Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Risk Register

Caricato da

Alhad PanwalkarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Risk Register

Caricato da

Alhad PanwalkarCopyright:

Formati disponibili

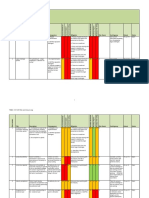

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

Risk Category

001

002

Printed 9/28/2012 9:45 PM

Technical

Technical

Risk Description

(Hazard/Risk

Scenario)

Differing soil

condition results in

chimney to bottom

of the Bay, blow-in

to TBM, lose tunnel,

submerge shaft and

start over.

Encounter reaches

of squeezing ground

causing TBM to get

stuck.

Bob Mues

Prepared Date:

10/8/2010

N/A

Approved Date:

CURRENT ASSESSMENT

F

Location

Tunnel

Tunnel

Cause

Effect

Unplanned

hyperbaric

intervention,

and results in

loss of pressure Unrecoverable

to face of EPB

loss of tunnel

TBM, which

and shaft.

cannot be

recovered due

to nature of the

material.

Differing site

conditions

(highly plastic

TBM gets stuck

clay) of the San

in these

Antonio

reaches, and

formation in

impacts

excess to those

Contractor

or at other

production rate.

locations than

those expected

from GBR.

Risk Plan

Owner

Wong,

Johanna

Wong,

Johanna

Risk

Status

Open

Open

Trigger Date

7/12/2011

7/12/2011

Expiration

Date

9/12/2013

9/12/2013

Probability of

Occurrence

(P)

1 - Rare

2 - Unlikely

Impact to

Costs, $

(S_cost)

3 - Moderate

4 - Major

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

5 - Catastrophic 5 - Catastrophic

N/A

MITIGATION

For PPPCM use only

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

15

14

520

19.5

Most Likely

Time, days

520

58.5

Page 1 of 7

Max. Time,

days

520

97.5

Min. Cost, $

75,000,000

1,312,350

Most Likely

Cost, $

112,500,000

3,937,050

Max. Cost, $

150,000,000

6,561,750

Mitigation Action Items

Scoring Rationale

Catastrophic event loss of completed work

and extensive delay in

starting over.

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

. Total Daily Rate =

$17,300. Add for loss

of productivity for half

of 75% of the tunnel =

9,750' - 10%, 20% &

50% reduction in

progress at average of

$1,000 per LF.

Strategy

Mitigate

Mitigate

Risk Plan

Action Items

Action Owner

Require maintenance of TBM

driving parameters (spoil

removal rate records)

against theoretical earth

volume to be removed, and Mues, Bob

tail grout quantity placed per

ring of TBM advance, to

verify possible "over

excavation").

Verify that Contractor's

remedial plan for this

Maintain full-time CM

condition is in place with

QA inspection on the

initial tunnel submittals, and

TBM when tunneling

that the equipment/materials

Mues, Bob

(per Spec 02311

noted are available and

requirements). Assure

functional throughout

Contractor maintains

tunneling. Require additional

adequate off-shift

remedial grouting or refill

monitoring of pressure

where necessary.

chamber and heading,

esp at high risk areas.

Verify the requirements of

Specification 02311 for

inspections and interventions

into the pressure chamber of

the EPB TBM are met

Mues, Bob

(Pressurized Face Tunneling

Plans, Method Statements,

Procedures, Tunnel Safety

Plans).

Verify that the TBM

On-going check of thrust and

thrust is at least as

lubrication data from TBM as Mues, Bob

specified and that the

progressing.

shield lubrication

(bentonite injection

port/injection system)

Assure TBM maintenance is

are functioning,

performed as specified or

lubrication material

more (if needed), particularly Hogan, Tom

mixing and supply

system are functioning prior to entering squeezing

ground regions.

and ready, and that

TBM maintenance is

current.

Actual

Completion

Action

Status

Action Start

Action End

7/12/2011

9/12/2013

Proposed

8/1/2010

9/12/2013

Proposed

8/1/2010

9/12/2013

Active

7/12/2011

9/12/2013

Proposed

7/12/2011

9/12/2013

Proposed

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

Risk Category

Risk Description

(Hazard/Risk

Scenario)

Technical

Unforeseen ground

conditions between

the Franciscan

Formation and San

Antonio Formation

interface.

003

004

Technical

005

006

Security

Regulatory

Printed 9/28/2012 9:45 PM

Hitting unforseen

Franciscan

Formation in

reaches not

surveyed in the

GBR

Location

Tunnel

Tunnel

Cause

Effect

Interface

Control of the

between San tunnel (vertical/

horizontal)

Antonio

Formation

alignment

(softer ground) between the San

and Franciscan

Antonio

Formation

Formation and

Differing site

conditions.

Breach in

Vandalism to site or Ravenswoo

perimeter fence

construction

d/ Newark

or bypass of

property, damage

Shafts

guard station.

Unanticipated

presence of

endangered

species.

Bob Mues

Prepared Date:

10/8/2010

N/A

Approved Date:

CURRENT ASSESSMENT

G

Additional

hyperbaric

interventions

needed to

change

cutterhead;

productivity loss;

TBM not

designed for

great lengths of

hard ground.

Risk Plan

Owner

Wong,

Johanna

Wong,

Johanna

Replacement or

repair to finished

permanent

works, safety Contractor

hazard to

"intruders" or

perpetrators.

Contractor

delayed from

starting work at

Protected

Newark and/or

species

NewarkShaf

additional

encountered

t

restrictions to

during surveys

site

or construction.

implemented

during site

activities.

Wong,

Johanna

Risk

Status

Open

Open

Trigger Date

3/1/2013

7/12/2011

Expiration

Date

7/5/2013

3/12/2013

Probability of

Occurrence

(P)

Impact to

Costs, $

(S_cost)

4 - Likely

0 - Contractor

Risk

2 - Unlikely

3 - Moderate

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

3 - Moderate

N/A

MITIGATION

For PPPCM use only

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

3 - Moderate

10

Most Likely

Time, days

15

Max. Time,

days

20

Min. Cost, $

673,000

Most Likely

Cost, $

1,009,500

Max. Cost, $

Scoring Rationale

Risk Plan

Action Items

Assure Contractor submittals

Although this

subsurface discontinuity

are in on schedule and

is well defined in the

properly reviewed and

Mitigate

GBR, assure that

approved.with any

Assist Contractor

Contractor's EPB TBM

other special measures

design includes a

needed.

suitable guidance

1,346,000

Strategy

Open

6/1/2010

3/1/2011

5/15/2015

5/15/2015

5 - Frequent

2 - Unlikely

0 - Contractor

Risk

2 - Minor

2 - Minor

2 - Minor

20

40

Page 2 of 7

60

766,000

1,532,000

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

. Total daily cost =

$17,300. Add for loss

of productivity using

$50,000 per day X the

additional days to

accomplish the work.

Assure that the

Contractor has planned

to perform maintenance

Assure Contractor submittals

interventions prior to

are in on schedule and

Mitigate

each reach with

properly reviewed and

geotechnical data

approved.

"gaps"; assure that

back-up equipment and

supplies are available.

2,298,000

Contractor Risk

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$21,000/day =

$32,500. Total daily

rate = $38,300/day.

Standby costs include

equipment, security,

core crew costs, tunnel

lighting & ventilation,

equipment

maintenance, etc.

Mitigate

Mitigate

Monitor and implement

safety and security plan.

Actual

Completion

Action

Status

Action Owner

Action Start

Action End

Mues, Bob

1/1/2013

7/5/2013

Proposed

Mues, Bob

1/1/2013

7/5/2013

Proposed

Mues, Bob

1/1/2013

7/5/2013

Proposed

6/1/2010

3/2/2015

Active

8/1/2010

5/15/2015

Active

On-going check of perimeter

fencing integrity and site sign Hogan, Tom

visibility.

On-going check of security

Wakefield,

guard's presence on site

Rick

24/7.

Open

Mitigation Action Items

Work area lighting functional

(include winter evenings).

Contractor

11/15/2010

12/31/2014

Proposed

Maintain and repair (if

needed) fencing.

Contractor

8/1/2010

5/15/2015

Active

Lock-ups inside site and

provide safety covers over

potential hazards such as

pipe trench at night.

Contractor

12/1/2010

5/15/2015

Proposed

1/1/2011

4/1/2011

Proposed

2/1/2011

3/1/2011

Proposed

2/1/2011

5/1/2011

Proposed

Coordinate with SFPUC BEM

to ensure they obtain a

Peterson,

Section 2081 Take

Megan

Authorization from CDFG

prior to working at Newark.

Conduct preconstruction

surveys prior to working at

Work in a proactive

Wilkerson,

Newark

and relocate CTS

manner to anticipate

Cullen and/or

individuals, if found. Hand

issues before they

Craighead,

become delays or cost excavate burrows during the

Kim

dry season if work begins

changes.

after May 1.

Wilkerson,

Cullen;

Monitor installation of

exclusion fencing and initial Craighead,

Kim;

ground-disturbing activities.

Peterson,

Eric

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

007

008

Risk Category

Regulatory

Regulatory

009

010

Printed 9/28/2012 9:45 PM

Safety

Safety

Risk Description

(Hazard/Risk

Scenario)

Location

Cause

Effect

Restrictions due to

Protected birds

nesting specialnesting in

status shorebirds

Contractor

adjacent

Ravenswoo

(CA clapper rail,

delayed due

marshlands

d/ Newark

implementation

black rail, least tern,

during future

Shafts

etc.) moving into an

of buffer zones.

nesting

active construction

seasons.

area.

Union Sanitary

District prohibits

discharge of

construction water

into their system

Handling of

contaminated

groundwater/soil at

Newarks shaft site

in excess of amount

specified.

Injuries resulting

from, or while

working in,

compressed air

environment.

Bob Mues

Prepared Date:

10/8/2010

N/A

Approved Date:

CURRENT ASSESSMENT

G

Newark

Shaft

Newark

Risk Plan

Owner

Wong,

Johanna

Contamination

Additional

is too high and

permits, water

Contractor

does not comply

treatment, or offwith USD

hauling of water.

requirements

Worker health &

safety concerns

if contaminated

groundwater not

Gravel lenses

handled

across site

appropriately.

causing greater

Contractor may

infiltration or

be required to

existing

shut-down

contaminant

Contractor

dewatering

plume has

operation (and

different

not be allowed

constituents or

to discharge by

higher

USD) if

concentrations.

contaminants

not properly

treated prior to

disposal.

Work will stop,

Exposure to

compressed air worker must be

Ravenswoo at face of TBM transported to

Contractor

surface and

d Shaft

during

inspections and quickly treated in

maintenance. decompression

chamber or at

Risk

Status

Open

Open

Open

Trigger Date

2/11/2011

3/1/2011

3/1/2013

Expiration

Date

5/15/2015

8/1/2011

12/31/2013

Probability of

Occurrence

(P)

3 - Possible

3 - Possible

5 - Frequent

Impact to

Costs, $

(S_cost)

2 - Minor

0 - Contractor

Risk

0 - Contractor

Risk

3 - Moderate

3 - Moderate

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

2 - Minor

N/A

MITIGATION

For PPPCM use only

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

40

Most Likely

Time, days

80

Max. Time,

days

160

Min. Cost, $

1,532,000

Most Likely

Cost, $

3,064,000

7/12/2011

9/12/2013

3 - Possible

0 - Contractor

Risk

3 - Moderate

Page 3 of 7

Mitigation Action Items

Max. Cost, $

6,128,000

Scoring Rationale

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$21,000/day =

$32,500. Total daily

rate = $38,300/day.

Standby costs include

equipment, security,

core crew costs, tunnel

lighting & ventilation,

equipment

maintenance, etc.

Contractor Risk

Contractor Risk

Strategy

1/1/2011

4/1/2011

Proposed

2/1/2011

3/1/2015

Proposed

Peterson,

Megan

2/1/2011

5/1/2015

Proposed

Contractor

2/1/2011

6/1/2011

Proposed

Contractor

12/1/2010

6/1/2011

Proposed

Contractor

12/1/2010

6/1/2010

Proposed

CM QA Inspectors to verify

that Contractor has tested

the water, and has a test

plan in place to continually Hogan, Tom

test and manage the water

throughout the Newark shaft

installation work.

3/1/2013

12/31/2013

Proposed

Verification by ECM,

QA Inspectors assure that

EIs, and QA Inspectors

the shaft is sealed to avoid

that Contractor has its

contaminated water from

plan, permits, disposal

interfering with the tunnel

site, and resources for

Mitigate

completion and installation of

this contaminated water

Hogan, Tom

the final lining pipe into the

in place prior to

tunnel and shaft, and the

commencement of the

surface pipe

Newark Shaft

installation/connection to the

installation.

existing BDPL1.

3/1/2013

12/31/2013

Proposed

Peterson,

Megan

3/1/2013

12/31/2013

Proposed

Mues, Bob

7/12/2011

9/12/2013

Proposed

Mues, Bob

5/1/2011

9/12/2013

Proposed

Look into the feasibility of

alternative mitigation

Peterson,

measures as opposed to

Megan

implementing a buffer zone

(e.g., barriers, etc.)

Conduct preconstruction

Wilkerson,

surveys according to the

Cullen and/or

MMRP during the early

Craighead,

portion of the 2011, 2012,

Kim

2013, 2014 and 2015

nesting seasons.

Maintain an open dialog with

regulatory agencies and take

proactive steps to minimize

delays.

Mitigate

Contractor Risk

Action Owner

Action

Status

Action End

Continually monitor

status of birds in the

area and develop an

initial strategy for

managing this risk.

Action Items

Actual

Completion

Action Start

Mitigate

Risk Plan

Initiate discussions with USD

early, and prior to moving

into NVL to understand the

requirements/restrictions

Obtain a NPDES VOC permit

as a backup in the event

Develop a water

USD discharge is not

discharge contingency

allowed.

plan

Evaluate additional design

techniques to limit the influx

of groundwater into shaft and

trench for tie-ins (e.g.,

extending Ranger's cut-off

wall).

On-going verification that

Contractor meets

requirements of their Union

Sanitary District discharge

permit with dewatering

operation.

Open

Ensure contractor

On-going verification that

provides the tools,

Contractor's hyperbaric work

equipment, and

facilities are operational.

Mitigate

hyperbaric work

Assure Contractor's

facilities, and follows

contingency planning is in

required contingency

place prior to the

planning for carrying out

interventions.

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

Risk Category

011

Safety

Technical

012

013

Community

Risk Description

(Hazard/Risk

Scenario)

Decompression

sickness

Bob Mues

Prepared Date:

10/8/2010

N/A

Approved Date:

CURRENT ASSESSMENT

F

Location

Tunnel

Blow-in through the

forward pressure

bulkhead of the EPB

TBM (the bulkhead

containing the face

pressure monitoring Ravenswoo

instruments beyond

d Shaft

which is the earth

plug, water table

pressure and the

Bay trying to come

in).

Cause

Effect

Risk Plan

Owner

Work will stop,

Exposure to

worker must be

compressed air transported to

at face of TBM

surface and

Contractor

during

quickly treated in

inspections and decompression

chamber or at

maintenance.

hospital.

Unintended

penetration of

the EPBM

pressure

bulkhead.

Potential loss of

EPB TBM and Contractor

tunnel.

Contractor's

Resident

failure to comply Potential work

complaints, and

with noise and stoppage until

irritation, with

Ravenswoo

vibration code complaints are

construction noise,

d

requirements, or addressed and

dust, lighting,

mitigated.

if compliant,

vibration, etc.

public irritation.

Contractor

Risk

Status

Trigger Date

Expiration

Date

Probability of

Occurrence

(P)

Impact to

Costs, $

(S_cost)

N/A

MITIGATION

For PPPCM use only

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

Most Likely

Time, days

Max. Time,

days

Min. Cost, $

Most Likely

Cost, $

014

015

Technical

Technical

Lack of sufficient

power supply.

Water leakage

around the

perimeter seal or

through the shaft

floor slab (tremie

concrete).

More abrasive

Printed 9/28/2012 9:45 PM

Wong,

Johanna

Contractor does

not follow

Potentially have

Ravenswoo specifications/

to replace shaft Contractor

d Shaft

Contractor

floor slab.

means &

methods faulty.

Different

subsurface

Excessive TBM

head, face

chamber, cutter,

and screw

conveyor wear

Max. Cost, $

Scoring Rationale

Strategy

Risk Plan

Action Items

Action Owner

Open

Open

7/12/2011

7/12/2011

7/1/2010

9/12/2013

9/12/2013

5/15/2015

3 - Possible

2 - Unlikely

3 - Possible

0 - Contractor

Risk

0 - Contractor

Risk

0 - Contractor

Risk

3 - Moderate

5 - Catastrophic

2 - Minor

Open

Open

3/31/2011

11/15/2010

9/12/2013

6/1/2011

2 - Unlikely

2 - Unlikely

3 - Moderate

0 - Contractor

Risk

3 - Moderate

2 - Minor

11

20

60

180

766,000

2,298,000

Contractor Risk

Contractor Risk

Contractor Risk

6,894,000

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$21,000/day =

$32,500. Total daily

rate = $38,300/day.

Standby costs include

Contractor Risk

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

Wong,

Page 4 of 7

Mitigate

Require expanded

engineering controls for

sound attenuation

(mufflers/enclosures of loud

Monitor site work to

equipment).

identify problem before Require increased distance

(if possible) from sound

recognized by the

source or sound walls (if

Mitigate

public; provide

required).

proactive outreach to

Remove/change out the

community of upcoming

source or noise emitter.

activities.

4/12/2011

9/12/2013

Proposed

4/12/2011

9/12/2013

Proposed

4/12/2011

9/12/2013

Proposed

Mues, Bob

5/1/2011

9/12/2013

Proposed

Mues, Bob

5/1/2011

9/12/2013

Proposed

Mues, Bob

7/1/2010

5/15/2015

Active

Mues, Bob

7/1/2010

5/15/2015

Active

Mues, Bob

7/1/2010

5/15/2015

Active

Kerby,

Christina

7/1/2010

5/15/2015

Active

4/1/2010

3/31/2011

Active

4/1/2010

3/31/2011

Active

9/15/2010

6/1/2011

Active

2/1/2011

6/1/2011

Proposed

2/1/2011

6/1/2011

Proposed

7/12/2011

9/12/2013

Proposed

Hold monthly coordination

Wong,

meetings with PG&E and

Johanna

Closely monitor

Contractor to mitigate issues.

progress of the

Mitigate temporary construction

Take appropriate steps to

power installations by

avoid any SFPUC caused

Mues, Bob

PG&E.

delays.

Verify Contractor follows

Mues, Bob

submittals and method

statements.

Verify that Contractor

Carefully inspect slab for

follows specifications,

Hogan, Tom

leakage (following

Mitigate places shaft floor slabs unwatering and cleaning).

accordingly, inspect for If required, verify submittal of

conformance.

Contractor's remedial plan to

Mues, Bob

repair leaks and assure

materials/methods are

viable.

Check to increase spare part

inventory once condition is

verified.

Action

Status

Action End

Mues, Bob

Compressed air

"hyperbaric" work

cannot commence

before all plans and Require Contractor to adhere

procedures are

to decompression

acceptable pursuant to procedures and hyperbaric Mues, Bob

California labor safety

work plans.

codes and standards,

Require

Contractor to have

including

medical resources in place

decompression

for response, transport, and

process, equipment,

Mues, Bob

care of decompression

and tables.

sickness, either on site of at

nearby hospital or other

qualified facilities.

Assure Contractor's plans

and employee training

Contractor's plans must specifically address high risk

nature

of work around the

address the high risk of

pressure bulkhead.

any maintenance work

around the pressure

Mitigate

bulkhead and the

dangers of any

penetration (separate

Assure Contractor provides

from the hyperbaric

training of high risk work to

intervention plans).

any new workers involved in

tunneling operation.

Actual

Completion

Action Start

Require all equipment and

systems for work under

pressure be in place and

tested prior to

commencement of work

Open

Mitigation Action Items

Provide on-going updates to

community via mailers, door

hangers, blog of activities.

Delay to start of

PG&E fails to

tunneling with

provide power

insufficient

Ravenswoo

service when power supply for

d

required; PG&E

TBM; loss of

power failure.

power during

tunneling.

Mues, Bob

Assure that there are

adequate spare parts

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

Risk Category

016

Technical

017

018

019

020

021

022

Safety

Regulatory

Regulatory

Regulatory

Regulatory

Risk Description

(Hazard/Risk

Scenario)

ground conditions

than anticipated.

Damage to BDPLs

1& 2 or PG&E

transmission lines

due to crane tip

over.

Location

Tunnel

Shafts

Cause

Effect

materials than and hyperbaric

those presented maintenance of

in the GBR.

those parts that

are exposed to

ground

pressure.

Unbalanced/

excessive load

or unstable

crane platform

base during

installation of

diaphragm

slurry wall rebar

Carelessness

Inadvertantly

and/or not

injuring or killing an

following project

endangered,

Ravenswoo requirements;

threatened, or fully d/ Newark

accidental

collisions with

protected species

(SMHM, CTS, etc.)

equipment; work

in wetlands, etc.

Subsurface

Easement is not

obtained from

Management

Cargill, SamTrans,

and Mid Peninsula

Open Space District.

Tunnel

Tunnel

Terms of

Agreement not

acceptable to

parties; Board

of Supervisors

reject purchase

of subsurface

easement.

Risk

Status

Trigger Date

Expiration

Date

Probability of

Occurrence

(P)

Impact to

Costs, $

(S_cost)

Wong,

Johanna

Open

7/12/2011

9/12/2013

3 - Possible

3 - Moderate

Wong,

Johanna

Work stoppage

by USFWS

and/or CDFG

until additional

Contractor

mitigation

measures can

be developed/

approved.

Additional time

Additional

and costs

requirements

incurred by

imposed by

Contractor and

higher risk level

Additional RWQCB

CM team

requirements as a

under NPDES

Ravenswoo

associated with

General

result of risk

d/Newark

sampling,

assessment prior to

Construction

monitoring and

Stormwater

Sept 2, 2011.

reporting;

Permit due to

additional

duration of

RWQCB

project.

coordination.

Various: BCDC

want removal of

BDPLs 1&2;

BCDC may

claim jurisdiction

below the Bay;

subsurface

easements are

Risk Plan

Owner

Electrocution, if

PG&E

transmission

lines hit; power Contractor

outage. Service

outage, if BDPLs

hit; damage

requiring

Bay Margin is

known to

Unanticipated

contain

Work stoppage

cultural or

prehistoric and

until the

paleontological

Ravenswoo paleontological resource can be

properly

discoveries during

d/ Newark resources, but

evaluated/

shaft excavation,

construction

tunneling, or tie-ins

methods

recovered.

prevent surveys

and monitoring

BCDC will not issue

permit for tunneling

under the Bay.

10/8/2010

N/A

Cannot start

tunnel

excavation.

Cannot start

tunnel

excavation.

Wong,

Johanna

Wong,

Johanna

Wong,

Johanna

Open

Open

Open

Open

Open

Open

8/1/2010

8/1/2010

5/20/2010

5/20/2010

9/20/2010

9/20/2010

11/15/2010

5/15/2015

5/15/2015

5/15/2015

6/30/2011

6/30/2011

3 - Possible

2 - Unlikely

1 - Rare

4 - Likely

2 - Unlikely

2 - Unlikely

0 - Contractor

Risk

2 - Minor

0 - Contractor

Risk

1 - Insignificant

3 - Moderate

2 - Minor

4 - Major

1 - Insignificant

5 - Catastrophic 5 - Catastrophic

5 - Catastrophic 5 - Catastrophic

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

2 - Minor

N/A

MITIGATION

For PPPCM use only

12

21

21

20

20

60

60

Max. Time,

days

Min. Cost, $

Most Likely

Cost, $

Max. Cost, $

30

40

1,346,000

2,019,000

2,692,000

40

120

120

60

240

240

766,000

50,000

1,488,000

1,488,000

1,532,000

100,000

2,976,000

2,976,000

2,298,000

250,000

Scoring Rationale

$100/day = $6,500/day

. Total daily cost =

$17,300. Add $1M,

$1.5M & $2M for

replacement parts, lost

time for replacement

and lost productivity.

Contractor Risk

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$21,000/day =

$32,500. Total Daily

Rate = $38,300/day.

Standby costs include

equipment, security,

core crew costs, tunnel

lighting & ventilation,

equipment

Contractor Risk

Additional SWPP

requirements and

monitoring. Estimated

costs by PUC/CM

Team.

Strategy

Mitigate

Mitigate

Mitigate

Risk Plan

adequate spare parts

available at start and

throughout tunneling.

Assure Contractor is

well prepared with

acceptable JHAs for

each portion of slurry

wall construction.

Action

Status

Action Owner

Action Start

Action End

Issue field order for

immediate spare parts

procurement, if schedule

(long lead item) becomes an

issue.

Mues, Bob

7/12/2011

9/12/2013

Proposed

Check that Contractor has

provided an adequate base

for crane support.

Hogan, Tom

8/1/2010

12/1/2010

Active

Check that Contractor is

following load limits and

Hogan, Tom

protocol as perscribed in the

JHAs.

8/1/2010

12/1/2010

Active

Hire specialty archaeological

and paleontological monitors

in the event of discoveries.

Peterson,

Megan

12/1/2010

2/1/2010

Completed

Peterson,

Eric

4/1/2010

12/31/2014

Active

Peterson,

Megan

4/1/2010

12/31/2014

Active

Peterson,

Eric

4/1/2010

12/31/2014

Active

Peterson,

Eric

4/1/2010

12/31/2014

Active

Peterson,

Megan

12/1/2010

3/1/2011

Active

4/1/2010

5/31/2010

Completed

4/1/2011

10/30/2010

Active

5/20/2010

3/1/2015

Active

5/20/2010

5/1/2015

Active

Implement existing

Ensure that worker training is

procedures for

conducted according to the

unanticipated

MMRP and specifications.

discoveries and work

quickly to mobilize

Coordinate with the

specialists to the field. Contractor in the event of a

find to quickly assess the

significance and possible

need for work stoppage.

Implement requirements

as specified in project

Mitigate documents and develop

comprehensive training

program

Actual

Completion

Action Items

Inspect the work area daily

for any cover or other

potential habitat.

Train individuals on

significance of "take" of the

species.Conduct tailgate

trainings prior to working in

sensitive areas.

Coordinate with SFPUC BEM

to ensure the 2081for CTS is

in hand prior to work

beginning Newark

Design water treatment Host SWPPP workshop for

plant to accommodate

Bay Division Region to

Peterson,

new permit

faciliate understanding of

Megan

requirements (e.g.,

requirements.

modular system that

Develop expandable

can easily be

Contractor

modular WTP for

expanded). Close

Mitigate

Ravenswood.

coordination between

CM team provides daily

Peterson,

CM team and

environmental inspection to

Eric and

Contractor to

help identify issues.

Mirzad, Slay

understand new

Provide QSP to oversee site

requirements and

Contractor

compliance with NPDES

prepare risk

permit.

assessment/SWPPP

5,952,000

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$7,500/day =

$14,000/day. Total

Daily Rate =

Avoid

Work with BCDC and

City Attorney to get

agreements in place

well before the start of

tunneling.

Work with BCDC. Enlist help from

City Attorney to avoid BDCD

claiming jurisdiction below the Bay.

Zhang, Yin

Lan

9/20/2010

6/30/2011

Active

5,952,000

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$7,500/day =

$14,000/day. Total

Daily Rate =

$24,800/day. Standby

costs include

equipment, security,

Avoid

Work with property

owners and City

Attorney.

Finalize Agreement with Property

Owners. Submit Agenda Item to

the Board of Supervisors

Morelli, Brian

9/20/2010

30-Jun-11

Active

Check on-going monitoring of

BDPLs and check that data is

consistent with no movement.

Hnat, Steve

8/1/2010

5/15/2015

Active

CM/SFPUC 9 FTE @

$150.00/hr =

$10,800/day and CS 8

FTE @ $100/hr =

$6,400 + office @

Page 5 of 7

Mitigation Action Items

Most Likely

Time, days

BDPLs will require

owner repair, which

Printed 9/28/2012 9:45 PM

Bob Mues

Prepared Date:

Approved Date:

CURRENT ASSESSMENT

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

Assure Contractor installs and

monitors survey monuments

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

Risk Category

Risk Description

(Hazard/Risk

Scenario)

Operations

Failure of BDPL1 or 2 in

vicinity of Ravenswood

or Newark shafts.

023

024

Printed 9/28/2012 9:45 PM

Operations

Delay in shut-down

schedule.

Bob Mues

Prepared Date:

10/8/2010

N/A

Approved Date:

CURRENT ASSESSMENT

F

Location

Cause

Effect

Risk Plan

Owner

owner repair, which

may be problematic

Possibly caused by

regarding access

Ravenswood/

non-construction

and safety concerns Mazza, Paul

means, such as age

Newark

with construction

related joint failure.

operations on-going

nearby. May cause

some delay.

Ravenswood

Potentially weeks of

Failure of the

delay while the

contractor supplied

submersible pumps pumps are either

repaired or rental

during disinfection

units are located; it

of the pipe within

might also result in

the tunnel.

re-disinfecting, etc.

Contractor

Risk

Status

Open

Open

Trigger Date

8/1/2010

9/1/2014

Expiration

Date

5/15/2015

2/10/2015

Probability of

Occurrence

(P)

2 - Unlikely

2 - Unlikely

Impact to

Costs, $

(S_cost)

3 - Moderate

0 - Contractor

Risk

3 - Moderate

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

2 - Minor

N/A

MITIGATION

For PPPCM use only

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

11

10

Most Likely

Time, days

20

Page 6 of 7

Max. Time,

days

30

Min. Cost, $

483,000

Most Likely

Cost, $

866,000

Mitigation Action Items

Max. Cost, $

1,249,000

Scoring Rationale

$6,400 + office @

$100/day = $6,500/day

+ Standby Costs @

$21,000/day =

$32,500. Total Daily

Rate = $38,300/day.

Standby costs include

equipment, security,

core crew costs, tunnel

lighting & ventilation,

Contractor Risk

Strategy

Mitigate

Mitigate

Risk Plan

monitors survey monuments

on BDPLs throughout

construction; consider

contingency planning for Ops

access in the event that

BDPLs fail and need to be

shut-down and repaired

adjacent to construction.

Actual

Completion

Action

Status

Action Items

Action Owner

Action Start

Action End

Assure Contractor's means and

methods are consistent with

specifications for protection of

existing improvements.

Mues, Bob

8/1/2010

5/15/2015

Active

Develop contingency plan in the

event of BDPL 1 or 2 failure and

need for Ops access and repair.

Mues, Bob

12/1/2010

5/15/2015

Proposed

Contractor

9/1/2014

2/10/2015

Proposed

Mues, Bob

9/1/2014

2/10/2015

Proposed

Assure Contractor's

Check functioning of submersible

submersible pumps are

pumps before planned shut-down.

functioning well before the

start of shut-down; check that

Check suppliers through Contractor

supplies of back-up pumps

to verify supply of available back-up

are readily available (if

pumps.

needed).

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

REGION/PROJECT:

Bay Tunnel

CONTRACTOR:

MJC-JV

Bay Tunnel

Project ID Number

PROJECT RISK REGISTER

Award: $215,294,530 - NTP: 4/1/2010

Bob Mues (Phone: 206-818-7353)

PROJECT CM:

CM CONSULTANT:

Jacobs Engineering

Risk Category

025

Safety

026

027

Security

Operations

Printed 9/28/2012 9:45 PM

Risk Description

(Hazard/Risk

Scenario)

Location

Earthquake (Major) Bay Tunnel

Terrorism - Direct

Impact

Bob Mues

Prepared Date:

10/8/2010

N/A

Approved Date:

CURRENT ASSESSMENT

F

Cause

Effect

Risk Plan

Owner

Risk

Status

Trigger Date

Expiration

Date

Probability of

Occurrence

(P)

Act of God

Temporary site

facilities may be

damaged. May

have to reexcavate shaft

and portions of

the tunnel to reaccess. Integrity

of shaft and

tunnel possisbly

compromised.

Wong,

Johanna

Open

8/5/2010

3/2/2015

1 - Rare

Physical

Bomb, projectile

damage or

of any kind,

biological

Bay Tunnel

biological

contamination to

contamination

SFPUC Water

etc.

System.

Failure to meet

contractual shutBay Tunnel

down schedule for

BDPL1 and BDPL2

Operations or

other projects

don't allow

shutdown to

make tie in at

appropriate

time.

Unable to

complete tie in

of Bay Tunnel

(BDPL5) to

BDPLs 1 and 2.

Wong,

Johanna

Wong,

Johanna

Open

Open

8/5/2010

9/14/2014

3/2/2015

2/10/2015

1 - Rare

1 - Rare

Impact to

Costs, $

(S_cost)

5 - Catastrophic 5 - Catastrophic

2 - Minor

2 - Minor

Impact to Costs, $

Impact to

Schedule,

Risk

Min. Time,

days

Calendar Days Score (R)

(S_schedule)

5 - Catastrophic 5 - Catastrophic

N/A

MITIGATION

For PPPCM use only

Severity of Impact (S)

Risk ID

Baseline Risk Register

Prepared By:

Approved By:

RISK IDENTITY & CAUSE

A

Status Update:

15

15

30

Max. Time,

days

Min. Cost, $

Most Likely

Cost, $

Max. Cost, $

Scoring Rationale

Strategy

Risk Plan

Contractor Risk

Accept

Implementation of

Safety Plan.

60

Page 7 of 7

365

100,000

200,000

Mitigation Action Items

Most Likely

Time, days

Contractor Risk

300,000

Possible de-mob/remob of contractor or

shift work to another

contractor if the

window is missed and

has to be rescheduled.

Action Items

Action Owner

Actual

Completion

Action

Status

Action Start

Action End

9/1/2013

2/10/2015

Proposed

9/1/2014

2/10/2015

Proposed

Ensure proper physical

security elements (fencing,

Mitigation and response

barriers, gates, etc.) and

through additional

ACAMS (access control and

security and improved

monitoring system) are in

emergency

place at all critical facilities.

Mitigate

preparedness to avoid

Communications (ensure

any damage that might

result from a terrorism safety plan, standard protcol)

event.

Keep current with WSIP

program shut-down

Mitigate schedules, contingency

plans, and any

changes.

Work with Ops on contingency

schedule (either before or after) the

Wong, Johanna

planned shut-down to see if

alternate date can be found.

Assure Contractor has all

required shut-down

submittals in on schedule.

Mues, Bob

RR Bay Tunnel - 2010 10 8 (DRAFT2)R2 3 pt estimates 11 12 10

Potrebbero piacerti anche

- Risk Register AllLevelsDocumento5 pagineRisk Register AllLevelsriyaz10100% (4)

- IRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterDocumento29 pagineIRP 22 Hazard and Risk Assessment Register: Column Headings Column LetterKhuda Buksh100% (2)

- Appendix L Warrington Risk RegisterDocumento2 pagineAppendix L Warrington Risk RegisterChris Findlay100% (1)

- Risk RegisterDocumento8 pagineRisk Registerresearchmanager100% (1)

- Proposed Six Story Building For Community Concern Society - Risk RegistryDocumento2 pagineProposed Six Story Building For Community Concern Society - Risk Registryjmaasa83% (6)

- Sample Risk RegisterDocumento38 pagineSample Risk Registerdioki100% (8)

- Risk Register enDocumento15 pagineRisk Register enamitdengle100% (1)

- Risk RegisterDocumento34 pagineRisk RegisterMohamedMoideenNagoorMeeran33% (3)

- Risk RegisterDocumento3 pagineRisk Registergroup2sd1314100% (1)

- Risk Register AllLevelsDocumento5 pagineRisk Register AllLevelsSam Atia100% (1)

- Project Risk RegisterDocumento2 pagineProject Risk RegisterNixon100% (4)

- Risk Assessment RegisterDocumento8 pagineRisk Assessment RegisterFareeha Waqar100% (10)

- Risk RegisterDocumento6 pagineRisk RegisterhaiderNessuna valutazione finora

- Risk RegisterDocumento6 pagineRisk Registergroup2sd1314100% (3)

- Risk RegisterDocumento20 pagineRisk Registerzayzan100% (2)

- Risk Register 001Documento4 pagineRisk Register 001SreekumarNessuna valutazione finora

- Final CB Risk Register v27-11-2019Documento18 pagineFinal CB Risk Register v27-11-2019Job Chaclan0% (1)

- Project Business Risk RegisterDocumento9 pagineProject Business Risk RegisterElhussain Hassan100% (2)

- IRP 22 Risk Register 2015Documento30 pagineIRP 22 Risk Register 2015Jeya Kumar100% (1)

- Risk RegisterDocumento41 pagineRisk RegisterCaroline D'Souza100% (1)

- Risk Register ExampleDocumento1 paginaRisk Register ExampleLuthfieSangKapten88% (16)

- Project Risk Register: Project Name: Construction Works For Sewers & Treated Effluent ConnectionsDocumento2 pagineProject Risk Register: Project Name: Construction Works For Sewers & Treated Effluent ConnectionsDilip KumarNessuna valutazione finora

- Risk RegisterDocumento15 pagineRisk Registerdammy0% (1)

- Risk Register-Project Flip Sushrut SoodDocumento1 paginaRisk Register-Project Flip Sushrut Soodravapu345Nessuna valutazione finora

- Project Risk RegisterDocumento14 pagineProject Risk RegisterNatarayan88% (8)

- Project Risk RegisterDocumento21 pagineProject Risk RegisterDIGITAL SIRNessuna valutazione finora

- Risk AssessmentDocumento8 pagineRisk AssessmentSubhransu Mohapatra50% (2)

- Risk Register - ERMDocumento22 pagineRisk Register - ERMSuman Mandal50% (2)

- BOARD1470 Risk RegisterDocumento14 pagineBOARD1470 Risk RegisterShahbaz AhmedNessuna valutazione finora

- AppendixHPreContractStageRiskRegister PDFDocumento3 pagineAppendixHPreContractStageRiskRegister PDFChris FindlayNessuna valutazione finora

- 2949 HSE Risk Register - 2013-06-16 RevD1-VB FreeDocumento3 pagine2949 HSE Risk Register - 2013-06-16 RevD1-VB Freesalic201388% (8)

- Risk Register of Common Project RisksDocumento6 pagineRisk Register of Common Project RisksShaenie Lou GatilloNessuna valutazione finora

- Risk RegisterDocumento9 pagineRisk RegisterKingNessuna valutazione finora

- Defra Badger Cull Risk RegisterDocumento9 pagineDefra Badger Cull Risk RegisterThe GuardianNessuna valutazione finora

- ITH Risk MatrixDocumento11 pagineITH Risk Matrixsanjai_rahulNessuna valutazione finora

- Risk / Opportunity Management Register For ProjectDocumento1 paginaRisk / Opportunity Management Register For ProjectnikunjNessuna valutazione finora

- 08Pr001C Risk Management: Safety Management System ProcedureDocumento22 pagine08Pr001C Risk Management: Safety Management System Procedurekenoly123Nessuna valutazione finora

- Hazard Identification Risk Assessment and Risk ControlDocumento7 pagineHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Risk RegisterDocumento1 paginaRisk RegisterKalyan MandalNessuna valutazione finora

- Project Risk Register - FormatDocumento6 pagineProject Risk Register - FormatSameer MuntodeNessuna valutazione finora

- OHS Risk Register-OldDocumento24 pagineOHS Risk Register-OldMohamed Rizwan100% (1)

- Risk RegisterDocumento8 pagineRisk RegisterfaradieNessuna valutazione finora

- Hses Risk Assessment Register: Equipment Description: N/ADocumento51 pagineHses Risk Assessment Register: Equipment Description: N/AHussain Ayub100% (2)

- Edge Lane West Highway and Environmental Improvement Scheme: The City of LiverpoolDocumento15 pagineEdge Lane West Highway and Environmental Improvement Scheme: The City of LiverpoolDindima100% (2)

- Risk Management Procedure TemplateDocumento39 pagineRisk Management Procedure Templatealexrferreira75% (4)

- Risk Register For Project EPM Assignment-2Documento1 paginaRisk Register For Project EPM Assignment-2Awais MalikNessuna valutazione finora

- Risk Register ProjectDocumento749 pagineRisk Register ProjectmanojmoryeNessuna valutazione finora

- Covid-Example-Workplace-Risk-Assessment (003) - 0Documento5 pagineCovid-Example-Workplace-Risk-Assessment (003) - 0Neha Arif100% (1)

- Risk Assessment FormDocumento9 pagineRisk Assessment FormAbu ZahidNessuna valutazione finora

- Risk, Value and Cost ManagementDocumento54 pagineRisk, Value and Cost ManagementEdward AveryNessuna valutazione finora

- Risk AssessmentDocumento7 pagineRisk AssessmentMuhammad Ibrahim100% (2)

- Master Hazards Risks RegisterDocumento113 pagineMaster Hazards Risks RegisterIvanNessuna valutazione finora

- Risk Screening and Assessment Procedure - PetrobelDocumento68 pagineRisk Screening and Assessment Procedure - Petrobelbtjajadi100% (1)

- Class #1 Risk Register 2017Documento142 pagineClass #1 Risk Register 2017Randy PrandykaNessuna valutazione finora

- Risk AssesmentDocumento6 pagineRisk AssesmentAnwar Mohiuddin0% (1)

- 1 WSF Risk Management PlanDocumento7 pagine1 WSF Risk Management PlanYong Kim100% (1)

- Risk ControlDocumento7 pagineRisk ControlDinesh AravindhNessuna valutazione finora

- Risk AssessmentDocumento13 pagineRisk AssessmentDisha Shah100% (3)

- Plant & Guide Wall ConstructionDocumento10 paginePlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPNessuna valutazione finora

- Soil TestDocumento3 pagineSoil TestArvie Batisla-ongNessuna valutazione finora

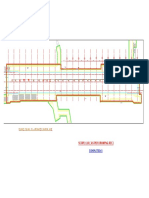

- List of Drawings: LTS-CAC-SCG-3920-001Documento1 paginaList of Drawings: LTS-CAC-SCG-3920-001Alhad PanwalkarNessuna valutazione finora

- Plunge Col Progress SCG PrésentationDocumento1 paginaPlunge Col Progress SCG PrésentationAlhad PanwalkarNessuna valutazione finora

- 2017-06-28 MMRC Presentation - Column Options-2017-06-28 - LatestDocumento49 pagine2017-06-28 MMRC Presentation - Column Options-2017-06-28 - LatestAlhad PanwalkarNessuna valutazione finora

- UGC-01-CAC-SCG-XXXXX-001: Churchgate Station GRID 14 - 24, LVL-4 Sheet 1 of 2Documento1 paginaUGC-01-CAC-SCG-XXXXX-001: Churchgate Station GRID 14 - 24, LVL-4 Sheet 1 of 2Alhad PanwalkarNessuna valutazione finora

- 2017-06-28 MMRC Presentation - Column Options-2017!06!28 - LatestDocumento49 pagine2017-06-28 MMRC Presentation - Column Options-2017!06!28 - LatestAlhad PanwalkarNessuna valutazione finora

- Pile Progress CG PrésentationDocumento1 paginaPile Progress CG PrésentationAlhad PanwalkarNessuna valutazione finora

- Pile Progress CG PrésentationDocumento1 paginaPile Progress CG PrésentationAlhad PanwalkarNessuna valutazione finora

- Mumbai Metro Rail Project Line - 3 Colaba-Bandra-SeepzDocumento1 paginaMumbai Metro Rail Project Line - 3 Colaba-Bandra-SeepzAlhad PanwalkarNessuna valutazione finora

- Pile Progress CG PrésentationDocumento1 paginaPile Progress CG PrésentationAlhad PanwalkarNessuna valutazione finora

- Ugc 01 Geo SCP 1101 005 ADocumento1 paginaUgc 01 Geo SCP 1101 005 AAlhad PanwalkarNessuna valutazione finora

- UGC-01-GEO-SCP-1101-001: Cuffe Parade Station Anticipated Settlement Contour PlanDocumento1 paginaUGC-01-GEO-SCP-1101-001: Cuffe Parade Station Anticipated Settlement Contour PlanAlhad PanwalkarNessuna valutazione finora

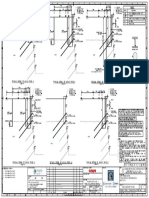

- LTS-CAC-SCG-3911-001: Churchgate Station Temporary Secant Pile Wall Depth 9.01 MDocumento1 paginaLTS-CAC-SCG-3911-001: Churchgate Station Temporary Secant Pile Wall Depth 9.01 MAlhad PanwalkarNessuna valutazione finora

- Cuffe Parade Cuffe Parade: UGC-01-GEO-SCP-1101-002Documento1 paginaCuffe Parade Cuffe Parade: UGC-01-GEO-SCP-1101-002Alhad PanwalkarNessuna valutazione finora

- Ugc 01 Geo SCP 1100 002 ADocumento1 paginaUgc 01 Geo SCP 1100 002 AAlhad PanwalkarNessuna valutazione finora

- Ugc 01 Geo SCP 1100 001 ADocumento1 paginaUgc 01 Geo SCP 1100 001 AAlhad PanwalkarNessuna valutazione finora

- UGC-01-GEO-SCP-1101-003: Cuffe Parade Station Typical Arrays of InstrumentationDocumento1 paginaUGC-01-GEO-SCP-1101-003: Cuffe Parade Station Typical Arrays of InstrumentationAlhad PanwalkarNessuna valutazione finora

- SCG - Strut Forces SummaryDocumento25 pagineSCG - Strut Forces SummaryAlhad PanwalkarNessuna valutazione finora

- LTS-CAC-SCG-3902-001: Churchgate Station Temporary Secant Pile Wall Depth 9.87mDocumento1 paginaLTS-CAC-SCG-3902-001: Churchgate Station Temporary Secant Pile Wall Depth 9.87mAlhad PanwalkarNessuna valutazione finora

- LTS Cac SCG 3904 001 CDocumento1 paginaLTS Cac SCG 3904 001 CAlhad PanwalkarNessuna valutazione finora

- Pile - Dwall Capacity CalculationDocumento5 paginePile - Dwall Capacity CalculationAlhad Panwalkar100% (1)

- UGC-01-GEO-SCP-1101-003: Cuffe Parade Station Typical Arrays of InstrumentationDocumento1 paginaUGC-01-GEO-SCP-1101-003: Cuffe Parade Station Typical Arrays of InstrumentationAlhad PanwalkarNessuna valutazione finora

- Specs - Steel CasingDocumento4 pagineSpecs - Steel CasingAlhad PanwalkarNessuna valutazione finora

- Specification - Tunnel Shotcrete LiningDocumento43 pagineSpecification - Tunnel Shotcrete LiningAlhad Panwalkar100% (1)

- SAQOL 39 Proxy Version Sr55z7Documento5 pagineSAQOL 39 Proxy Version Sr55z7Fernanda VegaNessuna valutazione finora

- Instructions:: Exam Papers Must Not Be Removed From The Exam Room Examiners: R.Russo T.KreouzisDocumento9 pagineInstructions:: Exam Papers Must Not Be Removed From The Exam Room Examiners: R.Russo T.KreouziszcaptNessuna valutazione finora

- Ifc 8thconf 4c4papDocumento29 pagineIfc 8thconf 4c4papgauravpassionNessuna valutazione finora

- LIS 209 - Special LibariesDocumento3 pagineLIS 209 - Special LibariesAnania Kapala SauloNessuna valutazione finora

- Polartek Plus Eeac331Documento84 paginePolartek Plus Eeac331Sodel MezaNessuna valutazione finora

- Richard OwenDocumento3 pagineRichard Owenbelli.vanillaNessuna valutazione finora

- Cap Analysis: (Municipality of Calinog)Documento21 pagineCap Analysis: (Municipality of Calinog)mpdo calinogNessuna valutazione finora

- Thetentrin: DeviceDocumento84 pagineThetentrin: Deviceorli20041Nessuna valutazione finora

- A12e IndicatorDocumento2 pagineA12e IndicatorCyril J PadiyathNessuna valutazione finora

- The Correlation Between Migraine Headache And.10Documento6 pagineThe Correlation Between Migraine Headache And.10Luther ThengNessuna valutazione finora

- Method For The Analysis of Health Personnel Availability in A Pandemic CrisisDocumento10 pagineMethod For The Analysis of Health Personnel Availability in A Pandemic Crisismaribel SalinasNessuna valutazione finora

- Factoring Perfect Square Trinomials: Lesson 4Documento29 pagineFactoring Perfect Square Trinomials: Lesson 4Jessa A.Nessuna valutazione finora

- ManualDocumento272 pagineManualAkash AroraNessuna valutazione finora

- Saudi Aramco Improves Field Management Practices With Intelligent SurveillanceDocumento4 pagineSaudi Aramco Improves Field Management Practices With Intelligent Surveillancereza mahaseniNessuna valutazione finora

- Alt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalDocumento19 pagineAlt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalSan JongNessuna valutazione finora

- Methodology For Bitumen MasticDocumento6 pagineMethodology For Bitumen MasticSudip MukhopadhyayNessuna valutazione finora

- Econ 620 SyllabusDocumento3 pagineEcon 620 SyllabusTOM ZACHARIASNessuna valutazione finora

- Degrees of Plagiarism Activity PDFDocumento20 pagineDegrees of Plagiarism Activity PDFDhamma_StorehouseNessuna valutazione finora

- DSP AssignmentDocumento16 pagineDSP AssignmentPunitha ShanmugamNessuna valutazione finora

- Spelling Homework 3rd GradeDocumento6 pagineSpelling Homework 3rd Gradeafnaxdxtloexll100% (1)

- Department of Education: Republic of The PhilippinesDocumento36 pagineDepartment of Education: Republic of The PhilippinesKristine Rose CADUTDUTNessuna valutazione finora

- Signed PAN: Erwin Panofsky's (1892-1968) "The History of Art As A Humanistic Discipline" (Princeton, 1938)Documento94 pagineSigned PAN: Erwin Panofsky's (1892-1968) "The History of Art As A Humanistic Discipline" (Princeton, 1938)Adrian Anton MarinNessuna valutazione finora

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocumento12 pagineRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARNessuna valutazione finora

- How To Develop Common SenseDocumento2 pagineHow To Develop Common SenseMacario Roy Jr AmoresNessuna valutazione finora

- Breeding Objectives, Selection Criteria and Breeding System of Indigenous Goat Types in Bale Zone, Oromia, EthiopiaDocumento10 pagineBreeding Objectives, Selection Criteria and Breeding System of Indigenous Goat Types in Bale Zone, Oromia, EthiopiareinpolyNessuna valutazione finora

- Ci CDDocumento19 pagineCi CDPriti KagwadeNessuna valutazione finora

- Philosophical Foundations of Curriculum DevelopmentDocumento34 paginePhilosophical Foundations of Curriculum DevelopmentAdeeb AhmadNessuna valutazione finora

- CAPE Entrepreneurship Module 1 (2023-2024 Syllabus)Documento22 pagineCAPE Entrepreneurship Module 1 (2023-2024 Syllabus)Shimmer100% (1)

- ECON2113 - 1 What Is Economics (Print)Documento53 pagineECON2113 - 1 What Is Economics (Print)Michael LeeNessuna valutazione finora

- Activity Sheet 1 Music 1Documento2 pagineActivity Sheet 1 Music 1Enah Sazi Ale ArbalNessuna valutazione finora