAME AND FLIGHT CONTROLS (ATA 53 AND 2:

1. GENERAL

1.1 The Jetstream is a low wing monoplane of conventional all

261

Printed in the UK

metal stressed skin construction. The aircraft is made

for a long fatique life, with extensive corrosion

protection.

2. FUSELAGE

The fuselage has seven main zones:

- The nose cone, which covers the radar and glideslope

antennae

- The nose landing gear bay, which contains the nose gear

and related hydraulic equipment

= An unpressurised nose equipment bay, which contains

electrical and avionic equipment

- A pressurised cabin, divided by bulkheads into three

areas; flight deck, passenger cabin and baggage

compartment

- An unpressurised rear equipment bay, which contains

flying control components and optional equipment

- A tail cone, (which can be removed) which covers part

of the rudder control system

- The lower fuselage centre bay, which contains

hydraulic, air and fuel system components

3. TATE UNIT

3.2

The tail unit is made up from a horizontal stabilizer and

a vertical stabilizer. The vertical stabilizer extends

from the rear fuselage and has the horizontal stabilizer

attached to it.

The stabilizers have a leading edge de-icing system. The

rudder and elevator control surfaces are installed on the

trailing edges.

‘The wings are box structures which have front, main, rear

and auxiliary spars covered by skin panels. They are

attached to three forged, hooped frames in the fuselage

centre section. There is an internal fuel tank and main

landing gear bay in each wing. These are found in the

area between the front and rear spars. Ailerons and

flaps are installed to the trailing edge of the rear

spar.

2-1-1

Aug 15/90

VETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

The leading edges (which can be removed) have a de-icing

system installed. The wing tips (which can also be

removed) contain the navigation/strobe light units

5. BAGGAGE POD

5.2

An optional external baggage pod can be installed below

the fuselage to increase the baggage capacity of the

aircraft.

6. ENTRANCE/EXIT DOOR

6.1

21-2

Ang 15/90

‘The entrance/exit door is installed on the left side of

the rear fuselage. It is hinged at the bottom, and opens

out and down. The door’s inner face is shaped into steps

which give access to the passenger cabin. A hand cable

and a hand rail are attached to the inner face of the

door.

When the door is open, it is locked down by the handrail

This limits tail down movement of the aircraft. A buffer

is installed to the door outer skin which prevents damage

to the door. When the door is opened and closed, the

door weight ic supported by gas struts. In the Closed

position, the door is sealed by a pressure seal which is

inflated by cabin pressurization.

The door is locked in the closed postion by six steel

drawbolts. The drawbolts are operated by an internal or

external handle in the door. The handles must be pulled

out to release a safety lock, then turned clockwise

through 90 degrees to unlock’ the door

Five drawbolts (the bottom bolt and four side bolts) have

visual indicators in the door to show when the drawbolts

are in the locked position. ‘he sixtn (upper) drawbolt

does not have an indicator. The drawbolts are locked

when the pin on the drawbolt is aligned with a red line

painted on the indicator window.

All six drawbolts and the door handle mechanism each

contact a microswitch when in the closed and locked

position. A CAP (red) caption comes on if

The door is open

A microswitch fails in the open position

A microswitch has moved to the unlock position from the

locked closed position

The door takes longer than 10 seconds to lock closed.

yan

9Sh 10022

JETSTREAM

Senies 3200

MANUFACTURERS OPERATING MANUAL PART 2

NOTE: The 10 second time delay (which prevents incorrect

warnings) starts when the first microswitch has

closed.

7. CABIN ESCAPE HATCHES

TL

An escape hatch is installed on each side of the passenger

cabin, above the wing. Each hatch has a window which is

demisted by it's own dessicator system. The two hatches

open into the cabin, and are unlocked by an internal or

external handle.

8. CABIN WINDOWS

8.1

The fourteen cabin windows are double glazed, with the air

gap between the panes demisted hy a dessicator system. The

windows are linked through the demist system to a master

dessicator cylinder installed on the rear pressure

bulkhead. An internal plastic panel is installed to protect

the window panes from damage.

In flight, the full pressure of the cabin pressurisation

system is taken by the window pane. If the window pane

becomes crazed or cracked, refer to the Emergency Check

List.

9. PLIGHT DECK WINDOWS

9.1

There are seven windscreen panels installed on the flight

deck. The left, centre and right main panels are made of

five layers of acrylic and vinyl sheets bonded together

The electrically healed left and right main panels use a

layer of indium trioxide as a heater element

The left and right Direct Vision (DV) windows each have a

dessicator installed to demist the inner and outer acrylic

panels. These windows can be opened and slid to the rear on

tracks. They are used for the crew emergency exits

The left and right rear panels are installed behind the DV

windows. They have an inner and outer acrylic panel and are

demisted by the cabin window dessicator system

10. FLIGHT DECK SEATS

10.1 The pilot’s seats have a lockable inertia reel safety

22001457

harness installed. They are adjustable in height and can be

moved forward or backward. Seat travel is limited by stops

on the seat rails. The seats are left or right handed

because of the position of the adjustment lever on each

seat.

2-1-3

Printed in the UK. Aug 15/90

10.2

Senies 3200

MANUFACTURERS OPERATING MANUAL PART 2

The seats are installed on plinths and attached to the

floor with quick release pins. A fire warning bell is

installed on the forward face of each plinth. A portable

oxygen bottle is installed on each plinth, outboard of

each seat.

11. PASSENGER SEATS

1.1

12, FLIGHT

12.1

12.2

12.3

2-1-4

Aug 15/95

A maximum of nineteen passenger seats can be installed.

Double seat units are installed on the right of the

cabin, single seat units on the left. Each seat is

equipped with a lap strap. A life jacket stowage is under

the seat.

CONTROLS

The flight control systems are controlled by a control

wheel and control column (aileron and elevator control

and a set of rudder pedals (rudder control). Bach rudder

pedal has a brake master cylinder installed, which

operates the toe brakes. The rudder pedals are adjusted

by the rotation of a handle below the ekirt panel. During

adjustment, the outboard pedal will move a little further

than the inboard pedal. A second control whecl, a control

column and set of rudder pedals are supplied for the

First Officer. The two sets of controls are linked

together, so movement of one set will move the other in

the same manner.

Trim function for each control system (ailerons, elevator

and rudder) is controlled by individual trim wheels

installed on Lhe centre console. A trim gauge for each

system is installed on the centre console to show how

much trim is selected. A trim jack in each system changes

the datum for balance tab (aileron and elevator) or

spring tab (rudder) operation. Yhe trim cables are

installed between the centre console and the trim jacks

They follow similar paths to the control cables in each

system.

The ailerons are controlled by cables which pass under

the floor on each side of the aircraft. The cables pass

through fuselage pressure seals to a control quadrant on

the rear face of the wing rear spar. Then rods and levers

are used to connect with an offset angle assmebly. The

angle assembly transmits rod movement to the aileron

which moves in the necessary direction

Printed in the UK. H01215

Printed in the UK.

22001459

12.4

12.5

12.6

12.7

12.8

JETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

The Frise type differential ailerons are hinged to the

wing rear spar. They have two balance weights, one

internal (in the horn) and one external (beneath the

aileron). A trim/balance tab is attached to each

aileron at the inboard end. The tabs are connected to a

trim jack installed on the wing rear spar. Two rods

connected to the wing rear spar supply the balance

function. The trim function is supplied by a cable and

chain mechanism to the trim jack.

The rudder cables pass from the rudder pedals, under the

floor on the right side of the aircraft. ‘They pass

through pressure seals in the rear pressure bulkhead to

a quadrant in the rear fuselage. Cables from the

quadrant operate a rudder mechanism made up of a torque

tube and an internal torsion bar

With no load on the rudder, the torque tube and torsion

bar assembly operate together. with a load on the

rudder (e.g. in flight) the rudder and spring/trim tab

move in opposite directions. This gives aerodynamic

help to move the rudder. If there is a load on the

rudder, the torsion bar can twist inside the torque

tube. ‘Thus, if the pilot moves the rudder pedals when

the control lock is in, he could think the rudder has

moved. But he has only moved the spring/trim tab. It

is necessary to make sure that the rudder is unlocked

before a full and free control check.

With the rudder trim gauge at neutral, the trim tab is

offset to 7.75 degrees to the right. This is to help

rudder control if the right (critical) engine faile on

take-off. Two spring struts are installed between the

rudder quadrant and the airframe. They supply

artificial feel for rudder control up to 5 degrees each

side of neutral.

The aileron and rudder systems are linked by a spring

strut. This is installed under the floor, on the right

side of the aircraft, forward of the wing rear spar

This link supplies co-ordinated aileron and rudder

movement to help the aircraft return from certain

attitudes. The load applied by the spring strut can be

over-ridden by the pilot’s operation of the ailerons and

rudder.

2-1-5

Aug 15/90

12.9

12.10

12:11

12.12

2-1-6

Aug 18/90

JETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

The elevators are interchangeable between the left and

right sides. They are hinged to the trailing edge of

the horizontal stabiliser. The elevator cables pass

from the control column under the floor on the right

side of the aircraft. They pass through pressure seals

in the rear pressure bulkhead to a quadrant in the rear

equipment bay. Rods pass from the quadrant up through

the vertical stabiliser to a torque shaft which joins

both elevators together.

Each elevator has a balance/trim tab installed at the

inboard end. The tabs are connected by two rods to the

horizontal stabilizer front spar to supply the balance

function. The trim function is supplied by a cable and

chain mechanism to the trim jack. The trim jack is

installed on the horizontal Stabilizer front spar. A

spring is installed between the elevator quadrant and

the rear equipment bay bulkhead. This supplies an

elevator down position on the ground, but it is

neutral/stable in flight.

Note: For added safety protection, aileron and elevator

trim connections between trim jacks and tabs are by dual

rods.

CAUTION: DO NOT TRY TO ENGAGE CONTROL LOCK WHEN POWER

LEVERS ARE IN THE FLIGHT RANGE. THIS WILL

RESULT IN DAMAGE TO THE MECHANISM.

The control surfaces can be locked in the neutral

position when the aircraft is on the ground. A handle

on the right side of the centre console is used to

engage the locks. when the handle is moved to the up

(locked) position, a system of cables and levers will

insert spring loaded lock pins in

- The aileron drive quadrant on the right side, behind

the instrument panel

- The elevator quadrant in the rear equipment bay

- The base of the rudder

Note: The rudder gust lock is covered with a rubber boot

for cold weather protection. This is to prevent a

frozen pin remaining in the locked position.

When the handle is moved to the down (unlocked

position, internal springs remove the pins from the

quadrants and rudder base. When the gust locks are

engaged, only one power lever can be moved to FLIGHT

IDLE. If the two power levers are above FLIGHT IDLE

the gust locks CAN NOT be engaged.

09710022

neato prod

prrrmese ammoarace

JETSTREAM

‘Sexies 3200

MANUFACTURERS OPERATING MANUAL PART 2

13. | STALL PROTECTION

13.1

13.2

13

13.4

22201263

Stall protection is supplied by two stall warning systems

and one automatic stall recover (stick pusher) system.

The stall warning systems give separate warnings for the

left and right wings. This occurs when a wing approaches

a stall angle and at stall identification angle. The two

warning systems must have a stall identification to

operate the automatic stall recovery system.

Stall warning vanes, installed on the left and right wing

leading edges, identify the wing angle of attack. If a

wing gets to the stall warning angle,the vane sends an

electrical signal to a Signal Summing Unit(SSU). The ssU

operates the stick shaker and the stall warning horn. If

a wing angle of attack increases to the stall

stauL| 4, | STALL | (yea)

identification angle, the fa RE

captions on the glareshield come on. The stick shaker

and the stall warning horn also operate.

The stall recovery system is hydraulically operated. When

each wing gets to the stall identification angle,each SsU

energises a solenoid valve in the stall recovery system.

When the two solenoids are energised (both wings at stall

identification angle) hydraulic pressure operates a stall

recovery arm on the elevator quadrant. This moves the

elevator to 8 degrees nose down. The stick push is

stopped immediately when a wing returns into the stall

warning range. This removes electrical power from the

solenoid which stops the flow of hydraulic pressure to

the system.

STALL STALL

When the ca or RH | (xed) captions are

on, the stick push will be cancelled, if the caption is

pressed. This makes the CAP STALL | (amber) caption

come on. ‘The stall warning systems are still armed but

the stick push can only be armed again on the ground.

The stick push will be cancelled when the aircraft

pitches down to less than 4g absolute. A pull force of

60 lbs on the control column will override the nose-down

pressure of the stick push.

2-1-7

Oct 15/93

Printed in the UK.

13.5

13.6

2-1-8

Oct 15/90

3200

MANUFACTURERS OPERATING MANUAL PART 2

The stall protection system is controlled by two STALL

PROTECTION switches on the roof panel. The switches

have three positions:

ON - arms the stall warning system, the CAP | STALL

(amber) caption goes out.

TEST - simulates a stall identification angle, operates

the stick shaker,operates stall warning horn,

STALL STALL

glareshield ty | and RH | (red) captions

and | STALL | (amber) caption come on.

OFF switches off the stall protection system,

cap | STALL | (amber) caption comes on.

If the two STALL PROTECTION switches are set to TEST at

the same time:

- The two CAP | STALL | (amber) captions and stable | and

STALL | (reg) giareshield captions will come on

- Stick shaker, stall warning horn and stick pusher will

operate.

The TEST function is cancelled in flight by the nose

landing gear weight-on-wheels (squat) switch.

the cap | statt. | (amber) caption will also come on when:

A signal summing unit fails

- Electrical power to a signal summing unit fails

A stall protection system is switched off

- A stall identification light is pressed when lit.

Printed inthe UK. 22201276

JETSTREAM

MANUFACTURERS OPERATING MANUAL PART 2

iS

FLIGHT CONTROL SYSTEM

2-2-1

22201652 Printedin the UK. Nov 15/94

pemsn amosnace:

JETSTREAM

‘Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

err

Ses

roworen }—} |—T ronan

ij e |

1 |

y

ae | Sage Suck | Sas] wart

= ae | a

Y ; +a

SR {it

sega , + sara

eau in|

ie meu] eee SORE

erie) ISOLATE RELAY + ® - {ISOLATE RELAY

Ww SWITCH a .

EFT SIDE ONY,

- SS du

‘STALL y tome “AES [TL bel v ‘StauL

»

vs ee = BR

re ie

+

ox723984.01

STALL PROTECTION AND RECOVERY SYSTEM

2-2-2

Aug 15/95 Printed inthe U.K. 401279

Print inthe UK

22001465

JETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

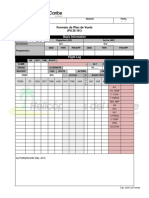

CENTRE PEDESTAL

ELEVATOR TRIM GAUGE RUDDER TRIM GAUGE

shows the amount of shows amount of trim

tim applied to. the, applied to rudder tab,

ELEVATOR TRIM WHEEL

-manual_ control

elevator trim

AILERON TRIM GAUGE

shows amount of trim

epplied to aileron tab.

RUDDER TRIM WHEEL a ~~ AILERON TRIM WHEEL

= manual control of rudder manual control of aileron

trim, trim,

TRIM CONTROL AND INDICATION

2-3-1

Aug 15/90

JETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

CENTRE PEDESTAL CAUTION: DO NOT TRY TO ENGAGE CONTROL

LOcK WHEN POWER LEVERS ARE IN

THE FLIGHT RANGE. THIS WILL RESULT

IN DAMAGE TO THE MECHANISM.

FLYING CONTROL LOCK

HANDLE

UP - will engage the

Tocks when the flying

contrals are moved to the

eutral position

Down

will disengage the locks

NOTE: 1 when loc are

disengaged the elevator

fontral gill go forward

‘ue tothe action of the

slevator down spring

2. the locks cannot be

engaged when bath

power levers are forward

of Flight idle

FLIGHT CONTROL (GUST) LOCK HANDLE

2-3-2

Aug 15/90

pene rae

99 10022

JETSTREAM

‘Senies 3200

MANUFACTURERS OPERATING MANUAL PART 2

jp STALL VANES (2)

Detects approaching stall

STALL PROTECTION SELECTOR (2)

ON. -arms related stall protection

stem

lated stal protection system is

switched off

= CAP STALL caption (Amber) on

TEST - tests related stall protection

system

Note!.- test is prevented in fight

2.- hydraulic pressure is requited

{or full system test

OFF

STALL PROTECTION

EF gy PORT

ey x. 7 &

STALL IDENT CAPTIONS (Red) (4)

Gx Showa hat stl conaon

has boon centieg for \

Ieated wing

It the stall ident caption (Red) is

pressed when on

* stickpusher is cancelled and

inhibited

- the caption is cancelled

= CAP STALL caption (Amber)

oN

Nolet. aller the stickpusher nas

been inhibited any stall

warnings will be given by

stickshaker and audio

‘warning horn, but no red

caption inaication.

2.+ the stickpusher can only be

rasal oa the ground

STALL CAPTIONS (Amber) (2)

ON. shows related stall protection

system has failed or is off

- of related stickpusher is

inhibited by the glareshield

STALL Ident caption (Fea)

being pressed while

ittuminated

STALL PROTECTION CONTROL AND INDICATION

HO1281

2-3-3

Printed inthe UX. Aug 15/95

EAMT

‘Semies 5200

MANUFACTURERS OPERATING MANUAL PART 2

INERTIA CONTROLLED SHOULDER STRAPS

LOCK/RELEASE

_— MECHANISM

ADJUSTABLE

LAP STRAP.

cup HOLDER

é ——

ASHTRAY ~

ARM REST

ADJUSTMENT BUTTON

SEAT HEIGHT

CONTROL LEVER J

SEAT FORWARD

STOP.

SEAT POSITION

CONTROL LEVER

SHOULDER STRAP

INERTIA REEL CONTROL

/ 5 \——

/

QUICK RELEASE PIN

RIGHT HAND CREW SEAT

2-3-4

May 15/95 Printedin the UX. 400046

Printed inthe UK

22001469

YETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

FOOT PEDAL DOOR INDICATIONS.

Press down to unlock LOCKED

door handrail. =when pin and red line

arealigned

TT - PINON brawaoLT

RED LINES ON WINDOW

‘AND SURROUND

Y

\

DRAWBOLT

Patt

UNLOCKED

“when pin end red line do

not align

PIN ON DRAWBOLT

/>RED LINES ON WINDOW

‘AND SURROUND,

Pr

|

seca

‘DOOR HANDLE INDICATOR,

PRESSED - unlocks door handrail

LOCKED

shows red line on

Centre dise aligned

with outer red lines

; INTERNAL DOOR HANDLE

EXTERWAL DOOR HANDLE

ENTRANCE DOOR

2-3-5

Aug 15/90

YSETSTREAM

‘Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

WARNING

support hatch at all

times during release.

- pulled inboard the hatch

Sisengages from hinges

at the extent of

movement.

RELEASE HANDLE

PULL inboard and upwards to

release hatch

FORWARD Wi

HiNGes.

NOTE: there is a similar escape

hatch installed on the left

side of the cabin which is,

opened in the sameway.

EMERGENCY ESCAPE HATCH

2-3-6

Aug 15/90

pin ow

0210022

Print in the UK.

22001471

YETSTREAM

‘Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

SUDER DESSICATOR SLIDER

DIRECT VISION WINDOW

HAND GRIP

2-3-7

Aug 15/90

YSETSTREAM

‘Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

TO OPEN DV. WINDOW

‘PULL STRIPED HANDLE DOWN AND REARWARDS.

2.PULL WINDOW INBOARD WITH 8OTH HANDLES

3.MOVE WINDOW REARWARD IN TRACK UNTIL

‘CATCH ENGAGES,

AUTION;00 NoTPULLON

(77 BESICEATOR

GRASP ROOF HANDLE

‘WITH RIGHT HAND,

THRUST LEFT SHOULDER &

HEAD OUT ——

FOR LEFT PILOT

eLy 10022

RIGHT FOOT ONTO SEAT

THEN SIT UPON RAIL

BOTH FEET ON RAIL

JUMP CLEAR

CREW EMERGENCY ESCAPE

2-3-8

Aug 15/90

Printed inthe UK.

22001473

JETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

BAGGAGE DOOR SPARE KEY

STOWED IN COCKPIT

EMERGENCY USE ONLY

BAGGAGE

COMPARTMENT

DOOR KEY

BAGGAGE COMPARTMENT DOOR

2-3-9

Aug 15/90

VYETSTREAM

Series 3200

MANUFACTURERS OPERATING MANUAL PART 2

ON shows make hachean

erected in the baggage

pod.

RIGHT SKIRT PANEL

P00 000R (amber)

(ON shows baggage pod door notlocked

winosHieto

Tver acm

|]: |

BAGGAGE LOADING

MAX. CAPACITY

435 Ib (198 kg)

MAX. FLOOR LOADING

35 Ib/ft? (16 kg/ft?)

BAGGAGE TO BE DISTRIBUTED

AS EVENLY AS POSSIBLE

BAGGAGE POD

ook HANDLE —_O_

BAGGAGE POD INDICATION

2-3-10

Aug 15/90

an eunut peng

vLvl0022

Potrebbero piacerti anche

- Pa28 Service PDFDocumento912 paginePa28 Service PDFMarcelo Nobrega75% (4)

- PBN Manual - ICAO Doc 9613 Final 5.10.08Documento294 paginePBN Manual - ICAO Doc 9613 Final 5.10.08Liviu Per100% (4)

- Pa28 IpcDocumento830 paginePa28 IpcJames Foster86% (7)

- Formato Plan de Vuelo PA-28 161 PDFDocumento2 pagineFormato Plan de Vuelo PA-28 161 PDFAviacion JlpNessuna valutazione finora

- 690A B Training ManualDocumento336 pagine690A B Training ManualAviacion Jlp100% (12)

- FlightSafety Commander Jetprop Training Manual Volume 2 Aircraft Systems 2Documento595 pagineFlightSafety Commander Jetprop Training Manual Volume 2 Aircraft Systems 2Aviacion Jlp100% (1)

- Continental Cylinder Application GuideDocumento6 pagineContinental Cylinder Application GuideAviacion JlpNessuna valutazione finora

- VFR Charts SymbolsDocumento29 pagineVFR Charts SymbolsGennaro PrioneNessuna valutazione finora

- POH JS 32 - 07 Fuel System ATA 28Documento16 paginePOH JS 32 - 07 Fuel System ATA 28Aviacion JlpNessuna valutazione finora

- Operating Instruction Manual For Chery A1 Series: AdviceDocumento176 pagineOperating Instruction Manual For Chery A1 Series: AdviceYahia BadredeenNessuna valutazione finora

- 2 Explanation of VFR Terms and Symbols PDFDocumento7 pagine2 Explanation of VFR Terms and Symbols PDFAviacion JlpNessuna valutazione finora

- 09 Hydraulic System & Landing Gear ATA 29 & 32Documento32 pagine09 Hydraulic System & Landing Gear ATA 29 & 32Aviacion JlpNessuna valutazione finora

- Beechcraft Baron POHDocumento367 pagineBeechcraft Baron POHAviacion Jlp100% (2)

- Turbo Commander 690B Checklist PDFDocumento30 pagineTurbo Commander 690B Checklist PDFAviacion Jlp90% (10)

- 1976 C310R PohDocumento322 pagine1976 C310R PohMike Fasano100% (1)

- POH JS 32 - 01 Aircraft General ATA 5 39 31 33Documento48 paginePOH JS 32 - 01 Aircraft General ATA 5 39 31 33Aviacion Jlp100% (1)

- POH JS 32 - 12 Communications & RecordingDocumento14 paginePOH JS 32 - 12 Communications & RecordingAviacion JlpNessuna valutazione finora

- POH JS 32 - 06 Engines and Propellers ATA 71 & 61Documento52 paginePOH JS 32 - 06 Engines and Propellers ATA 71 & 61Aviacion Jlp100% (1)

- CC 550 Airplane GeneralDocumento15 pagineCC 550 Airplane GeneralAviacion Jlp80% (15)

- 05 Electrical System ATA 24Documento16 pagine05 Electrical System ATA 24Aviacion JlpNessuna valutazione finora

- POH JS 32 - 04 Emergency Equipment & Oxigen ATA 25 & 35Documento16 paginePOH JS 32 - 04 Emergency Equipment & Oxigen ATA 25 & 35Aviacion Jlp100% (1)

- Aeropuertos de VenezuelaDocumento194 pagineAeropuertos de VenezuelaAviacion Jlp100% (2)

- Indice Aip VenezuelaDocumento0 pagineIndice Aip VenezuelaAviacion JlpNessuna valutazione finora

- POH JS 32 - 03 Air Conditioning & Presurization ATA 21Documento16 paginePOH JS 32 - 03 Air Conditioning & Presurization ATA 21Aviacion JlpNessuna valutazione finora

- B-200 PohDocumento168 pagineB-200 PohKoustubh Vadalkar100% (8)

- Be 200 Pilot's Training Manual JLPDocumento372 pagineBe 200 Pilot's Training Manual JLPAviacion Jlp100% (1)

- Chartsalo 2 EnrDocumento1 paginaChartsalo 2 EnrAviacion JlpNessuna valutazione finora

- BHT 47G 3B 1 FMDocumento82 pagineBHT 47G 3B 1 FMAviacion Jlp100% (3)

- Pre-Flight ChecklistDocumento2 paginePre-Flight ChecklistAviacion Jlp100% (2)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- A109E Rotorcraft Flight ManualDocumento1.418 pagineA109E Rotorcraft Flight Manualalex castro100% (1)

- Airport Planning and Design by Sunil Khyaju SirDocumento112 pagineAirport Planning and Design by Sunil Khyaju SirAmrit Rawat ChetriiNessuna valutazione finora

- Airport Facilities and EquipmentDocumento25 pagineAirport Facilities and EquipmentMelfred RicafrancaNessuna valutazione finora

- CRJ700CCC Mast R01 11nov2010Documento2 pagineCRJ700CCC Mast R01 11nov2010MACEDONIAN RESCUERNessuna valutazione finora

- Transponders: in AviationDocumento9 pagineTransponders: in AviationViankaMillionNessuna valutazione finora

- LSM-500-047 REV K Hawker 800 Nose Taxi LightsDocumento19 pagineLSM-500-047 REV K Hawker 800 Nose Taxi LightsWong BennyNessuna valutazione finora

- Attachment 2 Example Ata Codes: System Sub Code Code DescriptionDocumento9 pagineAttachment 2 Example Ata Codes: System Sub Code Code DescriptionferNessuna valutazione finora

- Tzu-Jen, Kuo CV 2023Documento4 pagineTzu-Jen, Kuo CV 2023Charles KuoNessuna valutazione finora

- Aircraft Fuel Handling ProceduresDocumento4 pagineAircraft Fuel Handling ProceduresMrWannNessuna valutazione finora

- Assembly - 40Th Session: Working PaperDocumento3 pagineAssembly - 40Th Session: Working PaperAlex KashulNessuna valutazione finora

- CAP741 BlankDocumento45 pagineCAP741 BlankTariq HameedNessuna valutazione finora

- Travel Reservation August 06 For MICAELA VAISEMBRUTDocumento2 pagineTravel Reservation August 06 For MICAELA VAISEMBRUTMica VNessuna valutazione finora

- De Cuong On Thi Hoc Ki T.A 12Documento6 pagineDe Cuong On Thi Hoc Ki T.A 12Hạnh NguyễnNessuna valutazione finora

- Edinburgh vMATS Part 2 2020 13Documento48 pagineEdinburgh vMATS Part 2 2020 13bob johnsomNessuna valutazione finora

- Theoretical and Applied Aerodynamics and Related Numerical Methods by J.J. Chattot and M.M. HafezDocumento625 pagineTheoretical and Applied Aerodynamics and Related Numerical Methods by J.J. Chattot and M.M. HafezPaladin64100% (4)

- A319 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsDocumento204 pagineA319 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsArun ChaudharyNessuna valutazione finora

- Composite Propeller Blade Field Maintenance and Minor Repair ManualDocumento232 pagineComposite Propeller Blade Field Maintenance and Minor Repair ManualCarlos Daniel Tantacalle BonifacioNessuna valutazione finora

- Aerospace: Aerodynamic Design Optimization and Analysis of Ducted Fan Blades in Dep UavsDocumento13 pagineAerospace: Aerodynamic Design Optimization and Analysis of Ducted Fan Blades in Dep UavsSơn Vũ TháiNessuna valutazione finora

- Little Joe II Test Launch Vehicle NASA Project Apollo. Volume 2 - Technical Summary Final ReportDocumento256 pagineLittle Joe II Test Launch Vehicle NASA Project Apollo. Volume 2 - Technical Summary Final ReportBob Andrepont100% (3)

- Notam 26 - 04 - 2023Documento29 pagineNotam 26 - 04 - 2023Filipe ChavesNessuna valutazione finora

- Landing Gear 3rd Review Suriya PrakashDocumento16 pagineLanding Gear 3rd Review Suriya PrakashprithvinatarajanNessuna valutazione finora

- Flying Scale Models Issue 169 2013-12Documento68 pagineFlying Scale Models Issue 169 2013-12Peter100% (1)

- Thakur Institute of Aviation Technology: Module 17.2: Propeller ConstructionDocumento10 pagineThakur Institute of Aviation Technology: Module 17.2: Propeller ConstructionAshwini ChaurasiaNessuna valutazione finora

- CE-560XL Rotary TestDocumento4 pagineCE-560XL Rotary Testgambit_zeta100% (1)

- Kclekjfk PDF 1645237576Documento44 pagineKclekjfk PDF 1645237576asfk;ajsdfNessuna valutazione finora

- Indian Space Programme PPT BriefDocumento24 pagineIndian Space Programme PPT Briefsai420100% (1)

- 03-GSR Summary Jul-Sep 2021Documento41 pagine03-GSR Summary Jul-Sep 2021vNessuna valutazione finora

- ATC Communication Issues During ApproachesDocumento12 pagineATC Communication Issues During ApproachesBatuhan AkgünNessuna valutazione finora

- Case Study Birmingham International AirportDocumento6 pagineCase Study Birmingham International AirportRoderick sidamonNessuna valutazione finora

- M4-1-SMS - Aerodrome - Safety Performance and MonitoringDocumento43 pagineM4-1-SMS - Aerodrome - Safety Performance and MonitoringNhut NguyenNessuna valutazione finora