Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SPE 110973 Understanding Stress Dependant Permeability of Matrix, Natural Fractures, and Hydraulic Fractures in Carbonate Formations

Caricato da

tomk2220Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SPE 110973 Understanding Stress Dependant Permeability of Matrix, Natural Fractures, and Hydraulic Fractures in Carbonate Formations

Caricato da

tomk2220Copyright:

Formati disponibili

SPE 110973

Understanding Stress Dependant Permeability of Matrix, Natural Fractures, and

Hydraulic Fractures in Carbonate Formations

H.H. Abass, I. Ortiz, M.R. Khan, J.K. Beresky, Saudi Aramco, and L. Sierra, Halliburton

Copyright 2007, Society of Petroleum Engineers

This paper was prepared for presentation at the 2007 SPE Saudi Arabia Technical Symposium

held in Dhahran, Saudi Arabia, 78 May 2007.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to an abstract of not more than

300 words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

Most carbonate reservoirs behave as dual porositypermeability systems in which the rock matrix and both

natural and created hydraulic fractures contribute to the

hydrocarbon transport in a very complex manner.

Understanding the behavior of the permeability of the

matrix frame, natural fractures, and created hydraulic

fractures, as a function of reservoir depletion, is vital to

designing optimum stimulation treatments and to

maximize the carbonate formations exploitation.

Core samples were selected from a carbonate reservoir

and a testing procedure was applied to determine the

stress dependant permeability as a function of various

combinations of effective stresses. A tensile natural

fracture was simulated by splitting a whole core by failing

it under tension using a Brazilian test procedure. The

stress dependant permeability was evaluated under

varied effective stresses simulating a reservoir depletion

scenario. A shear fractured core was selected from a

given carbonate formation and a stress dependant

permeability was established. The tensile fractured core

was then propped with a low concentration of small

mesh proppants and the permeability of the simulated

propped fracture was determined. Using a new reservoir

simulator the testing results and selective functions were

used to predict the production performance of a

carbonate reservoir under the effect of the stress

dependant permeability.

The experimental results indicate that the tensile

fractures are much less conductive than shear fractures

and the shear fractures are less conductive than

propped fractures. The concept of effective stress within

the rock matrix is totally different than that of natural

fractures; therefore, the effective stress function for both

matrix and natural fractures should be separately

evaluated to obtain representative functions for any

simulation study. The tensile fractures lose conductivity

at very early stages of reservoir depletion.

Recommendations to manage these tensile fractures for

optimum hydrocarbon recovery are suggested.

Practical outputs of this work are: 1) Understand how

natural fractures are controlled to efficiently contribute to

well productivity, 2) Quantify the effective stress concept

in the matrix and fracture systems, 3) Provide stressdependant correlations for simulation studies.

Introduction

Tight

carbonate

reservoirs

behave

as

dual

porosity/permeability systems in which the rock matrix,

natural fractures network and created hydraulic fractures

contribute to the hydrocarbon transport in a very

complex manner. Permeability loss due to increasing

effective stress as a result of reservoir depletion can

result in substantial cumulative recovery loss1. The

permeability of fissured/fractured reservoirs has been

postulated to be highly sensitive to changing effective

stresses. An increased effective stress, which is the

combined effect of stress and pore-pressure, may

decrease the reservoir permeability considerably. This

permeability sensitivity to changing stresses is most

pronounced in tight, over pressured, naturally fractured

reservoirs where the apertures of natural fractures are

very sensitive to applied closure stress resulted from

reservoir depletion.

A working model consistent in both fluid flow and

geomechanical considerations is required to link various

fluid-rock information (e.g., flow/storage properties, rock

mechanical properties, reservoir fluid pressure and

stress level) measured by different techniques and to

forecast reservoir performance2.

Identifying natural fractures is incumbent in the

economic optimization of fracture stimulation designs.

Techniques designed specifically to stimulate natural

fractures include low gel loadings, energized fluids and

100 mesh proppant for natural fracture preservation.3-5

Pressure depletion during production will significantly

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

Understanding the hydraulic characteristics of the matrix

frame, natural fractures, and created hydraulic fractures

as a function of effective confining stress is vital to

design optimum stimulation treatments, to predict

reservoir performance via reservoir simulation and to

maximize the carbonate formation exploitation.

The objective of this study was to investigate

permeability reduction characteristics of natural fractures

in highly stressed reservoirs with lowered pore pressure.

An understanding of production from fractured carbonate

reservoirs that exhibit permeability reduction with lower

bottom hole pressure (BHP) is required.

A pore

pressure versus permeability relationship is essential for

optimizing field development scenarios, is also required.

This matrix-fracture flow transfer function has been used

to simulate fluid flow through fractured porous medium.

A shape factor is usually imbedded within the transfer

function. Considering the work presented in this paper, a

new perspective for the transfer function including the

shape factor should be considered to include the stress

dependant fracture aperture and its permeability, in

addition to the stress dependant matrix permeability.

Effective Stress Concept

The effective stress concept as introduced by Biot

(1941) suggests that pore pressure helps counteract the

mechanical stress carried through the grain-to-grain

contact. The efficiency of reservoir pressure , pr , in

supporting the earth stresses is measured by the

poroelastic factor ; the relationship is:

= a p .... (1)

Where is the effective stress, and is the total stress.

The poroelastic constant, , is given by:

= 1

cma

,

cb

0 1 (2)

With the bulk compressibility, cb, given by:

cb =

3(1 2 )

(3)

E

If the rock has no porosity, the rock matrix

compressibility, cma, is equal to cb, and becomes zero.

Conversely, with high porosity, the matrix compressibility

is small compared to the bulk compressibility, and

approaches unity. The poroelastic constant can be

evaluated in the laboratory. This study provides a new

SPE110973

technique to indirectly determine this important

coefficient. The role of effective stress concept near the

wellbore is more pronounced as the reservoir pressure

declines rather rapidly approaching the bottom hole

flowing pressure. The reservoir pressure as a function of

radial distance from a given well is given by:

r

ln

rw

p (r ) = Pw + ( Pe Pw )

r

ln e

rw

... (4)

For example, lets assume pe = 8500 psi, pw = 2500 psi,

re = 9000 ft, rw = 0.5 ft, 8500, =12000 psi, and = 0.65.

Then the pressure and effect stress gradients around the

flowing wellbore for the given example is shown in

Figure 1.

Reservoir pressure

effective stress

9,000

12,000

6,000

8,000

3,000

4,000

0

0

1,000

2,000

3,000

E ffe c tiv e s tre s s , ps i

change the productivity of a reservoir with similar natural

fractures6. Natural fractures impact on production has

been studied by various authors whom have proposed

that these fissures if kept open can contribute

substantially to production.7-15

P re s s ure , ps i

4,000

Distance (ft)

Figure 1: Reservoir pressure and effective stress gradients

around a given wellbore.

The greatest pressure drop occurs within a short

distance from the wellbore. Therefore the effective stress

will be the highest near the wellbore causing

permeability reduction additional to that caused by radial

flow convergence and skin.

Although we assumed to be constant, it is really a

function of pressure. The near wellbore permeability in

specific and the reservoir permeability in general

changes with pressure depletion thus affecting our well

test analysis, single-well reservoir simulation studies,

and the reservoir management strategies as a whole.

Therefore modeling this mechanism is critical to these

petroleum engineering aspects.

Changes in fracture permeability caused by changes in

effective stress, caused by changes in pore pressure,

have been observed at both laboratory and field studies.

Although the terminology Stress-sensitive reservoirs

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

Stress Dependant Matrix Conductivity

Selected samples such that they do not appear to have

microfractures were tested to determine the stressdependant matrix permeability. Various combinations of

net effective stresses were applied and the permeability

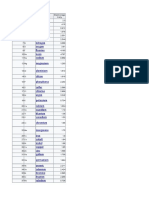

measured at each stress level. Table 1 presents all

combinations of applied confining stresses and the pore

pressure levels and gradients for a given flow test.

Recalling the definition of effective stress as given in

equation 1, it is required to assume a value for the Biots

coefficient (). Assuming is 1, and plotting matrix

permeability as a function of effective stress, we obtain

Figure 2. Close examination of Figure 2 suggests that

for a given effective stress multiple values of

permeabilities are measured. This is not an experimental

error rather the assumption of being one is not valid.

The next step is to change and replot the stressdependant permeability function until a meaningful trend

is obtained. Since is function of stress, then varying it

within the constraints from the first step would produce

the stress-dependant permeability presented in Figure 3

with estimated function (p).

Cp

Pout

Pin

Pav

psi

psi

psi

psi

psi

mlcc/m

2488

2004

1000

1502

1004

7.644

0.313

4519

4010

3000

3505

1010

6.359

0.2588

4506

2013

1000

1507

1013

4.224

0.1714

8555

8006

7000

7503

1006

5.124

0.2093

6495

4002

3000

3501

1002

3.616

0.1484

6487

1999

1000

1499

999

3.178

0.1308

8511

4006

3000

3503

1006

2.857

0.1167

8511

2005

1000

1502

1005

2.595

0.1061

10012

2005

1000

1502

1005

2.521

0.1032

Stress-dependant matrix permeability

0.4

0.3

0.2

0.1

0

0

2,000

4,000

6,000

8,000

10,000

Effective confining stress, psi

Figure 2: Stress-dependant matrix permeability ( =1).

Stress-dependant matrix permeability

0.9

0.5

-0.1236

y = 1.9989x

0.4

Perm

Biot Coeff.

0.8

0.3

0.7

0.2

-0.5937

y = 21.548x

0.1

0.0

0

2,000

4,000

6,000

8,000

Effective confining stress, psi

0.6

Biot Coefficient

Experimental Simulation

An experimental procedure was designed to simulate the

reservoir permeability (matrix, natural fractures and

induced fractures) reduction as a function of increasing

effective stress. Whole core samples were used with

dimensions of 4-in. diameter and various lengths (4 - 8

in). The sample is then tested for matrix conductivity. A

tensile fracture was created by failing a whole core

similar to a Brazilian test. The core would split into two

halves. A natural shear fracture from a cored formation

was used to study the hydraulic conductivity of a shear

fracture as a function of effective stress. A proppant bed

is sandwiched between the two splitted halves to form a

propped fracture. The sample (intact, with tensile

fracture, with a natural shear fracture, or propped

fracture) is then positioned inside the rock mechanics

loading frame. Then the confining pressure is applied

around the sample and a linear flow is established at a

given pore pressure to determine the hydraulic

conductivity of a given porous medium component

(matrix, tensile fracture, shear fracture, and propped

fracture).

Table 1: applied confining stresses for various flow

tests.

Matrix permeability, Micro-Darcy

has been widely used in the literature, all reservoirs

exhibit stress-sensitive permeability. The effective stress

magnitude and resulting deformation which produce

permeability changes, differs from one reservoir to

another. The effective stress is a function of pore

pressure, total stress, and Biots coefficient, and the

deformation is a function of the rock elastic and plastic

characteristics. Therefore the resulting permeability

change is a very complex function for an analytical

equation and should be experimentally evaluated for a

given rock formation at in-situ conditions.

Matrix perm, Micro-Darcy

SPE 110973

0.5

10,000

Figure 3: Stress-dependant matrix permeability with variable (p).

Stress dependant tensile fracture conductivity

When the reservoir pressure decreases, the elastic

displacement in response to the increase in effective

stress will cause natural fractures to close leading to a

decline in reservoir productivity. The matrix medium

feed the natural tensile fractures and the latter conduct

the fluids to the wellbore. The decline in conductivity with

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

increasing effective stress should follow a logical

declining rate to support a given production rate.

SPE110973

asperities. Compressive failure also generates rock

particles and fines that will further reduce fracture

conductivity. The fracture asperities in tensile and shear

fractures differ considerably, as the first one is not

accompanied with formation shifting while the rock in the

latter experience formation shifting which generate a

higher conductivity. As explained earlier, a 4-in sample

shown in Figure 4 is failed in tension following a

Brazilian test. The induced failure plain represents a

tensile fracture. The flow testing through the fracture was

performed and separated from the total permeability

using the following equation:

K t At = K f A f + K ma Ama ..... (6)

Stress dependant shear fracture conductivity

A natural shear fracture from a cored formation is shown

in Figure 5. Conductivity tests through the fracture were

performed similar to the tests conducted on the tensilefracture sample. The natural shear fracture as shown in

Figure 6 exhibits the shear fracture and its natural

surface.

Figure 4: Simulated tensile fracture; (Top) shows the failed whole

core and (Bottom) shows the resulting fracture surface.

The elastic closure response occurs when the net

effective horizontal stress increases as a result of

reservoir depletion. The elastic response to close the

fracture follows Hookes law of elasticity and it is

controlled by Youngs modulus of the formation:

e =

.. (5)

The aperture of the fracture will decrease causing a

corresponding reduction of fracture conductivity. If we

assume 50 ft of the rock perpendicular to the fracture will

contribute to fracture closure, then for a Youngs

modulus of 3 x 106 psi, the decrease in fracture width

corresponding to a decrease in reservoir pressure from

7,000 to 4,000 psi will be 0.05 inches. The fracture will

not close by 0.05 inches rather the contact points

(asperities) will carry the applied stress to prevent

fracture closure if they are strong enough to withstand

the stress. The compressive strength of the asperities

will determine the final fracture permeability. The

reduction in conductivity is due to a combined effect of

elastic response and compressive failure of the

Figure 5: Natural shear fracture from a retrieved core; (Top)

shows the naturally sheared fracture whole core and (Bottom)

shows the natural shear fracture surface.

SPE 110973

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

Stress

Dependant

Conductivity.

Proppant

hydraulic-fracture

Proppant hydraulic fracturing is used to create a

conductive fracture in the pay zone to enhance well

productivity. Proppant is used to keep a fracture open

during the life of the well.

Figure 6: A 100-mesh propped tensile fracture

A tensile-failed sample was propped with 100 mesh

Intermediate Strength Proppant (ISP) (Figure 6), or with

30 mesh Intermediate Strength Resin Coated Proppant

(ISRCP) (Figure 7), and flow testing was performed at

variable effective confining stress.

The permeability of a one layer 30 mesh RCP decreased

drastically and a lot of fines were generated (Figure 7)

at an effective closure of 4,000 psi. This is an important

criterion to consider when deciding on the type of

proppant to be used in the proppant fracturing treatment

of a given reservoir.

Figure 8 shows the stress-dependant permeability of the

porous media components considered in this study. The

best reservoir management will be produced if the

conductivity of all components declines at the same rate

assuming they start at similar original values. Figure 9

shows the stress dependant conductivity for the same

porous media components.

Normalized fracture conductivity defined as a

percentage of the initial conductivity is presented in

Figure 10. A 100-mesh proppant fracture will sustain

well productivity better than a 30-mesh RCP which

crushed at a closure stress of 6500 psi effective stress.

The 30-mesh proppant conductivity becomes less than

the ISP 100-mesh conductivity when

Figure 7: A tensile fracture propped with 30-mesh proppant (top),

and the re-sieved meshes observed after the test (bottom).

the effective stress becomes more than 7000 psi.

Although this high stress may not occur deep in the

reservoir, near the wellbore it may be very well

applicable. Low concentrations of proppant (Waterfracs)

have been very successful in stimulating tight gas

reservoirs17,18. A WaterFrac is a proppant fracturing;

however, proppant concentration used is very low

ranging from 0.5 to 2 Ib/gal. Therefore, it is possible that

a 100-mesh proppant perform better that a 30 mesh

resin-coated proppant if the later is exposed to crushing

stress as fines will be generated from the resin coat

resducing fracture conductivity below that of a 100 mesh

proppant.

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

Permeability, md

Tensile Frac

100 mesh frac

100000

1000

10

0.8

0.6

0.4

0.2

0

0.1

0.001

2,000

4,000

6,000

8,000

10,000

Effective Confining Pressure, psi

Figure 10: Normalized conductivity of various porous media

components associated with carbonate formation.

0.00001

2,000 4,000 6,000 8,000 10,000

Effective Confining Pressure, psi

Figure 8: Permeability of various porous media components

associated with carbonate formation.

Observing Figure 10, it be concluded that filling natural

fractures (tensile and shear) will improve productivity of

the given stress-sensitive reservoir under study. This is

not necessarily true in non-stressed reservoirs as it is

shown when the effective stress < 2000 psi, the shear

fracture is providing better conductivity than a 100 mesh

ISP propped fracture.

Matrix

Shear Frac

30 mesh RCP Frac

Tensile Frac

100 mesh Frac

10000

100

Mathematical Simulation

A mathematical model16 was used to achieve two

objectives; 1) Compare stress-dependant permeability

vs. constant permeability, and 2) Compare the effect of

100-mesh propped, a tensile, and shear hydraulic

fractures. The reservoir properties used in all simulation

cases were; a gas reservoir with a net pay of 46 feet,

reservoir pressure of 7620 psi, permeability is 0.5 md at

initial conditions and for fractured-well simulations; the

fracture is 150 feet long. The stress-dependant

permeabilities for all conductive components presented

above were used in the simulations. Two cases were

considered in the simulation runs; a single porosity

reservoir with constant matrix permeability and the other

case was considering the stress-dependant matrix

permeability. Figure 11 shows the results from these

two cases labeled as w/o stress and w/stress. In the

w/o stress case, the initial matrix permeability was kept

constant as the reservoir pressure decreases, while in

the w/stress case the initial matrix permeability

decreases as the reservoir pressure decreases following

the matrix function presented in Figure 11. The stress

effect is responsible for 50% loss of the PI, which can be

even more at higher production rate.

2.5

0.01

w/o stress

w/ stress

0.0001

0

2,000 4,000 6,000 8,000 10,000

Effective Confining Pressure, psi

Figure 9: Conductivity of various porous media components

associated with carbonate formation.

Figure 10 suggests that the tensile and shear fractures

losses more than 70% of its conductivity when the pore

pressure decreases by 1000 psi. This confirms rapid

decline in productivity in naturally fractured reservoirs

during early production. Propped fractures decline rather

much slower than natural fractures.

PI, Mscf/d/psi

Conductivity, md-cm

Matrix

Shear Frac

30 mesh RCP Frac

Tensile Frac

30 mesh RCP Frac

Normalized Conductivity

Matrix

Shear Frac

100 mesh Frac

SPE110973

1.5

1

0.5

0

50

100

150

200

250

Time (days)

Figure 11: PI as a function of time for single porosity model with

and without the effect of stress on matrix permeability.

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

Additional three simulation runs were made for

hydraulically fractured wells. The hydraulic fractures

considered followed the same characteristics of the

tensile, shear, and 100 mesh ISP propped fractures. The

initial conductivities of these fractures were kept

constant as the reservoir pressure decreases. The

results, represented by the well productivity index (PI)

behavior, for all fractured-well cases are presented in

Figure 12. The results show the benefit of the tensile,

shear and 100 mesh ISP propped fractures compared to

a single porosity non-fractured well. The 100-mesh

hydraulic fracture performed better than the hydraulic

fracture that has natural shear fracture conductivity or

the hydraulic fracture that has the tensile fracture

conductivity. This observation suggest that filling the

existing natural tensile and shear fractures with 100

mesh ISP proppant will lead to more production than

depleting the reservoir as a naturally fractured reservoir.

This conclusion does not carry a general consensus

rather it depends on the stress level and mechanical

characteristics of the reservoir formation. In shallow

reservoirs, the natural fractures may behave as infinite

conductivity fractures and filling them with 100-mesh

proppant will only reduce their contribution to the overall

reservoir flow efficiency.

Matrix

100 mesh

Shear fracture

Tensile fracture

P I, M scf/d/psi

6

5

4

3

2

1

0

0

50

100

150

Time, days

200

250

Figure 12: PI performance for various scenarios without the effect

of stress.

Considering the stress effect all the simulated cases

change drastically, as it is showed in Figure 13. The

effect of the tensile fracture stands only for a shorter

time due mainly to the high effect of the stress. This is a

scenario of injecting water only to create tensile fracture;

however this type of fractures will close upon producing

the reservoir and the effective stress increases. The

effect of shear fracture stands for a longer time for the

simulated case. The effect of the 100 mesh ISP propped

fracture is superior to all other cases with the effect of

stress dependant permeabilities.

8

Matrix

100 mesh

Shear fracture

6

PI, Mscf/d/psi

SPE 110973

Tensile fracture

5

4

3

2

1

0

0

50

100

150

Tim e (days)

200

250

Figure 13: PI for various completion scenarios with stress effect .

Conclusions

1. This study has uncovered an important phenomenon

related to the stress dependant poroelastic effect

during production of naturally fractured reservoirs.

The poroelastic coefficient in the matrix domain is

considerably different than that of the natural

fractures system. A new laboratory procedure to

determine the two different poroelastic functions is

presented. These functions should be implemented

in a dual porosity/dual permeability reservoir

simulation study to obtain reasonable prediction of

reservoir performance.

2. In stressed reservoirs or stress-sensitive reservoirs

where permeability loss is substantial, keeping the

natural fractures open should be the primary

objective. Propping these fractures with small

proppant mesh at early time should be considered

as an effective reservoir management strategy for

these reservoirs.

3. Many wells in naturally fractured reservoirs are

initially good producers but after a short period of

time a sharp decline in productions is observed.

This is frequently interpreted as a flush production

which is a rapid drainage of the fracture network,

whereas fluid bleed-off from the lower permeability

matrix rock occurs at much lower rates. This study

suggests

a

new

explanation

related

to

unsynchronized permeability reduction rate in the

matrix and fissures media. Effort to synchronize the

permeability decline rates of the matrix and fractures

systems should be carefully designed.

4. The contribution of matrix, tensile fractures and

shear fractures to the overall reservoir productivity

follow different stress-dependant permeability

functions. The permeability functions of these

porous components should be carefully determined

for any reservoir simulation study.

5. The stress-dependant proppant conductivity should

be evaluated in these highly stressed reservoirs

before any proppant fracturing is considered as a

stimulation treatment. A crushed large size proppant

may perform poorer than 100-mesh proppant.

6. In low permeability gas reservoirs, the abnormal

production lost is normally attributed to the

Understanding stress dependant permeability of matrix, natural fractures, and hydraulic fractures in carbonate formation

condensate banking phenomenon; however this

paper offers another alternative explanation related

to lost permeability.

7. This study provides an explination of why slickwater

hydraulic fractures work in certain reservoirs. The

tensile fractures in low stress reservoirs may

continue to contribute to the flow system before their

permeability becomes negligible. Additionally the

waterfrac may perform better than the natural

fractures which are assumed to have infinite

conductivity.

Nomenclature

A

: Fracture area

E

: Youngs modulus

K

: Bulk modulus, psi

K

: Permeability, md

Pe

: External pressure, psi

Pw

: Wellbore pressure, psi

PI

: Productivity Index, Mscf/d/psi

P

: Pressure drawdown (Pe-Pw), psi

re

: External radius, inch

rw

: Wellbore radius, inch

w

:

Fracture

displacement

during

development

: Biots coefficient

: Displacement due to elastic response

e

: Effective grain-to-grain stress.

t

: Total minimum horizontal stress

width

Subscript

t

: total

ma

: matrix

f

: fracture

b

: bulk

e

: external

e

: elastic

w

: well

References

1. Kasap, E. Schlumberger and Bush, E. S. Occidental

Petroleum Corporation; Estimating a Relationship

Between Pore Pressure and Natural Fracture

Permeability for Highly Stressed Reservoirs, SPE

84410, Denver, CO, October, 2003.

2. Ochs, D. E. Chen, H. Y. Teufel, L. W.; New Mexico

Insitute. Of Mining and Technology; Relating In Situ

Stresses and Transient Pressure Testing for a

Fractured Well, SPE 38674; 1997 Annual Technical

Conference, October 1997.

3. Cipperfield, S., Santos Ltd.; After Closure Analysis

for naturally Fractured Reservirs: Field Examples,

SPE 97015; SPE Annual Technical Conference,

Dallas, TX, October, 2005.

4. Duan, Y. Meng, Y., Luo, P, Su, W.; Southwest

Petroleum Institute; : Stress Sensitivity of Naturally

Fractured Porous Reservoir with Dual Porosity, SPE

50909; 1998 Annual SPE International Conference,

Beijing, China; November 1998.

5. Pinzon, C., Chen, H. Y., Teufel, L. W.; New Mexico

SPE110973

Institute of Mining and Technology; Complexity of

Well Testing Analysis of Naturally Fractured Gas

Condensate Wells in Colombia, SPE 59013; 2000

SPE International Conference, Villahemosa, Mexcio;

February, 2000.

6. Warpinski, N. R., Teufel, L. W., Graf, D. C.; Sandia

National Laboratories; Effect of Stress and Pressure

on Gas Flow Through Natural Fractures, SPE 22666;

66th Annual Technical Conference, Dallas, TX;

October, 1991.

7. Warpinski, N. R. Hydraulic Fracturing in Tight,

Fissured Media, SPE20154; JPT, February, 1991.

8. Ozkaya, S. I., Bolle, L. Baker Atlas GeoScience;

Modeling and Upscaling Fracture Corridors

Uncertainties, SPESA 0602; 2006 SPE Symposium,

Dhahran, Saudi Arabia, May 2006.

9. Jones, F. O.; Amoco Production Co.; A Laboratory

Study of the Effects of Confining Pressure on

Fracture Flow and Storage Capacity in Carbonate

Rocks, SPE 4569; 48th SPE meeting Las Vegas, NV;

September, 1974.

10. Cikes, M, Economides, M.; Mining U. Leoben;

Fracturing of High Temperature, Naturally Fissured,

Gas Condensate Reservoirs, SPE 20973; SPE

Production Engineering; May, 1992.

11. Stowell, J. F. W., Laubach, S. E. and Olson, J. E.,

2001, Effect of modern state of stress on flowcontrolling fractures: a misleading paradigm in need

of revision, in Elsworth, D., Tinucci, J. P. and

Heasley, K. A., eds., Rock Mechanics in the National

Interest: Proceedings of the 38th Annual U.S. Rock

Mechanics Symposium, Balkema, v.1, p. 691698.

12. Economides, M. J., Texas A & M; Buchsteiner, H.

Minin U. Leoben; Warpinski, N. R. Sandia National

Laboratories; Step Pressure Tests for Stress

Sensitive

Permeability

Determination,

SPE

27380;SPE Formation Damage Control Lafayette,

LA; February, 1994.

13. Economides, M. J., Texas A & M; Buchsteiner, H.

Minin U. Leoben; Warpinski, N. R. Sandia National

Laboratories;

Stress

Induced

Permeability

Reduction in Fissured Reservoirs, SPE 27380; 66th

SPE Conference Houston, TX; October, 1993.

14. J.C. Lorenz; Stress-Sensitive Reservoirs, SPE

50977; JPT, January, 1999, pp 61-63.

15. Conformance Technology, Halliburton Energy

Services Publication F-3373, 1996.

16. QuickLook Reservoir Simulator, Halliburton Energy

Services.

17. Mayerhofer, M.J., Richardson, M.F., Walker, R.N.,

Meehan, D.N., Oehler, M.W., Browning Jr, R.R.:

Proppants? We Dont Need No Proppants, SPE

38611 presented at the 1997 Annual Technical

Conference held in San Antonio, TX, Oct 5-8.

18. Walker, R.N., Hunter, J.L., Brake, A.C., Fagin, P.A.,

Steinberger, N., :Proppants, We still Dont Need No

ProppantsA

Perspective

of

Several

Operators,,SPE 49106 presented at the 1998

Annual Technical Conference held in New Orleans,

LA, Sept. 27-30.

Potrebbero piacerti anche

- 2effect of Reservoir Stress Path On Compressibility andDocumento10 pagine2effect of Reservoir Stress Path On Compressibility andBolton3Nessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Stress-Dependent Petrophysical Properties. An OverviewDocumento10 pagineStress-Dependent Petrophysical Properties. An OverviewbelahmeursNessuna valutazione finora

- SPE 26647 Application of Variable Formation Compressibility For Improved Reservoir AnalysisDocumento16 pagineSPE 26647 Application of Variable Formation Compressibility For Improved Reservoir AnalysisglsancorNessuna valutazione finora

- Spe-17425-PaDocumento9 pagineSpe-17425-Paleonelz6aNessuna valutazione finora

- SPE 87130 Stress Cage AstonDocumento8 pagineSPE 87130 Stress Cage AstonPTNessuna valutazione finora

- Yale1993 PDFDocumento16 pagineYale1993 PDFAlejandro Duvan Lopez RojasNessuna valutazione finora

- Analisa Pressure Build Up TestDocumento28 pagineAnalisa Pressure Build Up TestDerips PussungNessuna valutazione finora

- Analisa Pressure Build Up TestDocumento49 pagineAnalisa Pressure Build Up TestLuc ThirNessuna valutazione finora

- Spe 98329 MSDocumento8 pagineSpe 98329 MSdancelikedaveNessuna valutazione finora

- SPE 79698 Coupled Analysis of Geomechanics and Fluid Flow in Reservoir SimulationDocumento16 pagineSPE 79698 Coupled Analysis of Geomechanics and Fluid Flow in Reservoir SimulationlapinNessuna valutazione finora

- Build Up InformationDocumento18 pagineBuild Up Informationjose luis pachecoNessuna valutazione finora

- Spe 166439 MS PDocumento23 pagineSpe 166439 MS PdancelikedaveNessuna valutazione finora

- Easec-15 Full Paper ScossaDocumento8 pagineEasec-15 Full Paper ScossaManuelPérezNessuna valutazione finora

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocumento25 pagineWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAnonymous aQqan3bxA2Nessuna valutazione finora

- 2007 SPE 107142 MS PCHightJamiolahmadyEtal PDFDocumento10 pagine2007 SPE 107142 MS PCHightJamiolahmadyEtal PDFcristinaNessuna valutazione finora

- Spe 59690Documento15 pagineSpe 59690cmkohNessuna valutazione finora

- YtytDocumento13 pagineYtytعبدالله رعد حران 32Nessuna valutazione finora

- Walter2003 UnlockedDocumento13 pagineWalter2003 UnlockedLorena CamposNessuna valutazione finora

- SPE-115526-MS-P Fracture Ballooning in Naturally Fractured Formations - Mechanism and Controlling FactorsDocumento9 pagineSPE-115526-MS-P Fracture Ballooning in Naturally Fractured Formations - Mechanism and Controlling Factorszouke2002100% (1)

- SPE 62796 Wellbore Stability PredictionDocumento8 pagineSPE 62796 Wellbore Stability PredictionBruceNessuna valutazione finora

- The Influence of Vertical Fractures Intercepting Active and Observation Wells On Interference TestsDocumento12 pagineThe Influence of Vertical Fractures Intercepting Active and Observation Wells On Interference Testsleonelz6aNessuna valutazione finora

- Alberty2004 PDFDocumento8 pagineAlberty2004 PDFMuhammad ShehryarNessuna valutazione finora

- IADC/SPE-178881-MS Swab and Surge Pressures With Reservoir Fluid Influx Condition During MPDDocumento13 pagineIADC/SPE-178881-MS Swab and Surge Pressures With Reservoir Fluid Influx Condition During MPDqjbsexNessuna valutazione finora

- Spe 99074 MS PDFDocumento8 pagineSpe 99074 MS PDFMarcelo VeronezNessuna valutazione finora

- 2017 Ijts Cavitating-Flow PDFDocumento12 pagine2017 Ijts Cavitating-Flow PDFAdam AnugrahesaNessuna valutazione finora

- 55 - Formation FracturingDocumento12 pagine55 - Formation Fracturingrizal tri susiloNessuna valutazione finora

- CFD WaterjetDocumento8 pagineCFD WaterjettafocanNessuna valutazione finora

- Stress-Dependent Permeability On Tight Gas ReservoirsDocumento30 pagineStress-Dependent Permeability On Tight Gas ReservoirsAl JawadNessuna valutazione finora

- SIB2015 Paperr1Documento14 pagineSIB2015 Paperr1MEHDI FARROKHINessuna valutazione finora

- Geomechanics in Integrated Reservoir ModelingDocumento9 pagineGeomechanics in Integrated Reservoir ModelingMohamad TayeaNessuna valutazione finora

- SPE 25880 Using Polymer Injectivity Tests To Estimate Fracture Porosity in Naturally Fractured ReservoirsDocumento9 pagineSPE 25880 Using Polymer Injectivity Tests To Estimate Fracture Porosity in Naturally Fractured Reservoirscoke308Nessuna valutazione finora

- Prats 1962 Compressible FluidDocumento8 paginePrats 1962 Compressible FluidJoseph BimoNessuna valutazione finora

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocumento7 pagineIjesrt: International Journal of Engineering Sciences & Research TechnologyTONNessuna valutazione finora

- Well Stimulation On The Basis of Preliminary Triaxial Tests of Reservoir RockDocumento7 pagineWell Stimulation On The Basis of Preliminary Triaxial Tests of Reservoir Rockعلي صباحNessuna valutazione finora

- Spe 125043 MS P PDFDocumento18 pagineSpe 125043 MS P PDFDamir986Nessuna valutazione finora

- Spe 98035 MS PDocumento9 pagineSpe 98035 MS PJose Gregorio Fariñas GagoNessuna valutazione finora

- 780 2147 1 SMDocumento17 pagine780 2147 1 SMhari6622100% (1)

- SPE-187236-MS Proposed Refracturing Methodology in The Haynesville ShaleDocumento12 pagineSPE-187236-MS Proposed Refracturing Methodology in The Haynesville ShaleDavid Otálvaro Z.Nessuna valutazione finora

- A Short Reservoir Stimulation Course PDFDocumento26 pagineA Short Reservoir Stimulation Course PDFpdakovNessuna valutazione finora

- SPE 94062 Numerical Simulation of Fully Coupled Fluid-Flow/Geomechanical Deformation in Hydraulically Fractured ReservoirsDocumento5 pagineSPE 94062 Numerical Simulation of Fully Coupled Fluid-Flow/Geomechanical Deformation in Hydraulically Fractured ReservoirsAli NakhaeeNessuna valutazione finora

- Spe 0719 0065 JPTDocumento3 pagineSpe 0719 0065 JPTDedipyaNessuna valutazione finora

- Curtis H. WhitsonDocumento18 pagineCurtis H. WhitsonglsancorNessuna valutazione finora

- SPE 50421 MS Valko & Economides 1998Documento11 pagineSPE 50421 MS Valko & Economides 1998Devia SuswodijoyoNessuna valutazione finora

- IADC/SPE-178854-MS A New Method To Mitigate Annular Pressure Buildup by Using Sacrificial Casing, Case Study: A Deepwater Well in IndonesiaDocumento17 pagineIADC/SPE-178854-MS A New Method To Mitigate Annular Pressure Buildup by Using Sacrificial Casing, Case Study: A Deepwater Well in IndonesiaDivisi Riset Energi HMTM SPRUDA UPNessuna valutazione finora

- Wei 2016Documento13 pagineWei 2016bayuNessuna valutazione finora

- SPE/IADC-189331-MS Optimization of Tripping Speed To Minimize Surge & Swab PressureDocumento9 pagineSPE/IADC-189331-MS Optimization of Tripping Speed To Minimize Surge & Swab PressureBobby Rifki SaputraNessuna valutazione finora

- Saldanac 1986Documento15 pagineSaldanac 1986vastaguenNessuna valutazione finora

- Model Need PDFDocumento16 pagineModel Need PDFmucoNessuna valutazione finora

- SPE 02973 TeeuwDocumento9 pagineSPE 02973 TeeuwGrazielleLeiteNessuna valutazione finora

- Acharya FinalReportDocumento46 pagineAcharya FinalReportGonzalokpo69Nessuna valutazione finora

- Petroleum Research: Khalil Shahbazi, Amir Hossein Zarei, Alireza Shahbazi, Abbas Ayatizadeh TanhaDocumento15 paginePetroleum Research: Khalil Shahbazi, Amir Hossein Zarei, Alireza Shahbazi, Abbas Ayatizadeh TanhaLibya TripoliNessuna valutazione finora

- Wellbore Stability of Deviated Wells in Depleted Reservoir - Li2015Documento14 pagineWellbore Stability of Deviated Wells in Depleted Reservoir - Li2015Juan P MSNessuna valutazione finora

- Analysis of Driven Pile Setup With Abaqus/StandardDocumento4 pagineAnalysis of Driven Pile Setup With Abaqus/StandardihabmNessuna valutazione finora

- 04 Chapter - Brijesh Singh & Pankaj AgarwalDocumento17 pagine04 Chapter - Brijesh Singh & Pankaj AgarwalSri E.Maheswar Reddy Assistant ProfessorNessuna valutazione finora

- SPE Analysis of Slug Test Data From Hydraulically Fractured Coalbed Methane WellsDocumento14 pagineSPE Analysis of Slug Test Data From Hydraulically Fractured Coalbed Methane WellsJuan Manuel ContrerasNessuna valutazione finora

- Cipc 2009-105Documento5 pagineCipc 2009-105Ralf JonesNessuna valutazione finora

- Pokalaietal 2016 APPEADocumento15 paginePokalaietal 2016 APPEAabdullah nurdienNessuna valutazione finora

- Application of Decline Analysis in Fractured ReservoirsDocumento10 pagineApplication of Decline Analysis in Fractured Reservoirstomk2220Nessuna valutazione finora

- Application of Decline Analysis in Fractured ReservoirsDocumento10 pagineApplication of Decline Analysis in Fractured Reservoirstomk2220Nessuna valutazione finora

- Fluid Flow in Fractured and Fracturing Porous Media A Unified ViewDocumento11 pagineFluid Flow in Fractured and Fracturing Porous Media A Unified Viewtomk2220Nessuna valutazione finora

- A Simulation Approach For Screening of EORDocumento25 pagineA Simulation Approach For Screening of EORtomk2220Nessuna valutazione finora

- A Novel Integrated Approach To Modelling of Depletion-InducedDocumento12 pagineA Novel Integrated Approach To Modelling of Depletion-Inducedtomk2220Nessuna valutazione finora

- Matrix Fractures Exchanges in Naturally Fractured Reservoirs Under EOR MechanismsDocumento39 pagineMatrix Fractures Exchanges in Naturally Fractured Reservoirs Under EOR Mechanismstomk2220Nessuna valutazione finora

- Gravity Drainage Mechanism in Naturally Fractured Carbonate Reservoirs Review and ApplicationDocumento26 pagineGravity Drainage Mechanism in Naturally Fractured Carbonate Reservoirs Review and ApplicationNassr Al BadriNessuna valutazione finora

- Numerical Fluid Flow Modelling in MultipleDocumento23 pagineNumerical Fluid Flow Modelling in Multipletomk2220Nessuna valutazione finora

- Spe 79709 Pa P PDFDocumento9 pagineSpe 79709 Pa P PDFtomk2220Nessuna valutazione finora

- Spe 93253Documento10 pagineSpe 93253tomk2220Nessuna valutazione finora

- Hydraulic Fracture Propagation and Analysis in HeterogeneousDocumento17 pagineHydraulic Fracture Propagation and Analysis in Heterogeneoustomk2220Nessuna valutazione finora

- Spe 63030Documento7 pagineSpe 63030tomk2220Nessuna valutazione finora

- Modeling and Simulation of Fluid Flow in Naturally and HydraulicallyDocumento178 pagineModeling and Simulation of Fluid Flow in Naturally and Hydraulicallytomk2220Nessuna valutazione finora

- Spe 35742Documento2 pagineSpe 35742tomk2220Nessuna valutazione finora

- Spe 06071Documento8 pagineSpe 06071tomk2220Nessuna valutazione finora

- Spe 10791Documento30 pagineSpe 10791tomk2220Nessuna valutazione finora

- Spe 07921Documento10 pagineSpe 07921tomk2220Nessuna valutazione finora

- Spe 08945Documento12 pagineSpe 08945tomk2220Nessuna valutazione finora

- Stress Sensitivity of Saturation and End-Point Relative PermeabilitiesDocumento12 pagineStress Sensitivity of Saturation and End-Point Relative Permeabilitiesari_si100% (1)

- Spe 99Documento2 pagineSpe 99tomk2220Nessuna valutazione finora

- Spe 08952Documento7 pagineSpe 08952tomk2220Nessuna valutazione finora

- Spe 11182Documento11 pagineSpe 11182tomk2220Nessuna valutazione finora

- Spe 57439Documento8 pagineSpe 57439tomk2220Nessuna valutazione finora

- 1108Documento184 pagine1108tomk2220Nessuna valutazione finora

- Spe 84491 MSDocumento9 pagineSpe 84491 MSZoha AhmedNessuna valutazione finora

- Spe 84491 MSDocumento9 pagineSpe 84491 MSZoha AhmedNessuna valutazione finora

- Spe 171019 MSDocumento13 pagineSpe 171019 MStomk2220Nessuna valutazione finora

- Geo Mechanics Yn 3Documento32 pagineGeo Mechanics Yn 3tomk2220Nessuna valutazione finora

- Spe 133452Documento21 pagineSpe 133452tomk2220Nessuna valutazione finora

- SPE Estimating Gas Desorption Parameters From Devonian Shale Well Test DataDocumento12 pagineSPE Estimating Gas Desorption Parameters From Devonian Shale Well Test Datatomk2220Nessuna valutazione finora

- Stain Resistant FabricDocumento4 pagineStain Resistant FabricARCUSNessuna valutazione finora

- Uni ConveyerDocumento88 pagineUni Conveyerapi-26356646Nessuna valutazione finora

- Akzo Nobel Bitumen Emulsion ManualDocumento41 pagineAkzo Nobel Bitumen Emulsion Manualsukhmani jutla100% (1)

- The Top 10 Reasons Why You Shall Pick Tupperware Nano Water Filtration SystemDocumento12 pagineThe Top 10 Reasons Why You Shall Pick Tupperware Nano Water Filtration Systemsyahmi1337Nessuna valutazione finora

- Used Oil Recycling and Treatment in The United AraDocumento11 pagineUsed Oil Recycling and Treatment in The United AraEssam AlharthyNessuna valutazione finora

- Pages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignDocumento191 paginePages FromThakore, Shuchen B. - Bhatt Introduction To Process Engineering and DesignAhmed HassanNessuna valutazione finora

- Studying The Performance of Pongamia Biodiesel by Using Nano Partical Fuel AdditivesDocumento6 pagineStudying The Performance of Pongamia Biodiesel by Using Nano Partical Fuel Additivessemi1919Nessuna valutazione finora

- Practical Exercise 02Documento17 paginePractical Exercise 02FeRro ReniNessuna valutazione finora

- Oxy GraphDocumento2 pagineOxy Graphdavid_physiologyNessuna valutazione finora

- Yuli v. Nazarov, Jeroen Danon-Advanced Quantum Mechanics A Practical Guide-Cambridge University Press (2013)Documento370 pagineYuli v. Nazarov, Jeroen Danon-Advanced Quantum Mechanics A Practical Guide-Cambridge University Press (2013)Juan Diego Cutipa Loayza100% (1)

- Revision Worksheet Chapter Heat ANSWER KEYDocumento5 pagineRevision Worksheet Chapter Heat ANSWER KEYshamshadNessuna valutazione finora

- Experiment 6 PhosphorusDocumento4 pagineExperiment 6 PhosphorusMia Domini Juan Loa100% (1)

- A Simple Model For Carnot Heat EnginesDocumento6 pagineA Simple Model For Carnot Heat EnginesJohn Hernan Diaz ForeroNessuna valutazione finora

- TE Connectivity Raychem S01 03 R DatasheetDocumento7 pagineTE Connectivity Raychem S01 03 R DatasheetРоман ДяченкоNessuna valutazione finora

- EssDocumento5 pagineEssLivia BrendaNessuna valutazione finora

- Gas Equipment From ESAB: A Full Line of Gas Equipment Solutions For Every Application, Industry, and EnvironmentDocumento40 pagineGas Equipment From ESAB: A Full Line of Gas Equipment Solutions For Every Application, Industry, and EnvironmentDries VandezandeNessuna valutazione finora

- Biopharmaceutics VIOLET PACOPDocumento35 pagineBiopharmaceutics VIOLET PACOPLilian Daria100% (8)

- Report # MATC-UNL: 059 Final: Development of A Field Test Method For Total Suspended Solids AnalysisDocumento236 pagineReport # MATC-UNL: 059 Final: Development of A Field Test Method For Total Suspended Solids AnalysisHerwinnieNessuna valutazione finora

- Alfa Laval Ocm304Documento4 pagineAlfa Laval Ocm304The ProfessionalNessuna valutazione finora

- Physical Science With Earth Science NotebookDocumento341 paginePhysical Science With Earth Science NotebookJanice Read100% (1)

- Silfoam - Wackers PDFDocumento60 pagineSilfoam - Wackers PDFsrushtiNessuna valutazione finora

- Electronegativity (Allen Scale)Documento2 pagineElectronegativity (Allen Scale)YourMotherNessuna valutazione finora

- Organic ChemistryDocumento10 pagineOrganic ChemistryAshutosh paniNessuna valutazione finora

- Report For Experiment #21 Radioactive Decay: Monique DesrochersDocumento9 pagineReport For Experiment #21 Radioactive Decay: Monique DesrochersMonique DesrochersNessuna valutazione finora

- Ut 1 2Documento10 pagineUt 1 2MoNessuna valutazione finora

- 2-Excellent Chemistry Assignment The Solid StatesDocumento5 pagine2-Excellent Chemistry Assignment The Solid StatesSachin B SNessuna valutazione finora

- Hazardous Areas Stanwell Power StationDocumento19 pagineHazardous Areas Stanwell Power Stationghostamir100% (1)

- Unit-I Chemical Bonding and Molecular Structure: (18 Contact Hours)Documento3 pagineUnit-I Chemical Bonding and Molecular Structure: (18 Contact Hours)Imran Afzal BhatNessuna valutazione finora

- MP Lecture NotesDocumento125 pagineMP Lecture NotesTatenda SibandaNessuna valutazione finora

- Astm A529 1975Documento4 pagineAstm A529 1975dharlanuctcomNessuna valutazione finora

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (52)

- Environmental Justice: Issues, Policies, and SolutionsDa EverandEnvironmental Justice: Issues, Policies, and SolutionsNessuna valutazione finora

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaDa EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaValutazione: 4 su 5 stelle4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldDa EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldValutazione: 5 su 5 stelle5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontDa EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontValutazione: 4.5 su 5 stelle4.5/5 (18)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDa EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionValutazione: 3 su 5 stelle3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretDa EverandWaste: One Woman’s Fight Against America’s Dirty SecretValutazione: 5 su 5 stelle5/5 (1)

- Introduction to Ecology and Environmental Laws in IndiaDa EverandIntroduction to Ecology and Environmental Laws in IndiaNessuna valutazione finora

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionDa Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNessuna valutazione finora

- Debunking Creation Myths about America's Public LandsDa EverandDebunking Creation Myths about America's Public LandsNessuna valutazione finora

- Busted!: Drug War Survival Skills and True Dope DDa EverandBusted!: Drug War Survival Skills and True Dope DValutazione: 3.5 su 5 stelle3.5/5 (7)

- Obstacles to Environmental Progress: A U.S. perspectiveDa EverandObstacles to Environmental Progress: A U.S. perspectiveNessuna valutazione finora

- Slow Violence and the Environmentalism of the PoorDa EverandSlow Violence and the Environmentalism of the PoorValutazione: 4 su 5 stelle4/5 (5)

- Environmental Education in Practice: Concepts and ApplicationsDa EverandEnvironmental Education in Practice: Concepts and ApplicationsNessuna valutazione finora

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawDa EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawValutazione: 4 su 5 stelle4/5 (334)

- Introduction to Ecology and Environmental Laws in IndiaDa EverandIntroduction to Ecology and Environmental Laws in IndiaNessuna valutazione finora

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Da EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Valutazione: 5 su 5 stelle5/5 (2)

- Principles of direct and superior responsibility in international humanitarian lawDa EverandPrinciples of direct and superior responsibility in international humanitarian lawNessuna valutazione finora

- Down to the Wire: Confronting Climate CollapseDa EverandDown to the Wire: Confronting Climate CollapseValutazione: 4.5 su 5 stelle4.5/5 (8)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontDa EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontValutazione: 4.5 su 5 stelle4.5/5 (9)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Da EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Nessuna valutazione finora

- New Paradigms in Environmental Biomonitoring Using PlantsDa EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNessuna valutazione finora