Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LR10007.gb.11-09-01 - SA155W - 2-Pole Product Sheet PDF

Caricato da

Cesar GilDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LR10007.gb.11-09-01 - SA155W - 2-Pole Product Sheet PDF

Caricato da

Cesar GilCopyright:

Formati disponibili

2-Pole Turbine Generators

Stator Winding Construction

WEG Group

Class F stator insulation and Vacuum Pressure Impregnation (VPI)

is provided.

the stator winding process.

Strand Insulation

The strand insulation consists of polyester/

glass fibers.

Transpositions

individual turn in the end turn area.

Half coil strands are assembled using a

Roebel transposition.

Bonding

To prevent wire movement and provide a

uniform solid base for ground insulation,

the coil strands are bonded together under

heat and pressure with a thermosetting

adhesive.

Stator winding in progress.

Duraguard VPI Insulation

Duraguard VPI Insulation

System

MICA Tape Ground

Wall Insulation

DDGL Magnet Wire

System

The Duraguard insulation system is a

vacuum pressure impregnated epoxy-mica

The Duraguard

system is a

insulation

system thatinsulation

offers the following

vacuum

pressure

impregnated

epoxy-mica

benefits:

insulation

system

that offers the following

benefits:

Bonding Material

Conductive Tape for

Corona Suppression

s Full Class F (155C) Thermal Capability

Resistance

s Outstanding Dielectric Properties

s Superior

Moisture

and Chemical

Resistance

s TheWinding

Superb Mechanical Integrity of an

Stator

Resin

System

Epoxy

Stator Coil Cross Section.

loop multi-turn stator coils whereas for

series

2400

and

2800

Model

utilize full

winding process.

Stator Winding

loop multi-turn stator coils whereas for

reasons of larger size Model series 3100

utilizes half loop multi or single turn stator

coils. The stator is VPId after the stator

Coil Forming

The coils are precisely formed using steel

forming cradles.

Coil Insulation

turn insulation of multi turn coils is applied

to each turn using mica glass tape.

The main ground insulation is mica glass

materials are applied to the outside of

the coils.

Fabrication of a half loop stator coil with Roebel

transpositions.

Wound stator entering the VPI tank for impregnation.

Winding and VPI

Tests

the coils are carefully wound in to the

to the stator.

Extensive in process testing is performed

during coil manufacturing, stator winding

and on the complete stator. Tests include

turn insulation testing and high potential.

Temperature Detectors

During the stator winding process

resistance type temperature detectors

lower coil sections in the slot area to

provide stator coil temperature detection.

Detectors are positioned in each phase to

detect the hottest portions of the windings.

braced to prevent movement due to

separated by pads that conform and bond

half of each coil are connected using

is then applied.

Main High Voltage Terminals

The line and neutral leads are brought out

through the sides or bottom of the stator

through insulating support plates. The

leads project in to a larger terminal box

that can be arranged for a bus duct flange

potential transformers, surge capacitors

and lightning arrestors can be provided

as required.

VPI (Vacuum Pressure

Impregnation)

resin are all components of a specially

designed split component system which

is designed to assure process uniformity

and maximum retention of resin in the

insulating materials.

are fully cured in fixtures prior to winding

into the stator.

WEG Group

www.electricmachinery.com

The other names mentioned, registered or not, are the property of their respective companies.

Potrebbero piacerti anche

- Ultimate Guide: Wiring, 8th Updated EditionDa EverandUltimate Guide: Wiring, 8th Updated EditionValutazione: 3.5 su 5 stelle3.5/5 (4)

- Power PhrasesDocumento23 paginePower Phrasesname isNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Electrical SubstationDocumento16 pagineElectrical SubstationAjay Gahlot100% (3)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- 07 TransformersDocumento42 pagine07 TransformersRafael FurquimNessuna valutazione finora

- 500 MW GeneratorDocumento20 pagine500 MW GeneratorAshok Rasekar100% (1)

- Insulation Co-ordination in High-voltage Electric Power SystemsDa EverandInsulation Co-ordination in High-voltage Electric Power SystemsValutazione: 4.5 su 5 stelle4.5/5 (5)

- SubStation Structure DesignDocumento17 pagineSubStation Structure DesignCesar Gil100% (2)

- Citroen Xsara I - Wiring DiagramDocumento20 pagineCitroen Xsara I - Wiring DiagramDavid VasNessuna valutazione finora

- Chapter 5 Application of Insulating MaterialDocumento21 pagineChapter 5 Application of Insulating MaterialAmir nawazNessuna valutazione finora

- ABB Substation Condition Monitoring ScheduleDocumento16 pagineABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- Nexans CableDocumento8 pagineNexans CableQwerty1992ABCNessuna valutazione finora

- AMCRPS - AS 500 Design & Execution ManualDocumento64 pagineAMCRPS - AS 500 Design & Execution Manualphilou6259Nessuna valutazione finora

- Short Circuit StudyDocumento29 pagineShort Circuit StudyPramod B.Wankhade100% (3)

- 11 Power System Analysis and PlanningDocumento14 pagine11 Power System Analysis and PlanningRafael FurquimNessuna valutazione finora

- Clean Energy Council Installers Checklist PDFDocumento3 pagineClean Energy Council Installers Checklist PDFAndre SNessuna valutazione finora

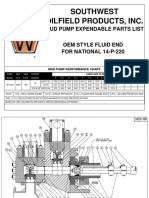

- Oem National 14-P-220 7500psiDocumento9 pagineOem National 14-P-220 7500psiandrew0% (1)

- SimonKucher Ebook A Practical Guide To PricingDocumento23 pagineSimonKucher Ebook A Practical Guide To PricingHari Krishnan100% (1)

- Iec 61439Documento7 pagineIec 61439goyalp7550% (2)

- HV BushingDocumento3 pagineHV BushingEdison SelvarajNessuna valutazione finora

- Team Mate+AM+IT+Overview+12Documento41 pagineTeam Mate+AM+IT+Overview+12epajueloNessuna valutazione finora

- Edp02 Coordinación Selectiva de Sobrecorriente en BTDocumento22 pagineEdp02 Coordinación Selectiva de Sobrecorriente en BTJose Duran ChaconNessuna valutazione finora

- 600 MW Stator Bar Training ReportDocumento21 pagine600 MW Stator Bar Training ReportHimanshu SharmaNessuna valutazione finora

- Viega Profipress ManualDocumento16 pagineViega Profipress Manualhasmit1Nessuna valutazione finora

- Energy Efficient Distribution TransformersDocumento32 pagineEnergy Efficient Distribution TransformersajaykumarparikhNessuna valutazione finora

- A Guide On Power World SimulatorDocumento8 pagineA Guide On Power World SimulatorAhmed Al-lehyaniNessuna valutazione finora

- Set-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationDocumento98 pagineSet-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationShauna MooreNessuna valutazione finora

- Basic Info TK-U.B.I Sleeves3Documento17 pagineBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNessuna valutazione finora

- Inductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVDocumento6 pagineInductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVOscar Francisco Astudillo Paillamilla100% (1)

- Substation DesignDocumento764 pagineSubstation Designprashious100% (2)

- Building Materials Reuse and RecycleDocumento10 pagineBuilding Materials Reuse and RecyclemymalvernNessuna valutazione finora

- Cement Retainer Bridge Plug PDFDocumento6 pagineCement Retainer Bridge Plug PDFcacalot93100% (1)

- Electrical Application Substation Design Guide PDFDocumento405 pagineElectrical Application Substation Design Guide PDFHimdad TahirNessuna valutazione finora

- LabVIEW Project Report Complete HPK Kumar DetailedDocumento62 pagineLabVIEW Project Report Complete HPK Kumar DetailedDanny Vu75% (4)

- 06 Products and DevicesDocumento94 pagine06 Products and DevicesRafael FurquimNessuna valutazione finora

- 08 ProtectionDocumento126 pagine08 ProtectionRafael FurquimNessuna valutazione finora

- 09 Energy ManagementDocumento44 pagine09 Energy ManagementRafael FurquimNessuna valutazione finora

- Gina GasketDocumento14 pagineGina GasketA_ValsamisNessuna valutazione finora

- 220kV GIS Tech Spec - TrackDocumento42 pagine220kV GIS Tech Spec - Trackaravind_k104100% (1)

- 220kV GIS Tech Spec - TrackDocumento42 pagine220kV GIS Tech Spec - Trackaravind_k104100% (1)

- Dlms DocumentDocumento71 pagineDlms DocumentSudarshan ReddyNessuna valutazione finora

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- SETFt RIP Transformer Outdoor BushingDocumento12 pagineSETFt RIP Transformer Outdoor Bushingp m yadavNessuna valutazione finora

- WEG Weg Insulation System Micatherm 50105432 Brochure EnglishDocumento8 pagineWEG Weg Insulation System Micatherm 50105432 Brochure Englishhsu cuterNessuna valutazione finora

- PPE I PR 005Documento11 paginePPE I PR 005MahanderOadNessuna valutazione finora

- SurveyDocumento10 pagineSurveyprateek559Nessuna valutazione finora

- Cable TSJ y TSJ-N PDFDocumento4 pagineCable TSJ y TSJ-N PDFmakv12100% (1)

- Insulators: Submitted byDocumento18 pagineInsulators: Submitted byGurpreet UppalNessuna valutazione finora

- Datasheet - CoronaShield C - 215.55 - EN - GLDocumento3 pagineDatasheet - CoronaShield C - 215.55 - EN - GLLECTORNessuna valutazione finora

- 036 Cs Installation ManualDocumento16 pagine036 Cs Installation ManualMarlou RabinaNessuna valutazione finora

- EEE - BEE601 - TRANSMISSION AND DISTRIBUTION - Dr. V. JayalakshmiDocumento21 pagineEEE - BEE601 - TRANSMISSION AND DISTRIBUTION - Dr. V. JayalakshmikrishnandrkNessuna valutazione finora

- (TOPIC 3) Solar Systems AccessoriesDocumento9 pagine(TOPIC 3) Solar Systems AccessoriesIan MutugiNessuna valutazione finora

- 3M Terminales 3MDocumento92 pagine3M Terminales 3MEDGARPRADOCNessuna valutazione finora

- Busbar Insulation PDFDocumento8 pagineBusbar Insulation PDFPipo KingNessuna valutazione finora

- Raychem TerminalesDocumento26 pagineRaychem TerminalesAcuario Chable Gomez100% (1)

- 3M-EMD High Voltage CableAss PBDocumento8 pagine3M-EMD High Voltage CableAss PBLiz Vilela ArízagaNessuna valutazione finora

- Expulsion & Valve Type Lightning Arresters: Presented By:-Somya Jain (0105EX101113) Shipra Dwivedi (0105EX101107)Documento13 pagineExpulsion & Valve Type Lightning Arresters: Presented By:-Somya Jain (0105EX101113) Shipra Dwivedi (0105EX101107)shreyaNessuna valutazione finora

- General Notes On Instrumentation Cable: Non-Fire Propagating CablesDocumento5 pagineGeneral Notes On Instrumentation Cable: Non-Fire Propagating CablesCharu ChhabraNessuna valutazione finora

- Hot-Air Generator: Operation ManualDocumento13 pagineHot-Air Generator: Operation ManualNur HidayatNessuna valutazione finora

- Fans FlexibleDuctingDocumento8 pagineFans FlexibleDuctingbinhvinavicoNessuna valutazione finora

- Electrical Power Transmission (EE-352) : Presenter: Dr. Umbrin Sultana Assistant Professor Eed, NeduetDocumento29 pagineElectrical Power Transmission (EE-352) : Presenter: Dr. Umbrin Sultana Assistant Professor Eed, NeduetFaizan ShaikhNessuna valutazione finora

- FOAM GLASS UG Piping Insulation Underground BrochureDocumento12 pagineFOAM GLASS UG Piping Insulation Underground BrochureSethuraman SaravanakumarNessuna valutazione finora

- Eurotrace Installation Instructions: Installation On A PipeDocumento6 pagineEurotrace Installation Instructions: Installation On A PipeNicolas150956Nessuna valutazione finora

- Cable Gland Installation InstructionsDocumento2 pagineCable Gland Installation InstructionsJairo WilchesNessuna valutazione finora

- Scotch TapeDocumento30 pagineScotch TapeCarlos AguiarNessuna valutazione finora

- Flange Insulating Gasket Kits: Advance Products & SystemsDocumento8 pagineFlange Insulating Gasket Kits: Advance Products & SystemsJF ZLNessuna valutazione finora

- Wire CoatingDocumento11 pagineWire Coatinglalalola12345Nessuna valutazione finora

- Wiring Systems and AccessoriesDocumento9 pagineWiring Systems and AccessoriesKirui CharlesNessuna valutazione finora

- Rotary Oven Manual South StarDocumento23 pagineRotary Oven Manual South StarTelapia Maach100% (3)

- CUTOUT Fuse Holders: (Standard)Documento9 pagineCUTOUT Fuse Holders: (Standard)MadyNessuna valutazione finora

- Fabrication Instructions For Split Repair Couplings: Electrical SpecificationsDocumento2 pagineFabrication Instructions For Split Repair Couplings: Electrical SpecificationsMai Thế ToanNessuna valutazione finora

- 26 05 13 Medium Voltage Power CablbDocumento5 pagine26 05 13 Medium Voltage Power Cablbesoares1990Nessuna valutazione finora

- Manufacturing Process of 600 MW Turbo Genertor Stator Winding BARDocumento21 pagineManufacturing Process of 600 MW Turbo Genertor Stator Winding BARanuragpugaliaNessuna valutazione finora

- Ebeam ManualDocumento11 pagineEbeam ManualMarco SalvatoriNessuna valutazione finora

- Stricker FuseDocumento65 pagineStricker FuseONILEDA1970Nessuna valutazione finora

- HSA enDocumento12 pagineHSA enAlex RibeiroNessuna valutazione finora

- DMK Stay SystemDocumento20 pagineDMK Stay SystemspqdragadosirelandNessuna valutazione finora

- Cable Terminal KitDocumento10 pagineCable Terminal KitJohn ThomasNessuna valutazione finora

- SecoGear Cat Final2Documento22 pagineSecoGear Cat Final2Eulalio HortaNessuna valutazione finora

- Sanyo - SPW W366 606HH58Documento38 pagineSanyo - SPW W366 606HH58GI CalbuthNessuna valutazione finora

- Overhead System: Produc T CatalogueDocumento16 pagineOverhead System: Produc T CatalogueEpsp MedNessuna valutazione finora

- Chill-In Insulation KitsDocumento4 pagineChill-In Insulation KitsAuburnMfgNessuna valutazione finora

- 3.specification and Description of Substation EuroMax (All)Documento13 pagine3.specification and Description of Substation EuroMax (All)Sayan KeawponwongNessuna valutazione finora

- Intro2MatlabCh2 PDFDocumento12 pagineIntro2MatlabCh2 PDFCesar GilNessuna valutazione finora

- PEST AnalysisDocumento3 paginePEST Analysisnguyenquocdien@gmail.comNessuna valutazione finora

- SWOT Analysis - GEOG (EME) 432 - Energy Policy PDFDocumento1 paginaSWOT Analysis - GEOG (EME) 432 - Energy Policy PDFCesar GilNessuna valutazione finora

- SWOT Analysis Energy Policy CanadáDocumento12 pagineSWOT Analysis Energy Policy CanadáCesar GilNessuna valutazione finora

- Fuzzy Clustering ToolboxDocumento77 pagineFuzzy Clustering ToolboxraphthewizardNessuna valutazione finora

- Crown Battery SustainabilityDocumento6 pagineCrown Battery SustainabilityCesar GilNessuna valutazione finora

- PEST AnalysisDocumento2 paginePEST AnalysisCesar GilNessuna valutazione finora

- Substation Bus Design Current Methods Compared With Field ResultDocumento10 pagineSubstation Bus Design Current Methods Compared With Field ResultCesar GilNessuna valutazione finora

- STUDY - Fixed or Withdrawable MV Switchgear PDFDocumento6 pagineSTUDY - Fixed or Withdrawable MV Switchgear PDFArun PandeyNessuna valutazione finora

- Lecture02 - Environments and OpenModelicaDocumento11 pagineLecture02 - Environments and OpenModelicaCesar GilNessuna valutazione finora

- Spanish Technical Report CMMI V 1 3Documento555 pagineSpanish Technical Report CMMI V 1 3rjsernaqueNessuna valutazione finora

- Weka TutorialDocumento32 pagineWeka TutorialAlgus DarkNessuna valutazione finora

- 2011 Nec Changes - Ieee - 1202Documento46 pagine2011 Nec Changes - Ieee - 1202Cesario GillasNessuna valutazione finora

- Aadhaar Application FormDocumento4 pagineAadhaar Application Formpan cardNessuna valutazione finora

- BTICINO Catalog Matix PDFDocumento80 pagineBTICINO Catalog Matix PDFsokolobanNessuna valutazione finora

- Group B04 - MM2 - Pepper Spray Product LaunchDocumento34 pagineGroup B04 - MM2 - Pepper Spray Product LaunchBharatSubramonyNessuna valutazione finora

- 165 NebulizerDocumento2 pagine165 NebulizerLotfi BahriNessuna valutazione finora

- IPv6 RoutingDocumento27 pagineIPv6 RoutingTtmManNessuna valutazione finora

- Odisha Current Affairs 2019 by AffairsCloudDocumento27 pagineOdisha Current Affairs 2019 by AffairsCloudTANVEER AHMEDNessuna valutazione finora

- Technical Data - Fan Model ECE152SM: Location: Designation: Performance - Required ActualDocumento2 pagineTechnical Data - Fan Model ECE152SM: Location: Designation: Performance - Required ActualJNessuna valutazione finora

- MAMC Pgguesthouse FormDocumento2 pagineMAMC Pgguesthouse FormbhupeshgalaniNessuna valutazione finora

- Atul Gaonkar Resume 2017Documento6 pagineAtul Gaonkar Resume 2017Vinod KaleNessuna valutazione finora

- 2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyDocumento12 pagine2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyAnonymous oKr1c2WNessuna valutazione finora

- Malhotra MR6e 02Documento29 pagineMalhotra MR6e 02Mohsin Ali RazaNessuna valutazione finora

- TG Synchronization Connections For RbsDocumento11 pagineTG Synchronization Connections For RbsJack Sprw67% (3)

- Mempower Busduct - PG - EN - 6 - 2012 PDFDocumento38 pagineMempower Busduct - PG - EN - 6 - 2012 PDFAbelRamadhanNessuna valutazione finora

- Dell's Marketing Strategy - 2006Documento58 pagineDell's Marketing Strategy - 2006Preeti IyerNessuna valutazione finora

- Method Statement of Refrigran Pipe Insulation and Cladding InstallationDocumento16 pagineMethod Statement of Refrigran Pipe Insulation and Cladding InstallationOdot Al GivaryNessuna valutazione finora

- Spare Parts List: Hand-Held Gas Saw DS HS80-14"Documento20 pagineSpare Parts List: Hand-Held Gas Saw DS HS80-14"mayoo1986Nessuna valutazione finora

- Mobile Networks and ApplicationsDocumento232 pagineMobile Networks and ApplicationsrabrajNessuna valutazione finora

- TWITCH INTERACTIVE, INC. v. JOHN AND JANE DOES 1-100Documento18 pagineTWITCH INTERACTIVE, INC. v. JOHN AND JANE DOES 1-100PolygondotcomNessuna valutazione finora

- Cebu Technological University: Republic of The PhilippinesDocumento2 pagineCebu Technological University: Republic of The PhilippinesEngelbert RespuestoNessuna valutazione finora