Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Iocl Shell & Tube He's Spec Ea-601 Rev 0

Caricato da

Rama Krishna Reddy DonthireddyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Iocl Shell & Tube He's Spec Ea-601 Rev 0

Caricato da

Rama Krishna Reddy DonthireddyCopyright:

Formati disponibili

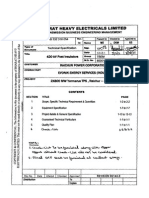

THIS DOCUMENT/DRAWING IS THE PROPERTY OF ABB LUMMUS GLOBAL B.V.

INCLUDING ALL PATENTED AND PATENTABLE FEATURES AND/OR CONFIDENTIAL INFORMATION AND ITS USE IS CONDITIONED UPON THE USERS AGREEMENT NOT TO REPRODUCE

THE DOCUMENT/DRAWING, IN WHOLE OR IN PART, NOR THE MATERIAL DESCRIBED THEREON, NOR TO USE THE DOCUMENT/DRAWING FOR ANY PURPOSE OTHER THAN AS SPECIFICALLY PERMITTED IN WRITING BY ABB LUMMUS GLOBAL B.V.

Indian Oil Corporation LTD. (IOCL)

SPECIFICATION

Plant

Naphtha Cracker Unit

Location

Panipat, Haryana, India

REV.

2005-11-03

FPM

DIS

JHWO

DATE

For Feed Package

DESCRIPTION

211

04184

EA-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120211-EA-601

PREPARED

CHECKED

Rev. 0

Specification For:

SHELL AND TUBE HEAT EXCHANGERS

EA-601

APPROVED

Page 1 of 5

Indian Oil Corporation LTD. (IOCL)

SPECIFICATION

Plant

Naphtha Cracker Unit

Location

Panipat, Haryana, India

Error:

Reference

Dept./Sect.

Doc. No.

04184

Project

Error: Reference source

not found

Specification

Error: Reference source

not found

Rev.

Error:

INDEX

SECTION

PAGE

1.

GENERAL

2.

FABRICATION

3.

INSPECTION AND TESTING

4.

NAMEPLATES

5.

STANDARD DRAWINGS

LGV SSPE 04-3205-01.003 (2001-01-23)

Page 2 of 4

Indian Oil Corporation LTD. (IOCL)

SPECIFICATION

Plant

Naphtha Cracker Unit

Location

Panipat, Haryana, India

Error:

Reference

Dept./Sect.

Error:

Reference

Project

Error: Reference source

not found

Specification

Doc. No.

Error: Reference source

not found

0Error:

Referenc

1.

GENERAL

1.1

This specification

Defines the minimum technical requirements for the design, fabrication,

inspection, testing and documentation of TEMA type Shell and Tube Heat Exchange

equipment.

Supplements the code under which the equipment has to be supplied.

Amends and supplements the latest editions of TEMA R standard.

Amends and supplements Specification Pressure Vessels D-611 and /or D612.

1.2

The term Shell and Tube Exchangers used in this specification shall be considered as a

collective name for the equipment that is to be in accordance with this specification. Shell and

tube heat exchangers shall be considered pressure vessels.

1.3

Definitions, supplementary codes, specifications and standards, seller obligations and

responsibilities and general pressure retaining equipment requirements are listed in the

specification pressure vessels. This specification shall be adhered to as far as applicable.

1.4

Following standards / specifications are in addition to those listed in the specification:

Pressure Vessels and requisition;

Standards of the Tubular Exchanger Manufacturers Association (TEMA). (TEMA class R as

specified per datasheets.) latest applicable edition at contract award date. List any other code,

specification or standard not mentioned in the pressure vessel specification. Note that project

specific specifications shall be listed in the requisition list of attachments.

1.5

In case of contradiction between codes, specifications and standards the following priority

shall apply:

1.

2.

3.

4.

5.

6.

7.

9.

Design and construction code, including national and/or local regulations.

The requisitition.

This Specification.

Specification Pressure Vessels.

TEMA standards.

Other project specifications.

International standards.

Accepted seller's specifications and standards.

Note:

2) trough 9) govern above 1) in case more stringent.

2.

FABRICATION

2.1

Partition plates shall be attached with full length fillet welds on each side with a minimum leg of

3/4 t (t=partition plate thickness).

2.2

Sliding strips shall be properly seated in the baffles, secured with a complete seal weld (both

sides) and attached to the stationary tube sheet with a full penetration weld. The sliding strips

shall protrude 2 mm beyond the periphery of the baffles, to prevent damage of baffles during

sliding.

2.3

Gasket seating surfaces, including gasket grooves in tube sheets and channel covers, shall

have the same nominal thickness of cladding as specified for shells or channels.

Page 3 of 5

Indian Oil Corporation LTD. (IOCL)

SPECIFICATION

Plant

Naphtha Cracker Unit

Location

Panipat, Haryana, India

Error:

Reference

Dept./Sect.

Error:

Reference

Project

Error: Reference source

not found

Specification

Doc. No.

Error: Reference source

not found

Rev.

0Error:

2.4

When tube sheets are subjected to heat treatment during fabrication the final machining of

tube holes shall be done after heat treatment.

2.5

Tube holes in tube sheets shall be machined after drilling.

2.6

The inside and outside edges of tube holes in tube sheets shall be chamfered after machining,

to prevent cutting of the tubes.

2.7

A minimum of three (3) jackscrews (3/8) shall be provided to facilitate opening shell to cover

gasketed joints and tube sheet to flange joints on floating head and U-tube units.

2.8

Channel and removable tube-sheet covers shall be provided with eye bolts or lifting lugs to

facilitate handling.

Due consideration shall be given to all problems of removal for cleaning.

2.9

The following exchanger parts shall be stamped with exchanger item number: tube sheets,

floating head cover, floating head back-up device, expansion bellows, test ring and/or test

flanges.

2.10

Dimensional tolerances shall be in accordance with TEMA standards.

3.

INSPECTION AND TESTING

3.1

A detailed hydro test procedure shall be submitted for acceptance for each type of heat

exchanger.

3.2

Units, which are to be stacked in service, shall be assembled in seller's factory for fit-up, final

hydrostatic testing and inspection prior to shipping.

3.3

Test rings and/or test flanges shall be supplied with heat exchangers.

When two or more heat exchangers of the same type and dimensions (except for stacked

units) are supplied by the same manufacturer, only one set of test rings and/or flanges is

required.

3.4

Test gaskets used for shop test shall be of the same type and material as the service gaskets,

except the shell cover gasket used with the test ring, which may be of another quality.

Gaskets shall not be replaced after successful pressure testing and the exchanger shall be put

into operation without disturbance of joints.

When a heat exchanger is dismantled for any cause, it shall be reassembled with new

gaskets of the same construction.

4.

NAMEPLATES

4.1

An additional Warning plate in accordance with standard drawing shall be supplied and

attached by seller on exchangers with parts designed for differential pressure.

Page 4 of 5

Indian Oil Corporation LTD. (IOCL)

SPECIFICATION

Plant

Naphtha Cracker Unit

Location

Panipat, Haryana, India

5.

Error:

Reference

Dept./Sect.

Error:

Reference

Project

Error: Reference source

not found

Specification

Doc. No.

Error: Reference source

not found

Rev.

0Error:

STANDARD DRAWINGS

The following standard drawings shall form part of this specification:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

DRAWING

NO.

04-3230-1.041

04-3230-1.042

04-3230-1.043

04-3230-1.044

04-3230-1.045

04-3230-1.046

04-3230-1.047

04-3230-1.048

04-3230-1.049

04-3230-1.050

04-3230-1.051

04-3230-1.052

04-3230-1.053

04-3230-1.054

04-3230-1.055

04-3230-1.056

04-3230-1.057

04-3230-1.058

04-3230-1.059

04-3230-1.067

04-3230-1.069

REV.

NO.

4

4

4

4

5

4

4

4

4

4

4

4

4

4

4

4

4

4

4

0

0

SHEET

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 1

1 of 2

2 of 2

1 of 2

2 of 2

1 of 2

2 of 2

1 of 1

1 of 1

DESCRIPTION

Solid Bull Plugs.

Eye Bolt Hole Plug.

Base Plug.

Jackscrew Arrangement.

Lifting Lug / Bundle Lug.

Details for Welds for Cold Exch.

Fastening Nuts to Tie Rods.

Sealing Strips for Special Long. Baffles.

Backing Ring & Connecting Piece Dims.

Detail of Dowel and Dowel Clip.

Exp. Bellow - Fixed Tube Sheet Exch.

Sacrificial Anodes.

Warning Nameplate for Diff. Pressure.

Supports for Horiz. Exch. Type 6.

Supports for Horiz. Exch. Type 6.

Supports for Horiz. Exch. Type 7.

Supports for Horiz. Exch. Type 7.

Supports for Vert. Units Type 10,11,12,13

Supports for Vert. Units Type 10,11,12,13

Nameplate for vess.,exchangers & air-coolers

Standouts for Nozzles & Manways

As a minimum the following standard drawings of specification Pressure Vessels form also a

part of this specification:

22

23

24

25

26

27

28

29

30

31

DRAWING

NO.

04-3230-01.002

04-3230-01.003

04-3230-01.004

04-3230-01.010

04-3230-01.011

04-3230-01.012

04-3230-01.026

04-3230-01.029

04-3230-01.037

04-3230-01.038

Rev.

NO.

5

5

5

4

5

5

4

5

7

7

SHEET

1 of 3

2 of 3

3 of 3

1 of 3

2 of 3

3 of 3

1 of 1

1 of 1

1 of 2

2 of 2

DESCRIPTION

Miscell. Nozzle Arrangements.

Miscell. Nozzle Arrangements.

Miscell. Nozzle Arrangements.

Steel Saddles for Dia 500-1000 mm.

Steel Saddles for Dia 1050-2000 mm.

Steel Saddles for Dia 2100-4500 mm.

Nameplate Bracket.

Earthing Connection.

Alloy Liner Details.

Alloy Liner Details

Page 5 of 5

Potrebbero piacerti anche

- IOCL InsulationDocumento43 pagineIOCL InsulationYogi17350% (2)

- Essar Steel PlantDocumento62 pagineEssar Steel PlantKrishnadev C.SNessuna valutazione finora

- Piping Design Plant LayoutDocumento23 paginePiping Design Plant Layoutluxvij100% (1)

- Noc G-07Documento21 pagineNoc G-07Rochdi SahliNessuna valutazione finora

- Rotary Pump Specification SummaryDocumento17 pagineRotary Pump Specification SummaryRochdi SahliNessuna valutazione finora

- X PGNDP0464 03 ECI SPC 020 Control Valve Specification RevADocumento7 pagineX PGNDP0464 03 ECI SPC 020 Control Valve Specification RevAgrantNessuna valutazione finora

- Ni 2543Documento11 pagineNi 2543marguepaNessuna valutazione finora

- Iocl Tank Spec F-601 Rev 0Documento18 pagineIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- GS114-8 HVAC - Terminal Units For Offshore UseDocumento14 pagineGS114-8 HVAC - Terminal Units For Offshore UseDH BNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento15 pagineNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNessuna valutazione finora

- 3-98-00 Spec. For Steam Inerting Valve StationDocumento11 pagine3-98-00 Spec. For Steam Inerting Valve StationlightsonsNessuna valutazione finora

- Tube To T Joints The Many Choices BJ SandersDocumento38 pagineTube To T Joints The Many Choices BJ Sandersscbd83Nessuna valutazione finora

- CAIRN ENERGY INDIA PTY STANDARD PIPE SUPPORTSDocumento77 pagineCAIRN ENERGY INDIA PTY STANDARD PIPE SUPPORTSAjadNessuna valutazione finora

- VEDST003 - Shell and Tube Heat Exchanger Specification SheetDocumento23 pagineVEDST003 - Shell and Tube Heat Exchanger Specification SheetyuganterNessuna valutazione finora

- Specification For Lube Oil and Dry Gas Seal SystemDocumento17 pagineSpecification For Lube Oil and Dry Gas Seal Systemjahosolaris5512Nessuna valutazione finora

- 24-87-01 Spec. For Motor Operated Globe & Gate ValvesDocumento13 pagine24-87-01 Spec. For Motor Operated Globe & Gate ValveslightsonsNessuna valutazione finora

- ASME B16.11 - Socket Welding and Threaded Forged FittingsDocumento71 pagineASME B16.11 - Socket Welding and Threaded Forged FittingspremNessuna valutazione finora

- Esstd0202scjp Pip Pnfj8000Documento71 pagineEsstd0202scjp Pip Pnfj8000Engr Tahir UL HaqNessuna valutazione finora

- (E-104) Air Cooled Heat Exchangers - Rev1 PDFDocumento13 pagine(E-104) Air Cooled Heat Exchangers - Rev1 PDFmihir_jha2Nessuna valutazione finora

- Technical: BTR-1.0 Tubing Retrievable MandrelDocumento3 pagineTechnical: BTR-1.0 Tubing Retrievable MandrelRebeca RodriguezNessuna valutazione finora

- 2.2 Functional Specification For Deluge ValveDocumento7 pagine2.2 Functional Specification For Deluge Valveramachandran_chem100% (1)

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocumento7 pagineDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967Nessuna valutazione finora

- Halfaya Project LV and Control Cable SpecificationDocumento6 pagineHalfaya Project LV and Control Cable SpecificationAshraf AbdulredhaNessuna valutazione finora

- FOAM TANK KEAMARI (14200 Litres) : 1.0 GeneralDocumento3 pagineFOAM TANK KEAMARI (14200 Litres) : 1.0 GeneralirfanlarikhotmailcomNessuna valutazione finora

- GS 142-4Documento23 pagineGS 142-4Diego100% (1)

- Technical SpecificationDocumento42 pagineTechnical SpecificationHadisupriadiNessuna valutazione finora

- Shell and Tube Heat Exchanger Specification SheetDocumento18 pagineShell and Tube Heat Exchanger Specification SheetAkram DriraNessuna valutazione finora

- JTS02 01 01ver9Documento25 pagineJTS02 01 01ver9Rafat ThongNessuna valutazione finora

- Functional Specification For Deck CraneDocumento31 pagineFunctional Specification For Deck Craneaiyubi20% (1)

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Documento7 pagineVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNessuna valutazione finora

- Annex - 3 - 108695Documento8 pagineAnnex - 3 - 108695Anaruzzaman SheikhNessuna valutazione finora

- Ges A 03Documento15 pagineGes A 03Chokri HmeidiNessuna valutazione finora

- Technical SpecificationsDocumento135 pagineTechnical SpecificationsSrinivasan RajenderanNessuna valutazione finora

- Welding Manual R01 Nov 2006Documento184 pagineWelding Manual R01 Nov 2006SHIVAJI CHOUDHURY100% (5)

- Agitator SelectionDocumento20 pagineAgitator SelectionRamakrishna Koushik100% (2)

- Crude Oil Sucker Rod SpecificationDocumento8 pagineCrude Oil Sucker Rod SpecificationmarguepaNessuna valutazione finora

- 02.34 25635-220-3PS-MHCB-00001 Technical PDFDocumento32 pagine02.34 25635-220-3PS-MHCB-00001 Technical PDFEl_memitoNessuna valutazione finora

- 5903f - Inert Gas GeneratorDocumento18 pagine5903f - Inert Gas GeneratorAvinash PatilNessuna valutazione finora

- Weld Manual 4 PowerDocumento77 pagineWeld Manual 4 PowerGyanendra Narayan NayakNessuna valutazione finora

- GS 142 4 PDFDocumento23 pagineGS 142 4 PDFjast111Nessuna valutazione finora

- Maintenance EquipmentsDocumento9 pagineMaintenance EquipmentsSuneed SkNessuna valutazione finora

- Mu-00-S08 Urs For Cooling Water Circulation PumpsDocumento13 pagineMu-00-S08 Urs For Cooling Water Circulation Pumpsdhanu_lagwankarNessuna valutazione finora

- Pip Vessp002-2014Documento9 paginePip Vessp002-2014d-fbuser-93320248Nessuna valutazione finora

- Igc PR B CorrosionDocumento33 pagineIgc PR B CorrosionsbktceNessuna valutazione finora

- P01-E08 Rev 1 Jun 2001 Cold Springing and Expansion JointsDocumento6 pagineP01-E08 Rev 1 Jun 2001 Cold Springing and Expansion Jointsjhunkujha11Nessuna valutazione finora

- 16 400 220 132KV C R PanelsDocumento87 pagine16 400 220 132KV C R PanelsShatrughna SamalNessuna valutazione finora

- Pneumatic Actuator SpecificationDocumento13 paginePneumatic Actuator Specificationrka0503Nessuna valutazione finora

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDocumento6 pagineVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorNessuna valutazione finora

- Ves 5200 R4 RDocumento21 pagineVes 5200 R4 RdanikakaNessuna valutazione finora

- Enquiry ValveDocumento4 pagineEnquiry ValvePradnyesh DivekarNessuna valutazione finora

- GS114-5 HVAC - Electric Air Heater Batteries For Offshore UseDocumento15 pagineGS114-5 HVAC - Electric Air Heater Batteries For Offshore UseDH BNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Major Process Equipment Maintenance and RepairDa EverandMajor Process Equipment Maintenance and RepairValutazione: 4 su 5 stelle4/5 (4)

- Boat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsDa EverandBoat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsNessuna valutazione finora

- Keyboard SettingDocumento10 pagineKeyboard SettingDiayana Amirah Mohd RadinNessuna valutazione finora

- A Guide To Aluminum WeldingDocumento2 pagineA Guide To Aluminum WeldingRama Krishna Reddy DonthireddyNessuna valutazione finora

- Excel 2007 FunctionsDocumento24 pagineExcel 2007 FunctionsPopescu AndreiNessuna valutazione finora

- Engineering CPWD Analysis of Rates - 1Documento571 pagineEngineering CPWD Analysis of Rates - 1javedk_33Nessuna valutazione finora

- 415V AC Distribution Board ChecklistDocumento136 pagine415V AC Distribution Board ChecklistRama Krishna Reddy Donthireddy100% (2)

- Fe-C Phase DiagramDocumento34 pagineFe-C Phase DiagramYoung-long Choi100% (1)

- Meng 6BDocumento67 pagineMeng 6BRama Krishna Reddy DonthireddyNessuna valutazione finora

- AutoCAD One Key Shortcut Guide - AutoCAD Commands - Autodesk StoreDocumento8 pagineAutoCAD One Key Shortcut Guide - AutoCAD Commands - Autodesk StoreRama Krishna Reddy DonthireddyNessuna valutazione finora

- The Iron-Carbon Equilibrium Diagram: AbstractDocumento4 pagineThe Iron-Carbon Equilibrium Diagram: AbstractRama Krishna Reddy DonthireddyNessuna valutazione finora

- Fe-Fe3c Diagram VerygoodDocumento3 pagineFe-Fe3c Diagram VerygoodRama Krishna Reddy DonthireddyNessuna valutazione finora

- 201397113331M293MP142P 0 Tech Spec BPI R00Documento27 pagine201397113331M293MP142P 0 Tech Spec BPI R00Rama Krishna Reddy DonthireddyNessuna valutazione finora

- C StructDesign Bendapudi Feb10Documento3 pagineC StructDesign Bendapudi Feb10samvendanNessuna valutazione finora

- WeldingDocumento3 pagineWeldingveera_saikumarNessuna valutazione finora

- SSDocumento4 pagineSSSaran KumarNessuna valutazione finora

- Pipe Inspection SpecificationDocumento10 paginePipe Inspection SpecificationRama Krishna Reddy DonthireddyNessuna valutazione finora

- Weldingappsmaw Fcaw Gmaw Gtaw SawDocumento20 pagineWeldingappsmaw Fcaw Gmaw Gtaw SawNguyen Huu TriNessuna valutazione finora

- Pipe Inspection SpecificationDocumento49 paginePipe Inspection SpecificationRama Krishna Reddy DonthireddyNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento99 pagineDisclosure To Promote The Right To InformationgovimanoNessuna valutazione finora

- Iocl Heavy Wall Vessels Spec D-612 Rev 0Documento8 pagineIocl Heavy Wall Vessels Spec D-612 Rev 0Rama Krishna Reddy DonthireddyNessuna valutazione finora

- QC EnggDocumento4 pagineQC EnggRama Krishna Reddy DonthireddyNessuna valutazione finora

- Piping BrochureDocumento2 paginePiping Brochureramesh00Nessuna valutazione finora

- Chandra Sekhar Naik - LinkedInDocumento4 pagineChandra Sekhar Naik - LinkedInRama Krishna Reddy DonthireddyNessuna valutazione finora

- ABB Lummus Global B.V. Piling SpecificationDocumento25 pagineABB Lummus Global B.V. Piling SpecificationRama Krishna Reddy DonthireddyNessuna valutazione finora

- Ga 603Documento9 pagineGa 603Rama Krishna Reddy DonthireddyNessuna valutazione finora

- 000007Documento34 pagine000007Rama Krishna Reddy DonthireddyNessuna valutazione finora

- The ABC's of Arc Welding and InspectionDocumento93 pagineThe ABC's of Arc Welding and Inspectionmichaeldtalbott100% (1)

- Iocl Tank Spec F-601 Rev 0Documento18 pagineIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDocumento5 pagineNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODRama Krishna Reddy DonthireddyNessuna valutazione finora

- Standard Pipe SizesDocumento5 pagineStandard Pipe Sizessivak78mduguhaNessuna valutazione finora

- VRF inverter multi-system overview and benefitsDocumento132 pagineVRF inverter multi-system overview and benefitslechepinitoNessuna valutazione finora

- Installation AND User Manual: Your PumpDocumento36 pagineInstallation AND User Manual: Your PumpDavid LynxNessuna valutazione finora

- Optimal Design of Cooling Water Systems: August 2011Documento23 pagineOptimal Design of Cooling Water Systems: August 2011Hansraj RahulNessuna valutazione finora

- Performance Evaluation of a Shell and Tube Heat ExchangerDocumento15 paginePerformance Evaluation of a Shell and Tube Heat ExchangerPaul Ryan GeneralNessuna valutazione finora

- Strada ExDocumento12 pagineStrada ExVaibhav DafaleNessuna valutazione finora

- Heat Exchanger Training Course Material 2 PDFDocumento161 pagineHeat Exchanger Training Course Material 2 PDFChico AlvesNessuna valutazione finora

- Refrigerant Charge CalculationDocumento30 pagineRefrigerant Charge Calculationnejat_arda200767% (3)

- Refrigeration Compressed Air Dryer Buran SD 0010 A - SD 1650 APDocumento2 pagineRefrigeration Compressed Air Dryer Buran SD 0010 A - SD 1650 APAljoša HribarNessuna valutazione finora

- Heating Cooling Product Catalogue PDFDocumento103 pagineHeating Cooling Product Catalogue PDFLupu IonNessuna valutazione finora

- Seamless and Welded Ferritic, Austenitic and Duplex Alloy Steel Condenser and Heat Exchanger Tubes With Integral FinsDocumento4 pagineSeamless and Welded Ferritic, Austenitic and Duplex Alloy Steel Condenser and Heat Exchanger Tubes With Integral FinsMartuaHaojahanSaragihSidabutarNessuna valutazione finora

- LVDH owners manual provides instructions for vacuum dehydratorDocumento26 pagineLVDH owners manual provides instructions for vacuum dehydratorAmit Biswas50% (6)

- Fundamentals of Refrigeration MethodsDocumento84 pagineFundamentals of Refrigeration MethodsibrahimNessuna valutazione finora

- Completecoat™ Corrosion Protection: Corrosion-Resistant, Flexible Coating Uniformly Bonded To All Condenser Coil SurfacesDocumento2 pagineCompletecoat™ Corrosion Protection: Corrosion-Resistant, Flexible Coating Uniformly Bonded To All Condenser Coil SurfacesdjoletetNessuna valutazione finora

- Discussion & Ref Refrigeration CycleDocumento3 pagineDiscussion & Ref Refrigeration CycleNur amirahNessuna valutazione finora

- CBX SeriesDocumento22 pagineCBX SeriesAtika AnjumNessuna valutazione finora

- Chapter - 9-Heat Transfer in Agitated VesselsDocumento44 pagineChapter - 9-Heat Transfer in Agitated VesselsSata Ajjam100% (2)

- Waste Heat Recovery TechniquesDocumento62 pagineWaste Heat Recovery TechniquesdhruvNessuna valutazione finora

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocumento37 pagineSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- BoilerDocumento94 pagineBoilersoumya19800000000100% (1)

- By Product PlantDocumento6 pagineBy Product PlantRajan BhandariNessuna valutazione finora

- M.SC Industrial Chemistry: Internship ReportDocumento44 pagineM.SC Industrial Chemistry: Internship ReportSahil BhuvaNessuna valutazione finora

- Haviland - Chiller Plant Design ConsiderationsDocumento76 pagineHaviland - Chiller Plant Design Considerationssusi_3i100% (1)

- 2008 March 4 Acetaldehyde From Ethylene OxidationDocumento4 pagine2008 March 4 Acetaldehyde From Ethylene OxidationameymurudkarNessuna valutazione finora

- Ai̇rlogi̇c2 Qui̇ncy enDocumento99 pagineAi̇rlogi̇c2 Qui̇ncy enNihat RustamliNessuna valutazione finora

- Quotation Screw Air Compressor Gas-15al VFC Zq20201005-01Documento22 pagineQuotation Screw Air Compressor Gas-15al VFC Zq20201005-01Maurice Alfaro ArnezNessuna valutazione finora

- Heat Transfer Jan2003 NR 320305Documento8 pagineHeat Transfer Jan2003 NR 320305Nizam Institute of Engineering and Technology LibraryNessuna valutazione finora

- Ejector Process Vacuum SystemsDocumento13 pagineEjector Process Vacuum SystemsLeon SanchezNessuna valutazione finora

- 11 - Oil Heat ExchangerDocumento4 pagine11 - Oil Heat ExchangerMoamenNessuna valutazione finora

- Carrier 38aks028 PDFDocumento82 pagineCarrier 38aks028 PDFsybreed88100% (3)

- AlfaNova 14Documento2 pagineAlfaNova 14Celio CostaNessuna valutazione finora