Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PQR Asme Blank

Caricato da

amirul8686Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

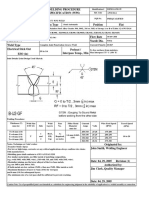

PQR Asme Blank

Caricato da

amirul8686Copyright:

Formati disponibili

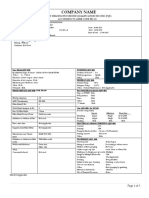

PROCEDURE QUALIFICATION RECORDS (PQR)

As per ASME IX

Page 1 of 3

Company Name :

Procedure Qualification Record No.

Welding Procedure Spec No.

Welding Process (es)

Date

CiTECH-WPS-001

Type (s)

(Automatic, Manual, Machine or Semi-Auto)

JOINTS (QW-402)

60

12.7 MM

SECTION 1 - SS

SECTION 2 - CS

1 MM

3 MM

Groove Design of Test Coupon

( For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used. )

BASE METALS (QW-403)

SECT. NO. 1 MAT'L

SECT. NO. 2 MAT'L

P-No. 8

Group No.

1

Thickness of Test Coupon

Diameter of Test Coupon

Maximum Pass Thickness

Other

POSTWELD HEAT TREATMENT (QW-407)

to P-No

Group No.

Temperature

Time

Other

GAS (QW-408)

Percent Composition

Shielding

FILLER METALS (QW-404)

SFA Specification

AWS Classification

Filler Metal F-No.

Weld Metal Analysis A-No.

Trailing

Backing

Other

ELECTRICAL CHARACTERISTICS (QW-409)

Size of Filler Metal

Filler Metal Product Form

Supplemental Filler Metal

Electrode Flux Classification

Flux Type

Brand Trade Name

Weld Metal Thickness

Other

Current

Polarity

Amps.

SEE WELDING PARAMETER

Volts

SEE WELDING PARAMETER

Tungsten Electrode Size

Mode of Metal Transfer for GMAW (FCAW)

Heat Input

Other

POSITION (QW-405)

Position of Groove

Weld Progression (Uphill, Downhill)

Other

-

TECHNIQUE (QW-410)

UPHILL

Travel Speed

String or Weave Bead

Oscillation

Multipass or Single Pass (Per Side)

PREHEAT (QW-406)

Preheat Temperature

Interpass temperature

Other

Single or Multiple Electrodes

Other

-

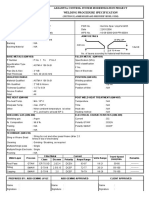

PROCEDURE QUALIFICATION RECORDS (PQR)

Section IX, ASME Boiler and Pressure Vessel Code

Page 2 of 3

PQR No.

MSI/PQR/002-14

Tensile Test (QW-150)

Specimen

No.

Width

Thickness

Ultimate Total Ultimate Unit Stress, (psi

Load

or Mpa)

Area

Type of Failure and Location

T1

T2

Guided-Bend Tests (QW-160)

Type and Figure No.

Result

S1

S2

S3

S4

Toughness Tests (QW-170)

Specimen No.

Notch Location

Comments

Specimen

Size

Test

Temparature

Impact Values

ft-lb or J

-

% Shear

-

Drop Weight Break (Y/N)

Mils (in.) or mm

-

Fillet-Weld Test (QW-180)

Result - Satisfactory : Yes

Macro - Results

No

Penetration into Parent Metal :

Yes

SATISFACTORY - REFER REPORT NO. :-

Other Tests

Type of Test

Deposit Analysis

Other

VICKERS HARDNESS TEST (HV 10) - REFER REPORT NO.:-

Welder's Name

Test conducted by :

I/C or Passport No.

Welder ID

Laboratory Test No.

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the Code.)

CERTIFIED BY

SIGNATURE / DATE

No

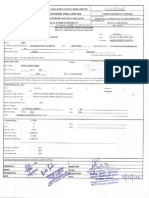

PROCEDURE QUALIFICATION RECORDS (PQR)

Section IX, ASME Boiler and Pressure Vessel Code

Page 3 of 3

PQR No.

WELDING PARAMETER

WELD

PASS NO.

1

ROOT

2

HOTPASS

3

HOTPASS

4

FILL

5

FILL

6

CAPPING

7

CAPPING

PROCESS

FILLER METAL

AWS

CLASS /

BRAND

SIZE

WELD CURRENT

POLARITY

DCEN / DCEP

TRAVEL

COUPON

LENGTH

AMPERAGE VOLTAGE

TIME

(min & sec)

SMAW

DCEP

SMAW

DCEP

SMAW

DCEP

SMAW

DCEP

SMAW

DCEP

SMAW

DCEP

SMAW

DCEP

= 300 MM

SPEED

(mm/min)

60

7

5

4

12 MM

SECTION 1

3

2

1

3 MM

SECTION 2

1 MM

HEAT INPUT

(kJ/mm)

INTERPASS

TEMP. ( C )

Potrebbero piacerti anche

- Weldspec ASME PQRDocumento2 pagineWeldspec ASME PQRSunil KumarNessuna valutazione finora

- PQRDocumento2 paginePQRSreenivas Kamachi Chettiar100% (1)

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- WPS FormatDocumento2 pagineWPS FormatAmit SarkarNessuna valutazione finora

- Gtaw Smaw 6 Inch 6G CSDocumento1 paginaGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- PQR Sample PrintoutDocumento2 paginePQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Wps 1010 IfrDocumento28 pagineWps 1010 IfrSyed Mahmud Habibur RahmanNessuna valutazione finora

- PQR & WPQ Standard Testing Parameter WorksheetDocumento4 paginePQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNessuna valutazione finora

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocumento2 pagineJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNessuna valutazione finora

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Documento14 pagineWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)

- WPS002 312Documento2 pagineWPS002 312proxywarNessuna valutazione finora

- WPS-PQR (Er309l Mo)Documento4 pagineWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocumento1 paginaPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNessuna valutazione finora

- 03 WPS CS 1Documento3 pagine03 WPS CS 1mohammadNessuna valutazione finora

- Procedure Qualification Record (PQR)Documento3 pagineProcedure Qualification Record (PQR)Senthil KumaranNessuna valutazione finora

- Manual Joints (QW - 402) : Page 1 of 12Documento12 pagineManual Joints (QW - 402) : Page 1 of 12miteshpatel191Nessuna valutazione finora

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Documento1 paginaWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS - 020Documento15 pagineWPS - 020MAT-LION100% (2)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- SS WPSDocumento1 paginaSS WPSMOHAMEDABBASNessuna valutazione finora

- Wps For Steel RodsDocumento5 pagineWps For Steel RodsHamid MansouriNessuna valutazione finora

- Butt JointsDocumento21 pagineButt JointsRaj1-23Nessuna valutazione finora

- Wps 316L Gtaw R00Documento3 pagineWps 316L Gtaw R00Richard Periyanayagam100% (3)

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocumento1 paginaIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNessuna valutazione finora

- Welder Performace Qualification Report 2014..Documento132 pagineWelder Performace Qualification Report 2014..Kayra Riri ChirulNessuna valutazione finora

- Wps Magi Tig Exemple PDFDocumento6 pagineWps Magi Tig Exemple PDFJaime PatrónNessuna valutazione finora

- API Welding Procedure Specification PDFDocumento3 pagineAPI Welding Procedure Specification PDFBob LeeNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 pagineCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Documento12 paginePoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNessuna valutazione finora

- WPS Sitelca S002Documento2 pagineWPS Sitelca S002Jose Antonio GomezNessuna valutazione finora

- Asme PQRDocumento4 pagineAsme PQRHong Dae Yoon100% (2)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPQR2Documento3 pagineWPQR2Thanasis KyrgiazoglouNessuna valutazione finora

- 1035 03Documento2 pagine1035 03Anuj ShahiNessuna valutazione finora

- wps63 PDFDocumento4 paginewps63 PDFErick HoganNessuna valutazione finora

- WPS-2 InchDocumento2 pagineWPS-2 InchKarthikeyan MpNessuna valutazione finora

- WPS PQR-09Documento11 pagineWPS PQR-09Ranjan KumarNessuna valutazione finora

- WPS - Smaw - 2Documento6 pagineWPS - Smaw - 2Harkesh RajputNessuna valutazione finora

- WPS PQRDocumento23 pagineWPS PQRHashim Khan88% (8)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocumento1 paginaWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNessuna valutazione finora

- WPQ Is 2062 Haresh Shah W1Documento1 paginaWPQ Is 2062 Haresh Shah W1Anand KesarkarNessuna valutazione finora

- WPS SampleDocumento182 pagineWPS Sampleaymenfr23Nessuna valutazione finora

- Approved Welding Procedures List RegioDocumento2 pagineApproved Welding Procedures List Regiogabriel__regio100% (1)

- ASME 9 - CalculatorDocumento2 pagineASME 9 - CalculatorEmel Besir100% (1)

- Gta+sma PQRDocumento3 pagineGta+sma PQRRahul MoottolikandyNessuna valutazione finora

- WPS Asme IxDocumento4 pagineWPS Asme Ixjcarlosherrerac7100% (1)

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDocumento2 pagineQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Gmaw Complete Aws d1.6Documento1 paginaGmaw Complete Aws d1.6Silvia CardenasNessuna valutazione finora

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Documento3 pagineWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNessuna valutazione finora

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Documento1 paginaTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- Aws d1.5 PQRDocumento2 pagineAws d1.5 PQRjacquesmayolNessuna valutazione finora

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocumento3 pagineWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNessuna valutazione finora

- QW-483 BlankDocumento2 pagineQW-483 BlankCraftyBob100% (1)

- 14033Documento2 pagine14033Priyanathan ThayalanNessuna valutazione finora

- Rke PQR 01Documento2 pagineRke PQR 01Satish KeskarNessuna valutazione finora

- BPVC Ix QW-483Documento2 pagineBPVC Ix QW-483ganesh82Nessuna valutazione finora

- PQR TipsDocumento4 paginePQR TipsWaqas WaqasNessuna valutazione finora

- Suggested Wps Forms ASME - IX 2010Documento5 pagineSuggested Wps Forms ASME - IX 2010Ajay ChodankarNessuna valutazione finora

- Standard Kemahiran Pekerjaan Kebangsaan: Welding Technology ManagementDocumento2 pagineStandard Kemahiran Pekerjaan Kebangsaan: Welding Technology Managementnizam1372Nessuna valutazione finora

- DMK4258Documento4 pagineDMK4258amirul8686Nessuna valutazione finora

- MC4 CoCU 6 - Welding Records and Report DocumentationDocumento8 pagineMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- MC4 CoCU 4 - Welding Activities SupervisionDocumento10 pagineMC4 CoCU 4 - Welding Activities Supervisionnizam1372Nessuna valutazione finora

- DMK 5233 - Quality AssuranceDocumento4 pagineDMK 5233 - Quality Assuranceamirul86860% (1)

- K Tugasan (A S)Documento5 pagineK Tugasan (A S)amirul8686100% (2)

- Standard PracticeDocumento12 pagineStandard Practicenizam1372Nessuna valutazione finora

- Calibration BookletDocumento12 pagineCalibration BookletGeorge Manuel50% (2)

- Basic CalculusDocumento292 pagineBasic Calculuslouis_kwan_10% (1)

- PatternDocumento13 paginePatternamirul8686Nessuna valutazione finora

- Btu KCH PTMDocumento1 paginaBtu KCH PTMamirul8686Nessuna valutazione finora

- 3 - Kertas Tugasan (Wa7)Documento4 pagine3 - Kertas Tugasan (Wa7)amirul8686Nessuna valutazione finora

- JD Bussiness Developement & Commercial HeadDocumento2 pagineJD Bussiness Developement & Commercial Headamirul8686Nessuna valutazione finora

- TNM Holdings Sdn. BHD.: Job DescriptionDocumento1 paginaTNM Holdings Sdn. BHD.: Job Descriptionamirul8686Nessuna valutazione finora

- Audit ChecklistDocumento8 pagineAudit Checklistamirul8686Nessuna valutazione finora

- Chapter 4 Member Under Axial LoadingDocumento60 pagineChapter 4 Member Under Axial Loadingamirul8686Nessuna valutazione finora

- Ansi FM 4950-2007 PDFDocumento21 pagineAnsi FM 4950-2007 PDFIgor Silveira100% (2)

- TNM Holdings Sdn. BHD.: Job DescriptionDocumento1 paginaTNM Holdings Sdn. BHD.: Job Descriptionamirul8686Nessuna valutazione finora

- JD HR & Admin ManagerDocumento1 paginaJD HR & Admin Manageramirul8686Nessuna valutazione finora

- Sample Job Description QMRDocumento2 pagineSample Job Description QMRamirul8686100% (1)

- Welder CardDocumento8 pagineWelder Cardamirul8686Nessuna valutazione finora

- Reading 2 What Is CIMDocumento6 pagineReading 2 What Is CIMamirul8686Nessuna valutazione finora

- Reading 2 What Is CIMDocumento6 pagineReading 2 What Is CIMamirul8686Nessuna valutazione finora

- Mechanic: Kheng Soon Services SDN BHDDocumento2 pagineMechanic: Kheng Soon Services SDN BHDamirul8686Nessuna valutazione finora

- Epe491 PDFDocumento5 pagineEpe491 PDFtheredwarrior92Nessuna valutazione finora

- Final Dimension Report BlankDocumento4 pagineFinal Dimension Report Blankamirul8686Nessuna valutazione finora

- Umpan JayaDocumento7 pagineUmpan Jayaamirul8686Nessuna valutazione finora

- Final Exam Dynamic PaperDocumento9 pagineFinal Exam Dynamic Paperamirul8686Nessuna valutazione finora

- Building Maintenance MethodDocumento7 pagineBuilding Maintenance Methodamirul8686Nessuna valutazione finora

- RR Trent 60Documento39 pagineRR Trent 60Ricardo Cabrera Osinaga100% (6)

- A Method of Creep Rupture Data Extrapolation Based On Physical ProcessesDocumento10 pagineA Method of Creep Rupture Data Extrapolation Based On Physical ProcessesAndrea CalderaNessuna valutazione finora

- Atomic Absorption SpectrometryDocumento64 pagineAtomic Absorption Spectrometryanilrockzzz786Nessuna valutazione finora

- What Is Quantum Mechanics - Quantum Physics Defined, ExplainedDocumento6 pagineWhat Is Quantum Mechanics - Quantum Physics Defined, ExplainedIsabel WilliamsNessuna valutazione finora

- Motors: Single and Multiple Vane Pumps & Vane MotorsDocumento120 pagineMotors: Single and Multiple Vane Pumps & Vane Motorsmephir666Nessuna valutazione finora

- Experiment On Non-Newtonian-FluidsDocumento15 pagineExperiment On Non-Newtonian-FluidsSonia GawadeNessuna valutazione finora

- Faculdade Estadual de Engenharia Química de Lorena - FAENQUILDocumento56 pagineFaculdade Estadual de Engenharia Química de Lorena - FAENQUILLuis Gustavo PachecoNessuna valutazione finora

- Frigoscandia: LVS Refrigeration™ SystemDocumento4 pagineFrigoscandia: LVS Refrigeration™ Systempatricebertrand100% (1)

- Self-Healing Concrete With Crystalline AdmixtureDocumento8 pagineSelf-Healing Concrete With Crystalline AdmixtureAlexander HierroNessuna valutazione finora

- Liftoff TechniquesDocumento4 pagineLiftoff TechniquesSwarnava SanyalNessuna valutazione finora

- 09 Silver 4 - M1 EdexcelDocumento13 pagine09 Silver 4 - M1 Edexcelsh.bonita.editsNessuna valutazione finora

- SpiraxSarco-B2-Steam Engineering Principles and Heat TransferDocumento186 pagineSpiraxSarco-B2-Steam Engineering Principles and Heat Transferdanenic100% (4)

- 2018Documento71 pagine2018Kamran AliNessuna valutazione finora

- Presentation - Cement - GenDocumento40 paginePresentation - Cement - Genpacoto livingstoneNessuna valutazione finora

- Petroleum Production Engineering Ii: Sucker Rod PumpingDocumento27 paginePetroleum Production Engineering Ii: Sucker Rod PumpingMohammed Khaled Al-ThobhaniNessuna valutazione finora

- 2.0 Theory: at The End of The Lab Session Students Should Be AbleDocumento5 pagine2.0 Theory: at The End of The Lab Session Students Should Be AbleMuhammad Danish Mohd SizaNessuna valutazione finora

- Lecture 2 Reciprocal Lattice NotesDocumento3 pagineLecture 2 Reciprocal Lattice Notesoluwasegunadebayo91Nessuna valutazione finora

- 1S1920 - SW - Fluid Mechanics: Name DateDocumento12 pagine1S1920 - SW - Fluid Mechanics: Name DateBosz' AceNessuna valutazione finora

- Newton's First and Second Laws - Print - QuizizzDocumento5 pagineNewton's First and Second Laws - Print - QuizizzZeinab ElkholyNessuna valutazione finora

- Entalpia de Fofmacion Del PoliisoprenoDocumento36 pagineEntalpia de Fofmacion Del PoliisoprenoNena Jessi LoveNessuna valutazione finora

- Ray Optics PDFDocumento21 pagineRay Optics PDF1996vishakNessuna valutazione finora

- Dynamic Balancing Machines, Soft-Bearing vs. Hard-BearingDocumento2 pagineDynamic Balancing Machines, Soft-Bearing vs. Hard-BearingS Kumar Pa VeluNessuna valutazione finora

- Comparison of Hardness For Mild Steel After Normalizing and Hardening ProcessesDocumento17 pagineComparison of Hardness For Mild Steel After Normalizing and Hardening Processesyaswanth kumarNessuna valutazione finora

- Compressor 1 6hp r600 110v Embraco Emu60clpDocumento4 pagineCompressor 1 6hp r600 110v Embraco Emu60clpWagner VenturaNessuna valutazione finora

- Well Testing Schlumberger GlossaryDocumento18 pagineWell Testing Schlumberger GlossaryDiana La Cruz100% (1)

- c5 Pre Frac Injection Tests PDFDocumento76 paginec5 Pre Frac Injection Tests PDFJames WallaceNessuna valutazione finora

- University BADJI MOKHTAR ANNABADocumento6 pagineUniversity BADJI MOKHTAR ANNABAmeghlaouirami5Nessuna valutazione finora

- Tray Dryer Final ReportDocumento13 pagineTray Dryer Final ReportHaziq AzliNessuna valutazione finora

- Lewatit® MonoPlus S 108-EN-GBDocumento4 pagineLewatit® MonoPlus S 108-EN-GBsimontin23Nessuna valutazione finora

- Pruebas Standar para PlasticosDocumento41 paginePruebas Standar para PlasticosEduardo SalgadoNessuna valutazione finora